News

Fiber Cutting Laser Machines: A Comprehensive Guide

In the ever-evolving world of manufacturing and metalworking, fiber cutting laser machines have emerged as a pivotal technology. Known for their speed, precision, and efficiency, fiber laser cutting has become the go-to solution for industries needing to cut metals with high accuracy. But what exactly is a fiber cutting laser machine, and how does it differ from other laser cutting technologies? In this article, we’ll explore the technology behind fiber lasers, their key advantages, and the industries that benefit from this cutting-edge technology.

1. What is a Fiber Cutting Laser Machine?

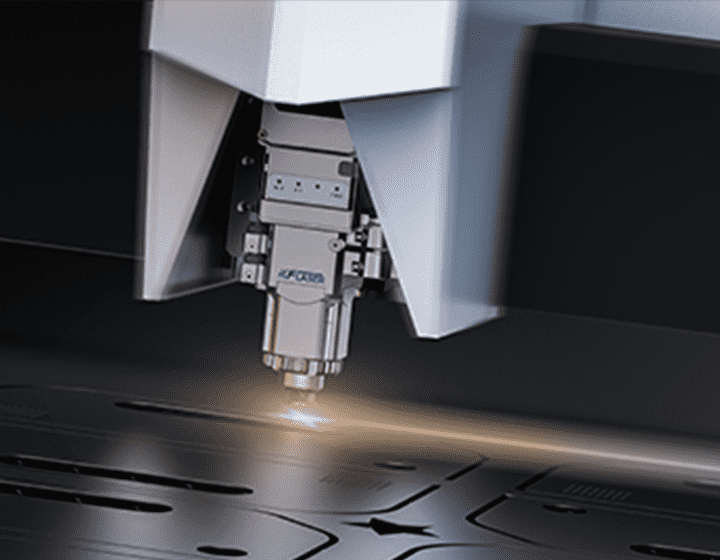

A fiber cutting laser machine is a type of laser cutting system that uses a fiber optic laser to cut through materials like stainless steel, aluminum, carbon steel, and more. The fiber laser is generated by a fiber optic cable, which transmits the laser beam to the cutting head. This allows for highly concentrated energy and precise cuts, particularly on metal materials.

The core difference between fiber laser technology and CO2 laser technology lies in the source of the laser beam. While CO2 lasers generate the beam using a gas-filled tube, fiber lasers use a solid-state fiber optic system, which results in better beam quality, higher energy efficiency, and less maintenance.

2. How Does a Fiber Laser Cutting Machine Work?

The operation of a fiber laser cutting machine can be broken down into a few simple steps:

Laser Generation: The machine uses a fiber laser source to generate a concentrated beam of light. This laser is created by passing electrical current through a fiber-optic material, which results in a powerful, coherent light beam.

Focusing the Laser: The laser is focused using high-precision lenses and mirrors. This ensures that the beam remains tightly concentrated, maximizing its cutting ability and minimizing material waste.

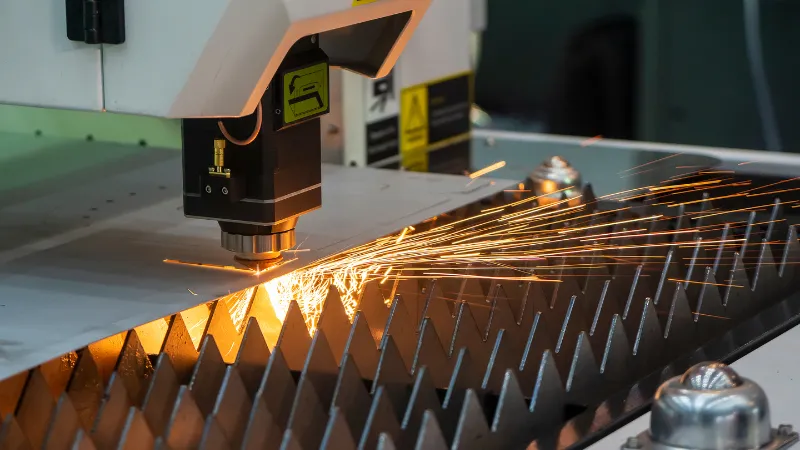

Cutting the Material: The focused laser beam is directed onto the material, where it melts, vaporizes, or burns through the metal. The machine’s CNC system controls the movement of the cutting head along the designated path, often using CAD software to guide the laser precisely.

Assist Gas: To aid the cutting process and blow away molten metal, assist gases like nitrogen or oxygen are used. This not only ensures a clean cut but also helps with the cooling process to prevent heat buildup.

The combination of high-powered lasers and a controlled environment makes fiber laser cutting especially effective for thin and thick metals alike.

https://www.kflaserpro.com/

3. Benefits of Fiber Cutting Laser Machines

Fiber cutting laser machines offer numerous advantages over other cutting technologies. Here are some of the main benefits:

1. High Precision and Accuracy

Fiber lasers deliver exceptional cutting precision, which is vital for industries requiring high-quality finished parts. Whether cutting complex shapes, small holes, or intricate designs, fiber laser machines can achieve tight tolerances with ease. This is particularly beneficial in sectors like aerospace, electronics, and automotive, where part accuracy is critical.

2. Speed and Efficiency

One of the standout features of fiber laser cutting machines is their speed. Fiber lasers cut much faster than traditional CO2 lasers, particularly on thin materials. This efficiency helps reduce production times and enhances overall productivity, making fiber lasers an ideal choice for industries with high-volume production needs.

3. Low Operational Costs

Fiber cutting laser machines are more energy-efficient compared to their CO2 counterparts. Fiber lasers consume less electricity, which translates into lower operational costs over time. Additionally, fiber lasers require less maintenance, as they don’t have consumable parts like the CO2 tubes, reducing downtime and operational costs.

4. Excellent Beam Quality

Fiber lasers provide a high-quality laser beam that maintains focus even during cutting. The small spot size and high intensity of the fiber laser beam ensure that cuts are precise, clean, and have minimal heat-affected zones. This makes fiber laser cutting ideal for thin materials, where fine detail is crucial.

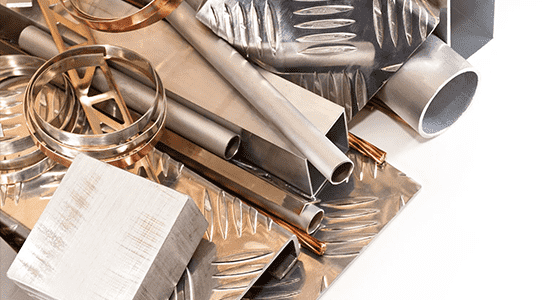

5. Versatility in Material Handling

Fiber lasers are highly effective at cutting a wide range of materials, especially metals like stainless steel, aluminum, titanium, and brass. The technology also works well on both thin and thick metals, giving manufacturers flexibility in their material choices.

6. Minimal Heat-Affected Zones

Fiber lasers generate minimal heat compared to other cutting methods, which helps prevent distortion or warping in delicate materials. This reduces the need for additional finishing processes, ensuring a smoother and more refined final product.

4. Applications of Fiber Cutting Laser Machines

Due to their precision and efficiency, fiber cutting lasers are used across a broad spectrum of industries. Some of the most common applications include:

Metal Fabrication

The metal fabrication industry relies heavily on fiber laser cutting for making custom metal parts and components. Fiber lasers are particularly useful for producing structural elements, brackets, and frames that require accurate cutting, high quality, and consistent results.

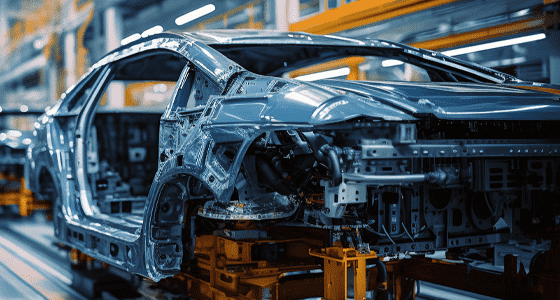

Automotive Industry

In the automotive sector, fiber cutting lasers are used for manufacturing body parts, chassis components, and exhaust systems. The ability to cut through materials like stainless steel and aluminum with high precision is essential for producing reliable and durable automotive parts.

Aerospace

Aerospace companies use fiber laser cutting for creating lightweight yet strong components such as engine parts, turbines, and aircraft body panels. The high precision and ability to handle advanced materials like titanium make fiber lasers an ideal tool for this industry.

Electronics

The electronics industry benefits from fiber laser cutting for tasks such as cutting circuit boards, connectors, and heat sinks. The precise and clean cuts produced by fiber lasers allow for the intricate and delicate work required in this sector.

Signage and Decorative Design

Fiber laser cutting is also widely used in creating custom signage and decorative panels. The ability to cut intricate designs in metals, such as aluminum sheets or stainless steel, makes it a favorite for designers looking to create eye-catching, custom-made signage or architectural features.

Medical Devices

In the medical field, fiber lasers are employed to create surgical tools, medical implants, and other precision components. Fiber laser cutting is especially important for materials like titanium, which are commonly used in medical applications due to their biocompatibility.

5. How to Choose the Right Fiber Cutting Laser Machine

When selecting a fiber laser cutting machine, it’s essential to consider a few key factors to ensure that the machine meets your specific needs:

Laser Power: The power of the fiber laser (measured in watts) plays a crucial role in determining the thickness of the materials that can be cut. Higher power lasers are better suited for thicker materials, while lower power lasers are ideal for thinner sheets.

Material Compatibility: Ensure that the fiber laser cutting machine is compatible with the materials you intend to cut. Different lasers perform better on different materials, so choose a machine that is well-suited for your specific applications.

Cutting Speed: Consider the machine’s cutting speed, particularly if you have large-scale production needs. A high-speed machine can significantly improve throughput and reduce production time.

Automation Features: Many modern fiber cutting machines come equipped with automated features such as automatic loading/unloading systems, material handling systems, and integrated software. These can improve efficiency and reduce human error in production.

Cost vs. Value: While fiber laser cutting machines can be an investment, consider the long-term value. With lower operating costs and reduced maintenance, fiber lasers provide substantial savings over time.

Fiber cutting laser machines offer numerous advantages, making them an ideal choice for businesses in industries like metal fabrication, automotive, and aerospace. With their ability to cut with high precision, speed, and energy efficiency, fiber lasers are redefining manufacturing processes and providing companies with a competitive edge in the global market.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine