News

Laser Cutting of Metal Sheets: Everything You Need to Know

Laser cutting technology has become one of the most popular methods for processing metal sheets in modern manufacturing. Offering unparalleled precision, efficiency, and versatility, laser cutting has transformed industries such as aerospace, automotive, and metal fabrication. But how does it work, what are its advantages, and what are its key applications? In this guide, we’ll break down the basics of laser cutting of metal sheets, its process, and why it’s the go-to technology for metalworking.

1. What is Laser Cutting of Metal Sheets?

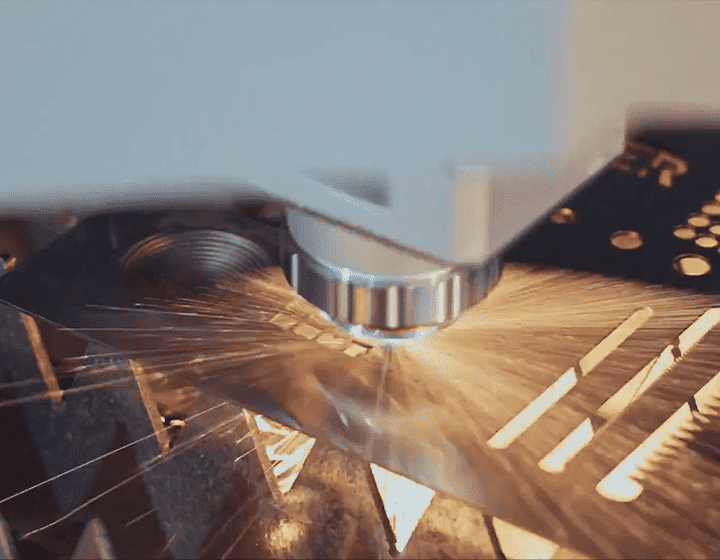

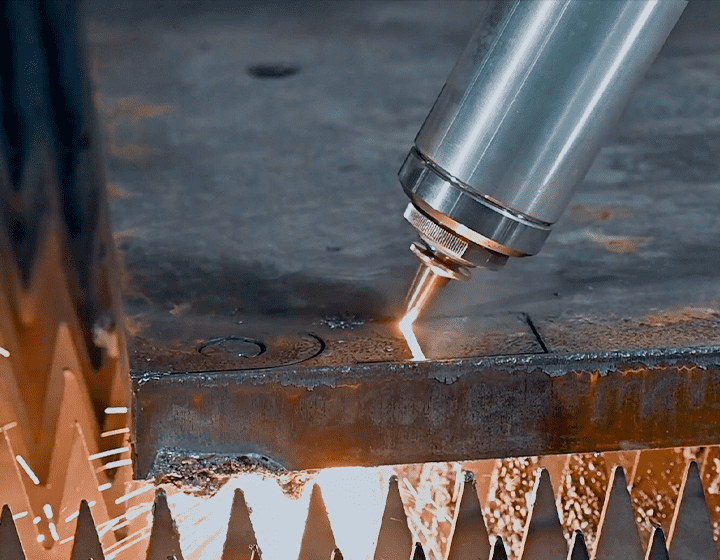

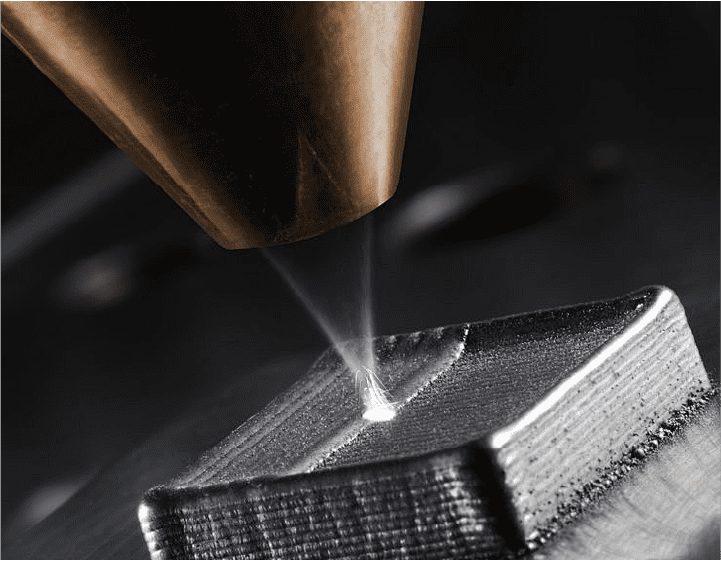

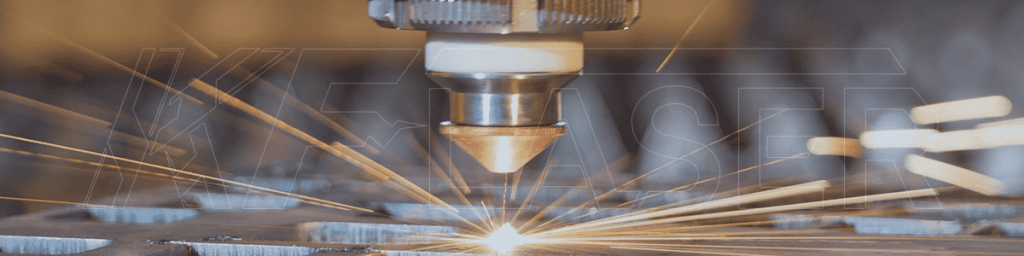

Laser cutting is a process that uses a focused laser beam to cut or engrave materials, with metal sheets being one of the most common materials involved. The laser beam is directed onto the metal sheet, where it melts, burns, or vaporizes the material along a predetermined cutting path.

There are different types of lasers used for cutting metal sheets, including CO2 lasers and fiber lasers. CO2 lasers are traditionally used for cutting non-metal materials like wood and plastic, but they can also cut metals. On the other hand, fiber lasers are more energy-efficient and effective for cutting metals, making them a preferred choice for cutting stainless steel, aluminum, and carbon steel.

2. How Does the Laser Cutting Process Work on Metal Sheets?

Laser cutting of metal sheets involves several key steps:

Laser Generation: The laser is generated using a high-powered laser source (either CO2 or fiber), which creates a focused beam of light. The laser beam has very high energy density, allowing it to cut through materials effectively.

Material Interaction: As the laser beam strikes the metal sheet, the heat causes the metal to melt or vaporize at the cutting location. This process is accompanied by the use of assist gases, such as nitrogen, oxygen, or compressed air, to blow away the molten material and facilitate a clean cut.

CNC System Control: The cutting head, equipped with mirrors and lenses, is controlled by a CNC (Computer Numerical Control) system. This system follows a set of instructions, often designed using CAD (Computer-Aided Design) software, to move the laser cutting head in precise patterns across the material.

Cutting Path: As the laser moves across the metal sheet, it follows the designated cutting path. The precision of the laser beam allows for intricate cuts and designs, even with the most complex geometries.

3. Advantages of Laser Cutting Metal Sheets

There are several reasons why laser cutting has become the preferred choice for cutting metal sheets in many industries:

High Precision and Accuracy

Laser cutting provides unparalleled precision. The focused laser beam can create intricate and detailed cuts with tight tolerances, which is especially beneficial for applications that require high levels of accuracy. This level of precision makes laser cutting suitable for industries such as aerospace, automotive, and electronics, where the smallest errors can lead to significant issues.

Minimal Material Waste

Laser cutting is a non-contact process, which means the laser doesn’t physically touch the material. This results in minimal material waste compared to other cutting methods like mechanical cutting or plasma cutting. The machine can achieve tight nesting, which optimizes material usage.

No Tool Wear

Unlike traditional cutting methods that rely on physical tools, laser cutting does not involve direct contact between the cutting tool and the material. This eliminates the problem of tool wear and reduces the need for frequent tool replacements, making the process more cost-effective over time.

Faster Cutting Speeds

Laser cutting offers high-speed operation, which is especially valuable in production environments where quick turnaround times are essential. Modern laser cutting machines are capable of cutting large volumes of metal sheets efficiently, without sacrificing quality.

Clean Edges

Laser cutting produces clean, smooth edges with minimal burrs or roughness. This is important for parts that need little or no post-processing, saving both time and money in manufacturing.

Flexibility in Design

Laser cutting allows for great design flexibility. Whether you need to cut complex shapes, holes, or engrave detailed patterns onto metal sheets, a laser cutting machine can accommodate a wide range of design requirements, giving you the freedom to explore creative possibilities.

4. Applications of Laser Cutting Metal Sheets

Laser cutting is used across many industries due to its ability to handle various metals and thicknesses. Some of the key applications include:

Automotive Industry

In the automotive industry, laser cutting is frequently used for cutting chassis parts, brackets, and exterior components. The precision of laser cutting ensures that these components meet strict dimensional requirements while reducing material waste.

Aerospace

The aerospace industry relies on laser cutting for making lightweight metal parts and structural components. Materials like aluminum and titanium are often used in aerospace applications, and laser cutting provides the accuracy and speed needed to meet tight production schedules.

Metal Fabrication

Laser cutting is a core technique in metal fabrication, used for cutting structural steel, sheet metal, and other fabricated parts. The precision and versatility make it ideal for creating complex metal components that require a high level of accuracy.

Signage and Decorative Panels

Laser cutting is also widely used for custom signage and decorative metal panels. The ability to cut intricate designs and fine details in metal sheets allows businesses to create unique and aesthetically pleasing products for architectural applications, interior design, and more.

Electronics and Electrical Components

Laser cutting is used to make small metal parts for electronics and electrical components. The accuracy and fine resolution provided by laser cutters ensure that parts like connectors, circuit boards, and heat sinks are fabricated with minimal tolerance for error.

Construction

In construction, laser cutting is used to produce metal roofing, gates, grills, and custom-designed structural parts. Laser cutting provides the precision needed to create durable components that will withstand the elements.

5. Choosing the Right Laser Cutting Machine for Metal Sheets

Selecting the right laser cutting machine is critical for achieving the best results in terms of speed, precision, and material handling. Here are a few factors to consider when choosing a machine:

Laser Type: Choose between CO2 lasers or fiber lasers based on your material needs. While CO2 lasers are versatile, fiber lasers are more efficient for cutting metals, especially reflective materials like aluminum.

Cutting Thickness: Different lasers have different cutting capabilities depending on the thickness of the metal. Ensure the machine you select can handle the thickness of the metal sheets you intend to cut.

Cutting Speed and Efficiency: Look for a machine with fast cutting speeds and minimal downtime. Efficient cutting speeds can increase your production throughput, which is important for meeting deadlines.

Automation and Software Compatibility: Many modern laser cutting machines are CNC-controlled and integrate with CAD software, allowing for automated cutting processes. Consider how well the machine integrates with your existing systems.

Support and Service: A reliable manufacturer that provides comprehensive customer support, maintenance, and service is crucial for minimizing downtime and ensuring the machine remains in optimal condition over time.

Laser cutting of metal sheets has revolutionized industries by offering high precision, efficiency, and versatility. Whether you are in automotive, aerospace, metal fabrication, or any other industry, investing in a laser cutting machine can significantly improve your manufacturing processes. By understanding the key features and benefits of laser cutting, along with the different types of lasers available, you can make an informed decision and ensure your operations remain competitive and efficient in a rapidly evolving market.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine