News

The Complete Guide to CNC Laser Cutting Machines for Sheet Metal

1. Understanding CNC Laser Cutting Machines for Sheet Metal

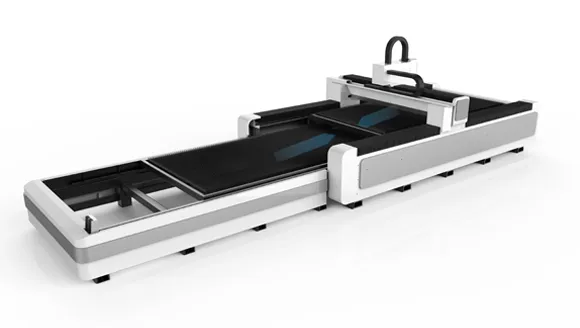

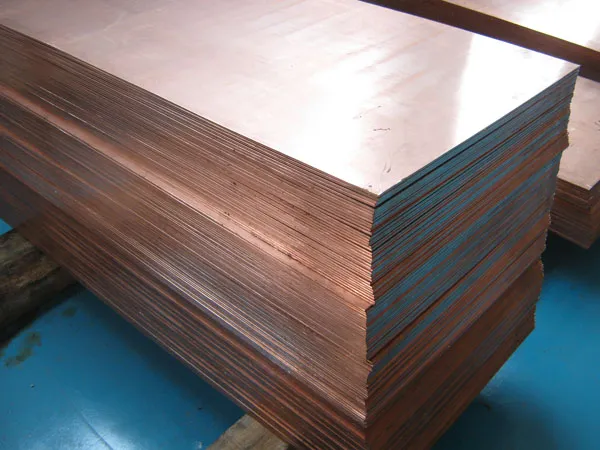

The world of metal fabrication has seen remarkable advancements with the introduction of CNC laser cutting machines, especially for sheet metal. These machines have become a cornerstone in industries where precision, speed, and efficiency are critical. Using a focused laser beam guided by computer numerical control (CNC) technology, these machines are capable of delivering clean and accurate cuts on various types of metal sheets, from stainless steel to aluminum. This guide will delve deep into the science behind CNC laser cutting, its advantages, the different types of machines, and the industries that benefit most from this technology.

2. What is a CNC Laser Cutting Machine for Sheet Metal?

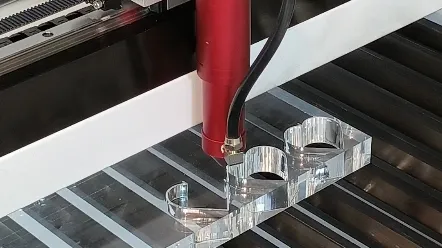

A CNC laser cutting machine for sheet metal is a high-tech, non-contact tool that uses a laser beam to cut through or engrave metal sheets with extreme accuracy. It combines the power of focused light and the precision of CNC programming, allowing for complex designs and intricate shapes to be cut out of metals.

- How It Works

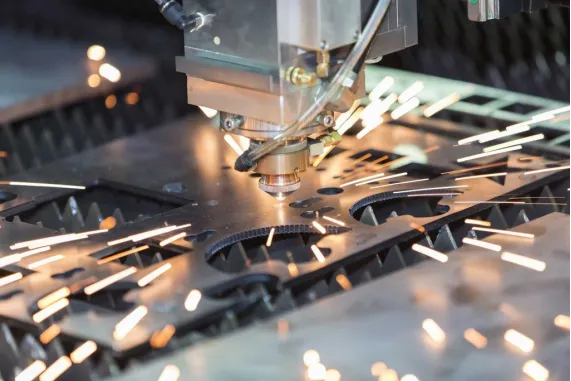

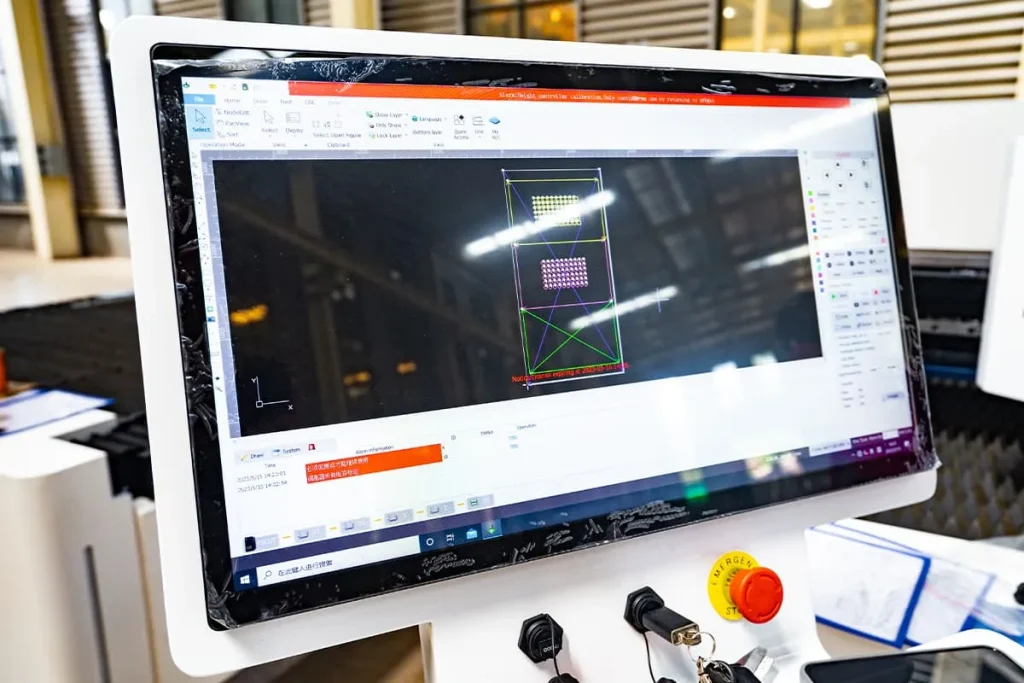

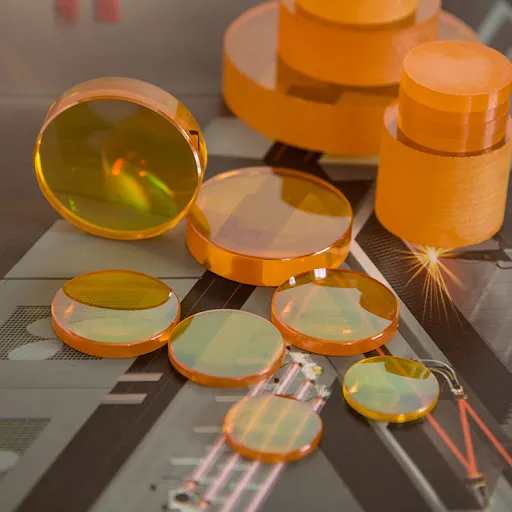

The cutting process begins with a CAD (Computer-Aided Design) drawing that is converted into G-code, which the CNC system uses to direct the movement of the laser. The laser itself, powered by either CO2 or fiber technology, generates a high-energy beam that is focused through a series of lenses and mirrors. When the laser hits the metal surface, it melts, burns, or vaporizes the material, creating a precise cut along the programmed path. Assist gases like nitrogen or oxygen are often used to blow away molten metal and improve the quality of the cut.

3. Types of CNC Laser Cutting Machines for Sheet Metal

Different CNC laser cutting machines cater to varying needs based on material type, thickness, and desired finish. Here’s a breakdown of the main types:

Fiber lasers are known for their efficiency and precision, especially when cutting thin to medium-thick metal sheets. They generate a concentrated beam using optical fibers, which is then directed through a cutting head. Fiber lasers are ideal for high-speed cutting and excel at working with reflective metals like aluminum, copper, and brass.

– Key Features:

– High-speed cutting capabilities.

– Low operational costs due to electrical efficiency.

– Minimal maintenance needs.

- CO2 Laser Cutting Machines

CO2 laser cutting machines use a gas mixture (carbon dioxide, nitrogen, and helium) to produce a powerful laser beam. They are particularly effective for cutting thicker metals and non-metal materials like wood or acrylic, making them versatile for a range of applications.

– Key Features:

– Suitable for thicker metal sheets.

– Versatility in handling non-metallic materials.

– Higher maintenance due to the gas mixture and cooling systems.

- Crystal Laser Cutting Machines

Crystal lasers, such as Nd:YAG (Neodymium-doped Yttrium Aluminum Garnet), are known for their ability to cut thick metals with high precision. These lasers are typically used for specialized applications where intense power is needed.

– Key Features:

– Capable of cutting hard metals and thick sheets.

– High precision for detailed engraving.

– Shorter lifespan of the laser medium compared to fiber and CO2 lasers.

4. Benefits of Using CNC Laser Cutting Machines for Sheet Metal

CNC laser cutting machines bring a host of advantages to the table, making them a preferred choice for modern metalworking projects.

- Precision and Accuracy

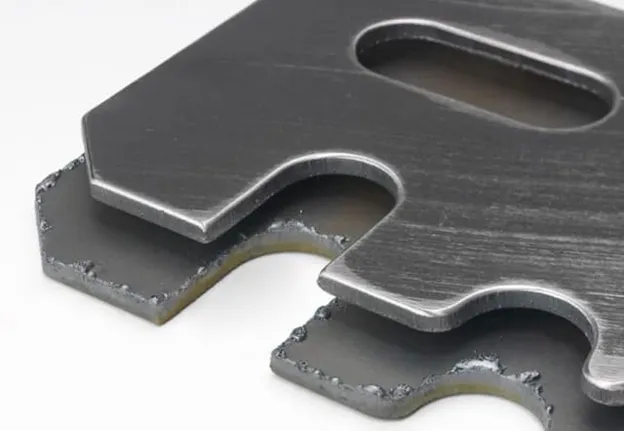

One of the standout benefits of CNC laser cutting machines is their precision. The focused laser beam can achieve tolerances as tight as +/- 0.005 inches, allowing for the creation of intricate designs without any physical contact with the material.

- Speed and Efficiency

Compared to traditional cutting methods like sawing or plasma cutting, CNC laser cutting is significantly faster. This speed is especially advantageous in mass production scenarios, where reducing the time per unit can lead to substantial productivity gains.

- Minimal Material Waste

The laser’s precision means that cuts are made exactly as programmed, reducing waste material. The narrow kerf width ensures that only the necessary material is removed, leading to a more sustainable manufacturing process.

- Versatility Across Materials

Whether you are working with stainless steel, carbon steel, or more delicate materials like aluminum, CNC laser cutting machines can handle a wide range of metal types. The ability to switch between materials with minimal adjustment makes them highly versatile.

5. Factors to Consider When Choosing a CNC Laser Cutting Machine

When selecting a CNC laser cutting machine for sheet metal, several factors come into play to ensure you get the best results.

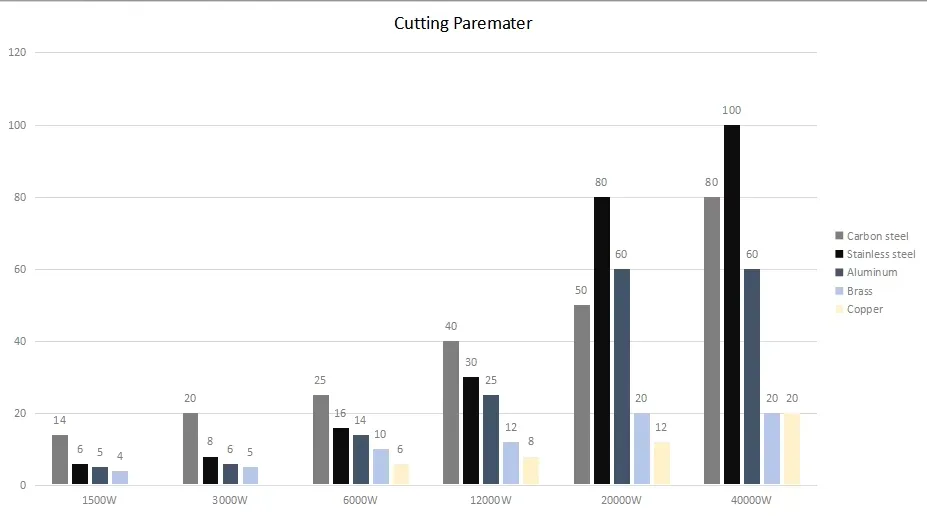

- Laser Power

The power of the laser determines the thickness of the material that can be effectively cut. Higher power lasers (e.g., 10 kW and above) are necessary for cutting thicker metals, while lower power machines are more cost-effective for thinner materials.

- Cutting Speed

Cutting speed is closely related to the power of the laser. Higher speeds are ideal for thin materials and intricate designs, while slower speeds can be used for thicker metals to ensure a clean edge.

- Work Area Size

The size of the work area dictates the maximum sheet size that can be processed. For larger projects, a machine with a broader work area is essential to avoid the need for repositioning the material.

- Maintenance Requirements

Maintenance needs vary between fiber, CO2, and crystal lasers. Fiber lasers require minimal upkeep due to their solid-state nature, while CO2 lasers may need more regular adjustments and cleaning of optics and gas systems.

6. The Science Behind Laser Cutting of Sheet Metal

The efficiency of laser cutting machines lies in their ability to manipulate focused light and heat. Understanding the underlying scientific principles can help operators optimize performance.

- Absorption and Heat Distribution

Metals like stainless steel absorb specific wavelengths of light effectively, especially those generated by fiber lasers. This absorption leads to rapid heating, allowing for clean cuts. The laser’s small heat-affected zone ensures minimal thermal distortion.

- Gas-Assisted Cutting

Using assist gases like nitrogen or oxygen can enhance the cutting process by removing molten material from the cut zone, cooling the cutting area, and preventing oxidation. Nitrogen, in particular, is favored for cutting stainless steel to ensure a clean, oxide-free edge.

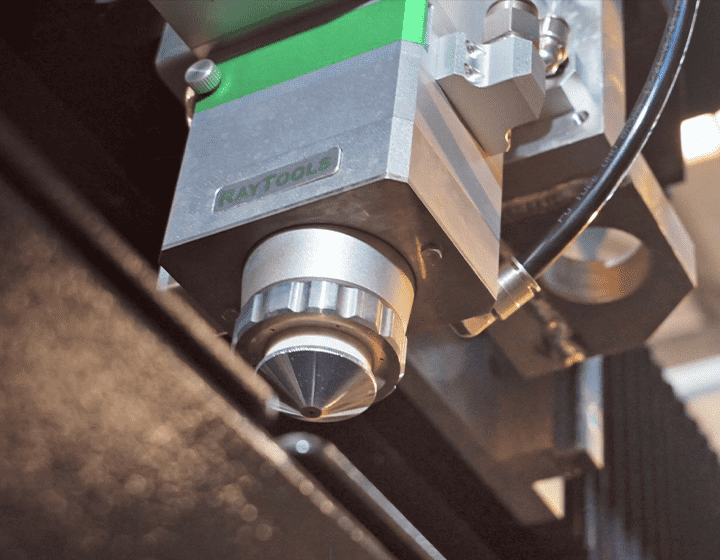

- Focusing the Laser Beam

The focal point of the laser must be adjusted according to the thickness and type of metal being cut. A precise focal adjustment ensures that the energy is concentrated at the exact cutting point, reducing the risk of burring or uneven cuts.

7. Common Challenges in CNC Laser Cutting and How to Overcome Them

While CNC laser cutting is highly efficient, certain challenges can arise, especially when cutting complex designs or thicker materials.

- Burr Formation

Burrs or rough edges can occur if the laser power is too low or if the cutting speed is too high. Adjusting the power settings and ensuring a proper focus can help minimize burrs.

- Reflective Materials

Materials like copper and brass are highly reflective, which can cause the laser to bounce back and potentially damage the machine. Using fiber lasers, which have a shorter wavelength, can reduce reflection issues.

- Heat Warping

When cutting thin sheets of metal, excessive heat can cause warping. This can be mitigated by adjusting the feed rate or using an assist gas to cool the cutting zone more effectively.

8. Applications of CNC Laser Cutting Machines in Various Industries

CNC laser cutting machines have found applications across numerous industries due to their precision and versatility.

- Automotive Industry

Laser cutting is used to create body panels, chassis components, and intricate parts for engines. The precision of laser cutting ensures that these parts fit perfectly, enhancing the overall performance and safety of vehicles.

- Aerospace Sector

In aerospace, where weight and precision are critical, CNC laser cutting is ideal for producing lightweight components with complex geometries. The ability to cut high-strength alloys makes it an essential tool for this industry.

- Medical Device Manufacturing

CNC laser cutting machines are crucial in creating small, intricate components for medical devices. The non-contact nature of the process ensures that there is no contamination, which is vital for medical applications.

- Construction and Architecture

In the construction industry, laser cutting is used to create structural components, decorative metalwork, and architectural facades. The ability to handle custom designs makes it a valuable tool for architects and designers.

9. Tips for Optimizing CNC Laser Cutting Performance

To ensure the best results from a CNC laser cutting machine, operators should follow certain best practices.

- Regular Calibration

Regularly calibrating the machine ensures that the laser’s focus and power output remain consistent, leading to better cut quality and reduced wear on the machine components.

- Use the Correct Assist Gas

Selecting the right assist gas based on the material being cut can significantly improve the finish and speed of the cut. Nitrogen is typically used for stainless steel to avoid oxidation, while oxygen can increase cutting speed for mild steel.

- Perform Routine Maintenance

Keeping the optics clean and inspecting the machine’s components regularly will help prevent downtime and ensure smooth operation. This is especially important for CO2 lasers, which have more components exposed to the environment.

10. Future Trends in CNC Laser Cutting for Sheet Metal

As technology continues to advance, CNC laser cutting machines are becoming more efficient, compact, and user-friendly. Innovations like AI-assisted cutting and automated material handling systems are poised to further enhance productivity. These advancements will make laser cutting even more accessible for small and medium-sized businesses, allowing them to benefit from the precision and efficiency of this technology.

By leveraging the power of CNC laser cutting machines, manufacturers can achieve exceptional precision and productivity in sheet metal fabrication, making them an indispensable part of modern manufacturing processes. The future of metalworking is bright, and it’s powered by lasers.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine