News

CNC Laser Cutting Machine for Stainless Steel: A Comprehensive Guide

1. Introduction to CNC Laser Cutting Machines for Stainless Steel

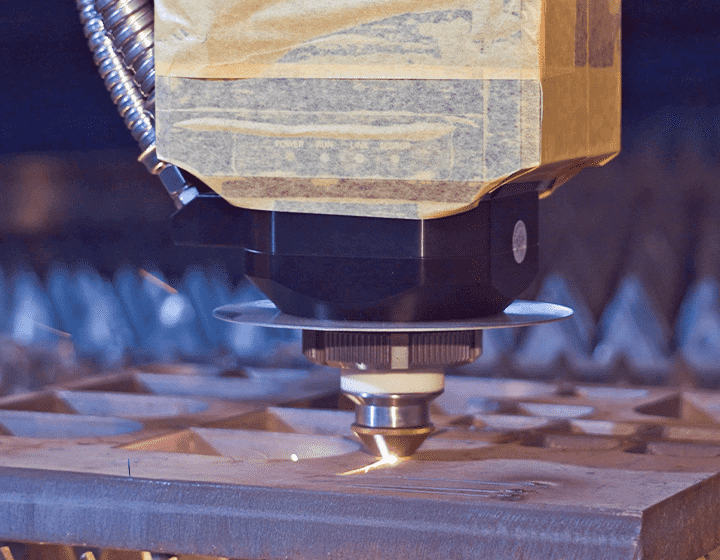

CNC laser cutting machines for stainless steel have become an essential tool in the manufacturing and metalworking industry. These machines offer unmatched precision, speed, and flexibility, making them an ideal choice for industries that demand high-quality cuts and efficiency. The process involves using a high-powered laser beam directed by CNC (Computer Numerical Control) technology to cut, engrave, or mark stainless steel with extreme accuracy. This guide explores the working mechanism, benefits, and considerations when using CNC laser cutting machines for stainless steel, while maintaining a practical approach for optimal results.

2. What is a CNC Laser Cutting Machine for Stainless Steel?

A CNC laser cutting machine is designed to cut various materials using a concentrated laser beam controlled by computer commands. For stainless steel, this process is particularly advantageous due to the material’s resistance to corrosion and heat. Stainless steel’s durability makes it suitable for applications across industries like automotive, aerospace, and medical devices. CNC laser cutting machines can handle intricate designs and patterns, making them a preferred choice for complex projects.

- How Does It Work?

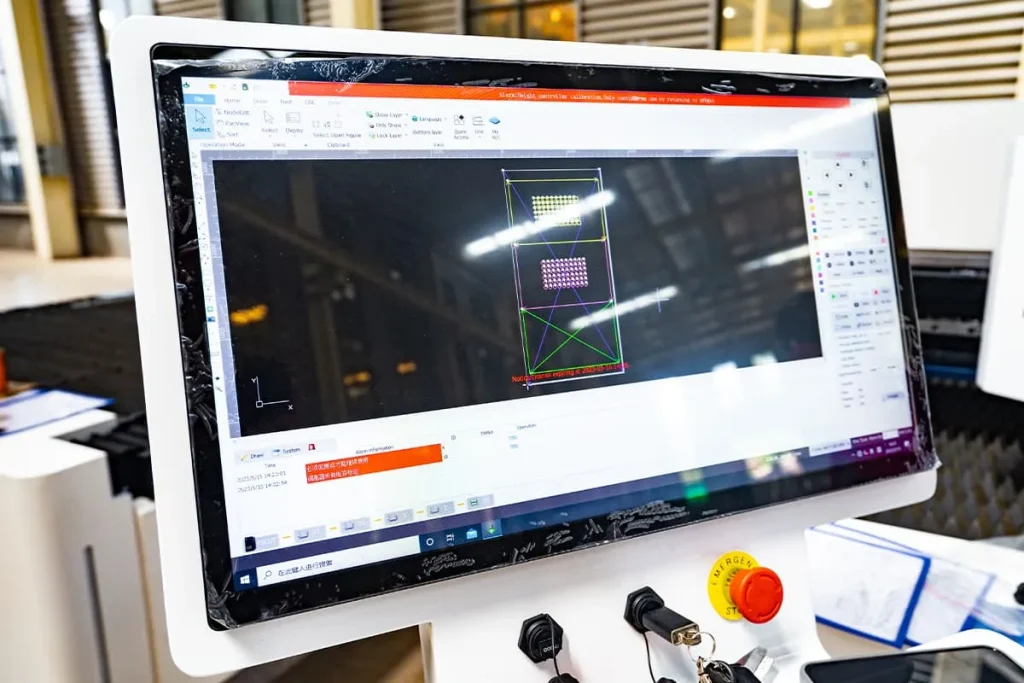

The laser cutting process starts with a design created using CAD (Computer-Aided Design) software, which is then loaded into the CNC machine. The CNC system translates the design into precise movements of the laser beam. The laser melts, burns, or vaporizes the stainless steel along the programmed path, resulting in a clean cut. Depending on the laser type, different gases, like nitrogen or oxygen, are used to assist the cutting process, keeping the cut area free of debris and ensuring a smooth finish.

3. Types of Lasers for Cutting Stainless Steel

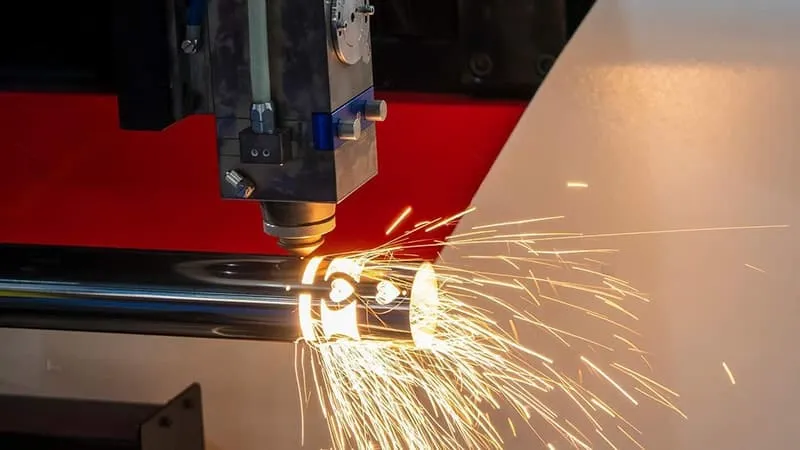

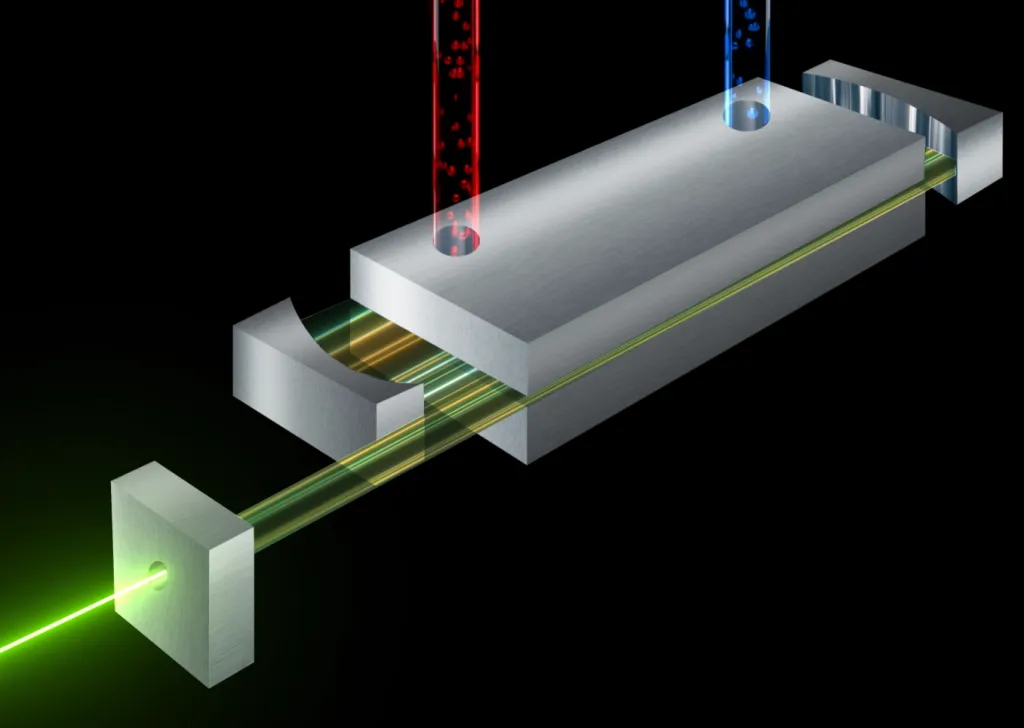

The performance of a CNC laser cutting machine depends significantly on the type of laser used. Two main types of lasers dominate this space: fiber lasers and CO2 lasers.

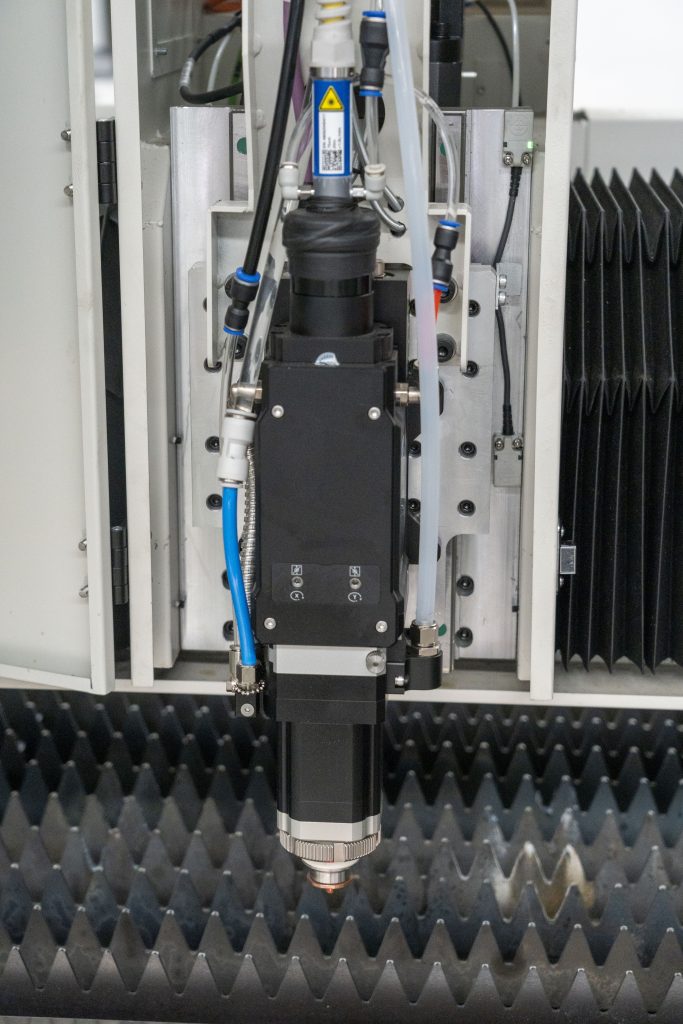

- Fiber Lasers

Fiber lasers utilize fiber optics to generate a narrow, high-intensity beam that is particularly effective for cutting stainless steel. The smaller beam diameter results in a more concentrated energy output, which translates to faster cutting speeds and higher precision.

- Advantages:

– Higher efficiency and lower power consumption compared to other laser types.

– Capable of cutting thin to medium-thick stainless steel with precision.

– Minimal maintenance due to solid-state construction.

- Considerations:

– Requires more shielding gas, such as nitrogen, to prevent oxidation during the cutting process.

– Best suited for projects that demand high precision and speed.

- CO2 Lasers

CO2 lasers, one of the oldest types of laser cutting technology, use a gas-filled resonator to produce a laser beam. They are known for their capability to cut thicker stainless steel and other materials with a wider beam.

- Advantages:

– Suitable for cutting thicker stainless steel sheets and plates.

– Lower initial investment compared to fiber laser machines.

– Versatile in handling a variety of materials beyond just stainless steel.

- Considerations:

– Higher operational costs due to gas consumption and power usage.

– Slower cutting speeds compared to fiber lasers when dealing with thinner materials.

4. Key Benefits of Using CNC Laser Cutting Machines for Stainless Steel

The adoption of CNC laser cutting machines for stainless steel is driven by several benefits that enhance manufacturing efficiency and quality.

- Precision and Accuracy

CNC laser cutting machines offer precise cuts with tolerances as tight as +/- 0.005 inches, making them ideal for applications where accuracy is critical. This precision ensures that complex shapes and designs can be consistently replicated, minimizing waste and reducing the need for secondary processing.

- Speed and Efficiency

The speed of laser cutting surpasses that of traditional cutting methods like mechanical sawing or plasma cutting. For manufacturers, this means faster turnaround times and higher productivity, especially in high-volume production runs.

- Versatility in Cutting

CNC laser cutting machines can handle various thicknesses and types of stainless steel, from thin sheets to thick plates. This versatility allows them to be used in diverse applications, from cutting intricate designs for decorative purposes to producing robust parts for industrial machinery.

- Minimal Heat Affected Zone (HAZ)

Laser cutting applies a concentrated heat source to the material, resulting in a narrow heat-affected zone. This minimizes warping and distortion, maintaining the structural integrity of the stainless steel. As a result, post-cutting treatments and adjustments are often not necessary.

5. Factors to Consider When Choosing a CNC Laser Cutting Machine for Stainless Steel

Selecting the right CNC laser cutting machine involves evaluating various factors to ensure optimal performance and cost-effectiveness.

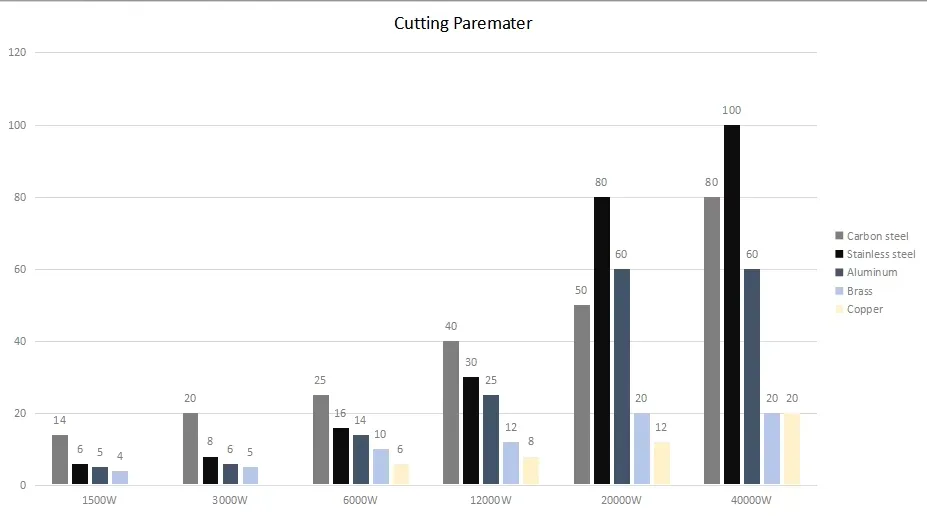

- Power Rating of the Laser

The power of the laser is a crucial factor in determining the machine’s ability to cut different thicknesses of stainless steel. Higher power lasers can cut through thicker materials, but they also consume more energy. For manufacturers handling a mix of thin and thick materials, a balance between power rating and speed is necessary.

- Work Area and Machine Size

The size of the machine’s work area directly impacts the size of the stainless steel sheets or parts that can be processed. For large-scale projects, a machine with a larger work area is essential to accommodate bigger pieces without repositioning the material.

- Maintenance and Durability

Maintenance plays a significant role in the long-term performance of CNC laser cutting machines. Machines with solid-state components, like fiber lasers, generally require less maintenance compared to those with moving parts, such as CO2 lasers. Understanding the maintenance needs and ensuring easy access to replacement parts can reduce downtime.

- Ease of Use and Automation

User-friendly interfaces and automation features, such as automated material loading and unloading, can significantly enhance productivity. Automation reduces the need for manual intervention, making it easier for operators to manage multiple projects simultaneously.

6. Common Challenges and Solutions in Laser Cutting Stainless Steel

While CNC laser cutting machines are highly effective, certain challenges can arise during the cutting process. Here are some common issues and solutions:

- Irregular Cuts and Burr Formation

Irregular cuts and burr formation are often due to incorrect settings or a misaligned laser focus. Adjusting the focal point and ensuring the correct gas flow can improve cut quality.

- Oxidation and Discoloration

Oxidation occurs when the gas shielding is insufficient, leading to a discolored edge. Using pure nitrogen gas instead of oxygen can minimize oxidation, resulting in cleaner cuts.

- Heat Buildup and Warping

Heat buildup can cause warping, especially in thin sheets of stainless steel. Increasing the cutting speed or using air-assist techniques can help dissipate heat and maintain a consistent cut.

- Material Thickness Limitations

The thickness of stainless steel that can be cut depends on the power of the laser. For extremely thick materials, choosing a high-power CO2 laser may be more appropriate. However, if precision is required for thick cuts, using a multi-pass technique with a fiber laser can achieve better results.

7. Applications of CNC Laser Cutting Machines in Various Industries

The versatility of CNC laser cutting machines extends across numerous industries, each benefiting from the unique capabilities of this technology.

- Automotive Industry

CNC laser cutting is extensively used in the automotive industry to create intricate components, such as engine parts, exhaust systems, and structural supports. The precision of laser cutting ensures a perfect fit for these critical components, enhancing the overall performance and safety of vehicles.

- Aerospace Sector

In the aerospace industry, where precision and material integrity are crucial, laser cutting machines offer a reliable solution for producing complex parts. Laser cutting allows for the creation of lightweight components without compromising strength, which is essential for aircraft manufacturing.

- Medical Device Manufacturing

Medical devices require high precision and hygiene standards, making laser cutting an ideal choice. CNC laser cutting machines can create small, intricate components for surgical instruments and implants from stainless steel, ensuring that each part meets stringent medical standards.

- Architecture and Construction

In architecture and construction, laser-cut stainless steel panels and fixtures are used for both functional and aesthetic purposes. Laser cutting enables designers to create custom patterns and shapes, adding unique elements to building facades and interiors.

8.Tips for Achieving Optimal Results with CNC Laser Cutting Machines

To maximize the potential of CNC laser cutting machines for stainless steel, consider these practical tips:

- Start with Clean Material

Ensure that the stainless steel surface is clean before cutting to avoid interference with the laser beam. Residues can lead to uneven cuts or damage to the laser optics.

- Calibrate the Machine Regularly

Routine calibration of the laser cutting machine ensures that the laser remains accurate over time. Regular checks of the focal length, power output, and gas flow are critical for maintaining consistent cut quality.

- Test Cut Settings

Before initiating a large project, perform test cuts to fine-tune the machine settings. This helps identify the best parameters for the material thickness and desired cut quality, reducing waste and errors.

- Monitor the Cutting Process

Even with automated systems, monitoring the cutting process helps detect any issues early on. This can prevent defects and ensure that the final product meets quality standards.

9. Future Trends in CNC Laser Cutting for Stainless Steel

The evolution of laser cutting technology continues, with trends focusing on increased automation, higher efficiency, and improved software integration. Future advancements include AI-driven laser systems that can adjust parameters in real-time based on material feedback, further reducing manual intervention and increasing precision. As technology progresses, the capabilities of CNC laser cutting machines will expand, offering new possibilities for innovation in stainless steel manufacturing.

By understanding the unique features of CNC laser cutting machines and applying best practices, manufacturers can achieve superior results in stainless steel processing, paving the way for more efficient, high-quality production.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine