News

Laser Sheet Metal Cutting Machine: The Future of Precision Metalwork

When it comes to achieving unparalleled precision in metal cutting, the laser sheet metal cutting machine stands as a game-changer. This advanced technology uses high-powered lasers to cut metal sheets with exceptional accuracy, making it a vital tool in industries such as aerospace, automotive, and manufacturing. If you’re considering investing in a cutting-edge metalworking tool, understanding the advantages and intricacies of laser cutting machines can significantly elevate your operations.

Ⅰ. What is a Laser Sheet Metal Cutting Machine?

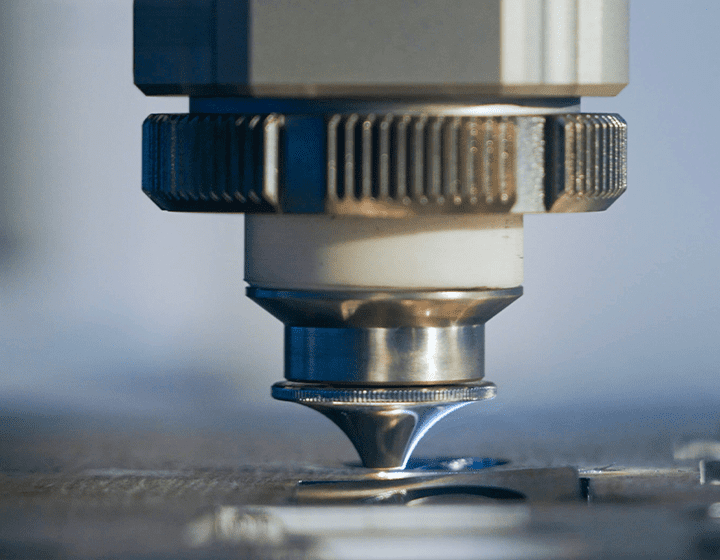

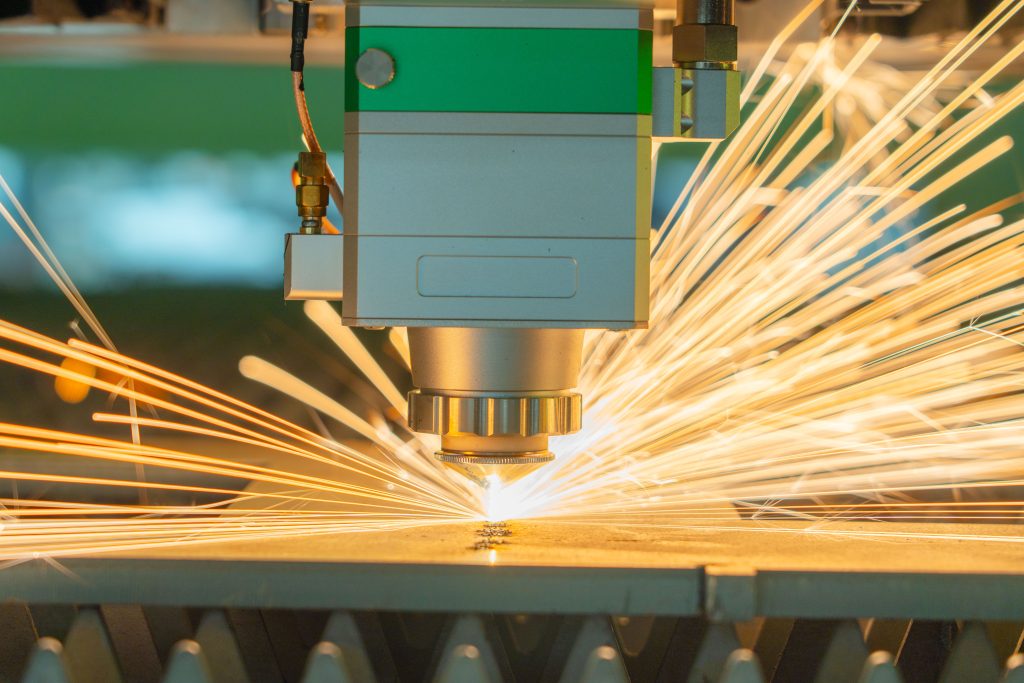

A laser sheet metal cutting machine uses a concentrated laser beam to cut through various metal sheets with high precision. The laser is generated by focusing light through a lens, melting, vaporizing, or burning through the metal. It’s a non-contact method, ensuring the metal sheet remains undamaged as it’s cut, making it ideal for both thin and thick metals.

◆ How Does It Work?

The operation begins when a computer-controlled system directs the laser beam onto the metal sheet. The laser’s heat melts the material, and high-pressure gas is used to blow away the molten metal, leaving behind a clean cut. This process allows for extremely detailed designs and complex shapes that would be challenging for traditional methods.

Ⅱ. The Advantages of Using a Laser Sheet Metal Cutting Machine

Laser cutting technology offers a range of benefits over traditional mechanical cutting methods. These benefits contribute to the increasing popularity of laser sheet metal cutting machines in industries worldwide.

◆ Precision and Accuracy

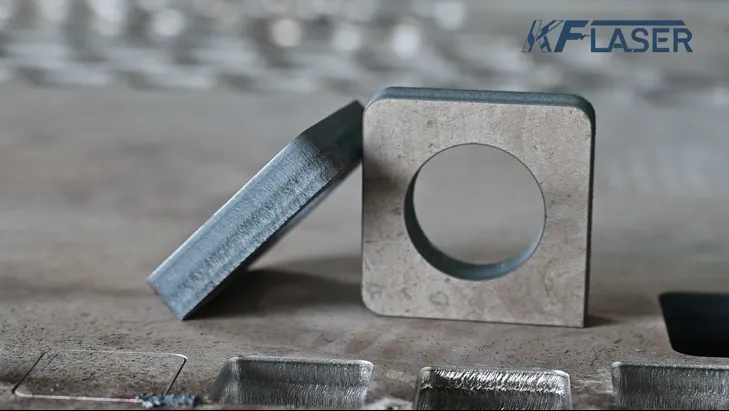

One of the biggest advantages of using a laser sheet metal cutting machine is its unparalleled precision. Laser cutting allows for tight tolerances and smooth edges, ensuring high-quality results. Whether you need to create intricate designs or basic shapes, laser cutting provides a high level of accuracy, significantly reducing the risk of errors in the final product.

◆ Speed and Efficiency

Laser cutting machines are incredibly fast. The process can quickly cut through various thicknesses of metal sheets, providing a level of speed that other cutting methods can’t match. This efficiency makes it an ideal choice for industries where time is of the essence, like automotive or mass production.

◆ Flexibility with Materials

A laser sheet metal cutting machine is versatile. It can be used to cut a wide variety of metals, including stainless steel, aluminum, copper, and more. This flexibility is especially valuable in industries that work with different types of metals, reducing the need for multiple machines for different materials.

◆ Reduced Material Waste

Since laser cutting is a precise process, it minimizes the material waste compared to traditional cutting methods. The high accuracy ensures that less metal is wasted, which is not only cost-effective but also environmentally friendly. This efficiency helps companies reduce operational costs over time.

Ⅲ. Laser Cutting vs. Traditional Cutting Methods

While laser sheet metal cutting machines offer many benefits, it’s important to understand how they compare to traditional methods such as mechanical cutting, plasma cutting, and water jet cutting.

◆ Laser Cutting vs. Mechanical Cutting

Mechanical cutting involves the use of physical tools like saws or shears, which can be slow and require regular maintenance. Laser cutting, on the other hand, doesn’t involve physical contact with the material, meaning there is less wear and tear on the machine. This leads to fewer maintenance requirements and greater longevity of the equipment.

◆ Laser Cutting vs. Plasma Cutting

Plasma cutting uses a plasma torch to melt and cut metals, but it doesn’t offer the same level of precision as a laser sheet metal cutting machine. Plasma cutting is often used for thicker materials, but the cuts are generally less clean and require additional finishing. Laser cutting, by contrast, provides smoother, more precise edges with less post-processing work.

◆ Laser Cutting vs. Water Jet Cutting

Water jet cutting uses high-pressure water mixed with abrasives to cut metal, and while it can be used for a variety of materials, it tends to be slower than laser cutting. Laser cutting is more efficient and better for precise, intricate designs, making it the preferred choice for many manufacturers who require fine detail in their products.

Ⅳ. Applications of Laser Sheet Metal Cutting Machines

The laser sheet metal cutting machine has a wide range of applications in various industries, from heavy-duty manufacturing to fine detail work in electronics.

Laser cutting is used extensively in the automotive industry to create components such as body panels, frames, and intricate brackets. The precision of laser cutting ensures that each part fits perfectly, contributing to the overall quality of the vehicle.

In aerospace and defense, laser cutting is used to cut parts that must meet strict safety and performance standards. The ability to cut through tough materials like titanium and aluminum with minimal distortion makes laser cutting an invaluable tool in this sector.

◆ Electronics and Electrical Industries

Laser cutting is essential in electronics for cutting circuit boards and other components with extreme precision. The accuracy of laser cutting ensures that the parts are consistent and fit together perfectly, which is critical in electronic assemblies.

◆ Signage and Decorative Metalwork

Laser cutting is also used in the creation of signage and decorative metal pieces. Its ability to cut fine details makes it ideal for intricate designs, logos, and patterns that would be difficult to achieve with traditional methods.

Ⅴ. How to Choose the Right Laser Sheet Metal Cutting Machine

When selecting a laser sheet metal cutting machine, several factors must be considered to ensure you invest in the best equipment for your needs.

◆ Material Type and Thickness

Different materials and thicknesses require different laser systems. CO2 lasers, for example, are often used for cutting thin metals, while fiber lasers excel in cutting both thin and thick metals efficiently. It’s essential to match the laser technology to the material you plan to work with.

◆ Cutting Speed and Power

Laser cutting machines come with varying levels of power, which affects the cutting speed. Higher-powered machines can cut through thicker materials more quickly, but it’s important to choose a machine that balances power and speed to suit your specific needs.

◆ Budget and Maintenance

While laser sheet metal cutting machines offer great advantages, they come with a higher initial investment compared to traditional cutting methods. Consider the total cost of ownership, including maintenance, consumables, and energy usage, to determine if the investment is justified for your operations.

Ⅵ.The Future of Laser Sheet Metal Cutting

As technology continues to advance, the laser sheet metal cutting machine will only become more efficient, precise, and versatile. New developments in laser technology, including improved energy efficiency and higher-speed cutting, promise even greater possibilities for industries that rely on high-precision metal cutting. The future of metal fabrication looks promising with these innovations driving productivity and quality to new heights.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine