News

Laser Cutting Tube Machine: Revolutionizing Precision in Tube and Pipe Fabrication

In the world of metal fabrication, the laser cutting tube machine is making waves, offering an unparalleled combination of precision, speed, and versatility. Whether you are cutting complex shapes or creating smooth edges in metal tubes and pipes, laser technology provides the accuracy required for even the most intricate designs. If you’re looking to streamline your manufacturing process or improve the quality of your metalworks, understanding the powerful capabilities of laser cutting technology is essential.

☺ You can share this article to:

1. What is a Laser Cutting Tube Machine?

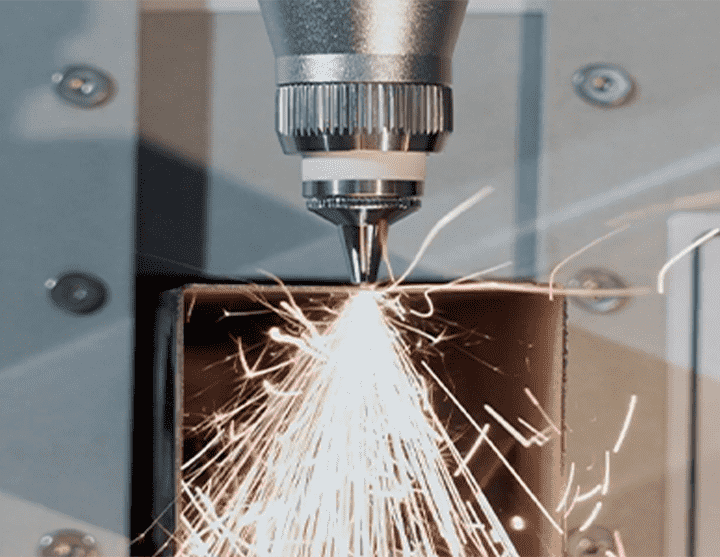

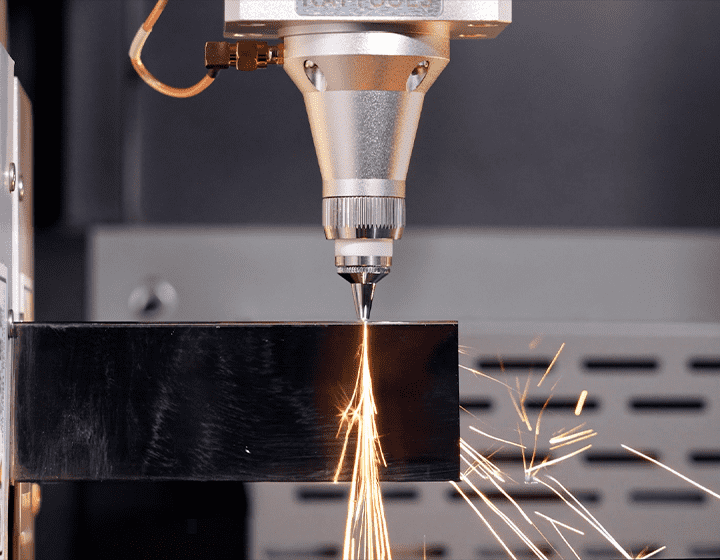

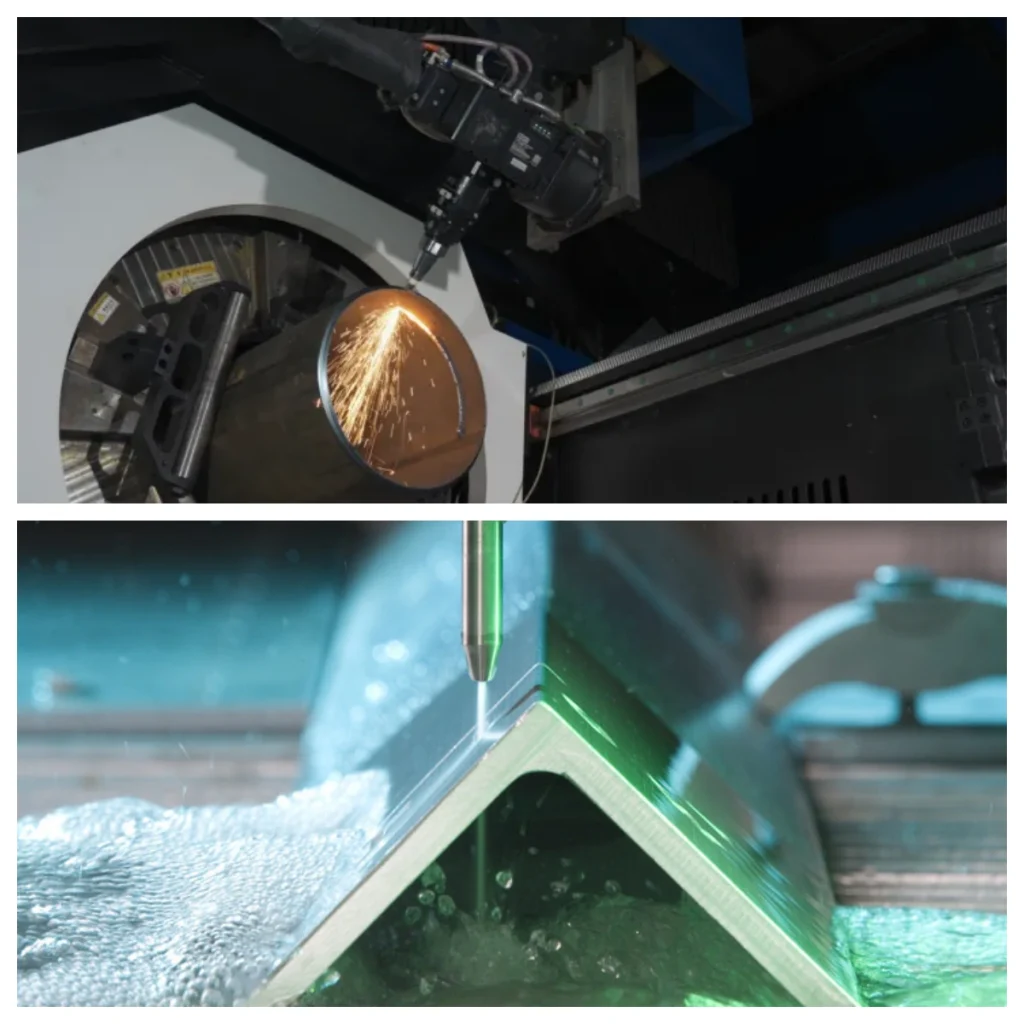

A laser cutting tube machine is a specialized machine that uses a high-powered laser to cut through metal tubes and pipes with exceptional precision. The laser beam melts, burns, or vaporizes the material, while high-pressure gas blows away the molten material, resulting in a clean, precise cut.

◆ How Does It Work?

The process begins when a computer-controlled system directs a laser beam onto the surface of the tube. As the beam is concentrated onto the material, the tube is heated to the point of melting or vaporizing. The high-pressure gas ensures that the material is removed, leaving behind a flawless cut. This method allows for precise control over both the cutting process and the shape of the finished product.

▶ KF Laser fiber laser tube cutting machine TN series cutting video.

2. Advantages of Using a Laser Cutting Tube Machine

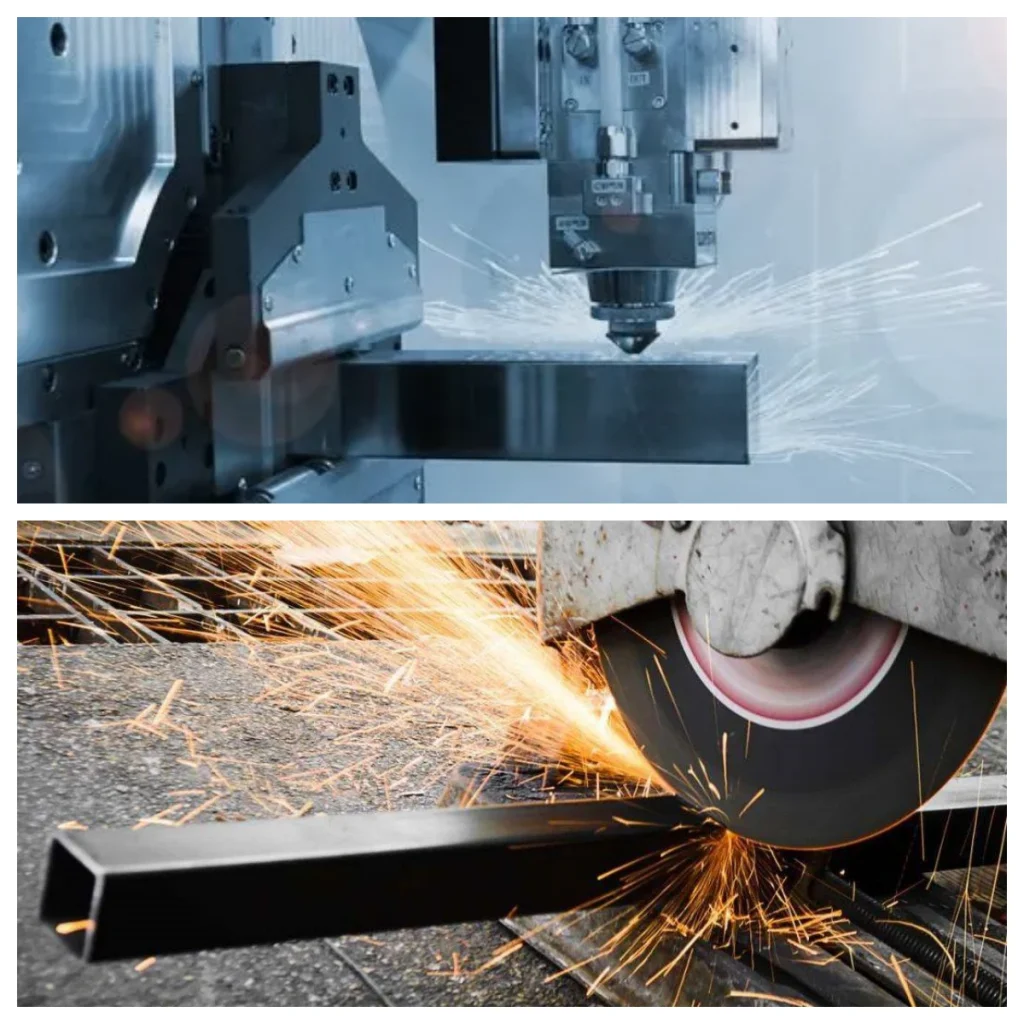

Laser cutting offers significant advantages over traditional methods of cutting tubes and pipes, such as saw cutting or plasma cutting. These benefits make laser cutting tube machines a preferred choice in industries where precision and speed are paramount.

◆ Unmatched Precision

Laser cutting machines provide exceptional accuracy, capable of cutting tubes and pipes to tight tolerances. The precision ensures that every component fits perfectly in its final application, reducing the need for rework and ensuring the high quality of each piece. This makes laser cutting ideal for industries such as aerospace, automotive, and construction, where small errors can lead to costly mistakes.

◆ Increased Speed and Efficiency

Laser cutting is faster than traditional cutting methods, allowing for quicker turnaround times and higher production rates. The ability to quickly cut through different types of metals, including steel, stainless steel, and aluminum, makes laser cutting an efficient choice for high-volume manufacturing. With minimal setup time and faster cutting speeds, businesses can enhance their productivity and meet demanding deadlines.

◆ Clean and Smooth Edges

One of the most notable benefits of laser cutting is its ability to create smooth, clean edges without the need for additional finishing work. Since the laser beam directly vaporizes the material, the edges are clean and do not require further deburring or sanding, making the process more efficient and cost-effective.

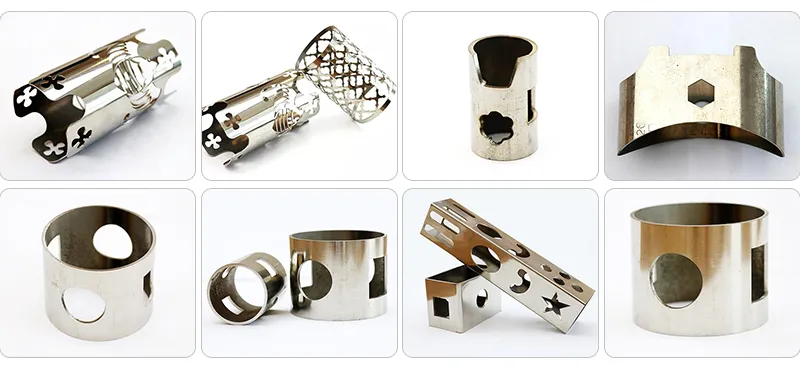

◆ Versatility in Design and Material Handling

Laser cutting tube machines are incredibly versatile and can handle a wide range of designs, from simple cuts to complex geometric patterns. The ability to create intricate cuts without compromising material integrity makes laser cutting suitable for a wide variety of applications. Moreover, these machines can cut through a broad range of materials, including thin and thick metals, making them highly adaptable to different industries and applications.

3. Laser Cutting vs. Traditional Tube Cutting Methods

While laser cutting tube machines offer significant advantages, it’s important to understand how they compare to other traditional cutting methods like mechanical saw cutting, plasma cutting, and water jet cutting.

◆ Laser Cutting vs. Saw Cutting

Saw cutting is one of the most common traditional methods used for cutting tubes and pipes. However, saw cutting requires physical contact with the material, which can result in burrs, rough edges, and a need for additional finishing processes. In contrast, laser cutting tube machines provide a non-contact method, ensuring that the material is not deformed or damaged during the cutting process.

◆ Laser Cutting vs. Plasma Cutting

Plasma cutting is often used for cutting thicker materials, but it doesn’t offer the same level of precision as laser cutting. Plasma cutting can produce rougher edges, which may require additional finishing work. Laser cutting tube machines offer cleaner cuts with smoother edges, which minimizes the need for post-processing and ensures higher quality finishes.

◆ Laser Cutting vs. Water Jet Cutting

Water jet cutting, although versatile and accurate, is slower than laser cutting. Additionally, water jet cutting requires the use of abrasive materials and may not be as effective when it comes to cutting thinner metals. Laser cutting machines, by contrast, can achieve faster cutting speeds and higher levels of accuracy, making them the preferred choice for many industries.

4. Applications of Laser Cutting Tube Machines

The versatility and precision of laser cutting tube machines make them invaluable across a wide range of industries. Below are just a few of the industries that rely heavily on this technology for their tube and pipe fabrication needs.

◆ Automotive Industry

Laser cutting is widely used in the automotive industry to produce components like exhaust pipes, chassis parts, and precision brackets. The speed and precision of laser cutting allow manufacturers to create high-quality parts that meet stringent safety and performance standards.

◆ Aerospace and Defense

In the aerospace and defense industries, precision is critical, and laser cutting tube machines offer the accuracy needed to fabricate complex components for aircraft and spacecraft. These components must meet exact specifications, and laser cutting ensures that each part is produced with flawless precision.

◆ Construction and Architecture

Laser cutting tube machines are often used in the construction and architectural sectors to cut steel tubes, structural supports, and decorative elements. The ability to handle both functionality and aesthetics makes laser cutting an essential tool for designers and engineers.

◆ Medical and Pharmaceutical Manufacturing

In the medical industry, precision is crucial, and laser cutting is ideal for fabricating parts such as surgical instruments, implants, and tubing for medical devices. The high level of accuracy ensures that each part fits perfectly, which is critical for the safety and efficacy of medical products.

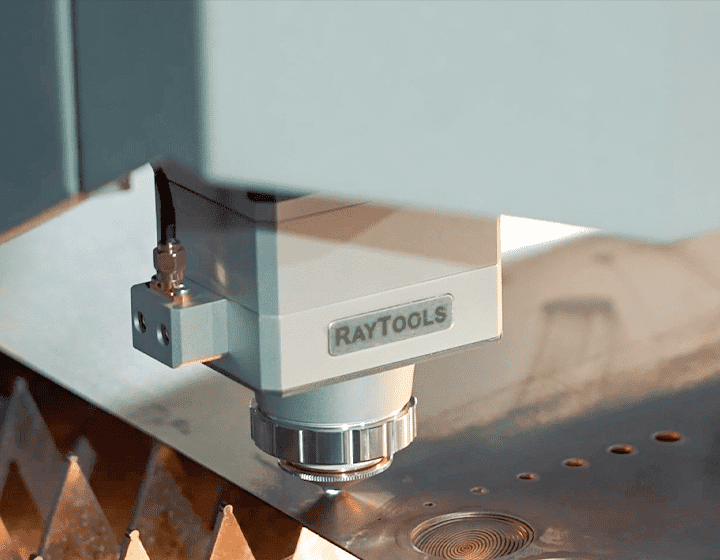

5. How to Choose the Right Laser Cutting Tube Machine

When selecting a laser cutting tube machine, there are several important factors to consider to ensure you choose the best system for your needs.

◆ Material Type and Thickness

Laser cutting systems are designed to handle various materials and thicknesses. Some machines are better suited for cutting thinner materials, while others can cut through thick metals with ease. Be sure to choose a system that matches the material types and thicknesses you will be working with.

◆ Power and Cutting Speed

The power of the laser cutting tube machine affects both cutting speed and material compatibility. Higher-powered systems are ideal for cutting thicker tubes and achieving faster cutting times, but it’s essential to balance power and speed to ensure quality results.

◆ Budget and Operating Costs

Laser cutting machines come with varying price points, and it’s essential to consider both the initial investment and the long-term operating costs. Maintenance, energy consumption, and consumables (like the laser beam) should all be factored into your budget.

6. Future Trends in Laser Cutting Technology

As technology continues to evolve, the laser cutting tube machine will only become more efficient, precise, and versatile. Advancements in laser power, cutting speed, and automation promise to further increase the capabilities of these systems. With innovations such as fiber lasers and increased integration with Industry 4.0 technologies, laser cutting is poised to play an even greater role in the future of manufacturing.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine