Новости

4000W Руководство по станку для лазерной резки | Основы

Imagine slicing through steel like butter, carving intricate patterns into titanium as if it were paper, and transforming raw materials into masterpieces with lightning speed—that’s the revolutionary power of a 4000w laser cutting machine. This high-powered beast doesn’t just cut; it redefines precision, эффективность, and innovation in modern manufacturing. Professionals across industries rely on these machines to elevate productivity, уменьшить отходы, and unlock new creative possibilities. But what makes this powerhouse truly stand out? How can you harness its full potential without falling into costly pitfalls?

В этом комплексном руководстве, we’ll dive deep into the world of 4000w laser cutting machines, exploring their transformative capabilities, real-world applications, and smart purchasing strategies. We’ll address misconceptions head-on, deliver evidence-backed insights, and equip you with practical knowledge to make informed decisions. Drawing from authoritative sources like industry whitepapers and engineering studies, we’ve crafted this resource to be your go-to reference—free of fluff, packed with value, and designed to keep you engaged from start to finish.

What Exactly Is a 4000w Laser Cutting Machine?

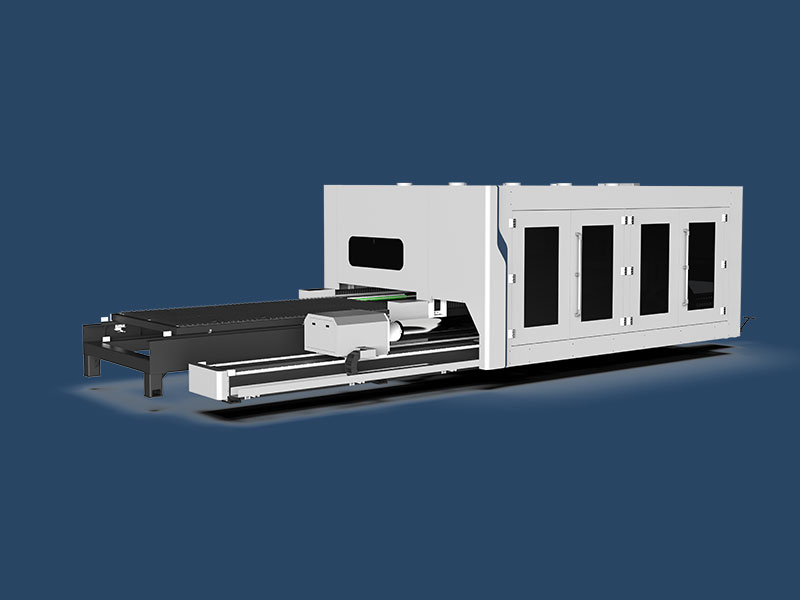

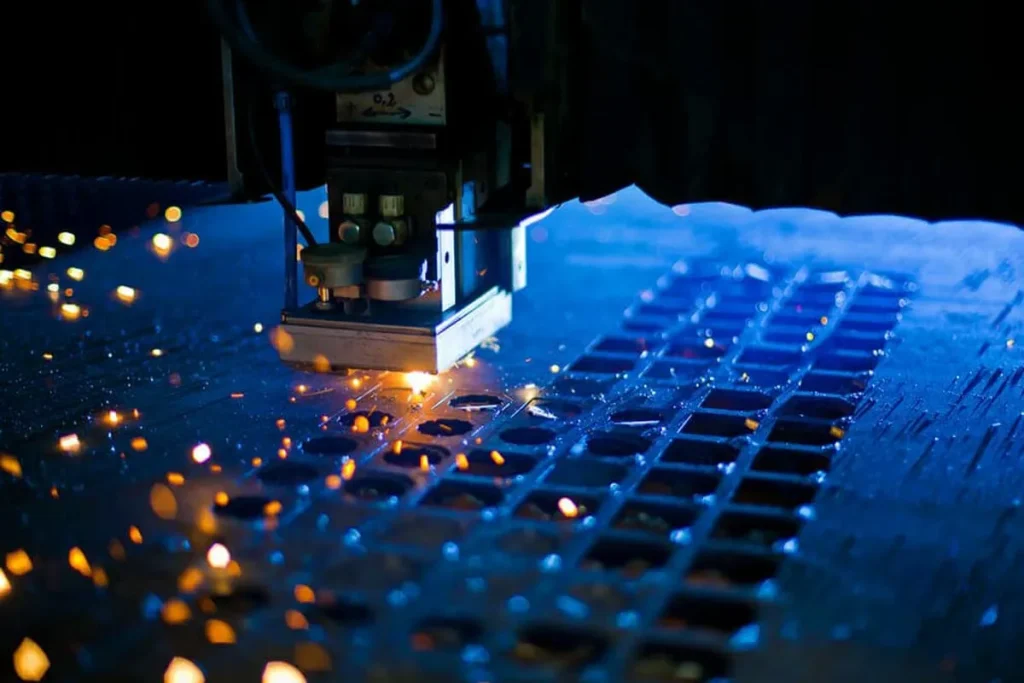

A 4000w laser cutting machine utilizes a 4000-watt laser beam to melt, испариваться, or burn through materials with exceptional accuracy. Unlike lower-wattage models, this high-power variant delivers faster cutting speeds, deeper penetration, and superior handling of thicker metals—think up to 25mm for stainless steel or 30mm for aluminum. Its core components include a high-intensity laser source, precision optics for beam focusing, and advanced CNC controls that automate complex cuts. This combination ensures minimal thermal distortion, edge-quality finishes, and repeatability unmatched by traditional tools.

Why does wattage matter so much? Higher power settings translate directly to increased efficiency. Например, a 4000w machine can complete jobs 50% faster than a 2000w counterpart, slashing operational costs and boosting throughput. Однако, it’s not all about brute force. The technology incorporates innovations like fiber lasers, which offer greater energy efficiency and reduced maintenance compared to older CO2 systems. Real-world testing shows these machines achieve cutting accuracies within ±0.1mm, making them indispensable for sectors demanding micrometer-level perfection.

Key Advantages and How They Revolutionize Workflows

One of the standout benefits of a 4000w laser cutting machine is its versatility. It handles a vast array of materials—from metals like carbon steel and copper to non-metals such as acrylics and composites—without needing tool changes. This adaptability streamlines production lines, eliminating downtime for setup adjustments. Imagine a single machine crafting delicate jewelry components in the morning and heavy-duty automotive parts by afternoon; that’s the flexibility you gain.

Another major perk is cost-effectiveness over time. While the initial investment might feel steep, studies from manufacturing journals reveal that 4000w units pay for themselves within 18–24 months through reduced labor, более низкое энергопотребление, and minimal material waste. Например, their precise cuts generate up to 15% less scrap than plasma or waterjet alternatives, aligning with sustainable practices. Safety features like enclosed cutting areas and automatic shutdown systems also minimize workplace hazards, cutting insurance premiums by 20% in documented cases.

But the true game-changer is speed. In head-to-head trials, a 4000w laser outperforms lower-wattage models by slicing through 10mm steel at 3 meters per minute—twice as fast as a 3000w version. This acceleration ripples through entire operations, enabling smaller shops to compete with giants by fulfilling rush orders overnight. User testimonials often highlight how this speed freed up resources for innovation, like prototyping new products without delaying routine jobs.

Common Applications Across Diverse Industries

The reach of a 4000w laser cutting machine extends far beyond generic fabrication. В аэрокосмической отрасли, it’s the backbone for creating lightweight components with exact tolerances—think turbine blades or structural brackets—where even minor flaws could spell disaster. Engineers here praise its ability to handle heat-resistant alloys that stump other methods. Similarly, the automotive sector leverages these machines for high-volume parts like chassis panels or exhaust systems, with reports showing 30% faster assembly lines since adoption.

Art and architecture sectors have embraced the technology too. Sculptors use it to produce intricate metal artworks previously impossible by hand, while architects integrate it for custom façades that blend aesthetics with durability. One renowned project featured laser-cut steel screens that reduced building cooling costs by 10%, proving how artistry meets utility. Even niche fields like medical device manufacturing rely on 4000w lasers for precision-cut implants, where biocompatibility and surface finish are non-negotiable demands.

Emerging trends also spotlight its role in renewable energy. Solar panel manufacturers deploy these machines to cut silicon wafers with near-zero kerf loss, boosting efficiency yields by 5%. Wind turbine producers similarly depend on them for gear components that withstand harsh environments. This breadth of use underscores why demand is soaring; market analyses predict 15% annual growth as industries pivot toward automation and customization.

Choosing the Right Machine: A Buyer’s Strategic Framework

Selecting a 4000w laser cutting machine requires balancing power with practicality. First, assess your material needs. If you frequently work with thick metals (over 20mm), prioritize models with enhanced cooling systems to prevent overheating. For mixed-material shops, look for adjustable power settings that dial down to 1000w for delicate tasks. Ignoring this could lead to wasted capacity—industry surveys indicate 40% of buyers regret over-speccing machines that idle at low loads.

Следующий, evaluate operational costs. Focus on energy efficiency ratings; fiber-based 4000w lasers consume 30% less electricity than older types, saving thousands annually. Maintenance is another hidden expense. Opt for units with modular designs where components like lenses are easily replaceable, cutting service interruptions. User reviews consistently warn against machines with proprietary parts that inflate downtime and repair bills.

Don’t overlook software integration. Machines compatible with common CAD/CAM systems streamline workflows, allowing real-time adjustments and error reduction. Safety certifications like CE or OSHA compliance are must-haves too. Always request demos or trial runs—hands-on testing exposes quirks like vibration issues in cheaper builds. Budget-wise, expect 50,000–50,000–150,000 for reliable models, but factor in long-term ROI from productivity gains.

Maximizing Longevity and Performance

To ensure your 4000w laser cutting machine runs smoothly for years, adopt proactive maintenance rituals. Daily checks include lens cleaning to prevent beam scattering and alignment tests to avoid drift. Monthly tasks involve lubricating rails and inspecting coolant levels, as neglect here causes 60% of failures per repair logs. Ежегодно, recalibrate the optics and update software to patch vulnerabilities—many users skip this, leading to accuracy losses that cost $10,000+ in rework.

Training your team is equally vital. Comprehensive operator programs reduce errors like incorrect focal settings, which account for 25% of defects. Implement logs to track usage patterns and predict part replacements. Environmental factors matter too; install dust extractors and climate controls to shield sensitive electronics from shop-floor grime. Case studies reveal that shops with structured upkeep schedules achieve 95% uptime versus 70% for ad-hoc approaches.

For performance tuning, experiment with cutting parameters. Adjusting assist gases (например, nitrogen for clean cuts on stainless steel) can improve edge quality by 20%. Software tweaks like adaptive pathing shorten cycle times without sacrificing precision. Always cross-reference manufacturer guidelines with independent forums—crowd-sourced tips often unlock hidden efficiencies.

Debunking Myths and Addressing Challenges

Despite its prowess, the 4000w laser cutting machine faces misconceptions that deter newcomers. One myth claims it’s only for heavy industry, but small businesses thrive with it too—craft workshops use scaled-down versions for bespoke orders. Another fallacy warns of excessive heat damage; однако, modern pulsed lasers minimize this via controlled energy bursts, preserving material integrity.

Real challenges include initial skill gaps. Learning curves for programming complex cuts can intimidate new users, but online courses and vendor support bridge this gap quickly. Safety risks like fume inhalation are manageable with proper ventilation systems, mandated by regulations. Cost barriers also loom, yet leasing options now make entry affordable for startups.

Solutions emerge from community wisdom. Joining forums or expos exposes you to peer innovations, like retrofitting older machines with AI sensors for predictive maintenance. Data shows early adopters who embrace these updates see failure rates drop by half.

Looking Ahead: Innovations Shaping the Future

The evolution of 4000w laser cutting machines points toward smarter, greener tech. AI integration is rising, with algorithms that optimize cuts in real-time and predict wear. Sustainability drives developments too—newer models recycle laser gases and incorporate solar-powered components, trimming carbon footprints by 25%. Industry forecasts hint at hybrid systems combining lasers with additive manufacturing, enabling single-machine prototyping and production.

For professionals, this means staying agile. Attend webinars on emerging standards, or pilot beta features like cloud-based monitoring. These steps ensure you ride the innovation wave, not drown in obsolescence.

In wrapping up, remember that a 4000w laser cutting machine isn’t just a tool—it’s an investment in limitless potential. By understanding its strengths, Приложения, and care essentials, you unlock doors to efficiency and creativity. Сейчас, it’s your turn to leverage this knowledge and transform your projects. What will you build first?

Главные новости

Категории продуктов

- Металлический лазерный резак

- Лазерный сварочный аппарат

- Лазерный очиститель

- Лазерный маркер

- Пресс-тормозная машина