Новости

Понимание цены на станок для лазерной резки металла: Полное руководство по инвестициям и затратам

1. Introduction to Metal Laser Cutting Machine Price

When exploring the world of metal fabrication, understanding the metal laser cutting machine price is crucial for making an informed decision. The cost of these machines varies greatly based on several factors, включая тип лазера, power output, и функции. This comprehensive guide will help you navigate the landscape of metal laser cutting machines, breaking down the elements that influence their pricing and how you can optimize your investment.

Whether you are considering a machine for a large-scale manufacturing operation or a smaller workshop, understanding the intricacies of metal laser cutting machine price will allow you to align your budget with your production goals effectively.

2. Factors That Influence Metal Laser Cutting Machine Price

Several factors play a role in determining the price of a metal laser cutting machine. Understanding these elements can help you find a machine that balances cost with capability, ensuring you get the most value for your investment.

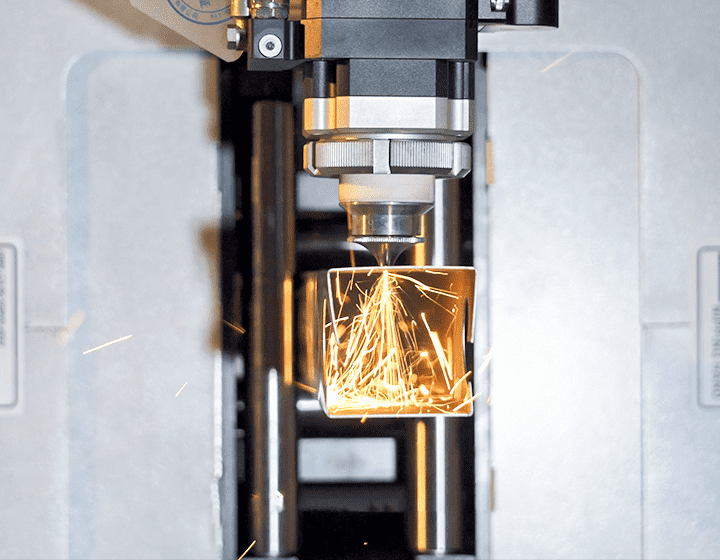

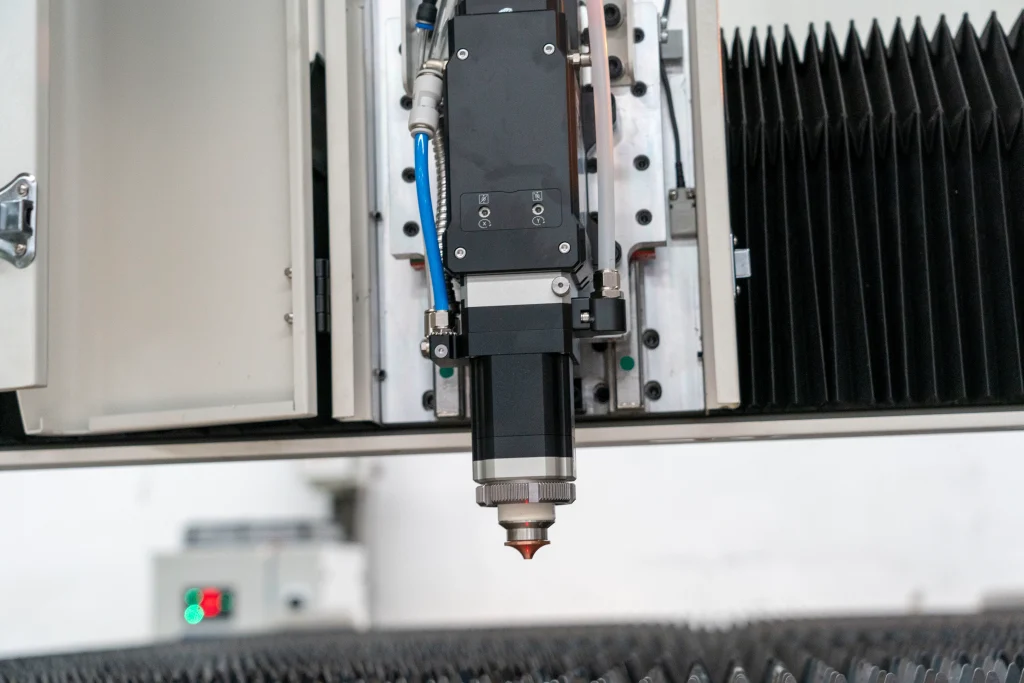

- Лазерный тип: Fiber vs. CO2

– Волоконные лазеры: Fiber lasers are known for their efficiency in cutting metals, в том числе нержавеющая сталь и алюминий. They offer a high degree of precision and are often preferred for cutting reflective materials. Однако, their advanced technology typically comes with a higher price tag.

– CO2-лазеры: СО2-лазеры, while versatile, are generally less efficient for metal cutting compared to fiber lasers. They are more suitable for a range of non-metallic materials but can handle certain metals with the right setup. CO2 laser machines tend to have a lower initial cost but can incur higher operational expenses due to their energy consumption.

- Выходная мощность

The power output of a laser cutting machine, обычно измеряется в киловаттах (кВт), is directly related to its ability to cut through thicker materials. Higher power output machines can cut faster and handle thicker metals, but they also come with a higher purchase price. The choice between a lower power machine and a high-power option depends on your specific material requirements and production volume.

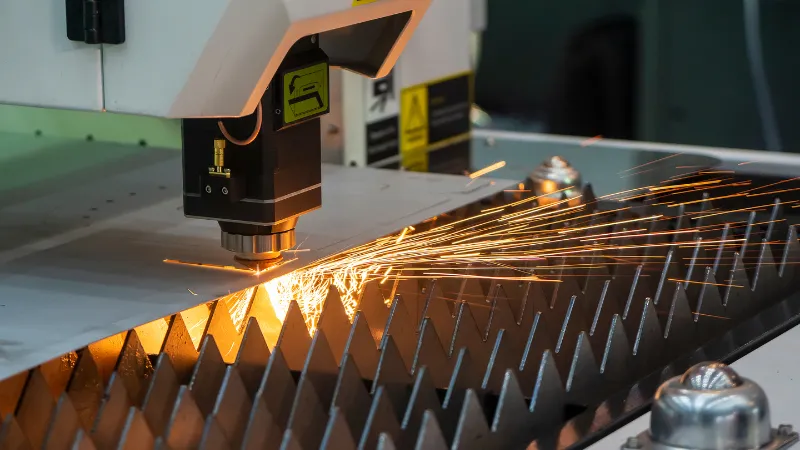

- Machine Size and Work Area

The physical size of a laser cutting machine and the size of its work area significantly influence its price. Machines designed for large-scale industrial applications often feature expansive cutting beds, allowing them to handle larger sheets of metal. These larger machines are more expensive, but they offer the advantage of increased productivity for high-volume operations.

- Automation and Advanced Features

Modern metal laser cutting machines often include features like automatic material loading, мониторинг в реальном времени, and software integration for CNC programming. While these automation features can increase the machine’s price, they can also significantly enhance efficiency, reduce labor costs, and minimize errors during production.

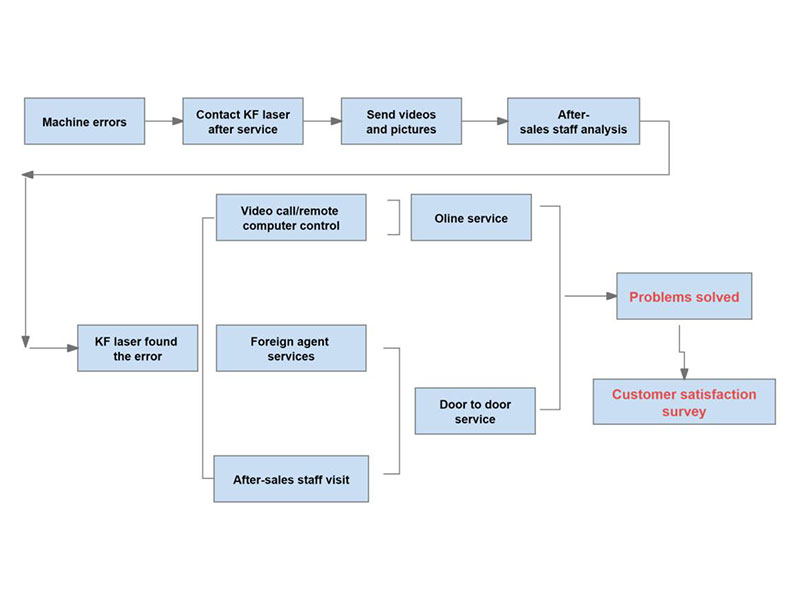

- Brand Reputation and Support Services

The brand of a laser cutting machine can impact its price. Established brands that offer reliable machines and comprehensive after-sale support tend to be more expensive. Однако, the investment may be worthwhile if it includes access to technical support, услуги по техническому обслуживанию, and training for operators.

3. Comparing Metal Laser Cutting Machine Prices

When evaluating metal laser cutting machine price, it’s essential to compare different types and their respective costs. Below is an overview of typical pricing ranges based on machine type and capabilities:

- Entry-Level Metal Laser Cutting Machines

Entry-level machines are designed for small businesses or workshops that have lower volume needs. They typically feature a power output between 0.5 kW and 2 кВт, making them suitable for cutting thin sheets of metal. The lower price range makes them accessible, but they may lack some advanced automation features.

- Mid-Range Metal Laser Cutting Machines

These machines strike a balance between entry-level and high-end models, offering power outputs between 2 kW and 6 кВт. They are ideal for businesses looking to expand their production capacity without the significant investment required for industrial machines. Mid-range options often include more robust software and better precision, making them versatile for various applications.

- High-Power Industrial Metal Laser Cutting Machines

Designed for large-scale manufacturing, high-power industrial laser cutters can handle thick metal plates with ease. These machines often feature power outputs from 6 kW to 30 кВт, allowing for rapid cutting speeds and the ability to process a wide range of metals. The investment in such a machine is substantial, but the efficiency gains can make it worthwhile for businesses with high production demands.

4. Calculating the True Cost of Ownership

Understanding the initial metal laser cutting machine price is only part of the equation. Calculating the total cost of ownership requires considering operational and maintenance expenses. Here are some key aspects to factor in:

- Energy Consumption

Higher-powered machines consume more energy, which directly impacts operational costs. Fiber lasers are generally more energy-efficient compared to CO2 lasers, making them a more economical choice for businesses focused on reducing their power consumption. It’s essential to estimate energy costs based on your expected machine usage.

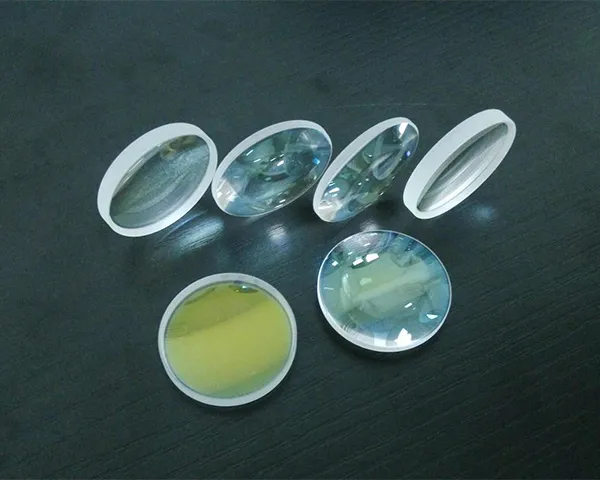

- Maintenance and Consumables

Regular maintenance is critical for keeping a laser cutting machine in optimal condition. Consumables like lenses, насадки, and protective covers must be replaced periodically. Maintenance costs can vary depending on the complexity of the machine and its usage level. Fiber lasers typically have fewer consumable needs than CO2 lasers, contributing to their lower long-term maintenance costs.

- Labor and Training Costs

Operating a metal laser cutting machine requires skilled labor, especially for machines equipped with advanced CNC systems. Training your team to use the machine efficiently is an important consideration. The initial investment in training can pay off by reducing the likelihood of errors and optimizing the machine’s performance.

- Material Handling and Storage

For businesses that handle large metal sheets, material storage and handling equipment can be an additional cost. Efficient material handling can improve productivity and reduce waste, but it requires space and equipment like forklifts and storage racks, which should be factored into the total investment.

5. Advantages of Investing in a Metal Laser Cutting Machine

Despite the substantial metal laser cutting machine price, there are several advantages to owning such equipment:

- Faster Production Turnaround

With an in-house laser cutting machine, businesses can accelerate production times by eliminating the need to outsource cutting jobs. This speed is especially valuable for custom projects and small batch production, where rapid prototyping and quick adjustments are essential.

- Enhanced Precision and Consistency

Owning a metal laser cutting machine allows for precise control over the cutting process. This results in consistent quality across production runs, reducing the need for rework and ensuring that parts meet strict tolerances. This is particularly important in industries like aerospace and automotive, где точность имеет первостепенное значение.

- Cost Savings Over Time

While the initial investment in a laser cutting machine can be high, the long-term savings from reduced outsourcing costs and increased production efficiency can make it a cost-effective solution. Businesses that frequently require laser-cut parts can achieve a return on investment (Рентабельность) within a few years, depending on their production volume.

6. Should You Buy or Outsource Metal Laser Cutting?

When weighing the metal laser cutting machine price against outsourcing costs, consider your production needs and financial resources. Here are some scenarios to help guide your decision:

- When to Buy

– High Production Volume: If your business regularly produces large quantities of laser-cut parts, owning a machine can reduce per-part costs and provide greater control over the production process.

– Потребности настройки: Businesses that require frequent design changes or prototyping can benefit from having a laser cutter in-house, enabling faster iteration and adjustments.

– Long-Term Investment: Companies planning to expand their operations and maintain consistent output over several years may find that the investment in a high-quality machine pays off over time.

- When to Outsource

– Low or Intermittent Demand: For businesses with fluctuating or low demand for laser-cut parts, outsourcing to a service provider can be more cost-effective than maintaining an in-house machine.

– Limited Budget: If the upfront cost of purchasing a laser cutting machine is prohibitive, outsourcing allows access to high-quality laser cutting without the initial investment.

– Specialized Cuts: For intricate or specialized projects, outsourcing to a provider with state-of-the-art equipment can ensure high-quality results without the need to invest in expensive machinery.

7. Trends in Metal Laser Cutting Technology

The market for laser cutting continues to evolve, with new developments aimed at improving efficiency and expanding capabilities. Here are some emerging trends:

– AI-Enhanced Cutting: Integration of AI in laser cutting machines can optimize cutting paths, adjust settings in real time, and reduce waste, offering even better value for the investment.

– Гибридные лазерные системы: Combining the advantages of both fiber and CO2 lasers, hybrid machines offer flexibility for businesses that need to work with diverse materials.

– Eco-Friendly Models: With an increasing focus on sustainability, manufacturers are developing energy-efficient laser cutters that reduce power consumption without sacrificing performance.

These advancements promise to make metal laser cutting more accessible and cost-effective, helping businesses to stay competitive.

Заключительные мысли

Investing in a metal laser cutting machine is a significant decision that requires careful consideration of various costs and benefits. Understanding the factors that influence the metal laser cutting machine price allows you to choose the right equipment that meets your needs while offering the best return on investment. By evaluating your production demands, бюджет, and the potential for long-term savings, you can determine whether owning a laser cutting machine is the right move for your business.

Главные новости

-

Fiber Laser Metal Cutting Machine For Sale05 декабрь 2025

Fiber Laser Metal Cutting Machine For Sale05 декабрь 2025 -

4000 Ватт Лазер | Промышленная мощность резки02 декабрь 2025

4000 Ватт Лазер | Промышленная мощность резки02 декабрь 2025 -

6 кВт лазерная резка | Руководство по промышленной точности28 ноябрь 2025

6 кВт лазерная резка | Руководство по промышленной точности28 ноябрь 2025 -

Революция в отрасли с помощью станка для лазерной резки стальных труб25 ноябрь 2025

Революция в отрасли с помощью станка для лазерной резки стальных труб25 ноябрь 2025 -

10кВт Лазерная резка | Точность & Власть21 ноябрь 2025

10кВт Лазерная резка | Точность & Власть21 ноябрь 2025

Категории продуктов

- Металлический лазерный резак

- Лазерный сварочный аппарат

- Лазерный очиститель

- Лазерный маркер

- Пресс-тормозная машина

Получите простое решение

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.