Новости

Овладение искусством лазерной резки листового металла: Полное руководство по точности и эффективности

1. Introduction to Sheet Metal Laser Cutting Machines

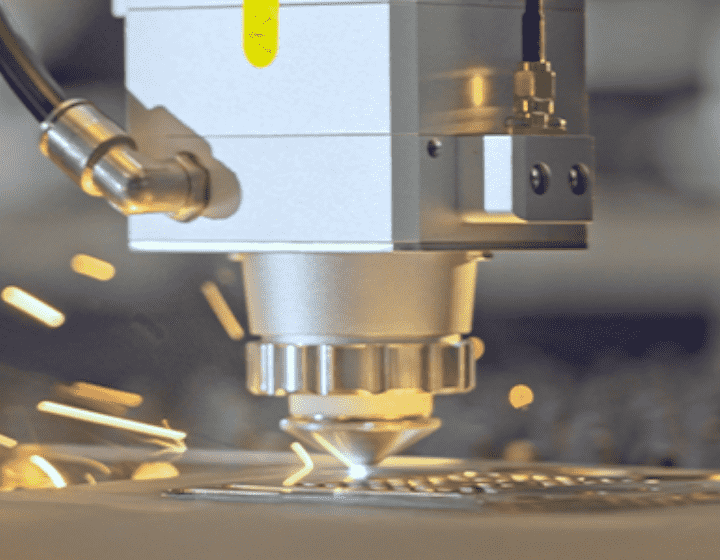

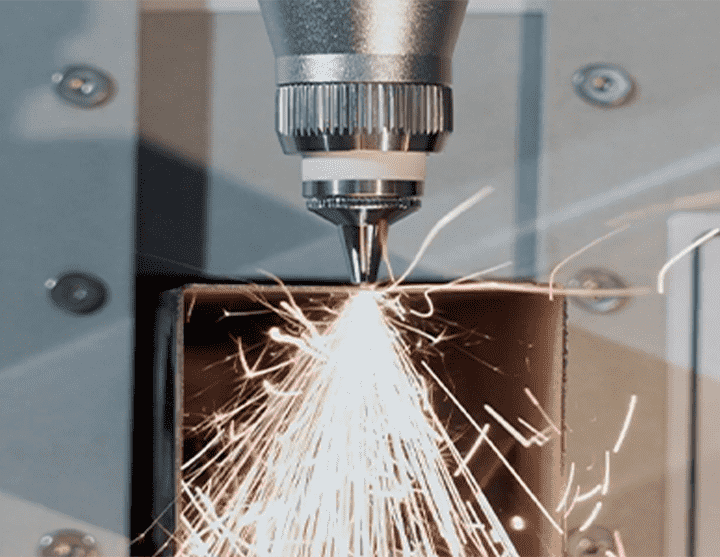

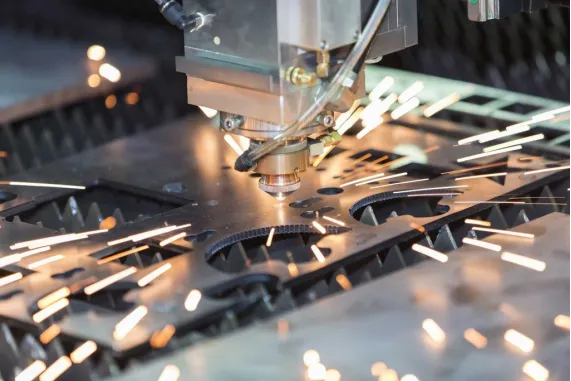

Sheet metal laser cutting machines have become indispensable in the modern manufacturing industry, offering unparalleled precision and efficiency in processing various metal types. These machines use focused laser beams to cut, форма, or engrave metal sheets, allowing for intricate designs and smooth edges. The adoption of sheet metal laser cutting machines has reshaped industries such as automotive, аэрокосмический, и электроника, where quality and speed are crucial.

This guide explores the core concepts, преимущества, типы, and applications of sheet metal laser cutting machines. Whether you are a seasoned professional or just entering the field, this detailed overview will provide valuable insights into making the most of this advanced technology.

2. How Sheet Metal Laser Cutting Machines Work

А sheet metal laser cutting machine uses a highly concentrated beam of light to melt or vaporize metal, achieving precise cuts without physical contact with the material. This process enables the creation of complex patterns and clean edges, even on thin metal sheets.

- Key Components of a Sheet Metal Laser Cutting Machine

– Лазерный источник: The heart of the machine, generating the laser beam that will cut through the metal. Fiber and CO2 lasers are the most common types for sheet metal cutting.

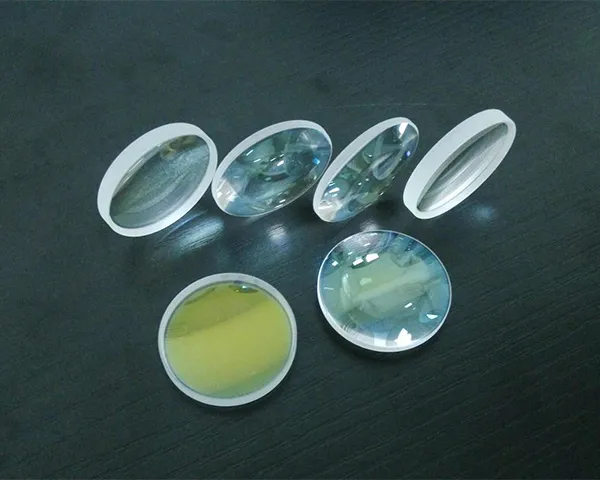

– Режущая голова: Contains lenses that focus the laser beam to a fine point, allowing for accurate cutting.

– CNC Control System: Компьютерное числовое управление (ЧПУ) guides the cutting head according to programmed designs, ensuring precision and repeatability.

– Помогать газовой системе: Uses gases like nitrogen or oxygen to clear molten material from the cut area, improving edge quality and cooling the cutting zone.

– Система охлаждения: Prevents the machine components from overheating, maintaining stable performance during long cutting sessions.

The video below can help you better understand how sheet metal cutting machines cut.

- The Cutting Process Explained

-Design and Programming: The cutting design is created using CAD software and translated into a CNC-compatible format.

-Материальное размещение: The metal sheet is placed on the cutting bed, where it is held securely to avoid any movement during cutting.

-Laser Beam Activation: The laser beam is focused on the metal sheet, melting or vaporizing it along the desired path.

-Помощь применению газа: Assist gases are used to blow away melted material, ensuring a clean cut.

-Completion and Quality Check: After cutting, the part is inspected for accuracy, and any necessary post-processing, like deburring, is performed.

3. Types of Sheet Metal Laser Cutting Machines

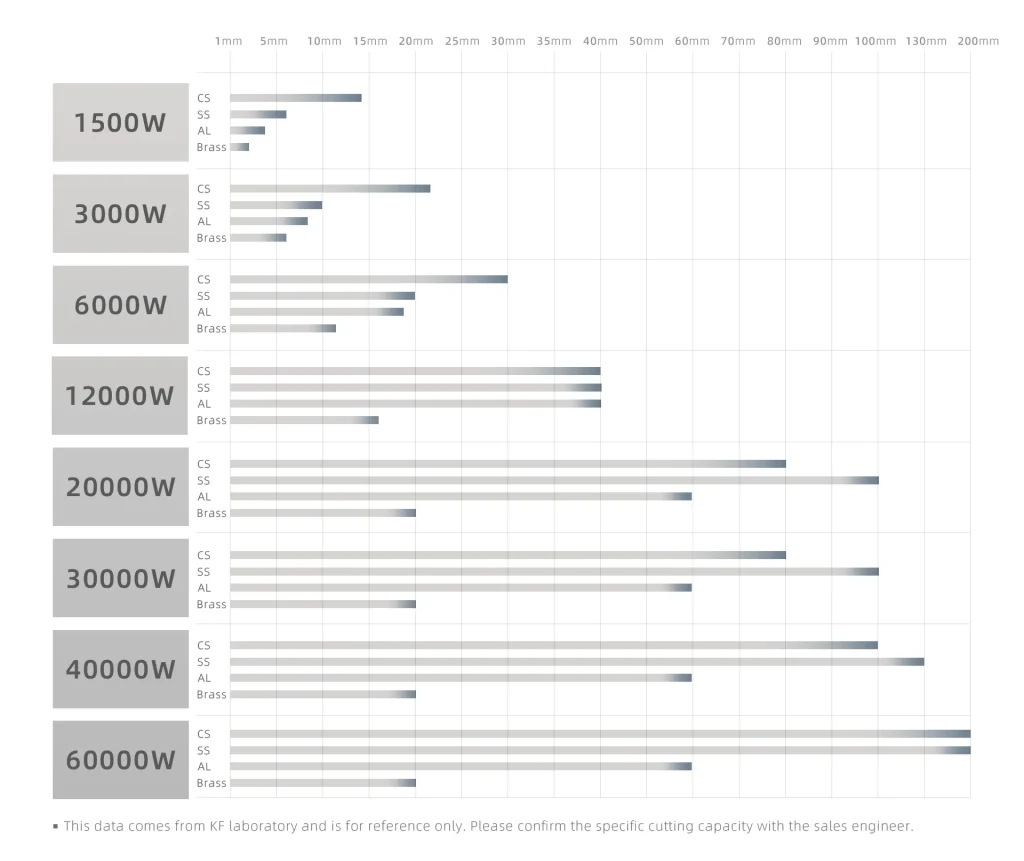

Selecting the right type of sheet metal laser cutting machine depends on factors like material thickness, required precision, and production scale. The primary types include fiber lasers and CO2 lasers, each offering unique benefits.

Fiber lasers have gained popularity due to their ability to cut various metals with high precision. Their solid-state laser source offers several advantages:

– Narrower Beam: Allows for highly detailed cuts, making them ideal for intricate designs and tight tolerances.

– Better Performance on Reflective Metals: Their shorter wavelength reduces the risk of damaging the machine when cutting reflective metals like aluminum.

– Энергоэффективность: Fiber lasers have a high energy conversion rate, reducing operational costs and making them suitable for continuous production environments.

- Станки для лазерной резки CO2

CO2 lasers use a mixture of gases to generate the laser beam and are known for their versatility:

– Wider Beam Width: Ideal for cutting thicker metal sheets, offering a good balance between speed and cutting power.

– Smooth Edges on Thicker Metals: CO2 lasers produce clean cuts, particularly useful for applications where the finish quality is critical.

– Более низкие начальные инвестиции: Although CO2 lasers might have higher operating costs due to maintenance, they can be a cost-effective solution for certain cutting needs.

4. Benefits of Using Sheet Metal Laser Cutting Machines

The use of sheet metal laser cutting machines brings numerous advantages that have made them a preferred choice in manufacturing. Here’s why they stand out:

- Высокая точность и точность

These machines excel in producing precise cuts, even on thin metal sheets, making them suitable for industries where accuracy is non-negotiable. Their ability to maintain tight tolerances ensures that parts are consistent, reducing the need for adjustments during assembly.

- Скорость и эффективность

Sheet metal laser cutting machines can process materials quickly, значительное сокращение времени производства. This efficiency is especially beneficial in high-volume manufacturing, where rapid turnaround times can translate into competitive advantages.

- Clean Cuts and Reduced Post-Processing

Лазерная резка производит гладкую, края без заусенцев, minimizing the need for additional finishing steps. This advantage not only saves time but also cuts down on labor costs, making laser cutting a more economical choice for many projects.

- Versatility Across Different Metals

These machines are capable of cutting a range of metals, включая нержавеющую сталь, мягкая сталь, and aluminum. This versatility allows manufacturers to handle diverse projects without needing multiple machines, enhancing operational flexibility.

- Integration with Automation

Modern sheet metal laser cutting machines can be seamlessly integrated into automated production lines, allowing for round-the-clock operation with minimal human intervention. Features like automated material handling and real-time process monitoring further boost productivity.

5.Applications of Sheet Metal Laser Cutting Machines

The versatility of sheet metal laser cutting machines makes them valuable across various industries. Вот некоторые из ключевых приложений:

- Автомобильное производство

В автомобильной промышленности, these machines are used to cut parts like body panels, exhaust components, и сложные скобки. The precision of laser cutting ensures that each part meets strict safety and quality standards.

- Construction and Architectural Design

Sheet metal laser cutting machines are vital for creating custom architectural elements, such as decorative panels, structural supports, and bespoke designs. The ability to cut complex shapes allows architects to explore innovative designs.

- Электроника и электрические компоненты

These machines are ideal for producing precise parts for electronics, such as metal enclosures, circuit board frames, и радиаторы. The clean cuts provided by laser technology ensure that components fit perfectly, enhancing product reliability.

- Аэрокосмические компоненты

The aerospace industry demands high precision and lightweight materials, making laser cutting ideal for producing parts like turbine blades, fuselage components, and other critical structures.

- Industrial Machinery and Tools

In the industrial sector, laser cutting is used to manufacture gears, housings, and frames for machinery. The ability to cut thick and durable metals ensures that these components can withstand demanding environments.

6. Key Considerations When Selecting a Sheet Metal Laser Cutting Machine

Choosing the right machine is essential to achieving the desired results in metal fabrication. Here are the critical factors to consider:

- Тип и толщина материала

Different metals and thicknesses require different laser power levels. Лазеры из волокна обычно более эффективны для более тонких материалов, while CO2 lasers are better suited for cutting thicker sheets.

- Desired Precision and Cut Quality

For projects requiring intricate designs and fine details, fiber lasers offer superior precision. For applications where smooth edges on thicker sheets are more critical, CO2 lasers might be the better choice.

- Затраты на техническое обслуживание и эксплуатацию

While fiber lasers have lower maintenance needs, it’s important to consider long-term costs, including energy consumption and component replacement. Understanding the total cost of ownership can help make a more informed decision.

- Automation Capabilities

For manufacturers looking to increase production speed and efficiency, automation features like automatic material loading and CNC programming are essential. These features can drastically reduce labor costs and improve consistency.

7. Optimizing Your Sheet Metal Laser Cutting Process

To achieve the best performance from your sheet metal laser cutting machine, optimizing the settings and maintaining the equipment is key:

- Adjusting Laser Power for Different Materials

Using the correct power settings ensures clean cuts without excessive heat affecting the material. Adjusting power levels based on the type of metal and its thickness can significantly enhance cut quality.

- Selecting the Right Assist Gas

Choosing between oxygen, азот, and air can impact the cutting speed and edge quality. Например, oxygen can speed up the cutting process but may cause slight oxidation, while nitrogen provides cleaner edges on stainless steel.

- Focus and Alignment Adjustments

Properly focusing the laser beam and ensuring that the machine’s components are aligned can improve cutting precision. Regular focus checks and adjustments help maintain optimal performance.

- Routine Maintenance and Cleaning

Keeping the machine clean and regularly checking for wear and tear ensures longevity and consistent performance. This includes cleaning the cutting head lenses, checking the cooling system, and monitoring the gas supply.

8. Future Trends in Sheet Metal Laser Cutting

The industry is continually evolving, with new technologies making sheet metal laser cutting machines more capable and efficient:

– Hybrid Laser Technologies: Machines that combine the advantages of fiber and CO2 lasers to offer versatility in cutting various materials.

– AI and Machine Learning Integration: Software that uses AI to optimize cutting paths and settings, reducing waste and increasing efficiency.

– Energy-Efficient Models: Advances focused on reducing power consumption, making laser cutting more sustainable and cost-effective.

These innovations promise to keep sheet metal laser cutting at the forefront of manufacturing technology, helping businesses stay competitive in an ever-changing landscape.

Финальные выводы

Sheet metal laser cutting machines provide a balance of speed, точность, and versatility that is unmatched in the metalworking industry. By choosing the right machine, optimizing its use, and keeping up with industry trends, manufacturers can significantly enhance their production processes, ensuring they meet the demands of quality and efficiency that today’s market requires.

Главные новости

-

Fiber Laser Metal Cutting Machine For Sale05 декабрь 2025

Fiber Laser Metal Cutting Machine For Sale05 декабрь 2025 -

4000 Ватт Лазер | Промышленная мощность резки02 декабрь 2025

4000 Ватт Лазер | Промышленная мощность резки02 декабрь 2025 -

6 кВт лазерная резка | Руководство по промышленной точности28 ноябрь 2025

6 кВт лазерная резка | Руководство по промышленной точности28 ноябрь 2025 -

Революция в отрасли с помощью станка для лазерной резки стальных труб25 ноябрь 2025

Революция в отрасли с помощью станка для лазерной резки стальных труб25 ноябрь 2025 -

10кВт Лазерная резка | Точность & Власть21 ноябрь 2025

10кВт Лазерная резка | Точность & Власть21 ноябрь 2025

Категории продуктов

- Металлический лазерный резак

- Лазерный сварочный аппарат

- Лазерный очиститель

- Лазерный маркер

- Пресс-тормозная машина