News

4KW Fiber Laser Cutter: Redefining Metal Fabrication with Precision and Speed

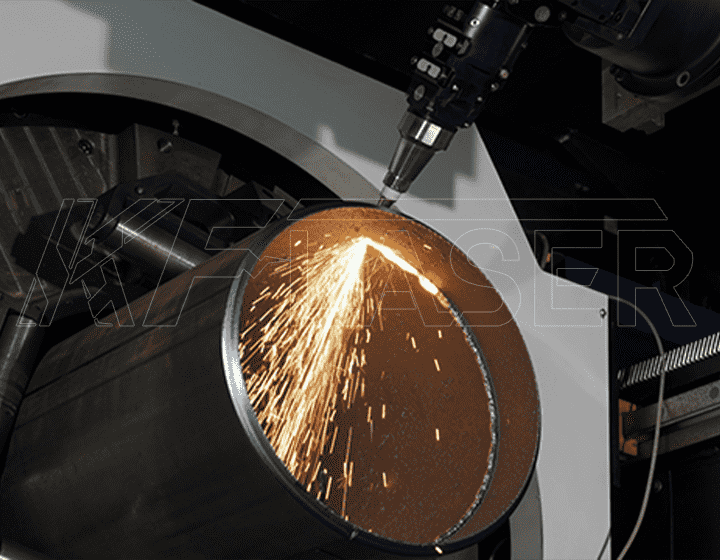

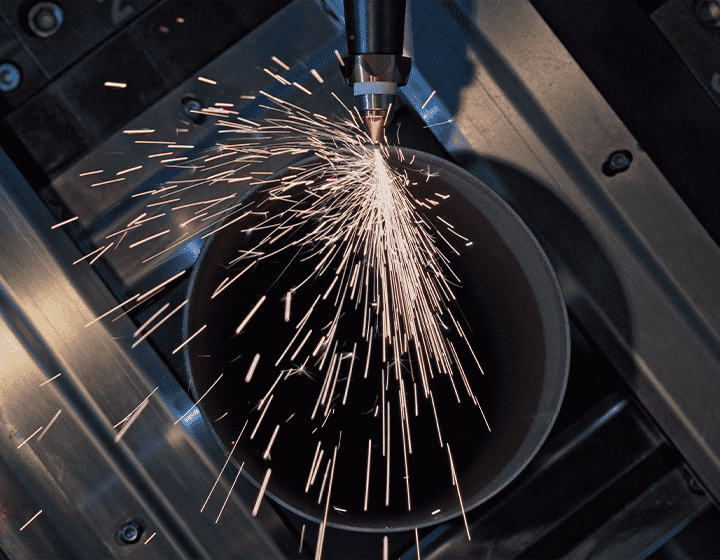

Imagine slicing through 25mm stainless steel with the smoothness of a hot knife through wax, leaving edges so clean they require no post-processing. This isn’t science fiction—it’s the reality of a 4KW fiber laser cutter, the workhorse that’s reshaping how manufacturers approach metal fabrication. In an industry where every millisecond and micrometer counts, this technology isn’t just an upgrade—it’s a paradigm shift.

1. The Science Behind the Power: Why 4KW Fiber Lasers Stand Out

At the heart of a 4KW fiber laser cutter lies a simple yet revolutionary principle: amplified light. Unlike traditional CO2 lasers, which rely on gas tubes and mirrors (and lose up to 30% of energy in transit), fiber lasers use doped optical fibers to generate a concentrated beam. This design delivers three game-changing advantages:

- Unrivaled Precision: The beam’s diameter is just 0.1mm—thinner than a human hair—allowing for intricate cuts in components like aerospace brackets or medical devices. A 2024 study by the Laser Institute of Americafound that 4KW fiber lasers reduce dimensional errors by 60% compared to plasma cutters.

- Blistering Speed: With a cutting rate of up to 15 meters per minute (for 10mm steel), these machines slash production time by 40% or more. One automotive parts supplier in Chicago reported doubling its output of exhaust components after switching to a 4KW fiber laser.

- Energy Efficiency: Fiber lasers convert 25–30% of electrical energy into usable light (vs. 10–15% for CO2 lasers). This translates to a 35% drop in monthly electricity bills—critical for manufacturers grappling with rising energy costs.

2. Real-World Impact: How Industries Are Leveraging 4KW Fiber Lasers

The versatility of 4KW fiber laser cutters makes them indispensable across sectors:

Industry | Application | Result |

Automotive | Cutting chassis parts and exhaust systems | 50% faster production; 20% fewer reworks |

Aerospace | Fabricating titanium alloy components | Precision within 0.02mm; compliance with FAA standards |

Metal Furniture | Creating custom table frames and decorative pieces | 30% reduction in material waste (thanks to nested cutting) |

Medical Devices | Manufacturing surgical instruments | Sterile, burr-free edges; 40% faster turnaround |

For a small business in Ohio specializing in custom metal signs, the switch to a 4KW fiber laser cutter was transformative. “We used to spend hours sanding edges after plasma cutting,” says owner Mike Thompson. “Now, we can cut a 3ft sign in 10 minutes—perfectly smooth, every time. Our customer base has grown 25% in a year.”

3. Choosing the Right 4KW Fiber Laser Cutter: Key Considerations

Investing in a 4KW fiber laser cutter is a big decision—here’s what to look for:

- Bed Size: Match it to your typical workpiece. A 3×1.5m bed works for most small to medium manufacturers, while larger shops may need 6x2m.

- Cooling System: Fiber lasers generate heat—opt for a closed-loop water cooling system to ensure consistent performance.

- Software Compatibility: Look for machines that integrate with CAD/CAM software like SolidWorks or AutoCAD. Some models even offer AI-powered nesting to minimize material waste.

- After-Sales Support: Laser cutters require regular maintenance. Choose a supplier with local service technicians and a 24/7 support line.

4. The Future of Metal Fabrication: What’s Next for 4KW Fiber Lasers?

As technology advances, 4KW fiber laser cutters are set to become even more powerful. Researchers are experimenting with ultra-short pulse lasers (USPL) to cut brittle materials like glass and ceramics, while AI-driven predictive maintenance could reduce downtime by 50%. For manufacturers, this means staying ahead of the curve isn’t just about buying a machine—it’s about embracing a culture of innovation.

The 4KW fiber laser cutter isn’t just a tool—it’s a catalyst for growth. By combining precision, speed, and efficiency, it’s helping manufacturers of all sizes compete in a global market. Whether you’re cutting steel for cars or crafting custom art, this technology has the power to take your business to the next level. And in an industry where every advantage counts, that’s not just valuable—it’s essential.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine