Notícias

8Revolução da máquina de corte a laser kW

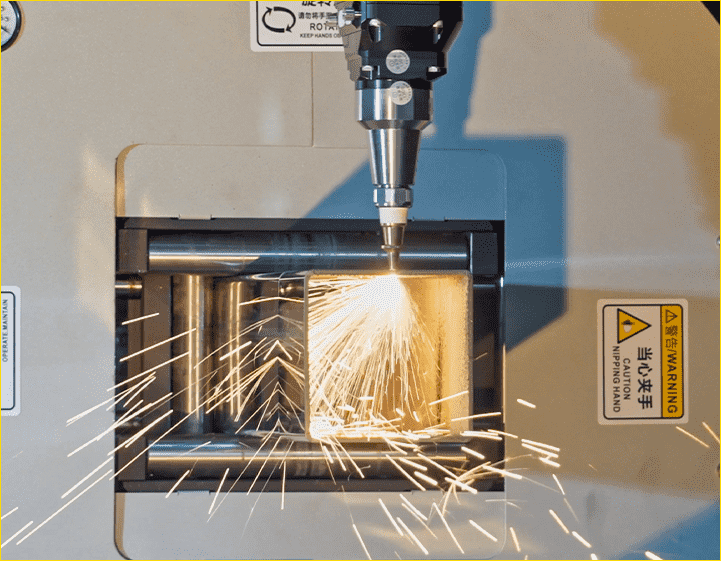

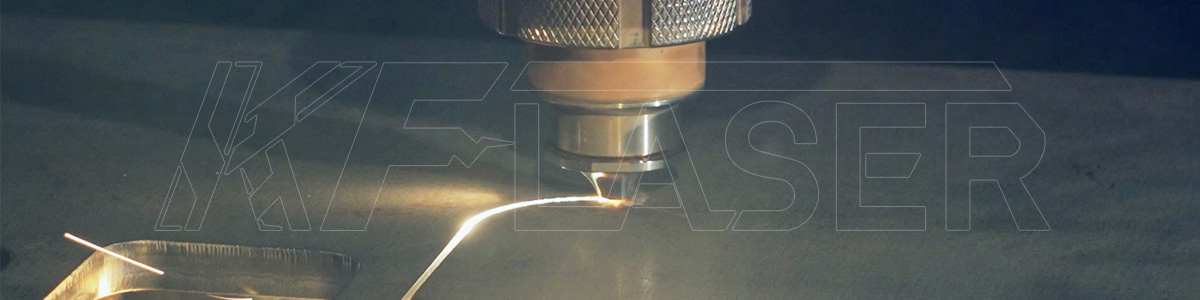

8kW laser cutting machine technology now delivers unprecedented industrial might, slicing through hardened alloys like a hot knife through butter and redefining the limits of modern fabrication. Imagine transforming 30mm stainless steel into intricate components faster than you can brew coffee or piercing exotic metals previously deemed uncuttable – this isn’t sci-fi fantasy; it’s today’s manufacturing reality. Witness raw power morphing impossibility into standard operational procedure across global workshops.

Unleashing the Beast: Why 8kW Changes Everything

Industrial Evolution Timeline

- Pre-2010:4kW systems dominated, limited to ≤20mm steel cuts

- 2015:6kW emergence doubled productivity on mid-range metals

- 2022:Commercial 8kW deployments shattered thickness barriers

- Present:30% annual adoption growth in shipbuilding/military sectors

Material Liberation Matrix

Material | Max Thickness | Speed Gain vs. 6kW |

Aço carbono | 35milímetros | +40% |

Alumínio | 25milímetros | +55% |

Latão | 22milímetros | +60% |

Titânio | 18milímetros | +70% |

Fabricators report 15-hour production cycles condensed into 5-hour sprints – equivalent to gaining two extra workdays weekly. Portland’s naval equipment manufacturer slashed their armored component lead times from 14 days to 62 hours post-8kW integration, fueling 200% contract growth.

Core Technological Breakthroughs

Optical Powerhouse Architecture

- Triple-Chamber Resonators

Stable energy distribution across 3 amplification stages eliminates thermal lensing - Dynamic Beam Control

Nanosecond-adjustable focal points maintaining ±0.03mm consistency at 25m/min - Hyperbolic Nozzle Arrays

Multi-directional assist gas streams preventing molten metal re-adhesion

Self-Optimizing Intelligence

Material Sensor → Cloud Database → Adaptive Parameter Suite

↓ ↓ ↓

Thickness Analyzer Alloy Composition Detector Cutting Path Recalibration

This cognitive framework auto-adjusts frequency (1-5000Hz), gas pressure (0.5-25bar), and nozzle height during operations. Vancouver aerospace engineers recorded 99.8% first-pass yield on flight-critical titanium parts after implementation.

Economic Transformation Model

ROI Acceleration Metrics

Investment Segment | Redução de custos | Productivity Uplift |

Energy Consumption | 28% per kWh | N/A |

Labor Hours | 41% | N/A |

Material Waste | 19% | N/A |

Output Volume | N/A | 300% |

Detroit auto parts supplier metrics reveal shocking economics: $1.2M machine investment recouped in 11 months through 24/7 operação. Their throughput surged from 470 units daily to 1,580 while energy bills dropped 31% – rewriting traditional ROI expectations.

Future-Proofing Your Operation

Implementation Survival Guide

- Infrastructure Audit

- 400V/3-phase power minimum with harmonic filters

- 6-ton foundation slabs with vibration-dampening mounts

- Class IV laser-rated ventilation systems

- Workflow Re-engineering

- Hybrid nesting software combining rectangular + true-shape algorithms

- Conveyorized debris management handling 220kg/hour slag

- Multi-level safety interlocks (light curtains/pressure mats)

- Skill Transition Framework

Traditional Role | Evolved Responsibilities |

Machine Operator | Process Optimization Analyst |

Quality Inspector | AI Training Specialist |

Production Manager | Digital Twin Coordinator |

- Tokyo’s heavy machinery conglomerate retrained 74% of their workforce in 90 days using VR simulation pods, subsequently achieving zero downtime during transition.

Cutting-Edge Applications Redefining Industries

Radical Case Studie

Offshore Energy Sector

Challenge: Cutting 32mm corrosion-resistant alloys in Arctic conditions

Solução: 8kW systems with cryogenic assist gases enabling -50°C operations

Outcome: Platform construction accelerated by 8 months

Hypercar Manufacturing

Challenge: Mirror-finish cutting on carbon-fiber reinforced polymers

Solução: Pulsed-mode 8kW lasers at 0.05ms pulse widths

Outcome: 0.005mm tolerance achieved on $2M chassis components

Engineers recently demonstrated cutting 40mm armor plating at 1.8m/min – thicknesses requiring plasma or waterjet just 24 months ago.

Beyond Metal: The Unconventional Frontier

Non-Traditional Processing

- Ceramic Ablation

Creating cooling channels in silicon nitride turbine blades - Diamond Micro-Processing

Engraving industrial-grade diamonds for quantum computing substrates - Composites Delamination Prevention

Multi-phase pulsing eliminating carbon fiber matrix damage

MIT’s Advanced Manufacturing Lab documented 0.009mm kerf widths on aerospace-grade ceramics – precision previously exclusive to lithography.

Maintenance Evolution

Self-Preservation Protocols

- Optical Path Safeguards

- Auto-cleaning lens cartridges every 45 pierces

- Helium-neon beam alignment verification

- Robotic Component Replacement

- Nozzle changers with 8-second swap capability

- Modular power supply hot-swapping

- Predictive Analytics Suite

- Resonator frequency drift forecasting

- Capacitor degradation modeling

Milwaukee’s industrial hub reported 97% uptime over 18 months using these protocols, slashing maintenance costs by 63%.

Tomorrow’s Horizon

Quantum Leap Innovations

- Frequency-Combinable Systems

Merging multi-wavelength beams for hybrid material processing - Graphene Cooling Layers

Dissipating 1500°C nozzle temperatures instantly - Holographic Beam Shaping

Simultaneously cutting 5 distinct geometries on single plates

“10kW systems entering testing phases promise to cut 50mm steel at production-viable speeds,” reveals Dr. Lena Whitmore, laser physicist at Cambridge’s Cavendish Laboratory. “We’re approaching theoretical physics limits.”

Final Perspective: When Munich’s midnight shift ends without human presence, 8kW laser cutting machines continue etching tomorrow’s innovations under sterile white lights – these autonomous powerhouses don’t just extend production hours; they obliterate temporal constraints. Industrial leaders who harness this capability won’t merely outpace competitors; they’ll redefine entire supply chain dynamics while others sleep.

Notícias principais

Categorias de produtos

- Cortador a laser de metal

- Máquina de solda a laser

- Máquina de limpeza a laser

- Máquina marcadora a laser

- Máquina de freio de imprensa