News

Which Material Should You Never Cut in the Laser Cutter?

Imagine standing before a high-powered laser cutter, the air crackling with energy, the machine ready to slice through materials with surgical precision. It’s a thrilling sight, a testament to modern technology’s power and versatility. But wait! Before you plunge headlong into this exciting world, there are critical safety considerations to address. Not all materials are suitable for laser cutting, and certain choices can lead to disastrous consequences, including damage to the machine, hazardous fumes, and even fires.

In this comprehensive guide, we will explore the materials you should absolutely avoid cutting with a laser cutter. Understanding these limitations is vital for anyone involved in manufacturing, crafting, or any form of material processing. Let’s dive into the details and ensure your laser cutting endeavors remain safe and effective.

1. The Basics of Laser Cutting Technology

- What is Laser Cutting?

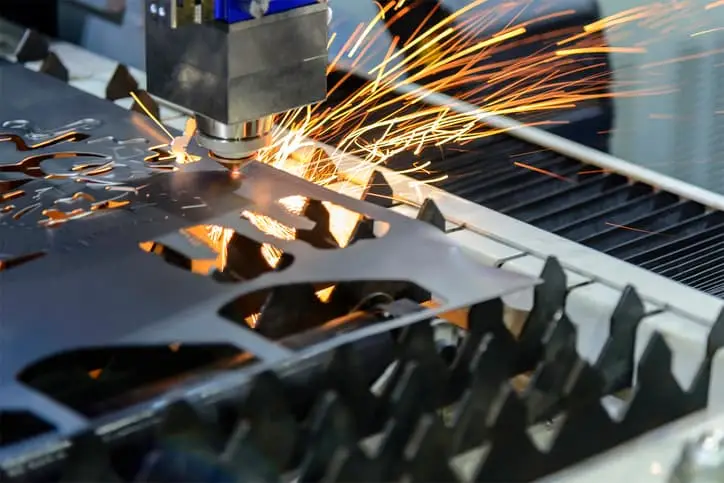

Laser cutting utilizes focused beams of light to cut or engrave materials with exceptional precision. The process involves directing a high-energy laser beam onto the material, melting or vaporizing it to create intricate designs. This technology has revolutionized industries ranging from aerospace to fashion, allowing for intricate designs and rapid production.

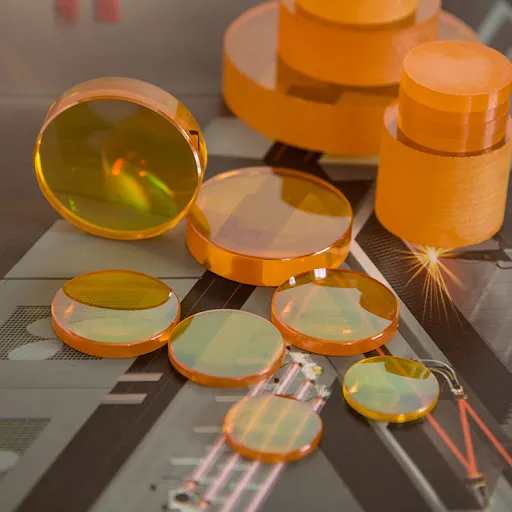

- How Does Laser Cutting Work?

Laser cutters work by emitting a concentrated beam of light that is amplified and focused through optics onto the material. The heat generated by the laser melts or vaporizes the material, and a jet of gas may be used to remove the molten material, creating a clean edge. The effectiveness of this process depends significantly on the material being cut.

2. Materials You Should Never Cut with a Laser Cutter

While laser cutters can handle a wide array of materials, several should be avoided at all costs due to safety hazards or machine damage. Here’s a detailed look at these materials:

- PVC (Polyvinyl Chloride)

Hazards: When cut, PVC releases highly toxic fumes, including hydrochloric acid, which can corrode metal components and pose serious health risks to operators.

Impact on Machine: The corrosive nature of these fumes can damage internal parts of the laser cutter, leading to costly repairs.

- ABS (Acrylonitrile Butadiene Styrene)

Hazards: Similar to PVC, cutting ABS can release harmful fumes. While not as toxic as PVC, the fumes can still be detrimental to health.

Impact on Machine: The combustion of ABS may lead to a buildup of residue in the machine, affecting its efficiency and requiring more frequent cleaning.

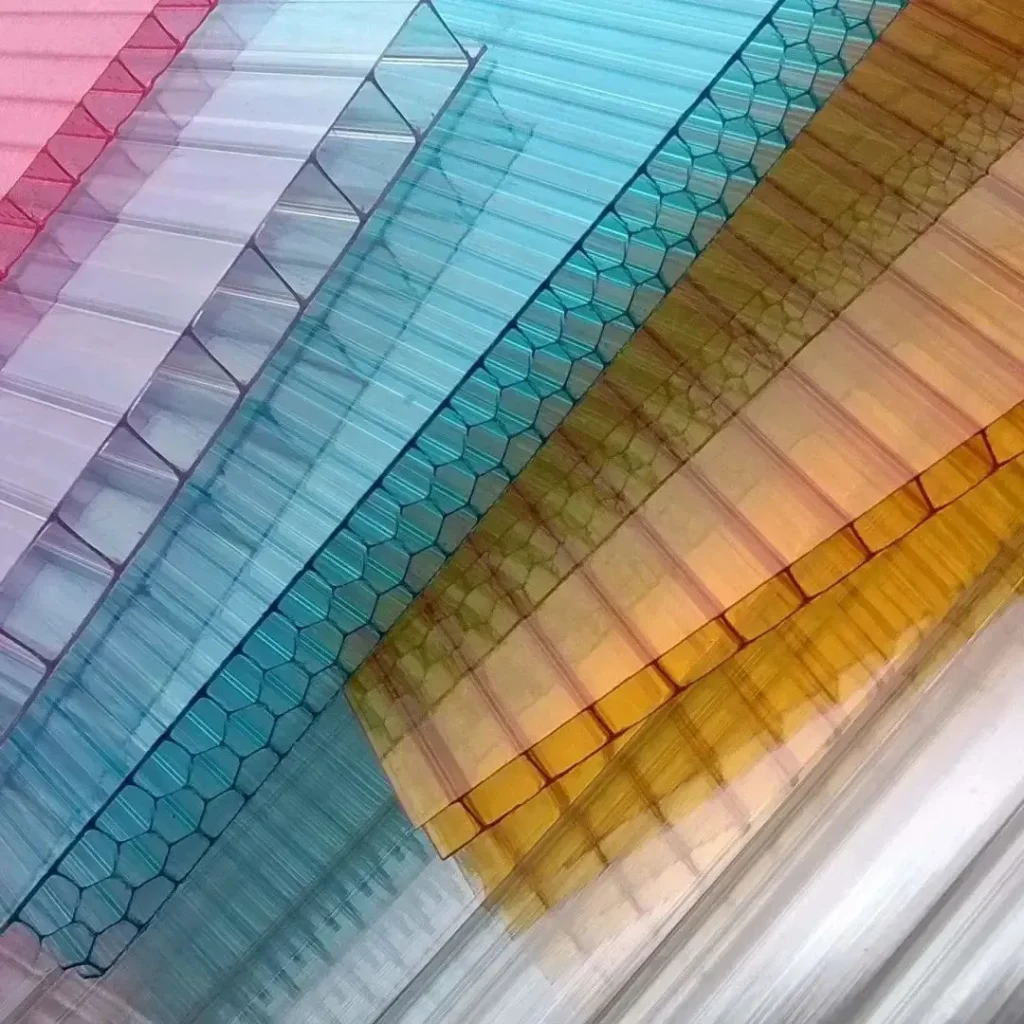

- Polycarbonate

Hazards: This plastic can melt and create a sticky residue that clogs the laser’s optics, compromising the cutting process.

Impact on Machine: Over time, the buildup can significantly reduce the laser cutter’s effectiveness and lead to potential downtime for maintenance.

- Some Metals

While laser cutters are designed for metal cutting, specific metals like aluminum can be tricky.

Hazards: If improperly set, cutting aluminum can create a lot of reflective debris, which can bounce back into the machine, causing damage.

Impact on Machine: The reflection can lead to inaccurate cuts and may even harm the laser lens over time.

- Composite Materials

Hazards: Composites often contain a mixture of materials that can produce harmful byproducts when cut, including toxic fumes.

Impact on Machine: The variety of materials can lead to inconsistent cutting results and may require different settings, complicating the process.

- Anything with Chlorine

Hazards: Materials containing chlorine, like certain types of foam, can produce toxic gases that are harmful to health.

Impact on Machine: These gases can corrode parts of the laser cutter, leading to long-term damage.

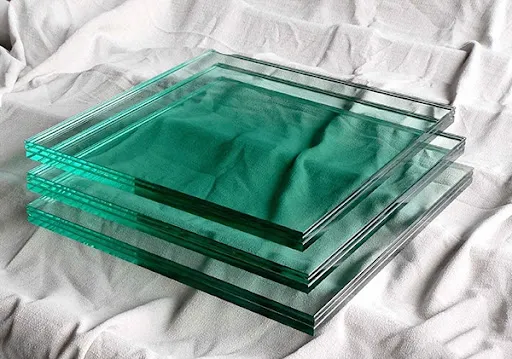

- Some Types of Glass

Hazards: While certain glass can be cut with lasers, others may shatter due to the rapid heating and cooling caused by the laser, posing safety risks.

Impact on Machine: Glass shards can damage the internal components of the machine, leading to costly repairs and downtime.

3. Understanding the Risks Involved

- Health Risks

Cutting unsuitable materials can produce toxic fumes that are harmful to both operators and bystanders. Proper ventilation and protective gear are essential when using a laser cutter.

- Equipment Damage

Using the wrong materials can lead to significant wear and tear on the laser cutter. Not only does this result in higher maintenance costs, but it can also reduce the machine’s lifespan.

- Downtime and Production Loss

Repairs caused by cutting inappropriate materials can lead to unexpected downtime, disrupting production schedules and impacting overall efficiency.

4. Best Practices for Laser Cutting

To ensure safety and efficiency while using a laser cutter, consider the following best practices:

- Material Selection

Always choose materials specifically designed for laser cutting. Consult the manufacturer’s guidelines and research materials suitable for your specific laser cutter model.

- Regular Maintenance

Implement a regular maintenance schedule for your laser cutter to ensure it remains in optimal condition. This includes cleaning the optics and checking for any damage.

- Proper Ventilation

Ensure your workspace is well-ventilated to mitigate the risks associated with toxic fumes produced during cutting operations.

- Operator Training

Invest in comprehensive training for operators to familiarize them with the machine’s capabilities and limitations, as well as safety protocols.

- Monitor Cutting Parameters

Keep a close eye on the cutting parameters to ensure they align with the material being cut. Adjustments may be necessary to optimize performance.

5.The Future of Laser Cutting

As technology advances, new materials and applications will continue to emerge in the field of laser cutting. Manufacturers, such as KF LASER, are constantly innovating, ensuring that laser cutting remains a relevant and efficient solution for various industries.

Understanding which materials should never be cut with a laser cutter is crucial for maintaining safety, efficiency, and the longevity of your equipment. By being informed and following best practices, you can harness the incredible potential of laser cutting technology while avoiding the pitfalls that can lead to costly mistakes and dangerous situations.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine