News

Understanding the Cost of Iron Laser Cutting Machines

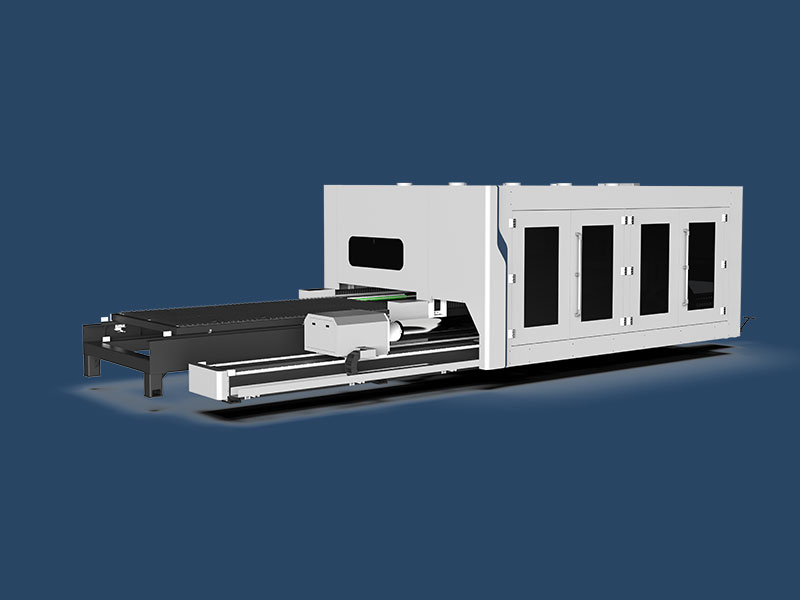

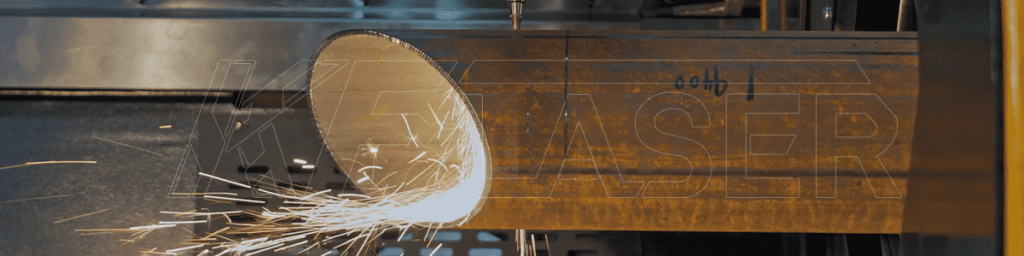

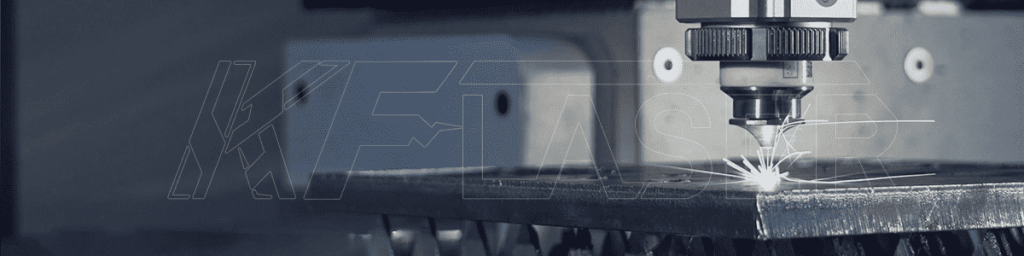

When it comes to manufacturing and metal fabrication, the iron laser cutting machine is a game-changer. It’s known for its ability to cut through tough materials with unmatched precision and speed. But while laser cutting technology has revolutionized various industries, one common question often arises: What is the cost of iron laser cutting machines?

The price of an iron laser cutting machine can vary widely depending on multiple factors, ranging from the machine’s size and power to the manufacturer and the features it offers. As businesses across industries seek to improve production efficiency and reduce labor costs, understanding the key elements that influence laser cutting machine pricing is crucial for making an informed purchasing decision.

Factors That Influence the Cost of Iron Laser Cutting Machines

The cost of an iron laser cutting machine isn’t determined by one simple figure. Several factors come into play, each contributing to the final price tag of the equipment. Let’s break down these factors:

1. Power of the Laser Source

The power of the laser source is one of the most significant determinants of cost. Laser cutting machines are available in various power ranges, typically measured in watts. The more powerful the machine, the higher the cost will be.

Low-Power Machines (500W – 1kW): These are suitable for thinner metals and more intricate cuts. They are more affordable but less efficient when cutting thicker materials.

Mid-Power Machines (1kW – 4kW): These machines offer a balance between performance and cost. They are versatile and can handle a wide range of material thicknesses.

High-Power Machines (Above 4kW): Designed for cutting thicker materials, these machines offer exceptional cutting speed and efficiency. Naturally, their price is significantly higher.

In essence, the higher the wattage of the machine, the more costly it will be. However, businesses investing in these machines often do so to increase productivity, especially when cutting thicker iron sheets or working on large-scale projects.

2. Machine Size and Working Area

The size of the machine and the work area it can accommodate are additional factors that influence cost. Laser cutting machines come in different sizes, and the larger the working area, the higher the cost.

Small Machines (Small Bed Sizes): These are typically more affordable and are ideal for smaller projects or businesses with limited production needs.

Large Machines (Large Bed Sizes): These machines can accommodate larger materials, and they are more expensive. They are suitable for businesses that require the processing of large iron sheets and need high throughput.

Businesses must assess their production needs to determine whether a smaller or larger machine is required. While large machines are more costly upfront, they may prove more cost-effective in high-demand environments.

3. Laser Technology Type

Different types of lasers are used in cutting machines. The most common are CO2 lasers and fiber lasers, and each comes with its own set of advantages and pricing structures.

CO2 Lasers: These are the most widely used for cutting thicker materials like iron. They are generally more affordable but tend to have lower cutting speeds compared to fiber lasers.

Fiber Lasers: Fiber lasers are faster and more efficient when it comes to cutting metals like iron, especially at higher powers. However, they come at a premium price. Their efficiency, however, might justify the investment for industries looking for high precision and speed.

The choice between CO2 and fiber laser technology depends on the application, material thickness, and production volume.

4. Cutting Speed and Efficiency

Laser cutting machines differ in their cutting speeds. A faster cutting speed means the machine can handle more material in less time, improving overall productivity. However, faster machines are often more expensive.

High-Speed Machines: High-speed lasers can cut through thicker metals faster, but they come with a higher price tag.

Standard-Speed Machines: While they may have slower cutting speeds, they are usually more affordable and sufficient for businesses with less demanding cutting requirements.

When considering an iron laser cutting machine, businesses need to weigh the trade-off between cutting speed and overall cost. While faster machines increase productivity, they may not be necessary for all types of projects.

5. Brand and Manufacturer

The manufacturer of the laser cutting machine plays a crucial role in determining the cost. Well-known brands with a reputation for quality and reliability tend to have higher prices, but they also offer more support and longevity. On the other hand, lesser-known brands may offer more affordable machines but could come with potential trade-offs in terms of quality, durability, and service.

6. Maintenance and Operating Costs

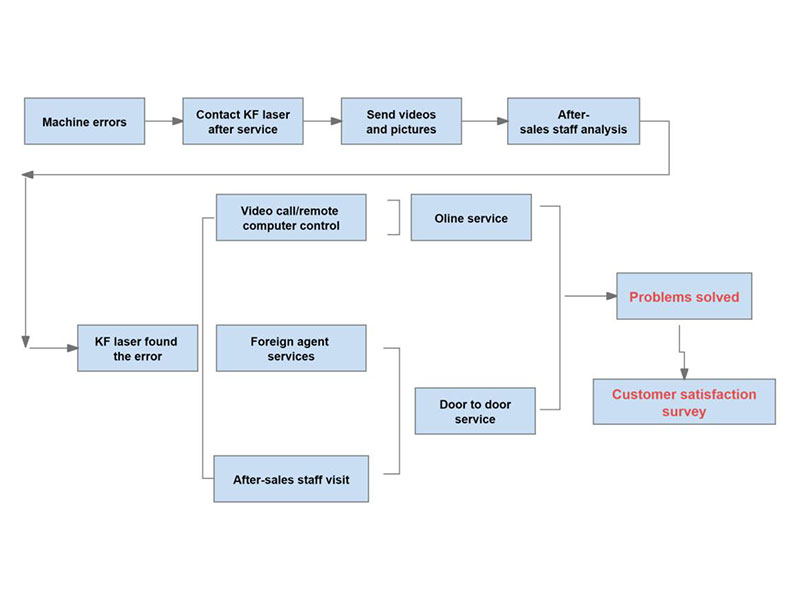

The ongoing costs of operating and maintaining an iron laser cutting machine should also be considered. These costs include:

Maintenance Costs: Regular maintenance is essential to keep the machine running efficiently. Higher-end models might have more advanced features but could be costlier to maintain.

Operational Costs: These include power consumption, which can vary based on the machine’s power rating and the materials being cut.

Understanding the total cost of ownership is crucial for businesses that want to calculate the long-term expenses involved in running a laser cutting machine.

How to Calculate the Total Cost of an Iron Laser Cutting Machines

When calculating the total cost of an iron laser cutting machine, it’s important to consider both the initial investment and the long-term costs. Here’s a simplified way to break it down:

Initial Machine Cost: This includes the price of the machine, which depends on the factors mentioned above.

Installation Costs: Some laser cutting machines require professional installation, which could add to the cost.

Training Costs: If employees need to be trained to operate the machine, this cost should be considered.

Maintenance and Operating Costs: These are the ongoing costs associated with keeping the machine in operation, including electricity, gas, and routine maintenance.

By factoring in all of these components, businesses can better understand the total financial commitment involved in purchasing an iron laser cutting machine.

Finding the Right Balance Between Price and Performance

When purchasing an iron laser cutting machine, businesses should aim to strike a balance between cost, performance, and long-term value. It’s not always about choosing the cheapest machine but rather finding the one that meets your production needs while remaining within your budget. Investing in a high-quality machine can lead to higher productivity, lower operating costs, and a better return on investment over time.

To make the best decision, it’s essential to evaluate your business’s production volume, the complexity of the parts being cut, and the materials used. A comprehensive understanding of these factors will ensure that your investment in a laser cutting machine is both cost-effective and beneficial in the long run.

By taking all these elements into account, you’ll be able to navigate the complexities of choosing the right machine for your iron cutting needs and ensure your operations run smoothly and efficiently.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine