Новости

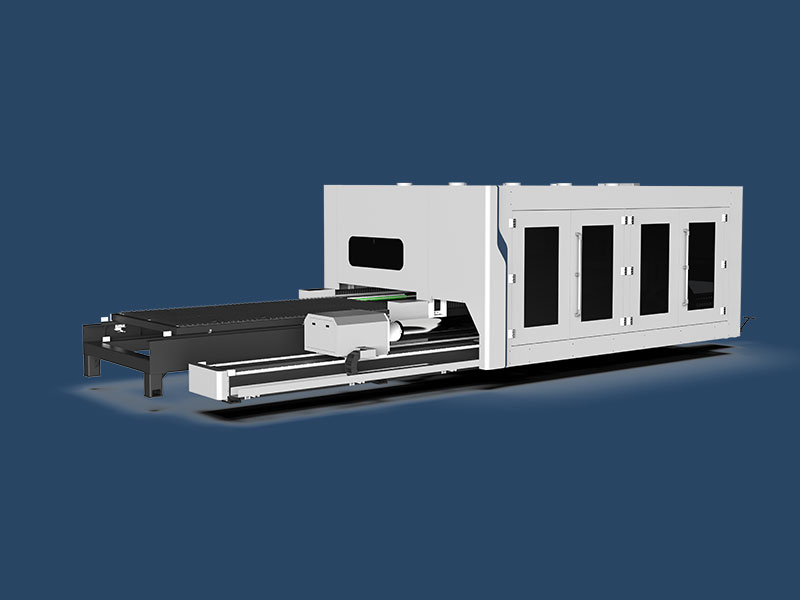

Automated Fiber Laser Cutting Systems

Automated волоконно -лазерные машины transform manufacturing floors into 24/7 production hubs where robotic arms move with ballet-like precision, intelligent sensors anticipate maintenance needs before failures occur, and raw metal sheets evolve into finished components without human intervention. Picture arriving Monday morning to find weekend’s worth of precision-cut parts perfectly stacked – this is the reality modern industrial automation delivers.

Automation Hierarchy

Operational Tiers

|

System Level |

Continuous Runtime |

Labor Reduction |

|

Entry-Level |

8 часы |

40% |

|

Mid-Tier |

56 часы |

75% |

|

Full Automation |

168 часы |

95% |

|

Core Automation Modules |

|

|

- Robotic material handlers with ±0.02mm placement accuracy

- AI-powered vision inspection systems

- Self-regulating cutting parameter database

- Cloud-based production monitoring dashboards

Sensory Intelligence Matrix

|

Технология |

Function |

Impact |

|

3D Topography Scanning |

Surface deformation detection |

97% collision prevention |

|

Spectrum Analysis |

Material composition verification |

92% cut quality consistency |

|

Thermal Profiling |

Component degradation tracking |

87% predictive maintenance accuracy |

Software Architecture

Autonomous Operation Framework

Production Scheduler → Nesting Optimizer → Motion Controller → Quality Auditor

↓ ↓ ↓ ↓

Cloud Analytics Material Inventory Process Library Defect Registry

Key Software Capabilities

- Adaptive Nesting Engine

- 72-hour production forecasting

- Dynamic remnant utilization

- 94% material efficiency

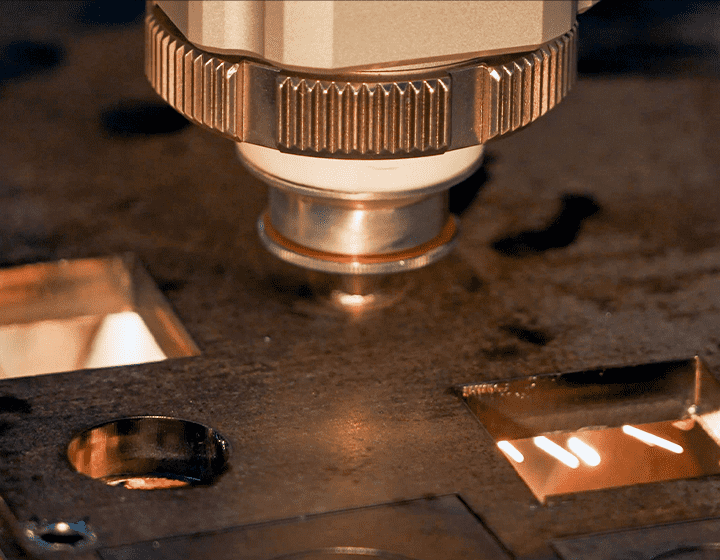

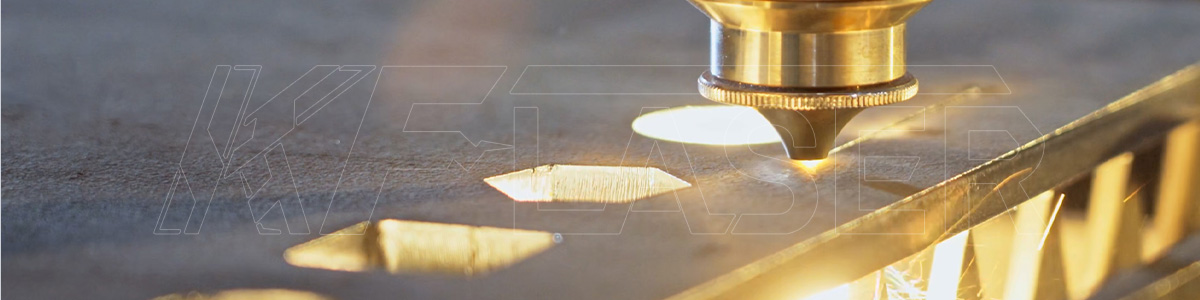

- Self-Correcting Parameters

- Real-time focal length adjustment

- Gas pressure modulation (±0.15 bar)

- Cutting speed compensation

- Remote Command Interface

- Multi-facility production monitoring

- Automated shift performance reports

- Maintenance alerts via mobile push

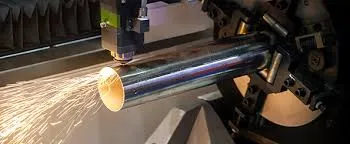

Cutting Performance Benchmarks

|

Материал |

Thickness |

Скорость |

Tolerance |

|

Мягкая сталь |

8мм |

18м/мин |

±0,03 мм |

|

Алюминий 6061 |

4мм |

20м/мин |

±0,05 мм |

|

Нержавеющая ставка 304 |

5мм |

14м/мин |

±0.04mm |

|

Quality Consistency Metrics |

|

|

|

- Kerf width stability: ±0.015mm over 48hr operation

- Angular deviation: <0.3° after 100,000 cuts

- Surface roughness: Ra 1.6μm maintained

Maintenance Autonomy Systems

Self-Preservation Mechanisms

- Nozzle Maintenance Station

- Automatic carbon removal every 15 pierces

- Non-contact alignment verification

- Optics Protection Protocol

- Ceramic thermal barriers

- Positive-pressure gas curtains

- 750-hour maintenance intervals

- Laser Diode Preservation

- Back-reflection monitoring

- Active cooling stabilization

- <0.08% monthly power degradation

Implementation Roadmap

Phase 1: Infrastructure Preparation (10 Days)

- Vibration-damped foundation installation

- Climate-controlled enclosure setup

- Dedicated power conditioning systems

Phase 2: System Integration (8 Days) - Robotic end-effector calibration

- Material handling synchronization

- Safety interlocks configuration

Phase 3: Operational Validation (5 Days) - 72-hour endurance testing

- Multi-material quality verification

- Remote access certification

Industry-Specific Solutions

Automotive Manufacturing

- Requirements:

- 22-second part cycle time

- Six-model mixed production

- 1mm positional repeatability

- Implementation:

- Dual-gantry loading system

- Quick-change fixture pallets

- In-line optical measurement

Aerospace Components- Challenges:

- Titanium cutting at 12mm+

| Requirement | Specification |

|——————-|——————-|

| Profile tolerance | ±0.04mm |

| Surface integrity | Ra 0.8μm maximum |

| Документация | AS9100 compliance |- Решение:

- Vacuum workholding technology

- Real-time geometry validation

- Automated NDT reporting

Emerging Technologies

Next-Gen Automation Frontiers

- Cross-Machine Orchestration

- Central AI controlling multiple systems

- Dynamic workload distribution

- Shared material resource pools

- Hybrid Processing

- Integrated cutting and cladding heads

| Capability | Benefit |

|———————|———————–|

| Repair-and-cut cycles | Reduced handling |

| In-situ hardening | Eliminated secondary ops |- Quantum-Scale Monitoring

- Sub-micron vibration detection

- Atomic-level thermal imaging

- Predictive failure algorithms

“The pinnacle of manufacturing automation isn’t machine replacement,” observes industrial technologist Dr. Robert Vance, “but human capability augmentation – where technicians transition from machine operators to production strategists.”

Operational Readiness Checklist

Pre-Deployment Verification

- Material flow simulation completed

- Power quality assessment passed

- Network security audit

- Staff training curriculum developed

Production Validation - 96-hour continuous run certified

- Quality benchmarks achieved

- Remote diagnostics operational

- Data backup protocols established

Final Insight: The ultimate validation of automated fiber laser systems occurs at 2:17 AM on holidays – when unmanned facilities produce precision components while competitors’ workshops stand silent, redefining what ‘working hours’ truly mean in modern manufacturing.

Главные новости

Категории продуктов

- Металлический лазерный резак

- Лазерный сварочный аппарат

- Лазерный очиститель

- Лазерный маркер

- Пресс-тормозная машина