Laser cutter metal technology plays a critical role in the automotive industry, offering precision and efficiency in cutting various metal components.

Chinese laser welders are increasingly popular in the automotive industry due to their affordability and high performance. Ofrecen numerosas ventajas sobre los métodos de soldadura tradicionales., Incluyendo la velocidad, precisión, y reducción de la distorsión por calor.

Laser cleaners for rust provide an efficient and eco-friendly solution for maintaining automotive components. Utilizan rayos láser para eliminar el óxido y otros contaminantes sin dañar el metal subyacente..

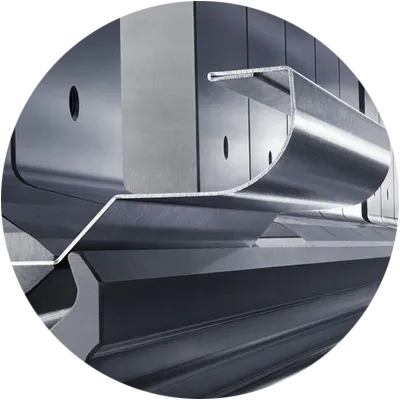

Sheet metal bending machines are essential in shaping metal sheets precisely, which is crucial for creating various automotive parts.

The integration of laser cutter metal technology, Chinese laser welders, laser cleaners for rust, and sheet metal bending machines in automotive production offers numerous benefits:

En conclusión, the adoption of laser cutter metal technology, Chinese laser welders, laser cleaners for rust, and sheet metal bending machines in the automotive manufacturing industry has transformed the way vehicles are produced and maintained. Estas tecnologías proporcionan una precisión incomparable, eficiencia, y calidad, ensuring that modern vehicles are durable, confiable, y alto rendimiento. As the automotive industry continues to grow, La integración de estas tecnologías láser avanzadas desempeñará un papel crucial para satisfacer las demandas y desafíos futuros..