Laser metal cleaner technology has revolutionized the way industries approach the cleaning and maintenance of metal surfaces. Utilizing advanced laser technology, these devices efficiently remove contaminants, óxido, pintar, and other unwanted layers from metal surfaces without causing damage to the underlying material. This article delves into the applications, beneficios, and technical aspects of laser metal cleaners, emphasizing the keyword “laser metal cleaner” for SEO optimization.

A laser metal cleaner is a sophisticated device that uses high-powered laser beams to clean and treat metal surfaces. The process, known as laser ablation, involves directing laser pulses at a metal surface to vaporize and remove contaminants. This non-contact, eco-friendly method is highly effective and precise, making it an invaluable tool in various industrial applications.

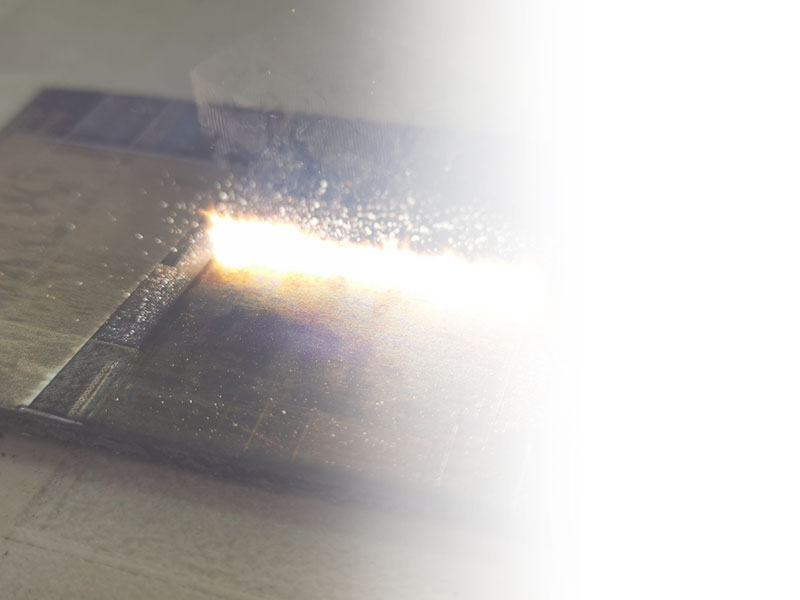

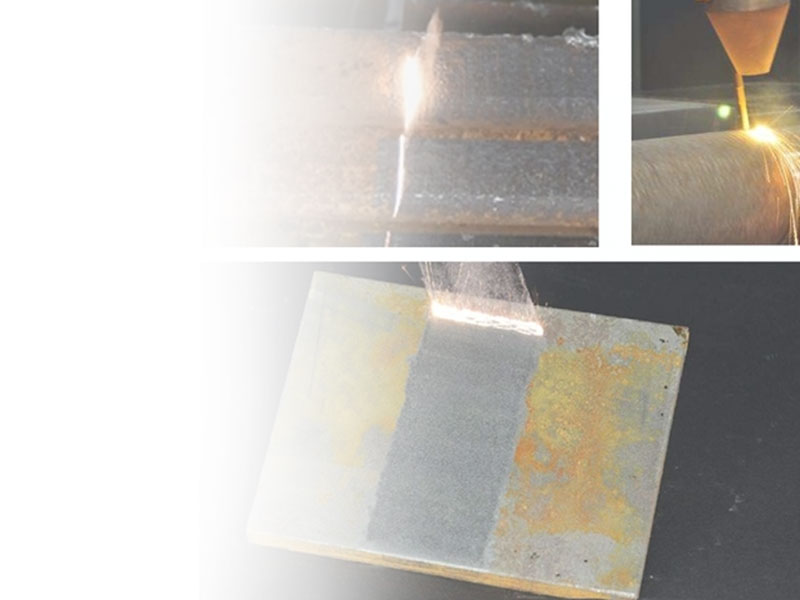

Laser metal cleaners operate by emitting laser pulses that target the contaminants on the metal surface. The laser energy is absorbed by the contaminants, causing them to vaporize without affecting the base metal. Here’s a step-by-step overview of the process:

Ablation Threshold: Every material has a specific ablation threshold, the minimum energy required to vaporize it. The laser metal cleaner is calibrated to exceed the ablation threshold of contaminants like rust, pintar, and oils, but not the metal substrate.

Laser Pulses: The device emits rapid, high-energy laser pulses. These pulses are short enough to prevent heat from spreading to the base material, ensuring only the contaminants are removed.

Limpieza de precisión: The focused laser beam provides high precision, allowing for selective cleaning of intricate parts without damaging surrounding areas.

Fume Extraction: As the contaminants vaporize, they are often converted into fine dust or fumes. A fume extraction system is typically integrated with the laser cleaner to capture and remove these particles, ensuring a clean and safe working environment.

Laser metal cleaners are versatile tools used in various industries for different applications:

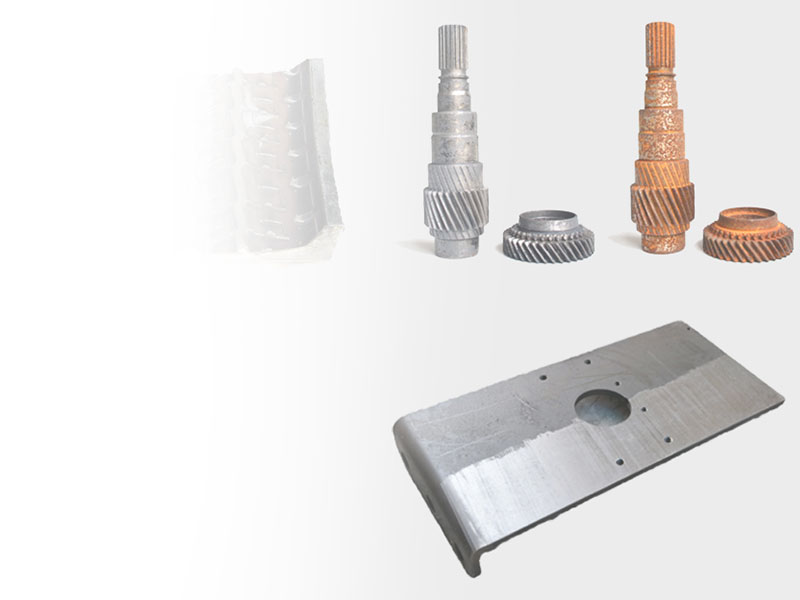

Eliminación de óxido: One of the most common uses of laser metal cleaners is the removal of rust from metal surfaces. This method is faster and more precise than traditional methods like sandblasting or chemical treatments.

Pre-Welding Treatment: Before welding, metal surfaces must be clean and free of contaminants. Laser cleaning ensures that rust, dirt, and oxides are removed, lo que resulta en soldaduras más fuertes y confiables.

Eliminación de pintura y revestimiento: Laser metal cleaners are highly effective at removing old paint and coatings from metal surfaces, preparing them for new applications without damaging the substrate.

Oxide Removal: In industries like aerospace and automotive, removing oxides from metal parts is crucial. Laser cleaning provides a clean surface that enhances the performance and longevity of these components.

Maintenance and Restoration: Laser metal cleaners are used in maintenance and restoration projects, such as cleaning historical monuments, sculptures, and machinery parts. The precision of laser cleaning ensures that the underlying material is preserved while contaminants are removed.

Precisión y exactitud: Laser metal cleaners offer unparalleled precision, making it possible to clean intricate and delicate parts without causing damage.

Ecológico: Unlike traditional cleaning methods that use chemicals or abrasive materials, laser cleaning is environmentally friendly. It eliminates the need for consumables and reduces waste.

Cost-Effective: While the initial investment in laser cleaning technology can be high, the long-term savings are significant. The reduction in labor, consumibles, and maintenance costs makes laser cleaning a cost-effective solution.

Proceso sin contacto: Laser cleaning is a non-contact process, meaning there is no physical interaction with the metal surface. This reduces the risk of damage and wear on the parts being cleaned.

Seguridad: When integrated with proper safety systems like fume extraction and laser enclosures, laser metal cleaners create a safer working environment. Operators are protected from harmful substances and do not need to handle hazardous chemicals.

Automation Potential: Laser metal cleaners can be easily integrated into automated systems, increasing productivity and consistency in industrial processes.

Understanding the technical aspects of laser metal cleaners is crucial for optimizing their use and achieving the best results.

Tipos de láser: The most common type of laser used in metal cleaners is the fiber laser, known for its efficiency and power. Other types include CO2 lasers and UV lasers, each suited for specific applications.

Power and Speed: The power of the laser and the speed at which it operates determine the efficiency of the cleaning process. High-power lasers can remove contaminants more quickly but may require more sophisticated control systems to prevent damage to the substrate.

Pulse Duration and Frequency: Short pulse durations and high pulse frequencies improve the precision of laser cleaning. Adjusting these parameters allows for fine-tuning the process to match the specific requirements of different materials and contaminants.

Fume Extraction: A critical component of laser cleaning systems is the fume extraction unit, which captures and removes vaporized particles. This ensures a clean working environment and prevents the release of harmful substances into the air.

Control Systems: Advanced laser metal cleaners are equipped with control systems that allow operators to adjust settings such as power, velocidad, y frecuencia de pulso. These systems ensure optimal performance and consistency in the cleaning process.

The future of laser metal cleaner technology is promising, with continuous advancements aimed at improving efficiency, precisión, y versatilidad.

Mayor automatización: Future laser metal cleaners will likely feature greater levels of automation, integrating seamlessly with robotic systems for fully automated cleaning processes.

Precisión mejorada: Ongoing research and development are focused on improving the precision of laser cleaning, making it possible to clean even the most intricate and delicate parts with greater accuracy.

Eficiencia energética: Los avances en la tecnología láser seguirán mejorando la eficiencia energética, reducing the overall power consumption of laser metal cleaners and making them more sustainable.

Broadening Applications: As laser cleaning technology evolves, its applications will expand to new industries and processes. This will drive further innovation and adoption of laser metal cleaners across various sectors.

Laser metal cleaners represent a significant advancement in industrial cleaning technology. Their ability to provide precise, eco-friendly, and cost-effective cleaning solutions makes them indispensable in many industries. From rust removal and pre-welding treatments to paint stripping and oxide removal, laser metal cleaners offer unparalleled performance and versatility. A medida que la tecnología continúa avanzando, these devices will become even more integral to industrial processes, driving innovation and efficiency in metal cleaning and maintenance.