Noticias

Máquinas de corte láser grandes: Revolución de la fabricación a gran escala

Laser cutting technology has become an essential tool in various industries, but big laser cutting machines take the game to another level. These machines are designed to handle large-scale materials, making them a staple in heavy industries such as aerospace, automotor, and shipbuilding. Their ability to cut, grabar, and mark large components with extreme precision and speed has led to greater efficiencies and enhanced productivity in large-scale manufacturing processes.

En este artículo, we will dive into the features of big laser cutting machines, explore their capabilities, and discuss how they are being utilized across different sectors.

1. What Are Big Laser Cutting Machines?

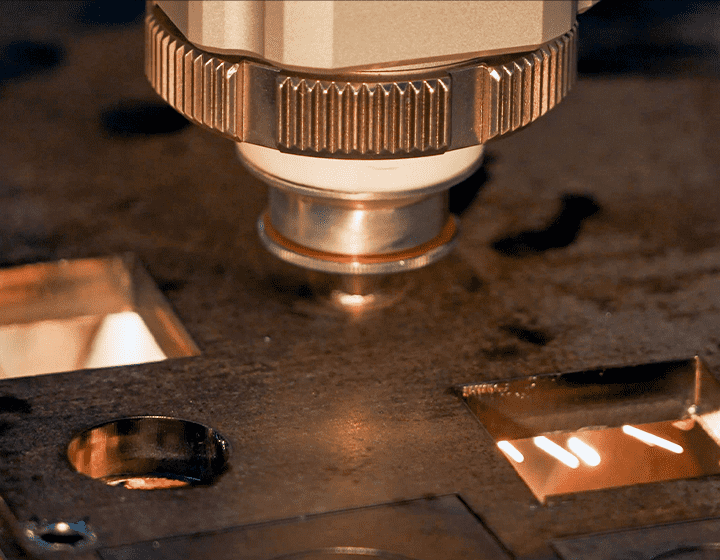

A big laser cutting machines is essentially a larger version of a traditional laser cutting machine. These machines are specifically engineered to cut large materials like thick steel plates, large sheets of aluminum, or even huge metal structures. They use powerful lasers to vaporize, melt, or burn through the material with a high degree of precision.

Big laser cutters typically utilize fiber laser technology, which offers several advantages over traditional CO2 lasers, including faster cutting speeds, greater energy efficiency, and lower maintenance needs. The size of these machines varies significantly, with some designed to handle massive pieces of metal or other materials, while others offer modular setups that can be customized for specific applications.

https://www.kflaserpro.com/

2. How Do Big Laser Cutting Machines Work?

The core mechanics of big laser cutting machines are quite similar to those of smaller systems but on a much larger scale. Here’s how they work:

Generación láser: The laser beam is created using a high-powered láser de fibra source. This concentrated beam is directed towards the material to be cut.

Beam Focus: The laser is focused using precise optics, ensuring the beam remains concentrated and can effectively cut through thick materials.

Proceso de corte: As the beam hits the material, the laser melts, quemaduras, or vaporizes it. The machine’s CNC controls manage the movement of the laser head, ensuring that the cutting path follows the exact specifications outlined by the operator.

Assist Gas: Assist gases, such as oxygen, nitrógeno, or compressed air, are used to blow away molten material, ensuring clean cuts and preventing material from warping due to excess heat.

El resultado es un limpio, precise cut with minimal distortion, even in materials that are several inches thick.

https://www.kflaserpro.com/

3. Advantages of Big Laser Cutting Machines

Big laser cutting machines offer numerous advantages for industries that require precision cutting of large materials. Below are some of the key benefits:

1. Ability to Handle Large Materials

As the name suggests, big laser cutting machines are specifically built to handle large workpieces, making them ideal for cutting large sheets of metal, oversized industrial parts, or heavy components. They can cut through materials ranging from acero suave a acero inoxidable, aluminio, y titanio, offering incredible versatility in terms of material handling.

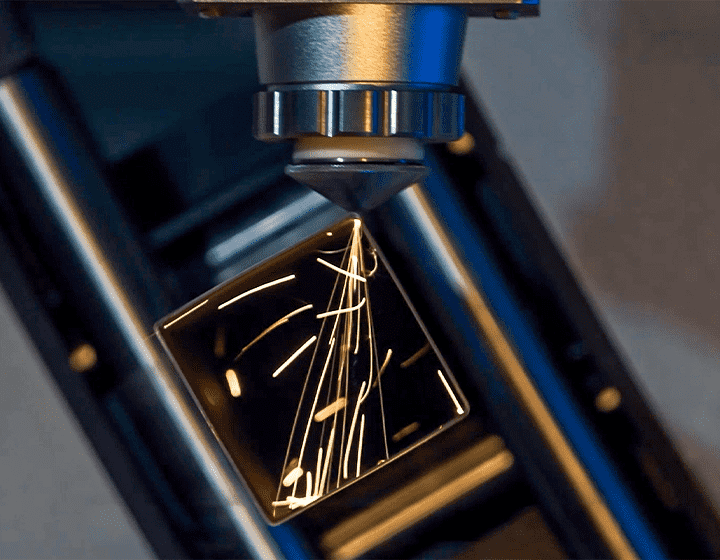

2. Alta precisión y calidad

One of the standout features of big laser cutting machines is their precision. With advanced CNC technology, these machines can produce intricate shapes and designs with tight tolerances and clean edges. Even for large materials, the laser beam remains concentrated, ensuring consistent cuts and minimal wastage.

3. Faster Processing Times

Big laser cutting machines are designed to cut large materials quickly, thanks to their high-powered lasers and advanced control systems. The ability to cut thick metals in a matter of minutes makes them significantly more efficient than traditional cutting methods, reducing production time and improving overall throughput.

4. Minimal Heat Affected Zones

Laser cutting is a cold cutting proceso, meaning it generates very little heat compared to other methods like plasma cutting or flame cutting. Como resultado, big laser cutting machines minimize the zonas afectadas por el calor (Cría) on the materials being cut, preventing warping, discoloration, or weakening of the material. This is especially important when working with sensitive metals that require precise, high-quality cuts.

5. Reduced Material Waste

With fiber laser technology, big laser cutters offer high material utilization, which reduces scrap material. The precision of the laser beam ensures that the cuts are exact, leaving minimal waste behind. Además, since fiber lasers operate with greater energy efficiency, they reduce energy consumption, further lowering costs for businesses.

6. Versatility and Customization

Big laser cutting machines can be equipped with various additional features such as rotary attachments for cutting cylindrical parts, automatic material loading/unloading systems, y advanced software for complex designs. These features make big laser cutters adaptable to a wide range of industries, incluido automotor, aeroespacial, y construcción.

4. Applications of Big Laser Cutting Machines

Big laser cutting machines are used in a variety of industries where high precision, velocidad, and the ability to handle large materials are required. Some of the most common applications include:

1. Aeroespacial

The aerospace industry requires high-strength materials like titanio y aluminio, which must be cut with precision for aircraft parts, fuselages, y otros componentes. Big laser cutting machines can easily handle these materials, making them essential for aerospace manufacturing.

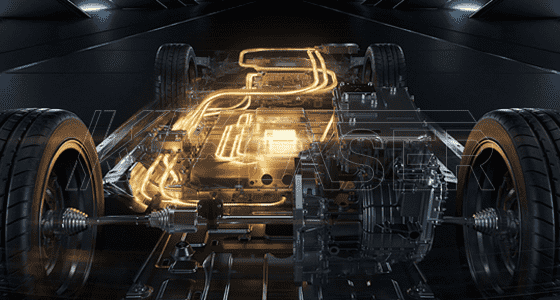

2. Automotor

En el sector del automóvil, big laser cutting machines are used to cut large sheets of metal for body panels, componentes del chasis, y sistemas de escape. These machines enable high-speed, high-precision cutting that meets the demanding standards of automotive manufacturers.

3. Shipbuilding

Shipbuilding requires the fabrication of large metal parts, such as hulls and structural frames, and big laser cutters are ideal for this. Their ability to cut thick steel plates with high accuracy ensures that shipbuilders can produce high-quality vessels efficiently.

4. Heavy Equipment Manufacturing

Big laser cutting machines are also used in industries like construcción y mining, where large, heavy-duty equipment is produced. From cutting frames to manufacturing bucket components for excavators and cranes, laser cutting provides the precision needed for heavy equipment parts.

5. Fabricación de metal

For metal fabricators, big laser cutting machines are a game-changer. They are used to cut large panels of metal into smaller, precise pieces that are then used for industrial applications, señalización, arquitectura, y más. The ability to cut large sheets of steel, aluminio, or other metals quickly and accurately enhances efficiency in metalworking shops.

5. Factors to Consider When Choosing a Big Laser Cutting Machines

Al elegir un big laser cutting machine, several factors should be taken into account to ensure that it meets your specific needs:

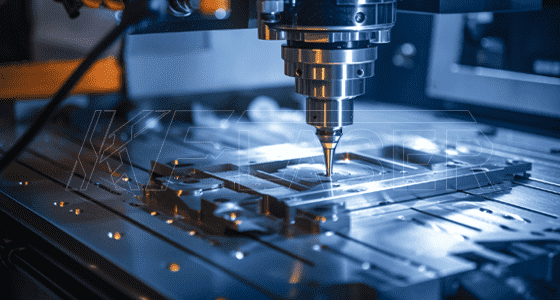

Potencia del láser: For cutting thicker materials, you’ll need a machine with higher laser power (measured in kilowatts). Laser power is directly linked to the cutting speed and thickness of the material that can be handled.

Tamaño del área de trabajo: The size of the work area or cutting bed is essential when choosing a big laser cutting machine. Larger work areas are necessary for handling oversized materials or multiple parts simultaneously.

Compatibilidad de materiales: Ensure that the machine is compatible with the materials you intend to cut. Some big laser cutters are designed to handle a wide range of metals, while others are more specialized.

Software y sistemas de control: A robust CNC control system y CAD/CAM software can significantly improve the efficiency of the machine. Look for advanced software options that allow for complex shapes and precise cut paths.

Budget and Total Cost of Ownership: While big laser cutting machines represent a significant investment, their efficiency and productivity gains often justify the upfront cost. Be sure to also factor in operating costs, mantenimiento, and the machine’s lifespan.

https://www.kflaserpro.com/

The versatility, velocidad, and precision of big laser cutting machines make them a game-changer in industries that require large-scale, high-quality cutting. Whether you are working in aeroespacial, automotor, shipbuilding, o heavy manufacturing, investing in a big laser cutting machine can significantly boost your production capabilities. With their ability to handle thick metals and large workpieces, these machines are well-equipped to meet the demands of modern manufacturing.

Historias destacadas

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora