In the world of metal fabrication, precision cutting is essential for producing high-quality parts and products. Sin embargo, cost is often a major consideration for businesses, especially small manufacturers and startups looking to invest in metal cutting technology. While metal laser cutting is known for its precision and efficiency, many wonder if there are affordable options that don’t compromise on quality.

This article will explore the cheapest metal cutting laser options available, what factors affect the price, and how to choose the right machine to meet your business needs without exceeding your budget.

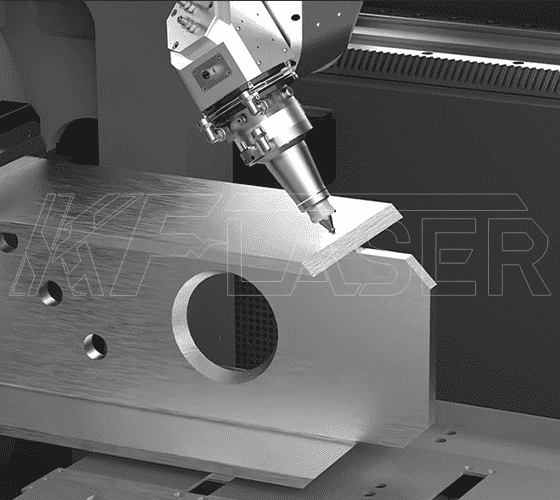

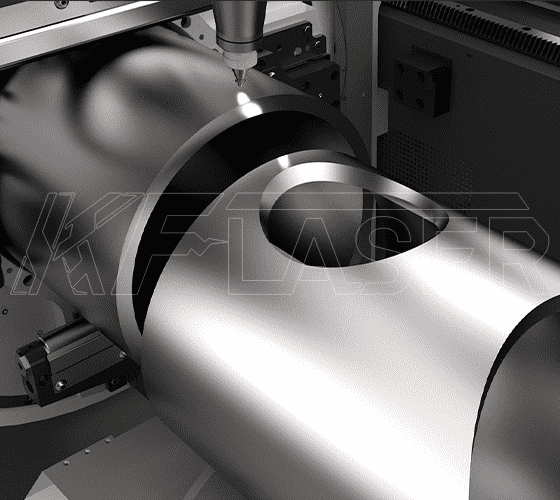

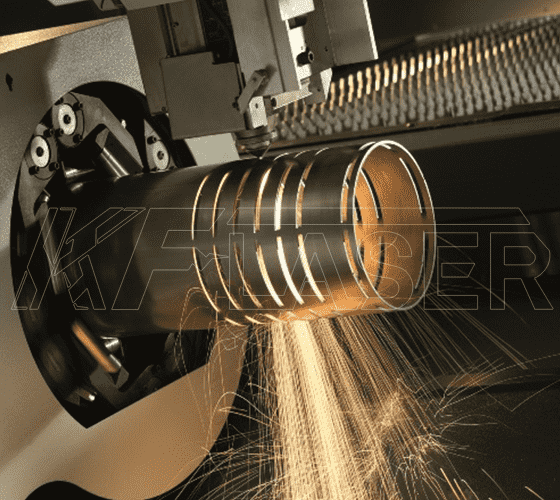

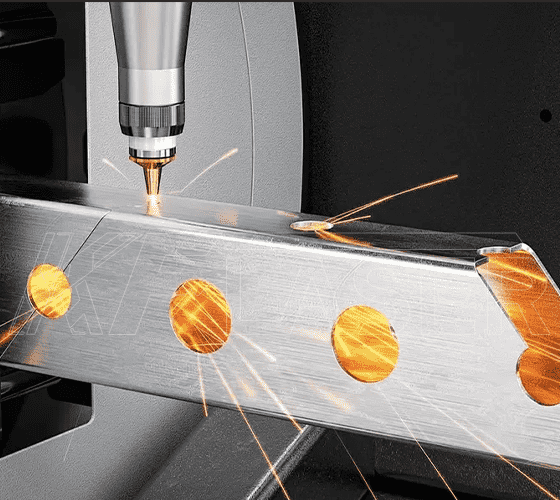

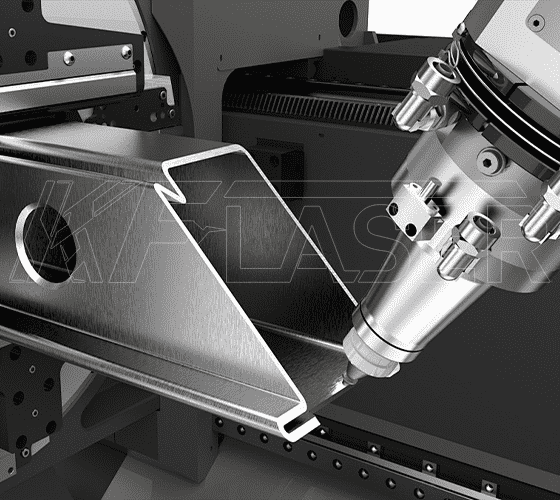

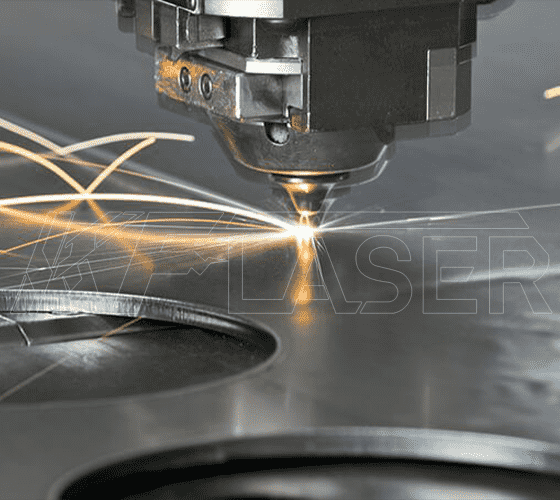

A metal cutting laser uses a focused beam of light to cut through metal materials with incredible precision. The laser beam melts, quemaduras, or vaporizes the metal along the cutting path. The key advantage of laser cutting over traditional methods is its ability to cut intricate shapes and complex designs with minimal distortion or waste. It’s commonly used for cutting metals like steel, aluminio, acero inoxidable, y latón.

Sin embargo, as with any advanced technology, laser cutting machines come with various price tags. The question remains: can you find a laser cutter that is affordable yet still performs well?

When searching for the cheapest metal cutting laser, it’s important to consider several factors that impact the price. Here’s a breakdown of the main factors that influence the cost of metal cutting lasers:

Laser cutting machines typically use either Láser de CO2 o láser de fibra.

Láser de CO2 are the older and more common type of laser cutter. While they are effective for cutting thicker materials, they are generally less energy-efficient than fiber lasers. CO2 lasers tend to be less expensive upfront, but their operational costs can be higher in the long run due to maintenance and energy consumption.

Láser de fibra are newer technology and offer better energy efficiency, velocidades de corte más rápidas, and the ability to cut thinner materials with greater precision. Láser de fibra, sin embargo, tend to be more expensive upfront, though their efficiency makes

them a cost-effective choice over time.

For those seeking the cheapest metal cutting laser, a CO2 laser may offer a lower initial cost, while a fiber laser might be worth the investment for its long-term savings and higher performance.

The size and power of the laser cutting machine significantly impact the price. Smaller, lower-power machines are usually cheaper, but they are suited only for cutting thin sheets of metal. On the other hand, larger machines capable of cutting thicker metals and delivering higher power will naturally come at a higher price.

Máquinas de nivel de entrada: Typically, these machines have a smaller working area and lower laser power, making them suitable for cutting thinner materials (1-6milímetros) at a lower cost.

High-Power Machines: These machines, which can cut thicker metal, require more advanced components and higher power, making them significantly more expensive.For budget-conscious buyers, opting for smaller, entry-level machines with lower laser power is the best way to keep costs down while still achieving quality cuts on thinner metals.

The cutting speed and precision of a laser machine also affect its price. Machines with higher cutting speeds and greater precision are generally more expensive due to their advanced technology.

Affordable Machines: Budget-friendly laser cutters may sacrifice speed and precision to reduce costs. While these machines may still provide decent cuts, they may not offer the same level of detail or efficiency as their higher-end counterparts.

High-End Machines: Machines that are optimized for speed and precision offer more control over the cutting process, making them ideal for intricate designs or high-volume production. These machines come at a higher price but can ultimately improve your bottom line by increasing efficiency and reducing the need for post-processing.

While the initial price of the machine is important, you should also factor in the ongoing maintenance and operational costs. El cheapest metal cutting laser may require more frequent maintenance or use more energy, increasing your total cost of ownership.

Low-Cost Options: Cheaper laser cutters may have higher maintenance requirements or lower energy efficiency, which could result in additional costs down the line.

High-Cost Machines: More expensive machines tend to have better durability, lower maintenance needs, and energy-efficient designs, which can reduce operational costs over time.

Here are some of the most affordable metal cutting laser machines available in the market:

For those just starting or businesses with low volume needs, entry-level CO2 lasers are the most affordable option. These machines are effective for cutting thinner sheets of steel, aluminio, and other metals. They are ideal for small businesses or hobbyists who need basic cutting capabilities.

Beneficios clave:

Low initial cost;Suitable for cutting non-ferrous metals like aluminum, latón, y cobre;Easy to operate with minimal training

Popular Models:Ten-High CO2 Laser Cutter: This budget-friendly option is perfect for small businesses or individuals working with thin materials. It’s one of the most affordable laser cutters for metal, offering reliable performance at a fraction of the cost of higher-end machines.

For those who want to cut thin metals with higher efficiency and faster speeds, fiber lasers are a great choice. While more expensive than CO2 lasers, entry-level fiber laser cutters are still relatively affordable compared to high-end models.

Beneficios clave:

Higher cutting speed compared to CO2 lasers;Minimal maintenance;Energy-efficient operation

Popular Models:Morn Tech Fiber Laser Cutting Machine: This affordable fiber laser cutter is ideal for thin steel, aluminio, and stainless steel cutting. It offers a good balance of performance and cost for small to medium businesses.

For small-scale operations or hobbyists who need a compact and affordable solution, desktop laser cutters are a great option. These machines are ideal for cutting small parts or thin metals, and they often come with user-friendly interfaces for easy operation.

Beneficios clave:

Compact size and low cost;Suitable for small businesses or prototype development;Can cut a variety of materials, including thin metal sheets

Popular Models:Glowforge Plus: A popular choice for hobbyists and small businesses, the Glowforge Plus offers affordable laser cutting capabilities for a range of materials, incluyendo metales. It’s not as powerful as industrial machines but offers great value for its price point.

Choosing the cheapest metal cutting laser requires balancing cost with the capabilities you need for your projects. Here are some steps to help guide your decision:

Consider the thickness and type of metal you plan to cut. If you primarily work with thin sheets of steel or aluminum, an entry-level CO2 or desktop fiber laser cutter may be sufficient. For cutting thicker metals, you might need a higher-powered fiber laser, even if it means spending a bit more upfront.

Take time to compare different machines within your budget. Look beyond the initial price to consider factors such as cutting speed, precisión, and ease of maintenance. It’s essential to find a machine that offers the best balance of performance and cost for your specific needs.

While lower-cost machines are appealing, consider the total cost of ownership, including maintenance and energy consumption. Sometimes a slightly higher upfront cost for a more efficient machine may save you money in the long run.

Finding the cheapest metal cutting laser doesn’t mean you have to compromise on quality or precision. By understanding the factors that affect the price and considering your specific needs, you can find a cost-effective solution that meets your business requirements. Whether you’re working with thin materials or require higher cutting speeds, there are affordable options available that can help you achieve high-quality cuts without breaking the bank. Be sure to balance your short-term budget with long-term operational costs to make the most informed decision.