News

Buy CNC Laser Metal Cutting Machine Guide

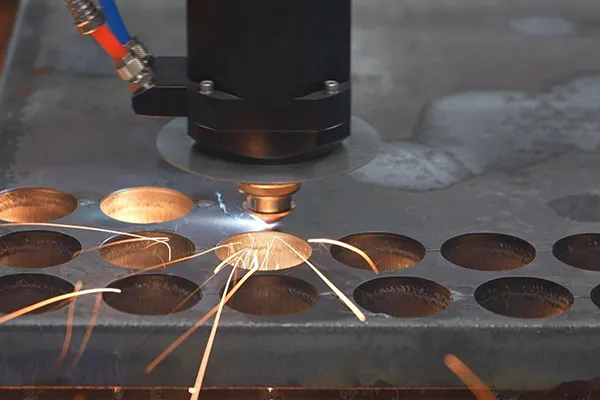

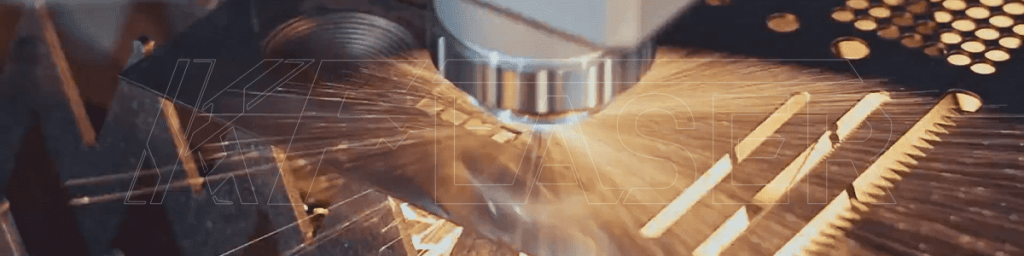

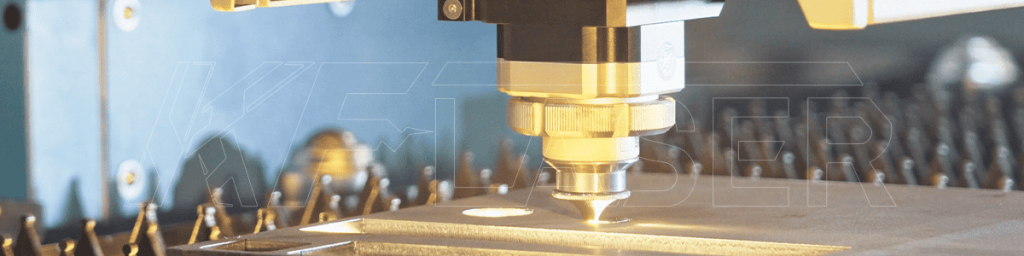

CNC laser metal cutting machines for sale ignite manufacturing revolutions daily, transforming raw metal sheets into aerospace components before lunch breaks conclude, crafting automotive frames with microscopic precision while operators sip coffee, and executing 24/7 production runs that outpace traditional machining by orders of magnitude. These photon-powered titans represent the pinnacle of industrial evolution – but navigating the purchase process requires surgical precision.

Critical Purchase Considerations

Power Capacity Analysis

Selecting laser wattage demands strategic calculation:

- Thin-Sheet Dominance: 2-3kW units slice 0.5-6mm steel at 25m/min

- Mid-Range Versatility: 4-6kW handles 20mm stainless at 1.2m/min

- Industrial Behemoths: 8-12kW penetrates 35mm carbon steel

*Energy consumption per kW/hour:

Power Rating | Electricity Cost/Hour |

3kW | $2.10 |

6kW | $3.85 |

12kW | $7.20 |

*Based on $0.70/kWh industrial rates |

Cutting Bed Configuration Matrix

Size-to-Application Matching

- Compact (1.5x3m): Ideal for prototyping shops

- Standard (2x4m): Automotive aftermarket balance

- Industrial (3x6m+): Shipbuilding/construction scale

Dynamic Loading Systems

- Automatic Pallet Changers: 90-second material swaps

- Forklift-Compatible Beds: 15-ton capacity platforms

- Tube Cutting Integration: Rotary axis add-ons

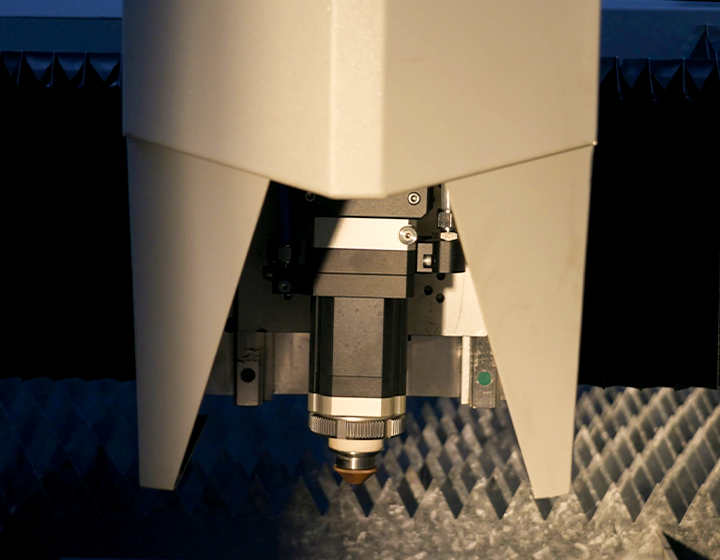

Laser Source Technology Breakdown

Fiber vs. CO₂ Comparison

Parameter | Fiber Laser | CO₂ Laser |

Efficiency | 40-50% | 8-12% |

Maintenance | 2hrs/year | 15hrs/year |

Cutting Speed (1mm SS) | 40m/min | 22m/min |

Consumable Cost | $580/year | $3,200/year |

Source: International Journal of Advanced Manufacturing Technology

Smart Factory Integration

Industry 4.0 Readiness

- OPC UA Protocol: Real-time machine data streaming

- MTConnect Compatibility: Shopfloor monitoring

- API Access: Custom software integration

Connectivity Essentials

- Ethernet/IP: 100ms cycle times

- PROFINET: Deterministic motion control

- Wireless Sensors: Vibration/thermal monitoring

Facility Preparation Checklist

Infrastructure Demands

- Electrical: 480V±2% three-phase supply

- Air Supply: 16bar@2000L/min (ISO 8573-1 Class 2)

- Floor Loading: 8,000kg minimum capacity

- Ventilation: 3500m³/hr fume extraction

Spatial Requirements

Machine Class | Floor Space |

Compact | 6x8m |

Standard | 8x12m |

Industrial | 12x20m |

Operational Cost Simulation

Five-Year Ownership Analysis

Cost Factor | Percentage |

Energy | 38% |

Maintenance | 27% |

Consumables | 18% |

Labor | 12% |

Facility | 5% |

*Sample ROI Calculation:

- Machine investment: $320,000

- Monthly production value: $48,000

- Payback period: 14 months

Technical Verification Protocol

Pre-Purchase Testing

- Material Trials: Submit actual production samples

- Tolerance Validation: Measure 25 critical dimensions

- Edge Quality: 25°-90° perpendicularity verification

- Speed Consistency: ±3% deviation monitoring

Acceptance Criteria

- Positional Accuracy: ≤±0.03mm/m

- Repeatability: ≤0.015mm

- Noise Level: <75dB(A) at 1m

- Safety Certification: CE/UL/GB compliance

Negotiation Strategy Framework

Contract Leverage Points

- Payment Terms: 30/60/10% milestone structure

- Warranty Extension: 36-month coverage minimum

- Training Package: Onsite certification for 3 operators

- Spare Parts Kit: $15,000 consumables credit

Hidden Cost Red Flags

- Software Licensing: Annual fees exceeding $3,500

- Remote Diagnostics: Mandatory subscriptions

- Calibration Services: Proprietary equipment requirements

Future-Proofing Considerations

Technology Roadmap Alignment

- 5G Connectivity: Latency under 5ms

- AI Optimization: Predictive parameter adjustment

- Hybrid Additive: Laser cladding capabilities

- Sustainability: Energy recovery systems

Upgrade Pathways

- Modular Power: 3kW → 6kW fiber upgrades

- Automation: Pallet system retrofits

- Multi-Axis: Tube cutting integration

“Purchasing a CNC laser metal cutting machine resembles strategic chess,” notes manufacturing consultant Elena Rodriguez. “Victory requires anticipating five technological moves ahead while precisely calculating immediate material advantages.”

Post-Installation Optimization

Performance Benchmarking

- OEE Tracking: Target >82% overall effectiveness

- Utilization Monitoring: 70% minimum machine activity

- Quality Metrics: <0.8% scrap rate

Continuous Improvement

- Monthly Power Calibration: 2% efficiency gains

- Nozzle Geometry Testing: 15% gas savings

- Cutting Database Expansion: 30-minute setup reduction

Final Implementation Timeline

Phase | Duration | Critical Tasks |

Site Prep | 3 Weeks | Floor reinforcement, power drops |

Installation | 10 Days | Crane operation, leveling |

Commissioning | 2 Weeks | Safety checks, test cuts |

Training | 1 Week | Operation/maintenance certification |

Production | 1 Week | First batch verification |

Total project timeline: 8-10 weeks from PO to production

Global Logistics Considerations

Shipping Complexities

- Ocean Freight: 40ft high-cube containers

- Customs Clearance: HS Code 8456.11 classification

- Rigging Requirements: 25-ton capacity forklifts

Import Cost Structure

Element | Percentage |

Machine Cost | 78% |

Shipping | 12% |

Duties | 6% |

Insurance | 4% |

Industry veteran Dr. Michael Thorne observes: “The most advanced CNC laser metal cutting machine for sale remains merely potential until integrated within a meticulously prepared ecosystem. True transformation occurs when photon meets purpose.”

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine