Notícias

CNC Laser Pipe Cutting Machine: Revolutionizing Precision in Metal Pipe Cutting

The CNC laser pipe cutting machine represents the cutting-edge technology used to precisely cut metal pipes with high efficiency. In industries ranging from aerospace to automotive, construction to manufacturing, the demand for precision and speed in metal cutting has led to the widespread adoption of CNC laser cutting systems. These machines offer incredible accuracy, versatilidade, e eficiência, making them indispensable in today’s competitive market.

Neste artigo, we’ll explore the functions, vantagens, and applications of CNC laser pipe cutting machines, and how they are reshaping manufacturing standards across multiple industries.

1. What Is a CNC Laser Pipe Cutting Machine?

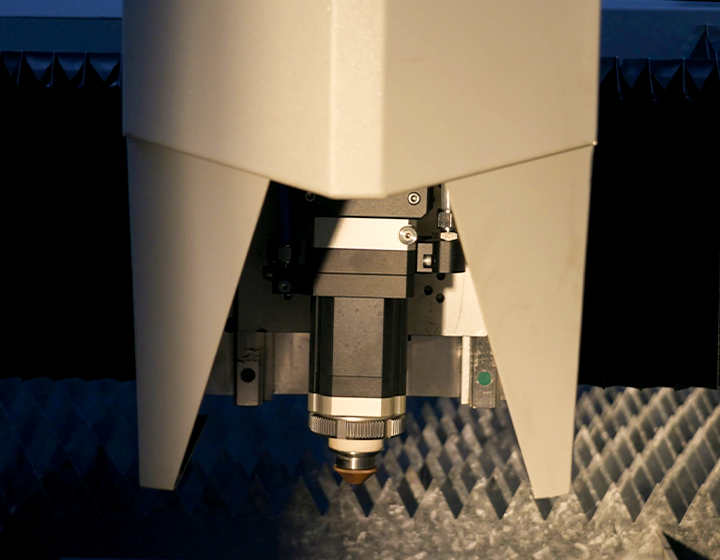

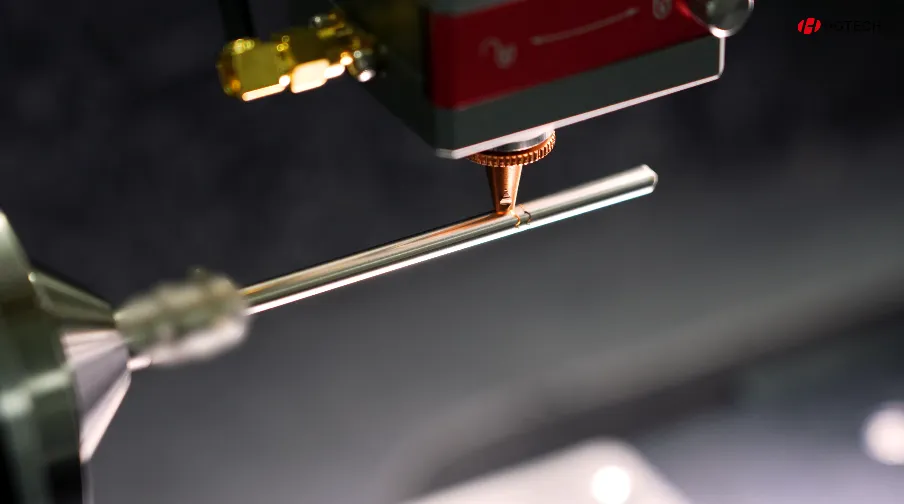

A CNC laser pipe cutting machine is a highly specialized device used for cutting metal pipes and tubes with a laser beam. The CNC (Controle numérico do computador) system allows for automated cutting, guided by precise programming that controls the movement of the laser head. This process ensures exact cuts every time, eliminating human error and reducing production time.

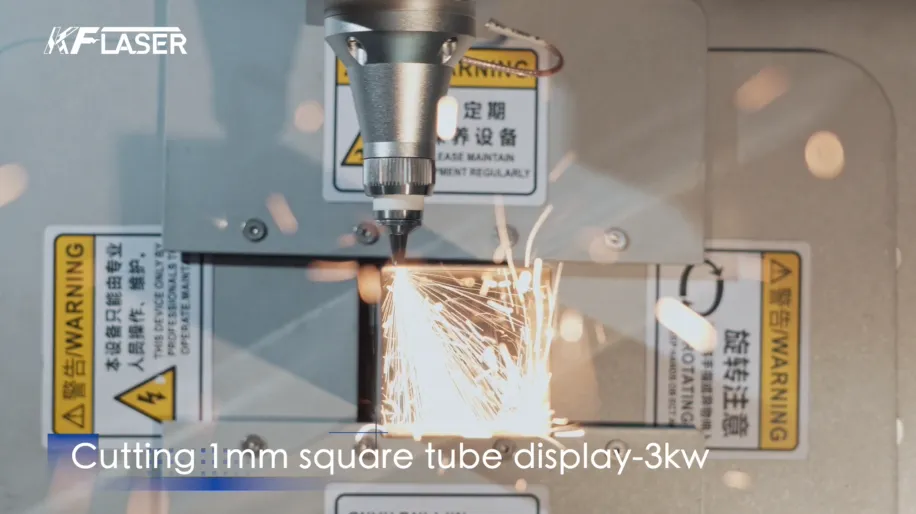

Ao contrário dos métodos de corte tradicionais, laser cutting involves focusing a high-powered laser beam on the material to melt or vaporize it, leaving a clean, accurate cut with minimal edge deformation. The high precision and speed of the process make it ideal for cutting complex shapes, ângulos, and holes in a variety of metals, incluindo aço inoxidável, alumínio, e aço carbono.

2. How CNC Laser Pipe Cutting Machines Work

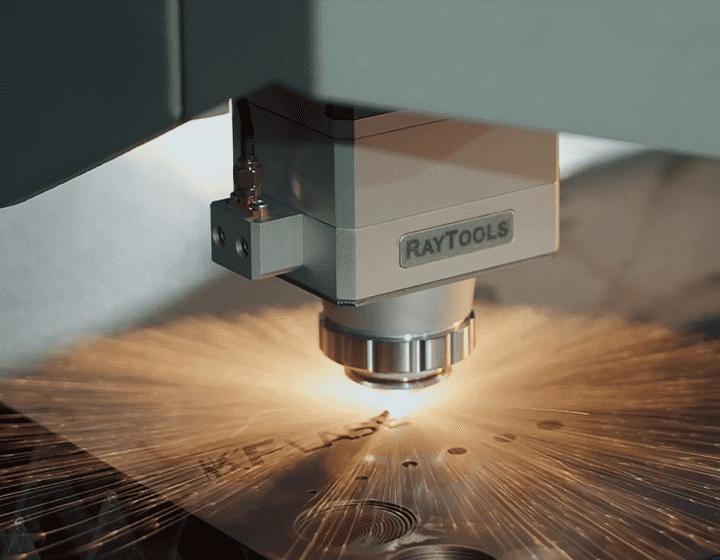

Laser Technology: The Heart of Pipe Cutting

At the core of a CNC laser pipe cutting machine is the laser beam, which can cut through materials with incredible accuracy. The laser is generated from a powerful source and focused onto the material by advanced optics, enabling it to melt or vaporize the metal in its path. The key advantages of this process are precision, clean cuts, and the ability to work with complex geometries that are difficult or impossible to achieve with traditional cutting methods.

CNC Automation: Precision and Control

The integration of CNC technology in laser pipe cutting machines ensures the high precision and consistency of each cut. Once the cutting parameters are set in the computer, the machine automatically follows the programmed instructions to perform the cutting operation. CNC control enables operators to input complex designs and make adjustments to the cutting process with ease, allowing for custom shapes, padrões intrincados, and detailed features.

This automation dramatically increases the speed of production and reduces labor costs, as the need for manual intervention is minimized. Adicionalmente, the consistent results provided by the CNC control system reduce the likelihood of human error, ensuring high-quality output.

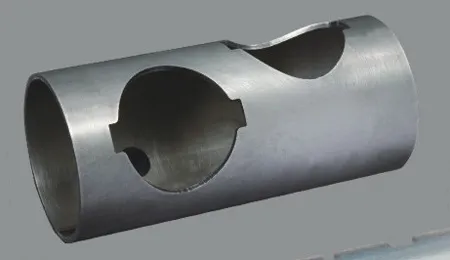

Types of Cuts and Features

CNC laser pipe cutting machines can perform a wide variety of cuts, including straight cuts, cortes angulares, slots, and holes, depending on the design requirements. Some machines also offer the ability to cut in 3D space, allowing them to handle more complex pipe geometries, such as tapered, spiral, and curved pipes.

With CNC programming, operators can easily adjust the cutting parameters, making it possible to create custom-designed tubes and pipes for various applications. This adaptability allows manufacturers to switch between different pipe sizes, materials, and designs without the need for time-consuming machine reconfigurations.

3. Advantages of CNC Laser Pipe Cutting Machines

Alta Precisão e Exatidão

The primary advantage of CNC laser pipe cutting machines is their precision. The laser’s focused energy allows for very tight tolerances, which is crucial in industries that require high-quality, exact cuts. Whether cutting for structural integrity in construction or manufacturing components for delicate medical devices, the precision of laser cutting ensures that each pipe is fabricated to the highest standards.

Increased Efficiency and Productivity

CNC laser cutting is a fast process. The automation and speed at which these machines operate make them significantly more efficient than traditional cutting methods, allowing manufacturers to complete projects quicker. The ability to perform multiple cuts at once and handle complex tasks without the need for manual adjustments or secondary operations also enhances productivity.

4. Applications of CNC Laser Pipe Cutting Machines

Indústria automobilística

Na fabricação automotiva, precision and speed are paramount. CNC laser pipe cutting machines are used to cut components for frames, sistemas de escape, and suspension parts. The precision of the cuts ensures that parts fit perfectly, which is critical for safety and functionality in automotive applications.

Aerospace Sector

The aerospace industry requires the highest standards of quality and precision. CNC laser pipe cutting machines are used to fabricate lightweight, high-strength pipes and tubes for structural components, peças do motor, and fluid systems. The laser’s ability to cut through thick materials with high precision is essential for meeting the stringent standards of the aerospace sector.

Construction and Structural Applications

From handrails to structural beams, CNC laser pipe cutting machines are indispensable in the construction industry. These machines can cut metal pipes to exact specifications, ensuring that each piece fits perfectly in construction projects, whether for aesthetic purposes or structural support.

Energy and Oil & Gas Industries

The energy sector relies on high-quality pipes for power plants, oil and gas pipelines, and renewable energy projects. CNC laser pipe cutting machines are used to ensure that these pipes are cut accurately, with tight tolerances that meet safety and regulatory requirements. The ability to work with various metals, including resistant alloys, makes these machines ideal for energy applications.

5. Choosing the Right CNC Laser Pipe Cutting Machine

Tamanho e capacidade da máquina

The size and cutting capacity of a CNC laser pipe cutting machine should be selected based on the types of projects you plan to undertake. Consider factors such as the diameter and thickness of the pipes, as well as the machine’s cutting speed and power.

Compatibilidade de materiais

Different CNC laser machines are capable of cutting different materials. When choosing a machine, ensure that it can handle the types of metal used in your operations. Some machines may be better suited for thinner materials, while others are designed to handle thicker pipes.

Orçamento e manutenção

While CNC laser pipe cutting machines can be a significant investment, their long-term savings in terms of productivity and material waste can make them cost-effective. It’s important to factor in both the initial cost and the ongoing maintenance costs when selecting a machine, ensuring that it fits your budget while meeting your manufacturing needs.

In summary, the CNC laser pipe cutting machine is a revolutionary tool in the metal fabrication industry, oferecendo precisão incomparável, velocidade, e versatilidade. Whether for automotive, aeroespacial, energy, or construction applications, these machines are reshaping the way we approach pipe cutting, offering efficient, cost-effective, and highly customizable solutions.

Notícias principais

-

Fiber Laser Metal Cutting Machine For Sale05 Dec 2025

Fiber Laser Metal Cutting Machine For Sale05 Dec 2025 -

4000 Watt Laser | Industrial Cutting Power02 Dec 2025

4000 Watt Laser | Industrial Cutting Power02 Dec 2025 -

6 corte a laser kw | Guia de precisão industrial28 novembro 2025

6 corte a laser kw | Guia de precisão industrial28 novembro 2025 -

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025 -

10Corte a laser kW | Precisão & Poder21 novembro 2025

10Corte a laser kW | Precisão & Poder21 novembro 2025

Categorias de produtos

- Cortador a laser de metal

- Máquina de solda a laser

- Máquina de limpeza a laser

- Máquina marcadora a laser

- Máquina de freio de imprensa