Notícias

Fiber Laser Metal Cutting Machine For Sale

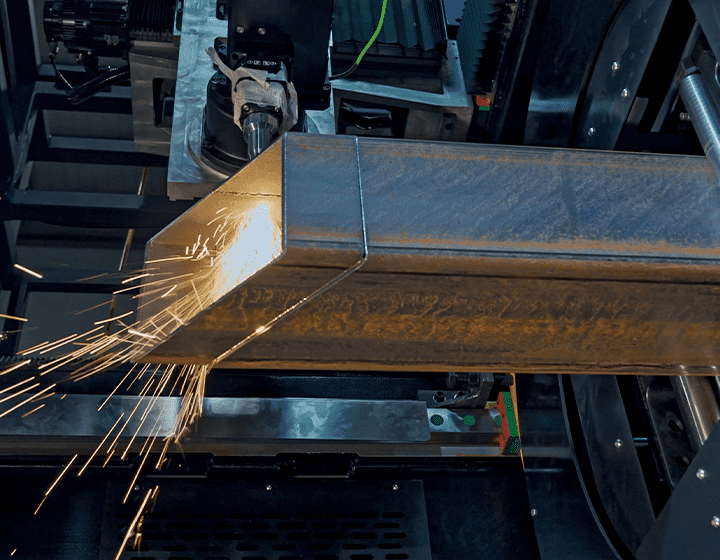

Fiber laser metal cutting machine for sale isn’t just a product listing—it’s a gateway to transforming your manufacturing workflow, slashing production times, and unlocking new possibilities in metal fabrication. Imagine a tool that can slice through 20mm steel like butter, carve intricate designs into aluminum with micron-level precision, and do it all while reducing energy costs by up to 70% compared to traditional cutting methods. In today’s fast-paced industrial landscape, where efficiency and accuracy are non-negotiable, choosing the right fiber laser metal cutting machine isn’t just a purchase; it’s an investment in the future of your business. But with hundreds of options flooding the market—each claiming to be “the best,” “the fastest,” or “the most affordable”—how do you separate marketing hype from genuine value? This guide cuts through the noise, blending technical expertise with real-world insights to help you navigate the process of buying a fiber laser metal cutting machine. Whether you’re a small workshop owner scaling up operations or a large manufacturer upgrading aging equipment, we’ll cover everything from key specifications to avoid hidden pitfalls, ensuring your investment delivers returns for years to come.

Why Fiber Laser Technology Dominates Modern Metal Cutting

To understand why fiber laser metal cutting machines are revolutionizing the industry, let’s start with the basics: como eles funcionam. Unlike CO2 lasers, which use gas as a lasing medium, fiber lasers generate a high-intensity beam by amplifying light through optical fibers doped with rare-earth elements like erbium or ytterbium. This design gives them three critical advantages:

1.Unmatched Energy Efficiency: Fiber lasers convert up to 30% of electrical energy into usable laser power, compared to just 10% for CO2 lasers. For a manufacturer running the machine 8 hours daily, this translates to annual savings of 5,000–5,000–15,000 in electricity costs alone. 2.Superior Beam Quality: The focused, coherent beam of a fiber laser delivers a smaller spot size (as tiny as 0.01mm), enabling precision cuts with minimal heat-affected zones (HAZ). This is game-changing for industries like aerospace, where even a 0.1mm deviation can compromise structural integrity. 3.Low Maintenance Requirements: Without mirrors or gas chambers to align or replace, fiber lasers have a mean time between failures (MTBF) of 100,000 hours—10 times longer than CO2 systems. This reduces downtime and cuts maintenance costs by up to $20,000 over five years for a mid-sized machine.

These benefits explain why the global fiber laser market is projected to grow at a CAGR of 14.2% de 2023 para $7.8 billion by 2028, according to Grand View Research. For businesses considering a fiber laser metal cutting machine for sale, this growth isn’t just a trend—it’s proof of the technology’s staying power.

Key Factors to Consider When Buying a Fiber Laser Metal Cutting Machine

Not all fiber laser metal cutting machines for sale are created equal. To ensure you’re investing wisely, prioritize these six critical factors:

1. Potência Laser: Matching Wattage to Material and Thickness

Laser power (medido em watts) dictates what materials and thicknesses you can cut. A 1kW laser might handle 3mm stainless steel, but for 25mm carbon steel, you’ll need 4kW or higher. No entanto, higher wattage isn’t always better—overpowering thin materials can cause warping or burning. Here’s a quick guide:

- 1–2kW: Ideal for sheet metal (up to 12mm steel, 8mm aluminum) in industries like automotive parts or signage.

- 3–6kW: Suited for heavy-duty tasks (15–30mm steel, 12–20mm aluminum) in construction or industrial manufacturing.

- 8kW+: Reserved for specialized applications like shipbuilding or oil pipeline fabrication, where cutting 40mm+ metal is routine.

Para dica: Ask suppliers for cutting speed and edge quality samples at your target thicknesses. A 4kW machine from one brand might outperform a 6kW from another due to beam quality differences.

2. Área de Corte: Size Matters for Production Flexibility

The machine’s bed size determines the maximum workpiece dimensions. Common options include:

- Small (1.5m x 3m): Perfect for small workshops or prototyping.

- Medium (2m x 4m): The sweet spot for most manufacturers, handling standard sheet sizes (por exemplo, 4’x8’).

- Large (3m x 6m+): For industrial-scale projects like structural beams or armor plating.

But don’t just focus on length and width—check the Z-axis (vertical) travel, too. If you plan to cut 3D parts or thick plates, a larger Z-axis clearance (150mm+) prevents collisions and allows for clamping.

3. Sistema de resfriamento: The Unsung Hero of Longevity

Fiber lasers generate intense heat, so a robust cooling system is non-negotiable. Air-cooled systems work for 1–2kW lasers but struggle with higher wattages. Water-cooled chillers are more efficient, maintaining laser diodes at a stable 25°C–30°C. Look for:

- Closed-loop systems: Prevent mineral buildup and corrosion.

- Temperature control accuracy: ±0.5°C is standard; tighter tolerances (±0.1°C) extend diode life.

- Noise levels: Industrial chillers can be loud—opt for models under 70dB if the machine is near workers.

4. Software: The Brain Behind the Machine

Even the best hardware is useless without intuitive, powerful software. Prioritize systems with:

- CAD/CAM integration: Seamless import of DXF, IA, or SVG files (no manual redrawing!).

- Nesting optimization: Automatically arranges parts to minimize material waste—saving up to 15% on raw materials annually.

- Real-time monitoring: Alerts for issues like lens contamination or gas pressure drops, preventing costly downtime.

Avoid proprietary software that locks you into expensive updates. Open-source or widely used platforms (por exemplo, LightBurn, RDWorks) offer better long-term flexibility.

5. Suporte pós-venda: Don’t Buy a Machine—Buy a Partnership

A fiber laser metal cutting machine is a 10–15 year investment. When evaluating suppliers, ask:

- Tempo de resposta: Will they fix a breakdown in 24 hours or 2 weeks?

- Spare parts availability: Are critical components (lentes, nozzles, diodes) in stock locally?

- Treinamento: Do they offer on-site training for operators and maintenance staff?

- Red Flag: Suppliers who hesitate to share customer references or warranty fine print. A reputable brand will stand behind their product with a 2–3 year warranty on the laser source and 1 year on mechanical parts.

6. Custo: Beyond the Sticker Price

A fiber laser metal cutting machine for sale can range from 30,000(small1kW)to30,000(small1kW)to500,000+ (industrial 12kW). But total cost of ownership (TCO) includes:

- Consumables: Lenses (200–200–800 each, 6–12 month lifespan), nozzles (50–50–150, monthly replacement), and assist gases (nitrogen/oxygen, 50–50–200 per tank).

- Electricity: A 4kW machine uses ~15kWh/day—around 1,800/yearat1,800/yearat0.10/kWh.

- Manutenção: Annual service contracts (2,000–2,000–5,000) to clean optics and calibrate the beam path.

Savings Hack: Used machines (2–3 years old) can cost 40% less than new ones, but verify laser hours (under 10,000 is ideal) and ask for a performance test before buying used fiber laser metal cutting machine for sale.

Avoiding Scams and Low-Quality Machines

The fiber laser market is flooded with cheap imports, especially from Asia, that promise “top-tier performance” at rock-bottom prices. Here’s how to spot red flags:

- Too Good to Be True Pricing: A 3kW machine for $20,000? It likely uses low-grade diodes (lifespan <10,000 hours vs. 100,000+ for premium brands).

- Vague Specifications: If a supplier can’t provide beam quality (M² factor <1.1 is excellent), cutting speed data, or warranty details, walk away.

- No Local Support: Overseas suppliers may offer “24/7 support,” but time zone delays and language barriers make troubleshooting a nightmare.

Instead, focus on established manufacturers with a 5+ year track record. Look for certifications like CE (safety), ISO 9001 (quality management), or FDA approval (for laser safety).

How to Finance Your Fiber Laser Metal Cutting Machine

For many businesses, purchasing a fiber laser metal cutting machine means a significant upfront payment. Fortunately, several financing options are available:

- Leasing: Monthly payments (starting at $1,500/month for a 3kW machine) preserve capital, with the option to buy at the end of the term.

- Equipment loans: Banks offer 5–7 year terms with interest rates (5–8%) lower than credit cards.

- Government grants: In the EU, programs like Horizon Europe or the U.S. Small Business Administration (SBA) offer subsidies for energy-efficient manufacturing equipment.

Estudo de caso: A Michigan-based metalworking company used a loan from the U.S. Small Business Administration (SBA) to purchase a 4kW fiber laser worth $180,000. By reducing outsourcing costs and increasing production capacity, they paid off the loan in 2.5 years and now generate over $500,000 in new revenue annually.

The Future of Fiber Laser Cutting: What’s Next?

À medida que a tecnologia evolui, fiber laser metal cutting machines for sale will only get better. Keep an eye on:

- Lasers verdes: Emerging 532nm green lasers cut copper and brass (traditionally tricky for IR lasers) with minimal reflection issues.

- AI-Powered Predictive Maintenance: Machine learning algorithms that predict diode failures or lens wear before they happen.

- Hybrid Systems: Combinations of laser cutting and welding in one machine, streamlining workflows for complex parts.

For now, though, the best strategy is to invest in a machine that meets your current needs while leaving room to grow. A 3kW laser with a large bed might cost $50,000 more upfront but avoid the need for an upgrade in 2 years.

In the end, a fiber laser metal cutting machine for sale is more than a tool—it’s a partner in your business’s success. By focusing on power, precisão, e confiabilidade, and by vetting suppliers thoroughly, you’ll find a machine that pays dividends for decades. Whether you’re cutting mild steel, stainless, or aluminum, the right fiber laser will turn raw metal into profit, one precise cut at a time. Ready to take the next step? Start by requesting quotes from 3–5 suppliers, ask for on-site demos, and talk to their existing customers. The perfect machine isn’t just out there—it’s waiting to transform your shop floor.

Notícias principais

Categorias de produtos

- Cortador a laser de metal

- Máquina de solda a laser

- Máquina de limpeza a laser

- Máquina marcadora a laser

- Máquina de freio de imprensa