Noticias

Comprensión de las máquinas de corte con láser comerciales: Una guía completa

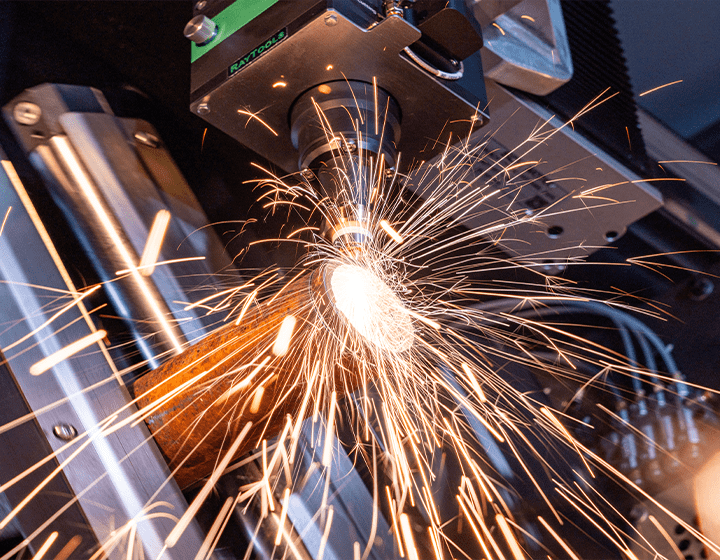

In today’s manufacturing landscape, commercial laser cutting machines have become indispensable tools for cutting a variety of materials, ranging from metals to plastics and even wood. Whether you’re running a large-scale industrial operation or a small fabrication business, these machines offer the precision and efficiency needed to meet demanding production schedules.

But what exactly are commercial laser cutting machines? How do they work, and what makes them such a popular choice in industries ranging from aerospace to signage? En este artículo, we’ll break down the key elements of commercial laser cutting, explore their benefits, and provide insights into selecting the right machine for your needs.

1. What is a Commercial Laser Cutting Machine?

A commercial laser cutting machine is a high-powered device that uses a focused laser beam to cut, etch, or engrave materials with high precision. The cutting process involves directing a concentrated laser beam onto the material’s surface, where it melts, quemaduras, or vaporizes the material along a predetermined path.

Commercial laser cutting machines come in several types, incluido Láser de CO2, láser de fibra, y YAG lasers, with each designed to handle specific materials and applications. Láser de CO2, for example, are ideal for cutting non-metal materials like plastics and wood, while fiber lasers are better suited for metal cutting due to their higher energy efficiency and precision.

2. How Do Commercial Laser Cutting Machines Work?

The basic mechanism behind a commercial laser cutting machine involves several steps:

Generación láser: The laser beam is generated by a laser source, typically a CO2, fiber, or YAG laser. The laser source generates light energy, which is then amplified to create a concentrated beam.

Beam Focusing: The beam is focused onto the material’s surface using a series of mirrors or lenses. The focused beam is extremely powerful and can melt or vaporize even the toughest materials.

Assist Gas: An assist gas, such as oxygen, nitrógeno, or compressed air, is often used to blow away the molten material during the cutting process, preventing the cut edges from being contaminated and promoting cleaner cuts.

Motion Control: The machine’s cutting head moves across the material along the programmed path, guided by a CNC (Control numérico por computadora) sistema. This ensures the cuts are made with high accuracy and repeatability.

3. Types of Commercial Laser Cutting Machines

There are several types of laser cutting machines available for commercial use, cada uno diseñado para aplicaciones y materiales específicos.

Máquinas de corte por láser de CO2

CO2 lasers are one of the most common types of lasers used in commercial settings. They are versatile and can cut through a wide range of materials, incluyendo plásticos, madera, acrílico, and non-ferrous metals. CO2 lasers are best for thin to medium-thick materials and offer high-quality cuts with smooth edges.

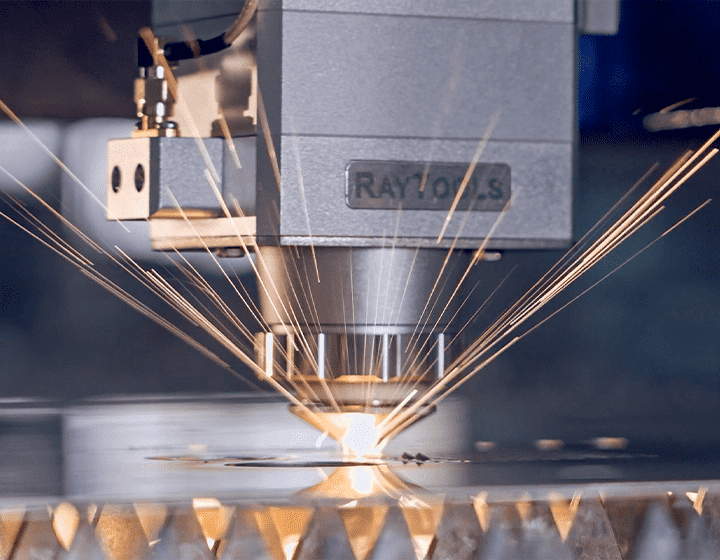

Máquinas de corte por láser de fibra

Fiber lasers use a solid-state laser technology and are known for their energy efficiency y precisión. These lasers are commonly used for cutting metals, incluido acero inoxidable, aluminio, y acero carbono. Fiber lasers are highly efficient at cutting reflective metals and can handle thicker materials more effectively than CO2 lasers.

YAG Laser Cutting Machines

YAG (yttrium-aluminum-garnet) lasers are primarily used in metal cutting aplicaciones, especially for acero inoxidable y titanio. YAG lasers tend to be more expensive and are less common than CO2 or fiber lasers but are used in specialized industrial applications requiring precision cutting.

4. Benefits of Commercial Laser Cutting Machines

There are several advantages to using commercial laser cutting machines in industrial and manufacturing environments:

Precisión y exactitud

Laser cutting machines are known for their alta precisión and the ability to make extremely detailed cuts with tight tolerances. Whether you’re producing small components o geometrías complejas, the laser’s focused beam ensures that cuts are accurate to the smallest detail.

Desperdicio mínimo de material

El corte láser es un proceso sin contacto, which means that the laser doesn’t physically touch the material during the cutting process. Como resultado, the cuts are clean and efficient, with very little material waste. This makes it an ideal option for maximizing material usage and minimizing costs.

Versatilidad en Materiales

Commercial laser cutting machines can handle a wide variety of materials, incluyendo metales, plástica, madera, cerámica, vaso, y más. Depending on the laser type and power, these machines can cut materials of varying thicknesses and complexities.

Faster Production Times

El corte por láser es un proceso rápido y eficiente, reducing the time needed to complete jobs. Since the machines are CNC-controlled, they can operate autonomously with minimal human intervention, allowing for continuous production without downtime. This is particularly important for industries that need to meet tight deadlines.

Minimal Heat Affected Zone (Cría)

Laser cutting generates very little heat compared to other cutting methods, resulting in a minimal heat-affected zone (Cría). This prevents the material from warping or distorting, ensuring that the final product remains true to its design specifications.

5. Applications of Commercial Laser Cutting Machines

Commercial laser cutting machines are used across a broad range of industries, incluido:

Automotor

Laser cutting is commonly used in the automotive industry for making precise cuts in parts such as body panels, paréntesis, y sistemas de escape. The ability to handle high-volume production while maintaining precision is a major advantage.

Aeroespacial

Aerospace manufacturers rely on laser cutting for making complex components, especialmente en lightweight materials such as aluminum and titanium. The need for high precision and minimal waste makes laser cutting an essential tool in this industry.

Signage and Display

Laser cutting is used to produce custom signs, logotipos, and displays from materials such as metal, acrílico, and wood. The precision offered by laser cutters ensures that intricate designs can be created without distortion or loss of detail.

Electrónica

In the electronics industry, laser cutting is used for producing precise components, such as heat sinks, covers, and housings for electronic devices. The ability to make fine cuts with high accuracy is critical in electronics manufacturing.

Fabrication

Laser cutting is a standard practice in metal fabrication for creating structural components, paréntesis, and other parts. The precision of the laser allows fabricators to create complex shapes quickly and efficiently.

6. How to Choose the Right Commercial Laser Cutting Machine

When selecting a commercial laser cutting machine for your business, several factors should be considered to ensure you choose the right equipment for your needs:

Compatibilidad de materiales: Ensure the laser cutter can handle the types of materials you plan to cut, whether it’s metal, plástico, o madera.

Corte de velocidad y potencia: Choose a machine with the right power and speed for your materials. Láser de fibra, for instance, offer faster cutting speeds for metals, while CO2 lasers are better for non-metals.

Tamaño y capacidad de la máquina: Consider the size of the materials you will be cutting. Larger machines may be necessary if you need to cut big sheets or thicker materials.

Presupuesto: Commercial laser cutting machines can be a significant investment. While it’s important to balance cost with quality, consider long-term operational costs, incluyendo mantenimiento, consumo de energía, y consumibles.

Support and Service: Look for a supplier that offers strong customer support and after-sales service, including machine maintenance, troubleshooting, and training.

Commercial laser cutting machines have revolutionized industries by offering unmatched precision, velocidad, y eficiencia. From automotive to electronics, laser cutting has found its place in nearly every industry, providing manufacturers with the ability to produce high-quality parts with minimal waste. By understanding the types of machines available, sus aplicaciones, and how to choose the right one, businesses can optimize their production processes and meet the growing demands of today’s market.

Historias destacadas

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora