Notícias

Máquina de corte a laser de fibra para venda: Por que é um divisor de jogo para o seu negócio

Introduction: The Rise of Máquinas de corte a laser de fibra

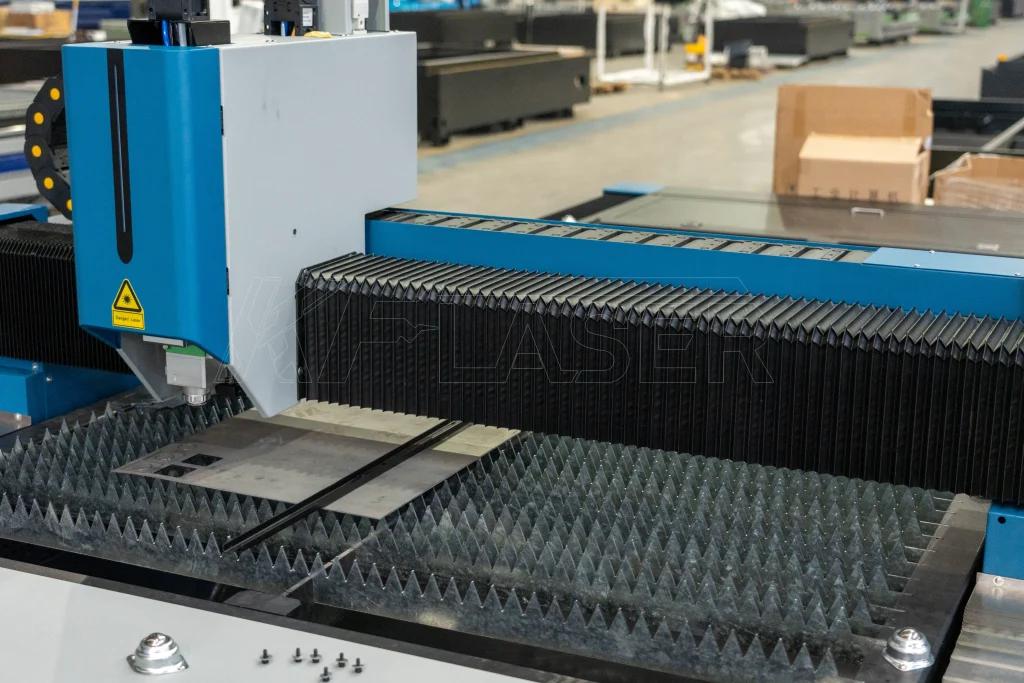

When you search for a fiber laser cutting machine for sale, you’re diving into the world of one of the most precise, eficiente, and cost-effective technologies in modern manufacturing. From automotive components to intricate designs in aerospace and electronics, fiber laser cutting machines have transformed industries by providing unmatched cutting precision, velocidade, and cost-effectiveness. But how do you navigate the landscape of fiber laser cutting machines to find the right one for your business?

☺ Você pode compartilhar este artigo para:

Ⅰ. What Is a Fiber Laser Cutting Machine?

◆ Understanding the Basics of Fiber Laser Cutting

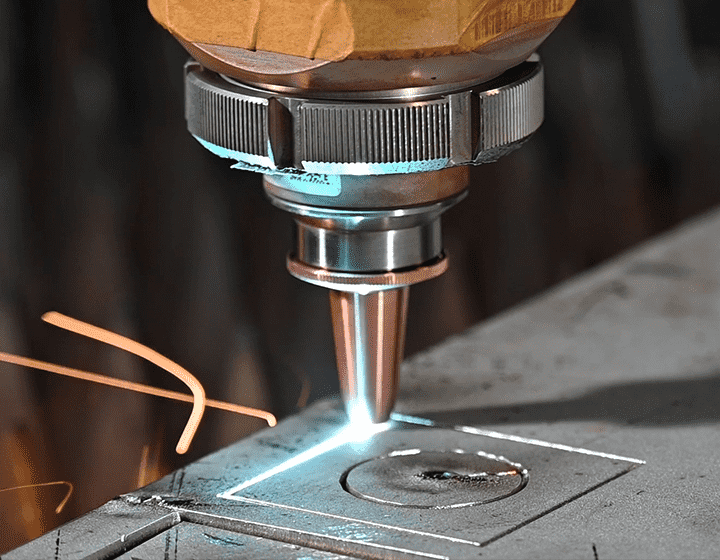

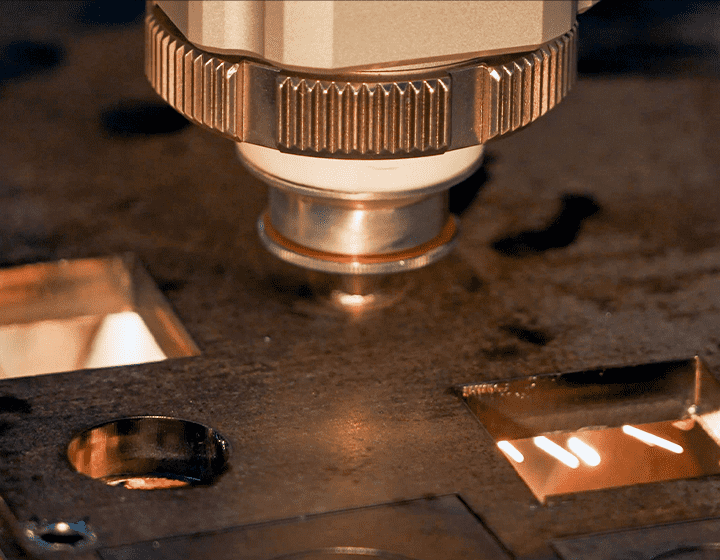

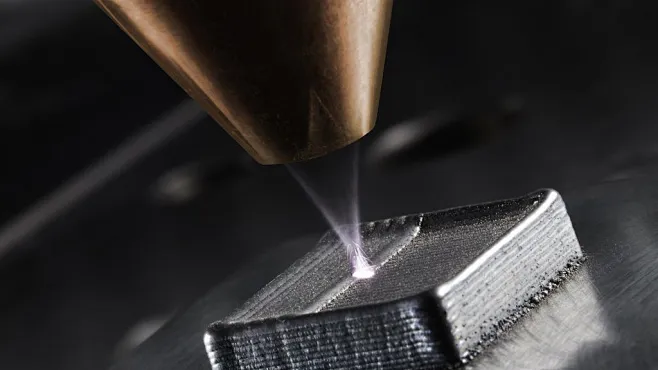

A fiber laser cutting machine utilizes a high-power fiber laser to cut materials with extreme precision. The fiber laser beam is directed onto the material’s surface, onde derrete, queimaduras, ou vaporiza o material, leaving a clean and accurate cut. This type of cutting is fast, preciso, and can cut through a variety of metals, incluindo aço inoxidável, alumínio, e aço carbono.

◆ How Does a Fiber Laser Cutting Machine Work?

The fiber laser cutting machine works by converting electrical energy into laser light, which is transmitted through optical fibers to the cutting head. Unlike CO2 lasers, which use mirrors to direct the beam, fiber lasers rely on fiber-optic cables to provide greater efficiency, stability, and cutting speed. Fiber laser cutting machines are ideal for precision cutting and complex designs, especially for metals.

Ⅱ. Key Benefits of Fiber Laser Cutting Machines

◆ High Precision and Accuracy

The primary advantage of fiber laser cutting is its ability to create precise cuts with extremely fine details. The laser beam is focused tightly, allowing for highly accurate cuts in materials of various thicknesses. This precision ensures that parts fit together with exact tolerances, o que é crucial em indústrias como a aeroespacial, eletrônica, and automotive manufacturing.

◆ Faster Cutting Speeds

When you choose a fiber laser cutting machine for sale, one of the standout features is speed. Fiber lasers cut faster than their CO2 counterparts, which significantly boosts productivity. They can cut through thin and thick materials alike without sacrificing precision. The high cutting speeds result in lower production times and increased efficiency, making fiber laser machines ideal for large-scale operations.

◆ Lower Operating Costs

While fiber laser cutting machines are an investment, they can save you money over time due to their energy efficiency and low maintenance requirements. Compared to traditional cutting methods, fiber lasers require less power to operate and have fewer components that wear out. This results in lower energy costs and reduced downtime. Adicionalmente, the laser-cut quality reduces the need for post-processing, which further minimizes costs.

◆ Versatility

Another advantage of fiber laser cutting machines is their ability to handle a wide range of materials. From thin stainless steel to thicker aluminum plates, fiber lasers are versatile enough to handle different metals with ease. This versatility makes them ideal for industries that require a variety of materials and applications, como fabricação de dispositivos médicos, Fabricação de chapa metal, and artistic designs.

Ⅲ. Factors to Consider When Buying a Fiber Laser Cutting Machine

◆ Cutting Power and Material Thickness

The cutting power of the machine is crucial in determining the types of materials and the thicknesses that can be effectively cut. Por exemplo, machines with a 1000W laser are generally suitable for cutting thin metals, while those with 3000W or higher can handle thicker materials with ease. When looking for a fiber laser cutting machine for sale, it’s important to match the machine’s power with the material thickness and the cutting speed required for your operations.

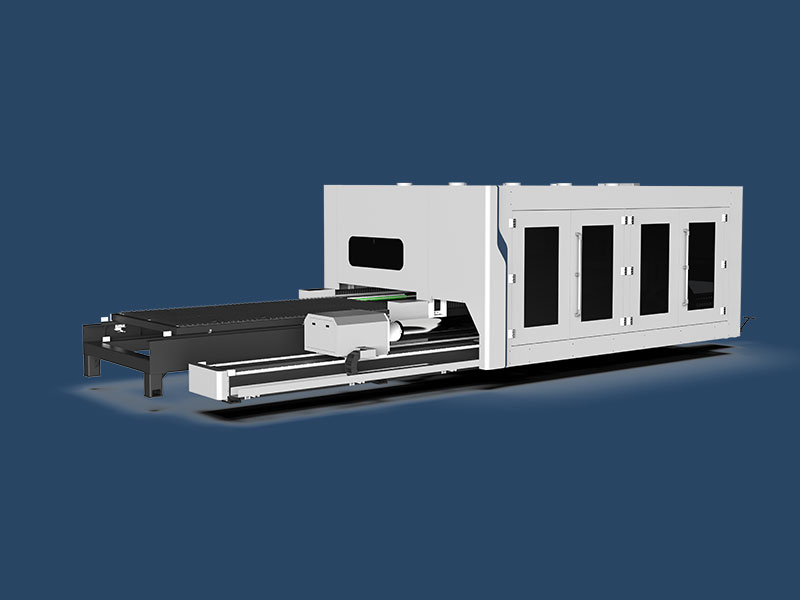

◆ Size of the Machine and Bed Capacity

The size and bed capacity of the machine should be considered based on the size of the materials you typically cut. Larger materials will require a bigger bed and a larger machine. If your business focuses on small to medium-sized parts, a compact machine may be more suitable. The larger the bed, the higher the price, so you should choose based on your specific needs.

◆ Automation and Software Features

Modern fiber laser cutting machines come equipped with advanced software and automation features. These can include auto-focus systems, cutting path optimization, and automatic material loading. Such features not only improve the speed and precision of the cutting process but also reduce the amount of manual labor required. When shopping for a fiber laser cutting machine for sale, consider whether you need these advanced features, as they can increase the price.

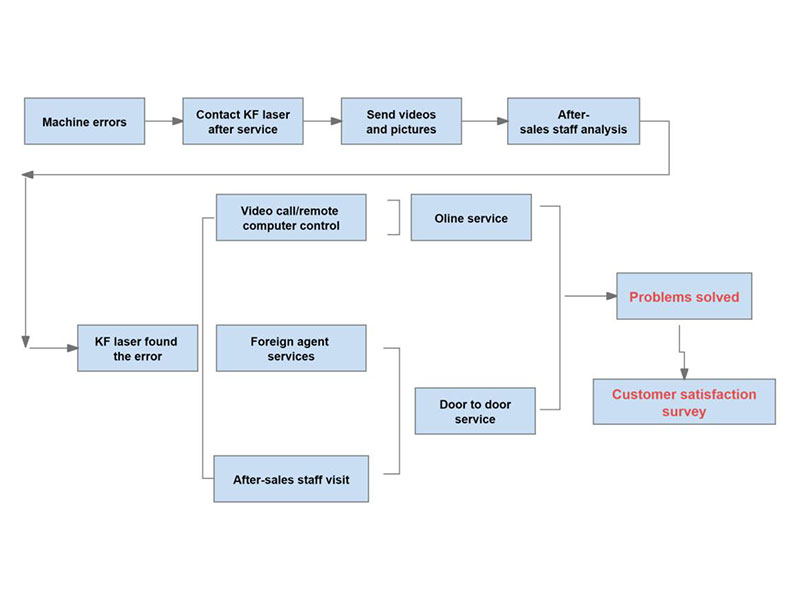

◆ Maintenance and Support

To ensure the longevity and performance of your fiber laser cutting machine, it’s important to consider the maintenance needs and the level of technical support available. Fiber laser cutting machines are generally low-maintenance, but regular servicing and timely repairs are essential to keep the machine running at peak performance. Always check the warranty and customer support options before making a purchase.

Ⅳ. Price Range of Fiber Laser Cutting Machines

| type | Price range | poder | Vantagens |

| Entry-Level Fiber Laser Cutting Machines | $10,000 para $30,000 | around 1000W | Best suited for smaller businesses or companies with limited production needs and are adaptable to cutting thinner materials. |

| Mid-Range Fiber Laser Cutting Machines | $30,000 para $80,000 | 2000W to 4000W | A wider range of materials and thicker metals can be processed. |

| High-End Fiber Laser Cutting Machines | $80,000 para $200,000 ou mais | 5000W e acima | Capable of high-volume production, with automation, cutting-edge software and the ability to efficiently cut thick materials, it can be used in industries that demand the highest precision and performance. |

◆ Entry-Level Fiber Laser Cutting Machines

Entry-level fiber laser cutting machines are typically priced between $10,000 para $30,000. These machines are best suited for small businesses or companies with limited production needs. They generally offer lower power (around 1000W) and have smaller bed capacities. Despite their lower price, they still provide good precision and cutting speed for thinner materials.

◆ Mid-Range Fiber Laser Cutting Machines

Mid-range machines with 2000W to 4000W lasers are priced between $30,000 para $80,000. These machines are versatile enough to handle a wider range of materials and thicker metals. For businesses that need to balance cost and capability, mid-range fiber lasers offer great value while delivering high-quality results and improved productivity.

◆ High-End Fiber Laser Cutting Machines

High-end fiber laser cutting machines with 5000W and above can range from $80,000 para $200,000 ou mais. These machines are capable of high-volume production and are used in industries that demand the highest precision and performance, such as automotive manufacturing, aeroespacial, and defense sectors. They feature advanced automation, cutting-edge software, and the ability to cut through very thick materials efficiently.

Ⅴ. How to Find the Best Deals on Fiber Laser Cutting Machines

◆ Compare Multiple Vendors

When shopping for a fiber laser cutting machine for sale, it’s always a good idea to compare prices from several reputable suppliers. Request quotes, read customer feedback, and assess the services each vendor offers. Adicionalmente, you may want to check if the supplier offers any financing options, especially for more expensive machines.

◆ Consider the Total Cost of Ownership

When looking at prices, don’t just focus on the initial cost. Consider the total cost of ownership (TCO), which includes operating costs, manutenção, and energy consumption over time. A machine with a higher upfront cost but lower long-term expenses might offer better value in the long run.

◆ Look for Promotions and Discounts

Keep an eye out for special promotions, discounts, or seasonal sales that may lower the overall price of the machine. Many manufacturers and suppliers offer periodic deals to attract customers, and purchasing during these times can help you save money.

By considering the factors outlined in this article and doing thorough research, you can find the fiber laser cutting machine for sale that fits both your budget and business needs, ensuring a solid return on investment.

▼ You can contact us through the following ways to get a quote immediately.

Notícias principais

-

Fiber Laser Metal Cutting Machine For Sale05 Dec 2025

Fiber Laser Metal Cutting Machine For Sale05 Dec 2025 -

4000 Watt Laser | Industrial Cutting Power02 Dec 2025

4000 Watt Laser | Industrial Cutting Power02 Dec 2025 -

6 corte a laser kw | Guia de precisão industrial28 novembro 2025

6 corte a laser kw | Guia de precisão industrial28 novembro 2025 -

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025 -

10Corte a laser kW | Precisão & Poder21 novembro 2025

10Corte a laser kW | Precisão & Poder21 novembro 2025

Categorias de produtos

- Cortador a laser de metal

- Máquina de solda a laser

- Máquina de limpeza a laser

- Máquina marcadora a laser

- Máquina de freio de imprensa