Notícias

Máquina de corte a laser de alumínio: Revolucionando a indústria de fabricação de metal

Introduction: Why Choose an Aluminum Laser Cutting Machine?

An aluminum laser cutting machine is a game-changer in the world of metal fabrication. With the increasing demand for precision and high-quality products, businesses are turning to laser cutting technology to deliver intricate designs, fast production times, and clean edges in aluminum processing. Whether you’re creating industrial components, custom parts, or artistic designs, the efficiency and precision of laser cutting have made it the go-to choice for professionals across industries.

But why has the aluminum laser cutting machine become so indispensable? Neste guia abrangente, we’ll explore the reasons behind the growing popularity of this technology, its benefits, formulários, and how it stands out compared to traditional cutting methods.

☺ Você pode compartilhar este artigo para:

Ⅰ. What is an Aluminum Laser Cutting Machine?

◆ Understanding Laser Cutting Technology

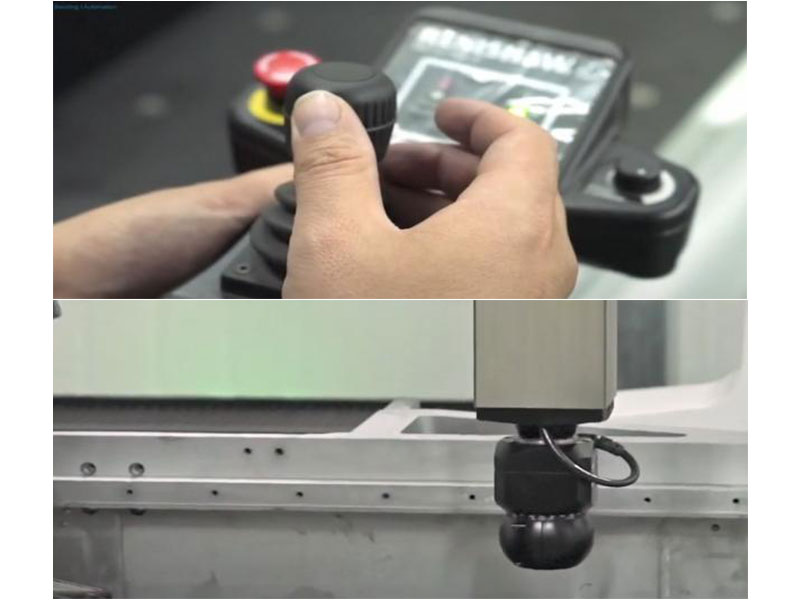

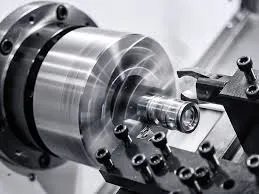

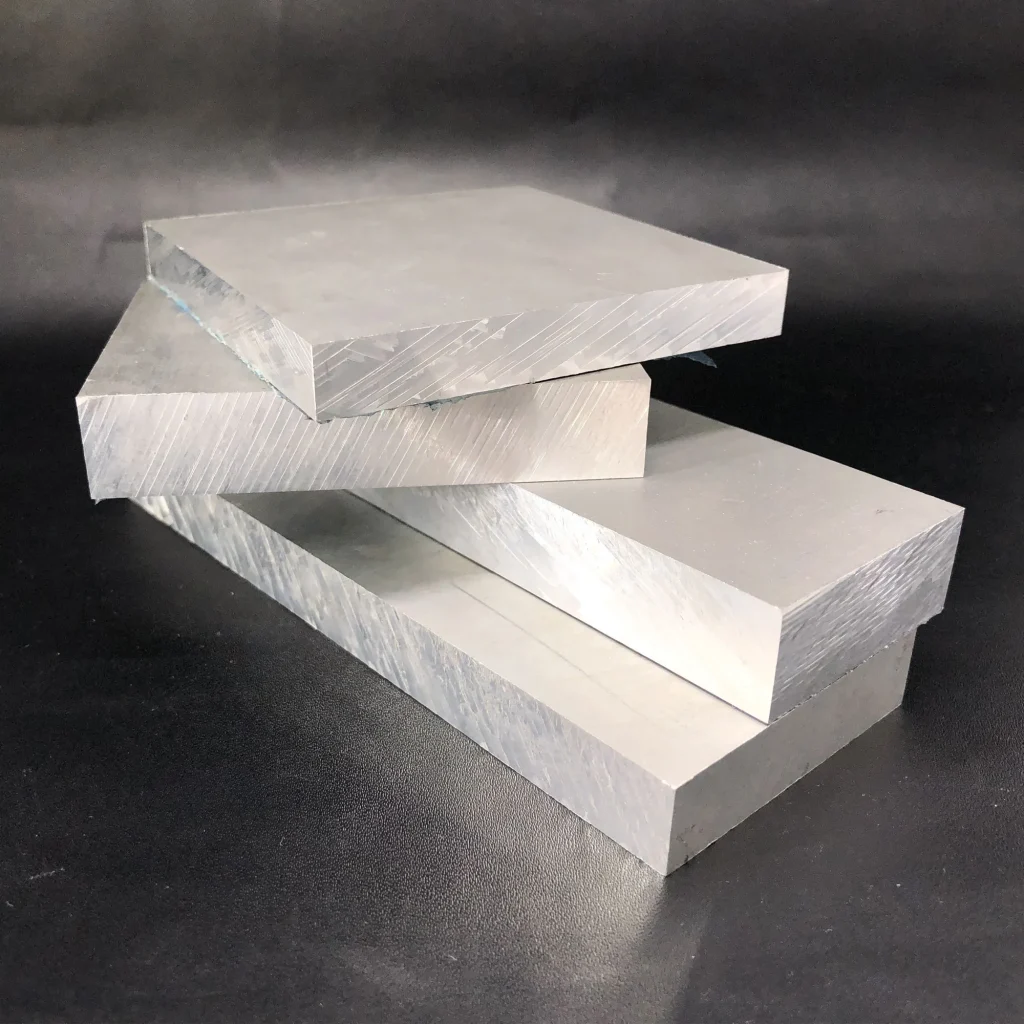

An aluminum laser cutting machine uses a high-powered laser beam to cut through aluminum sheets with exceptional precision. The laser beam is focused onto the surface of the material, where the heat causes the metal to melt, vaporizar, ou queimar, creating a smooth, corte preciso. The process is controlled by CNC systems, allowing for the design of complex geometries with high repeatability.

◆ Types of Aluminum Laser Cutting Machines

The two most common types of lasers used for cutting aluminum are CO2 lasers and fiber lasers. Each has its own benefits, with fiber lasers often being the preferred choice for aluminum due to their higher power density and ability to cut through thicker materials more efficiently. The selection of the right machine depends on the specific cutting needs, such as material thickness and cutting speed.

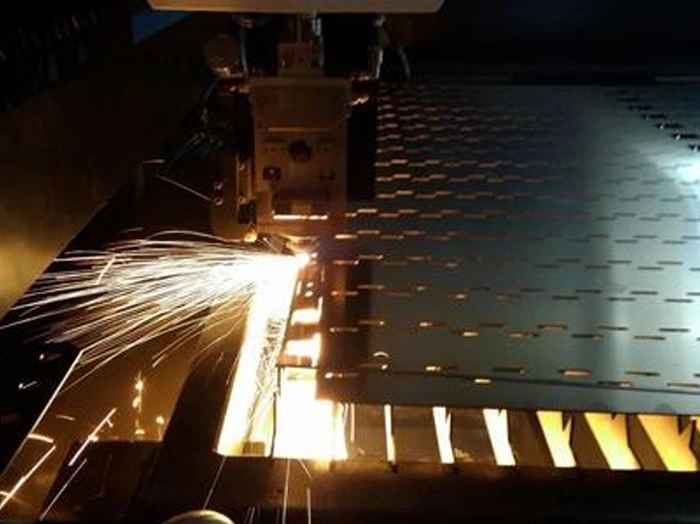

▶ The video below shows KF Laser’s 6KW laser cutting machine cutting a 10mm aluminum plate.

Ⅱ. The Advantages of Using an Aluminum Laser Cutting Machine

◆ Precision and Accuracy

One of the most significant advantages of using an aluminum laser cutting machine is the unmatched precision it offers. The laser beam’s fine point of focus allows for cuts with tolerances as tight as 0.1mm, ensuring that every part meets the desired specifications. This level of accuracy is especially crucial when creating intricate designs or small parts where even the slightest deviation can compromise functionality.

◆ Speed and Efficiency

O corte a laser é mais rápido que os métodos tradicionais, especially when cutting thin aluminum sheets. The high cutting speeds of an aluminum laser cutting machine allow manufacturers to complete projects in less time, melhorando a produtividade e reduzindo os prazos de entrega. Adicionalmente, the automated process reduces human error and minimizes the need for additional finishing work, economizando tempo e dinheiro.

◆ Clean Cuts with Minimal Waste

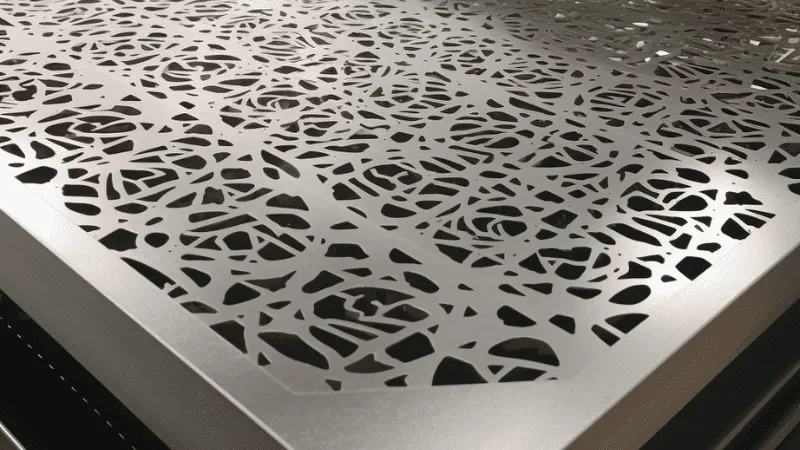

The precision of the laser ensures that material waste is minimized. Ao contrário dos métodos de corte mecânico, which may generate rough edges or require additional clean-up, laser cutting provides smooth, clean edges that typically require no further processing. This not only improves the overall quality of the cut but also reduces the amount of aluminum wasted during production, leading to lower costs.

◆ Versatility in Material Thickness

An aluminum laser cutting machine is versatile and can handle a wide range of material thicknesses. Whether you are working with thin aluminum sheets or thicker aluminum plates, laser cutting technology can accommodate both with ease. This flexibility makes it ideal for industries that need to work with varying aluminum thicknesses for different products.

Ⅲ. Applications of Aluminum Laser Cutting Machines

◆ Automotive Industry

Na indústria automotiva, laser cutting machines are used to create precision components such as body panels, colchetes, and chassis parts. The ability to make accurate cuts ensures that parts fit together perfectly, which is essential for vehicle assembly.

◆ Aeroespacial e defesa

The aerospace industry relies on laser cutting to create lightweight, durable components that can withstand extreme conditions. Laser cutting machines can precisely cut aluminum parts used in aircraft, satélites, and defense equipment, ensuring high performance and safety standards.

◆ Electronics and Electrical Industry

Na indústria eletrônica, laser cut aluminum is used for creating electrical enclosures, placas de circuito, and other precision parts. Aluminum is an excellent choice for these applications due to its lightweight and conductive properties. Laser cutting helps ensure that the intricate components are cut to exact specifications, with no room for error.

◆ Metal Fabrication

For metal fabrication, laser cutting provides an efficient way to create custom parts, decorative designs, and industrial components. The clean cuts produced by laser machines ensure that parts are ready for assembly with minimal post-processing.

◆ Artistic and Decorative Applications

Laser cutting has become increasingly popular in the art world, where it is used to create artistic sculptures, wall art, and decorative panels from aluminum. The fine detail achievable with an aluminum laser cutting machine allows artists to bring complex designs to life with stunning results.

Ⅳ. Factors to Consider When Choosing an Aluminum Laser Cutting Machine

◆ Laser Power and Cutting Thickness

The power of the laser is one of the most important factors when selecting an aluminum laser cutting machine. Machines with higher laser power can cut through thicker aluminum materials more effectively. If you plan to cut thicker sheets of aluminum, you will need a machine with higher wattage (por exemplo, 4000W to 6000W) to achieve clean, cortes precisos.

◆ Cutting Speed

The cutting speed of the machine is another crucial consideration. Faster cutting speeds improve productivity but may sacrifice edge quality. It’s essential to balance speed with the precision required for your specific applications.

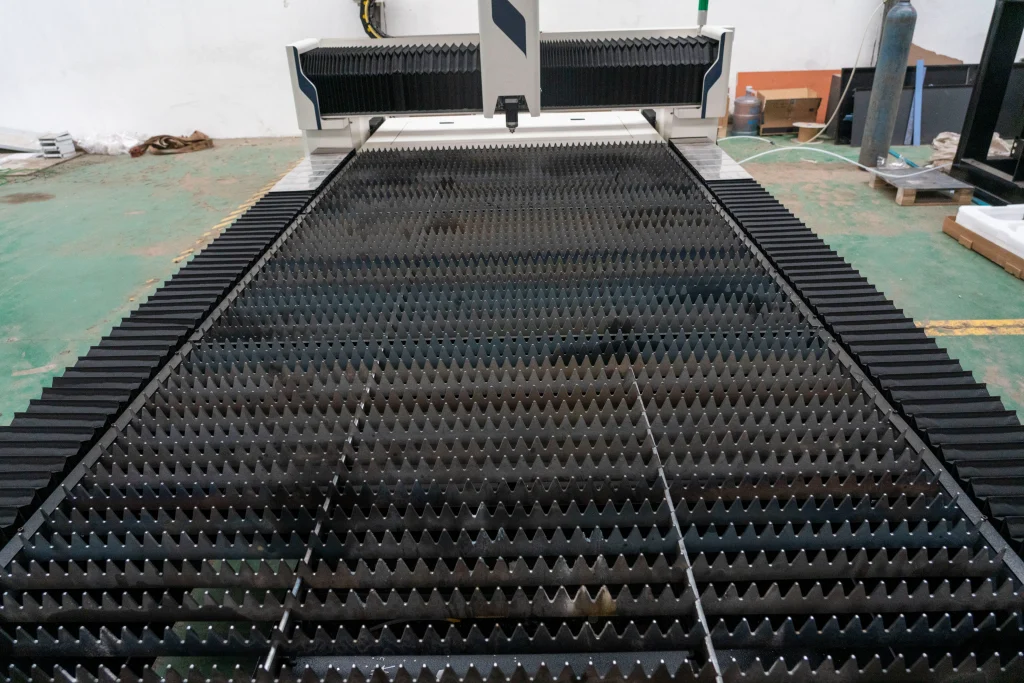

◆ Machine Size and Bed Capacity

Consider the size of the aluminum sheets you plan to cut. Some laser cutting machines have larger beds that can accommodate full-sized sheets, while others are more suitable for smaller parts. Select a machine with a bed capacity that fits your typical material sizes.

◆ Automation Features

Many modern laser cutting machines come with advanced features such as automatic material handling, cutting path optimization, and real-time monitoring. These features can greatly enhance the efficiency and accuracy of your operations, especialmente para produção de alto volume.

Ⅴ. The Future of Aluminum Laser Cutting Machines

À medida que a tecnologia continua a evoluir, so does the laser cutting process. In the future, aluminum laser cutting machines will likely become even more efficient, preciso, and cost-effective. The integration of AI-driven optimization, energy-efficient lasers, and smarter automation systems will revolutionize the way industries use laser cutting for aluminum and other metals.

The ability to process thicker materials faster, improve edge quality, and reduce energy consumption will only make aluminum laser cutting machines more attractive to businesses in the years to come.

An aluminum laser cutting machine is a powerful tool that combines precision, velocidade, and efficiency to revolutionize industries like automotive, aeroespacial, e fabricação de metal. By understanding the factors that influence machine selection, and by choosing the right equipment for your needs, you can unlock the full potential of laser cutting technology and produce high-quality aluminum parts faster and with fewer resources.

Notícias principais

-

4000Guia da máquina de corte a laser W | Fundamentos09 dezembro 2025

4000Guia da máquina de corte a laser W | Fundamentos09 dezembro 2025 -

Máquina de corte de metal a laser de fibra para venda05 dezembro 2025

Máquina de corte de metal a laser de fibra para venda05 dezembro 2025 -

4000 Watt Laser | Poder de corte industrial02 dezembro 2025

4000 Watt Laser | Poder de corte industrial02 dezembro 2025 -

6 corte a laser kw | Guia de precisão industrial28 novembro 2025

6 corte a laser kw | Guia de precisão industrial28 novembro 2025 -

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025

Categorias de produtos

- Cortador a laser de metal

- Máquina de solda a laser

- Máquina de limpeza a laser

- Máquina marcadora a laser

- Máquina de freio de imprensa