Notícias

Preço da máquina de corte a laser de fibra: O que esperar e fatores que influenciam o custo

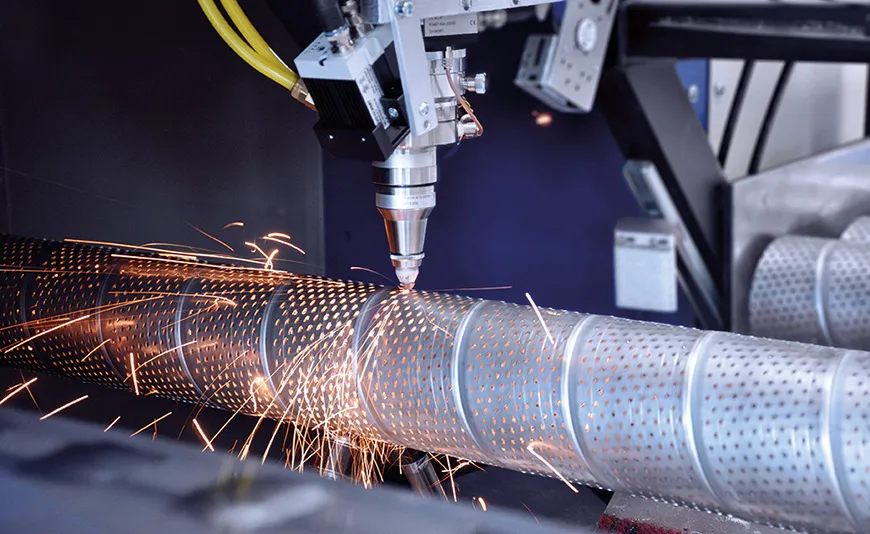

Fiber laser cutting machines have become the go-to technology for high-precision, high-speed metal cutting in industries like automotive, aeroespacial, e fabricação. But when it comes to buying one, a key question always arises: how much does a fiber laser cutting machine cost?

Neste guia, we’ll explore the price range for fiber laser cutting machines, the factors that influence their cost, and how to make the best investment based on your business requirements.

What is the Average Fiber Laser Cutting Machine Price?

The price of a máquina de corte a laser de fibra varies significantly based on several factors, including the machine’s power, size, brand, e recursos. Em média, fiber laser cutting machines are priced between $15,000 para $500,000 ou mais, depending on these factors.

Entry-Level Fiber Laser Cutting Machines (Under $50,000)

For small businesses or light-duty tasks, there are fiber laser cutting machines designed for cutting thin metals or non-ferrous materials. These machines generally offer lower power (less than 1000W) and are often compact, making them ideal for smaller-scale applications.

Price Range: $15,000 para $50,000

Materials: Suitable for cutting thin sheets of stainless steel, alumínio, and other non-ferrous metals.

Typical Power: 500C – 1000C

Aplicações: Small to medium-sized enterprises (SMEs) or hobbyists needing basic cutting capabilities for thin metals.

Mid-Range Fiber Laser Cutting Machines ($50,000 – $150,000)

Mid-range fiber laser cutters are more powerful, versátil, and equipped with more advanced features. These machines are perfect for businesses that need to cut thicker metals, such as 1mm to 6mm thick stainless steel, aço carbono, e alumínio.

Price Range: $50,000 para $150,000

Materials: Suitable for cutting a wider range of metals, incluindo aço inoxidável, Aço suave, and some thicker alloys.

Typical Power: 1500C – 3000C

Aplicações: Medium-sized manufacturing operations and job shops needing consistent, high-quality cuts for a variety of metals.

High-End Fiber Laser Cutting Machines ($150,000 – $500,000+)

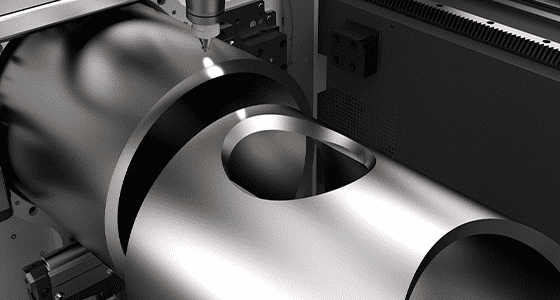

For large manufacturers and industrial applications, high-end fiber laser cutting machines offer the highest precision, velocidade de corte, and power. These machines are ideal for cutting thicker sheets of metal (up to 30mm) and are equipped with advanced features like automated loading/unloading systems, higher-powered lasers, and advanced motion systems.

Price Range: $150,000 para $500,000+

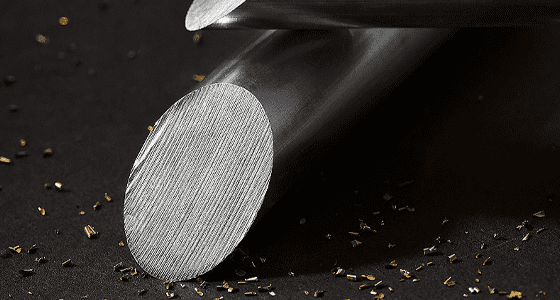

Materials: Best suited for cutting thick metals, such as heavy-duty stainless steel, high-carbon steel, e titânio.

Typical Power: 4000C – 12000C

Aplicações: Large-scale manufacturing plants, aeroespacial, Automotivo, and metal fabrication industries.

Factors That Affect the Price of a Fiber Laser Cutting Machine

While the above price ranges provide a general idea, several factors influence the fiber laser cutting machine price. Here are the key factors to consider:

1. Potência Laser

The power of a fiber laser cutting machine directly influences its ability to cut through materials at high speeds. More powerful lasers are capable of cutting thicker materials, but they also come with a higher price tag.

Low Power (Under 1000W): Ideal for cutting thin metals and non-ferrous materials. These machines are more affordable, with prices starting from $15,000.Potência Média (1000C – 3000C): Suitable for cutting medium-thickness materials. Machines in this range typically cost between $50,000 e $150,000.

Alta potência (Over 4000W): Best for industrial applications where cutting thick materials is required. Machines with this power typically cost $150,000 ou mais.

2. Machine Size and Bed Size

Larger fiber laser cutting machines with bigger cutting beds generally come with a higher price. These machines can handle larger sheets of metal, which makes them ideal for mass production or handling large workpieces.

Small Machines (up to 1m x 1m): Typically cheaper and more compact. They can cost around $15,000 para $50,000.

Medium Machines (up to 2m x 4m): These machines are capable of handling larger sheets and have prices ranging from $50,000 para $150,000.

Large Machines (over 2m x 4m): Industrial-grade machines capable of cutting large metal sheets. Prices can exceed $150,000.

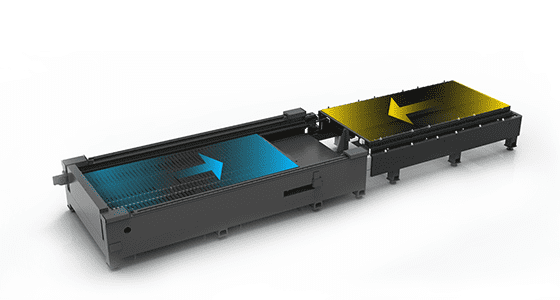

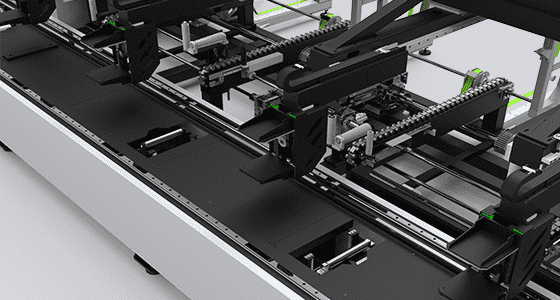

3. Recursos de automação

The level of automation included in a fiber laser cutting machine can also impact its price. Machines with advanced features like automatic material loading and unloading, real-time cutting head adjustments, and automatic focus control are more expensive than basic machines.

Modelos básicos: Simples, manual machines with minimal automation are priced at the lower end, typically ranging from $15,000 para $50,000.

Advanced Models: Machines equipped with automation systems (like robotic arms for material handling) can cost significantly more, starting from $100,000 and going up to $500,000.

4. Brand and Manufacturer

The brand and manufacturer of the machine also play a role in its pricing. Renowned companies such as Trumpf, Bystronic, e Amada tend to charge premium prices for their high-quality machines and reliable customer service. Meanwhile, less established brands or Chinese manufacturers may offer more budget-friendly options, though these machines may not have the same longevity or support.

Premium Brands: Machines from well-known brands may cost $100,000 ou mais, but they often come with better quality, longer warranties, and advanced features.

Economy Brands: Machines from lesser-known brands may be priced from $15,000 para $50,000 for entry-level models.

5. Additional Features and Software

Modern fiber laser cutting machines often come with sophisticated software and additional features such as improved cutting heads, faster motion systems, and better cooling mechanisms. These features can drive up the price of the machine.

Standard Software: Some basic fiber laser machines come with free or low-cost software, but more sophisticated software systems can add an extra $5,000 para $15,000 to the total price.

Upgraded Features: Advanced features like precision-cutting heads and automated cooling can increase the overall price by as much as $50,000.

Custos Adicionais a Considerar

Besides the initial price of the fiber laser cutting machine, there are other ongoing costs to consider, Incluindo:

- Operating Costs: Fiber laser cutting machines require electricity and often compressed air or gases (como nitrogênio ou oxigênio) to operate. Operating costs can range from $10 para $50 per hour depending on the materials being cut and machine power.

- Custos de manutenção: Regular maintenance and the replacement of consumables (such as lenses and nozzles) are necessary to keep the machine running efficiently. These costs can range from $1,000 para $5,000 annually.

- Training and Software: Many companies provide training for machine operators, which may cost anywhere from $1,000 para $10,000, depending on the level of expertise required. Adicionalmente, the software may come with licensing fees ranging from $500 para $5,000.

- Shipping and Installation: Shipping and setting up a large fiber laser cutting machine can also be a significant cost. Shipping alone can range from $500 para $10,000, depending on the machine size and delivery distance.

Conclusão

When considering fiber laser cutting machine prices, it’s important to recognize that the cost is influenced by several factors including laser power, size, automation features, brand, and additional functionalities. Entry-level machines can cost around $15,000, while high-end industrial models can go beyond $500,000.

For businesses with limited budgets, entry-level fiber laser cutters provide a cost-effective solution, while larger companies focused on high-volume production may find the investment in a higher-power machine worthwhile. Always evaluate your specific cutting needs, materials, and production volume before making a decision.

Understanding these key factors and price ranges will help you choose the right máquina de corte a laser de fibra to match your business requirements and budget.

Notícias principais

Categorias de produtos

- Cortador a laser de metal

- Máquina de solda a laser

- Máquina de limpeza a laser

- Máquina marcadora a laser

- Máquina de freio de imprensa