Notícias

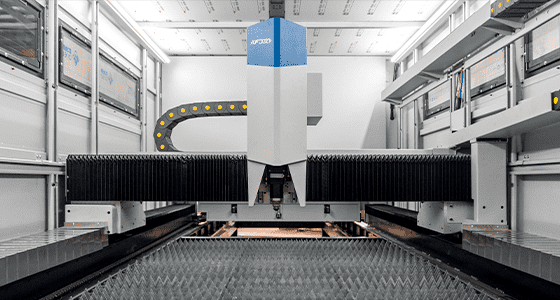

How Much is a Laser Cutting Machine? A Complete Guide to Pricing and Cost Factors

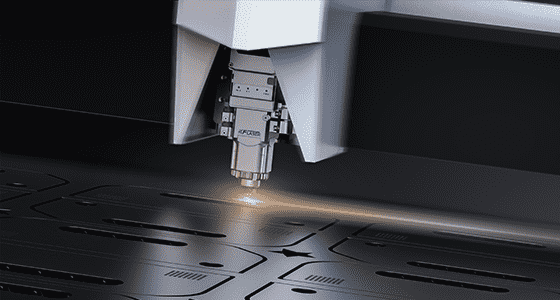

Laser cutting machines have become an essential tool in many industries, from manufacturing and automotive to aerospace and architecture. Whether you’re a small business owner or a large industrial manufacturer, entendimento how much a laser cutting machine costs is crucial before making an investment.

Neste guia, we’ll break down the factors that influence the price of a laser cutting machine, give you a rough idea of what you can expect to pay, and explain how to make the best decision based on your budget and requirements.

Key Factors Influencing the Cost of a Laser Cutting Machine

O preço de uma máquina de corte a laser pode variar significativamente com base em vários fatores. Let’s take a look at the most important elements that impact pricing:

1. Tipo de cortador a laser

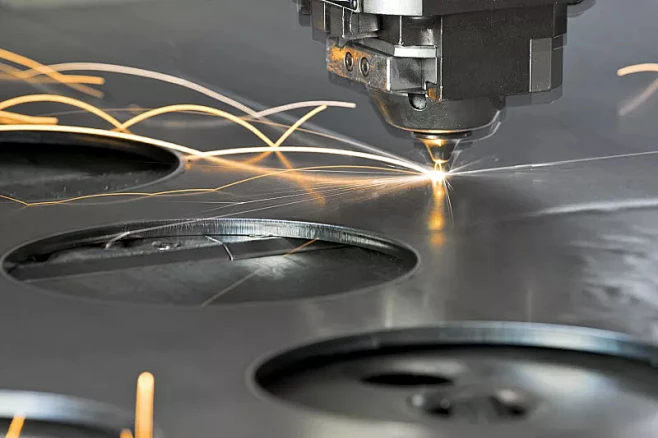

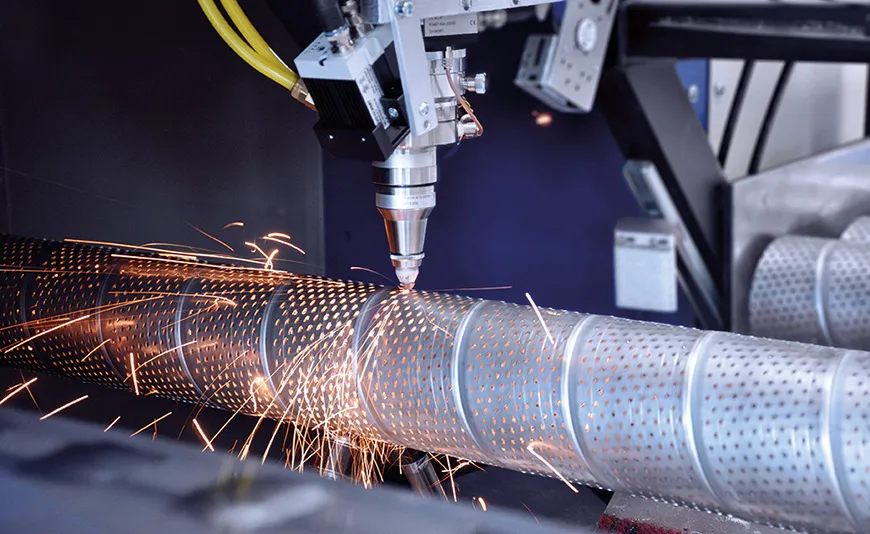

There are different types of laser cutting machines, and each comes with its own price range. The most common types are Lasers de CO2 e lasers de fibra.

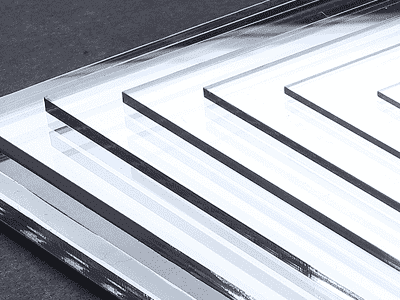

- Máquinas de corte a laser de CO2: These are typically used for cutting non-metal materials (madeira, plástico, etc.) as well as thin metals. CO2 laser machines tend to be more affordable compared to fiber lasers, with prices ranging from $5,000 para $100,000 depending on size, características, and specifications.

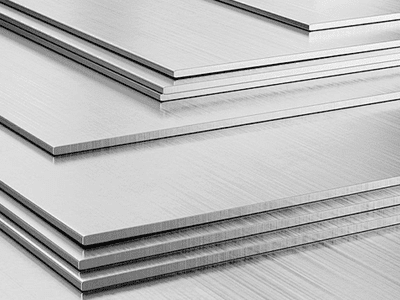

- Máquinas de corte a laser de fibra: These are best for cutting metal materials, especially thin to medium thickness metals such as steel, alumínio, e latão. Fiber lasers are generally more expensive than CO2 lasers, but they offer higher efficiency, velocidades de corte mais rápidas, and lower operational costs. The price range for fiber laser cutting machines is generally $15,000 para $500,000, depending on their size, capabilities, and brand.

2. Tamanho e potência da máquina

The size and power of a laser cutting machine also significantly impact its cost.

- Small Machines: Entry-level machines designed for small businesses or hobbyists typically have lower power (under 500W) and smaller cutting beds (less than 1 meter). Prices for small machines start at $5,000 and can go up to $30,000.

- Máquinas industriais: Larger machines designed for high-volume production and thicker materials typically have greater power (2,000W to 15,000W) and larger cutting beds (over 1 meter). These machines can cost anywhere from $50,000 para $500,000 dependendo de suas especificações.

3. Potência Laser

Laser power is measured in watts (C) and directly affects the machine’s cutting ability. More powerful lasers can cut through thicker materials and perform faster.

- Low Power (Under 500W): Suitable for cutting thin metals and non-metal materials. These machines generally cost between $5,000 e $30,000.

- Potência Média (1,000C – 2,000C): These lasers are ideal for cutting moderate thickness metals, including carbon steel and stainless steel. The price range is around $30,000 para $100,000.

- Alta potência (Over 3,000W): These machines can cut through thick metals like heavy-duty steel and are typically used in heavy industrial applications. Expect to pay anywhere from $100,000 para $500,000.

4. Velocidade e precisão de corte

Laser cutting machines with higher speeds and greater precision generally come with a premium price tag. Faster cutting speeds and higher precision are essential for high-volume manufacturing, where downtime needs to be minimized.

- Máquinas de nível básico: These typically have slower cutting speeds and lower precision but are still sufficient for smaller-scale projects. The prices can range from $5,000 para $30,000.

- Máquinas de última geração: Industrial-grade machines with top-notch precision and fast cutting speeds can cost anywhere from $50,000 para $500,000, depending on the brand and specific features.

5. Brand and Manufacturer

The reputation of the brand and the quality of the components used in the machine can also affect the price. Well-known brands like Trumpf, Bystronic, e Amada often charge a premium for their high-quality machines and customer support.

Affordable Brands: Chinese and lower-cost brands can offer competitive pricing, with entry-level machines starting around $5,000 para $30,000.

Premium Brands: High-end brands that offer more advanced features, reliability, and customer service can push the cost to $100,000 e além, particularly for industrial or high-precision machines.

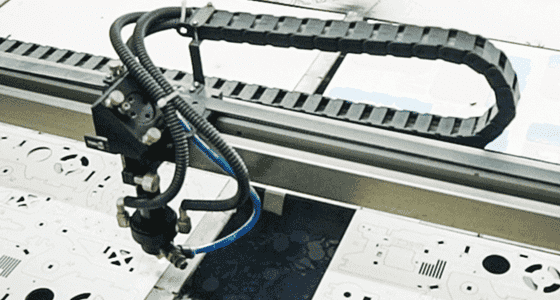

6. Additional Features

Laser cutting machines come with a variety of additional features, such as automatic loading/unloading systems, cutting head height control, dust extraction systems, e mais. Machines with advanced automation and additional features will naturally be more expensive.

Basic Features: Machines with minimal automation and simple controls are generally more affordable, ranging from $5,000 para $50,000.

Fully Automated Systems: Machines equipped with automation, advanced cooling systems, and software integration can cost anywhere from $50,000 para $500,000.

General Price Ranges for Laser Cutting Machines

Now that we’ve covered the key factors influencing the price of a laser cutting machine, here’s a general breakdown of what you can expect to pay based on different machine categories:

- Entry-Level Laser Cutting Machines: Ideal for small businesses and hobbyists. These machines are typically Lasers de CO2 and are priced between $5,000 e $30,000.

- Mid-Range Laser Cutting Machines: These machines typically feature lasers de fibra with power capacities around 1,000W to 2,000W. Prices for these machines range from $30,000 para $100,000.

- High-End Laser Cutting Machines: Industrial machines with high precision, velocidade de corte, and large cutting beds. Prices for these machines typically range from $100,000 para $500,000.

Additional Costs Associated with Laser Cutting Machines

Aside from the initial cost of the machine itself, there are additional costs you should consider:

1. Custos de manutenção e operação

Laser cutting machines require regular maintenance to keep them running efficiently. This can include costs for replacing laser sources, optics, e outros componentes. Adicionalmente, the cost of consumables like gas and power needs to be factored into the total operating cost.

Maintenance costs can range from $1,000 para $5,000 annually, depending on the machine’s complexity and usage.Operating costs for gas and electricity will depend on the type of laser (CO2 ou fibra) and how often the machine is used. These costs typically range from $10 para $50 per hour.

2. Software and Training

Many laser cutting machines come with proprietary software for designing and controlling the cuts. Software licenses, as well as any additional training for operators, can add to the overall cost.

Software costs range from $500 para $5,000, depending on the functionality.

Training programs may cost anywhere from $1,000 para $10,000 depending on the complexity of the machine and the level of training required.

3. Shipping and Installation

The cost of shipping and installing a laser cutting machine is another important factor. Depending on the size and complexity of the machine, shipping can cost anywhere from $500 para $10,000. Installation may also involve additional costs for setting up the machine, calibration, and system integration.

Conclusão

When asking, “how much is a laser cutting machine?” the answer depends on various factors, including the type of machine, poder, size, e recursos adicionais. Entry-level machines can be found for as low as $5,000, while high-end industrial models can range from $100,000 para $500,000.

Before making a purchase, it’s important to carefully consider your needs, the type of materials you’ll be working with, the level of automation required, and your budget. Doing so will help you find the best Máquina de corte a laser that suits your requirements while maximizing the return on investment.

Notícias principais

Categorias de produtos

- Cortador a laser de metal

- Máquina de solda a laser

- Máquina de limpeza a laser

- Máquina marcadora a laser

- Máquina de freio de imprensa