Notícias

Equipamento de corte a laser para chapas metálicas: O guia definitivo para precisão e eficiência na fabricação de metal

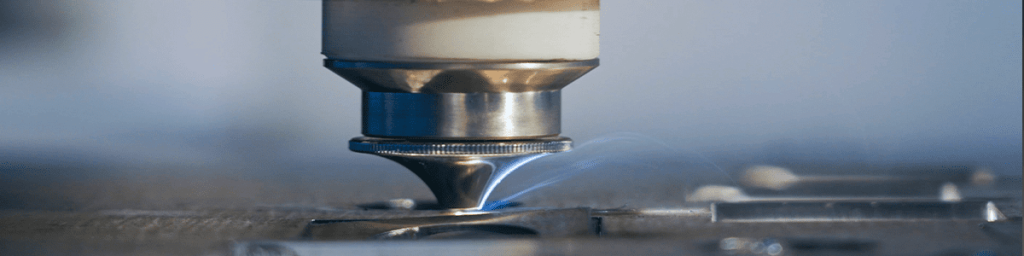

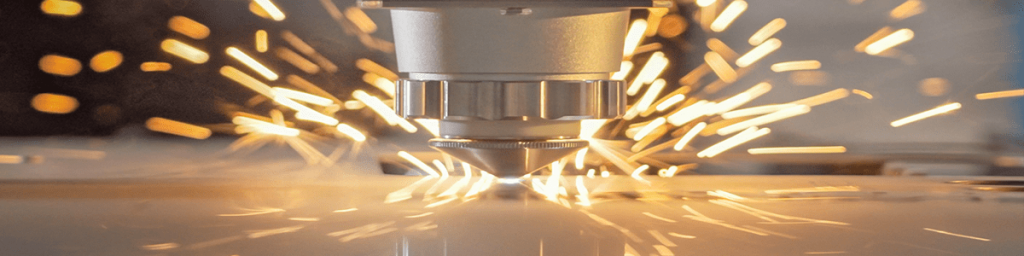

In the modern manufacturing world, sheet metal laser cutting equipment has become a cornerstone of precision fabrication. This cutting-edge technology enables the precise cutting, gravação, and perforating of sheet metal materials, ensuring high-quality results with minimal waste. As industries demand higher precision, velocidades de produção mais rápidas, and more versatile cutting capabilities, laser cutting technology has risen to meet these needs.

Neste artigo, we will explore the key components, benefícios, and applications of sheet metal laser cutting equipment, providing insight into how it’s shaping the future of metal fabrication.

What is Sheet Metal Laser Cutting Equipment?

Laser cutting is a precise and controlled process that follows these basic steps:

Laser Beam Generation: The laser source produces an intense beam of light that is directed toward the stainless steel surface.

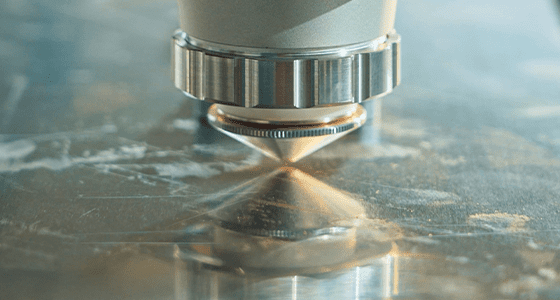

Focando o feixe: The laser beam is focused into a narrow, concentrated spot by using lenses or mirrors. The focused beam generates temperatures high enough to melt or vaporize the stainless steel.

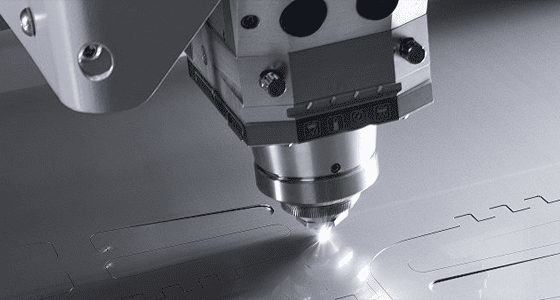

Caminho de corte: Using CNC technology, the machine guides the laser head along the pre-programmed cutting path. The precision of CNC allows for accurate and intricate designs to be cut with minimal deviation.

Auxiliar gás: Often, an assist gas like nitrogen or oxygen is used during the cutting process. The gas helps to blow away molten material from the cut, resulting in cleaner cuts and faster processing times.

Benefits of Laser Stainless Steel Cutting

Sheet metal laser cutting equipment refers to the machines and tools used to cut, gravar, or perforate sheet metal using a laser beam. The process works by directing a high-powered laser beam through the sheet metal, focusing it into a precise spot to melt, queimar, or vaporize the material along a pre-programmed path.

Tipicamente, CNC (controle numérico de computador) technology is integrated into laser cutting systems to ensure high precision and accuracy. Lasers de fibra e Lasers de CO2 are the most common laser types used in sheet metal cutting, each with its specific advantages depending on the material and thickness of the metal.

How Does Sheet Metal Laser Cutting Work?

The process of sheet metal laser cutting can be broken down into the following stages:

- Geração a laser: The laser cutting machine generates a highly focused beam of light, often using a fiber laser or CO2 laser source.

- Focando o feixe: The laser beam is focused into a small, intense spot by lenses or mirrors, generating a high temperature that is capable of melting or vaporizing the sheet metal.

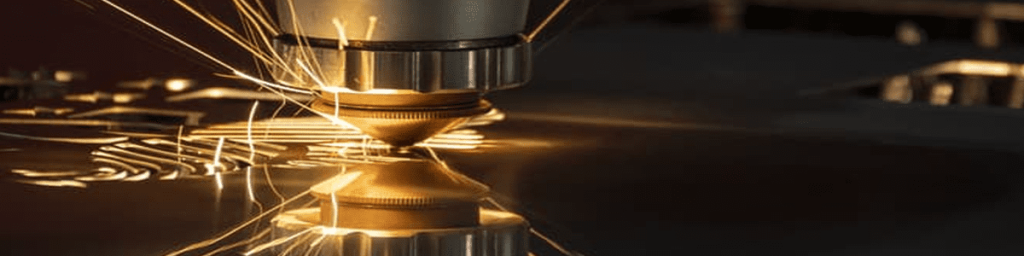

- Cutting the Sheet Metal: CNC technology moves the laser cutting head along a pre-programmed path, following the exact shape and design of the part to be cut. The precision of CNC ensures that the cut follows the exact specifications.

- Auxiliar gás: In many cases, um gás de assistência (como nitrogênio ou oxigênio) is used to blow away the molten material from the cutting zone, improving the quality of the cut and increasing the cutting speed.

Benefits of Sheet Metal Laser Cutting Equipment

1. Alta Precisão e Exatidão

One of the main advantages of sheet metal laser cutting equipment is its exceptional precision. Laser cutting technology allows for extremely tight tolerances, making it perfect for intricate designs and high-precision applications. Whether the task is cutting complex patterns or simple straight lines, laser cutting ensures accuracy that can’t be matched by traditional methods.

2. Velocidades de corte mais rápidas

Compared to conventional cutting methods, laser cutting provides significantly faster processing times. O operação de alta velocidade of laser systems can dramatically reduce production times, especially when working with large volumes of sheet metal. This makes laser cutting a highly efficient choice for mass production.

3. Minimal Heat-Affected Zone (HAZ)

Sheet metal laser cutting equipment generates significantly less heat compared to methods like plasma cutting. This results in a zona mínima afetada pelo calor (HAZ), meaning there is less risk of distortion, warping, or discoloration of the material. This is particularly important when working with thin or high-precision sheet metal, such as stainless steel or aluminum.

4. High-Quality Edge Finish

The precision of corte a laser ensures that the edges of the cut sheet metal are clean and smooth, with little to no burrs or roughness. This reduces or eliminates the need for secondary finishing operations such as deburring, polishing, or grinding, saving both time and labor costs.

5. Versatility and Flexibility

O corte a laser é incrivelmente versátil, allowing it to handle a variety of materials, incluindo aço inoxidável, alumínio, latão, e até mesmo não-metais como plásticos e madeira. It can cut through sheet metal of varying thicknesses, from ultra-thin sheets to thick plates, with consistent precision.

Adicionalmente, laser cutting can also be used for other processes such as gravação, marcação, e perforating, making it a flexible solution for a wide range of applications.

6. Desperdício de material mínimo

Laser cutting produces a narrow kerf, which means it wastes very little material. O precise cutting results in fewer off-cuts and less scrap, which is an important consideration in industries where material costs are a significant factor.

7. Automation and Efficiency

Most sheet metal laser cutting equipment is fully automated, which increases productivity and reduces the need for manual intervention. The ability to automate the cutting process allows for continuous, high-volume production with minimal downtime, making laser cutting ideal for large-scale manufacturing operations.

Key Components of Sheet Metal Laser Cutting Equipment

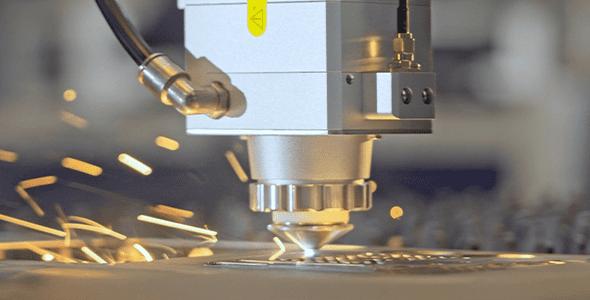

To understand sheet metal laser cutting, it’s important to know the key components that make up the equipment:

Fonte a laser: The laser source generates the light energy used for cutting. Common types include lasers de fibra e Lasers de CO2, with fiber lasers being more efficient and better suited for cutting thin to medium thickness metals.

Laser Cutting Head: This is the component that focuses the laser beam onto the sheet metal. It also controls the cutting speed and quality of the cut.

Sistema de controle CNC: O Sistema CNC ensures that the laser cutting head follows the exact path needed for precision cutting. This is critical for ensuring accurate dimensions and maintaining tight tolerances.

Sistema de gás auxiliar: This system provides the gases needed for cutting, como oxigênio, azoto, ou ar. The gas helps to blow away molten material and can also improve the quality of the cut.

Sistema de movimento: The motion system, which includes linear rails, motores, and gears, moves the laser head along the programmed cutting path, ensuring that the laser follows the design specifications.

Sistema de resfriamento: Since laser cutting generates a lot of heat, cooling systems are in place to maintain optimal operating temperatures for the laser and other components.

Applications of Sheet Metal Laser Cutting Equipment

Sheet metal laser cutting is used across a variety of industries due to its versatility, precisão, e eficiência. Below are some of the common applications:

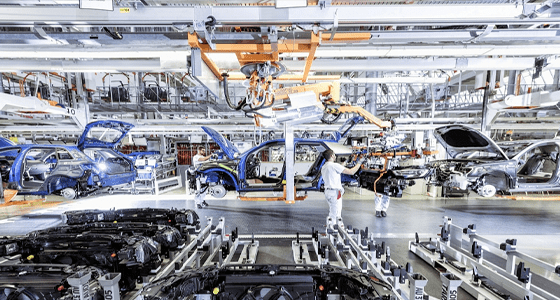

1. Indústria automobilística

Laser cutting is widely used in the automotive industry to create intricate components such as chassis parts, body panels, colchetes, e sistemas de exaustão. The ability to achieve complex cuts with high precision makes laser cutting a valuable tool for automotive manufacturers.

2. Indústria aeroespacial

The aerospace sector demands high-quality, lightweight parts that meet strict tolerances and safety standards. Sheet metal laser cutting equipment is used to manufacture parts such as wing panels, colchetes, e componentes estruturais.

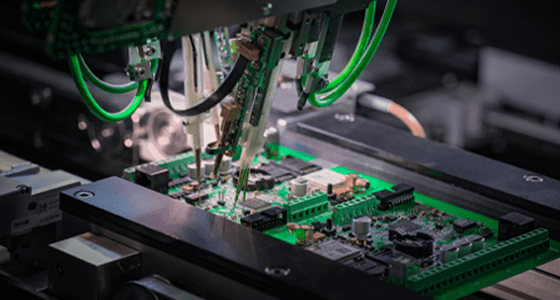

3. Indústria de eletrônicos

Laser cutting is also used in the production of electronic enclosures, conectores, e outros componentes. The precision and speed of laser cutting make it ideal for producing small, complex parts in high volumes.

4. Architectural Metalworking

Laser cutting plays a significant role in the creation of custom metal designs for architectural features such as decorative panels, grades, and facades. The ability to cut through sheet metal with intricate designs allows for highly customized aesthetic solutions.

5. Manufacturing of Industrial Equipment

Sheet metal laser cutting is used extensively in the manufacturing of industrial machinery, such as heavy equipment, piping systems, and conveyor components. The precision and reliability of laser cutting allow manufacturers to produce high-quality parts that fit together seamlessly.

6. Custom Fabrication and Prototyping

Laser cutting is ideal for custom metal fabrication and prototyping. It allows designers and engineers to quickly cut prototypes or small batches of custom parts with high precision, helping to streamline the development and testing phases of new products.

Conclusão

Sheet metal laser cutting equipment has revolutionized the metal fabrication industry, providing a fast, eficiente, and precise method for cutting, gravação, and perforating sheet metal. With its ability to produce high-quality results with minimal material waste, laser cutting is the go-to solution for a wide range of applications in industries such as automotive, aeroespacial, eletrônica, and architecture.

Investing in sheet metal laser cutting equipment can provide manufacturers with increased productivity, cost savings, and the ability to produce complex designs that are not possible with traditional cutting methods. À medida que a tecnologia continua a evoluir, corte a laser will undoubtedly remain a crucial tool in the future of metal fabrication.

This guide to sheet metal laser cutting equipment provides a comprehensive understanding of how the technology works and the wide range of benefits it offers. With its precision, eficiência, e versatilidade, laser cutting is a powerful tool for anyone involved in the fabrication of sheet metal products.

Notícias principais

Categorias de produtos

- Cortador a laser de metal

- Máquina de solda a laser

- Máquina de limpeza a laser

- Máquina marcadora a laser

- Máquina de freio de imprensa