Notícias

The Ultimate Guide to Fiber Laser Cutting Machines in South Africa: Revolucionando a precisão e a eficiência

★ Introduction: The Power of Fiber Laser Cutting Machines in South Africa

In the fast-evolving world of industrial manufacturing, precisão, eficiência, and cost-effectiveness are critical factors that determine success. Enter fiber laser cutting machines in South Africa, an advanced technology that is revolutionizing metal cutting with unmatched accuracy and speed. Businesses across industries, from automotive to construction, are rapidly adopting these high-tech machines to enhance productivity and reduce operational costs.

But what makes fiber laser cutting machines the preferred choice? How do they compare to traditional cutting methods? And most importantly, how can South African industries leverage this technology for maximum output?

This comprehensive guide explores everything you need to know about fiber laser cutting machines in South Africa—how they work, their advantages, formulários, and factors to consider before investing in one.

1. Understanding Fiber Laser Cutting Technology

◆ What is a Máquina de corte a laser de fibra?

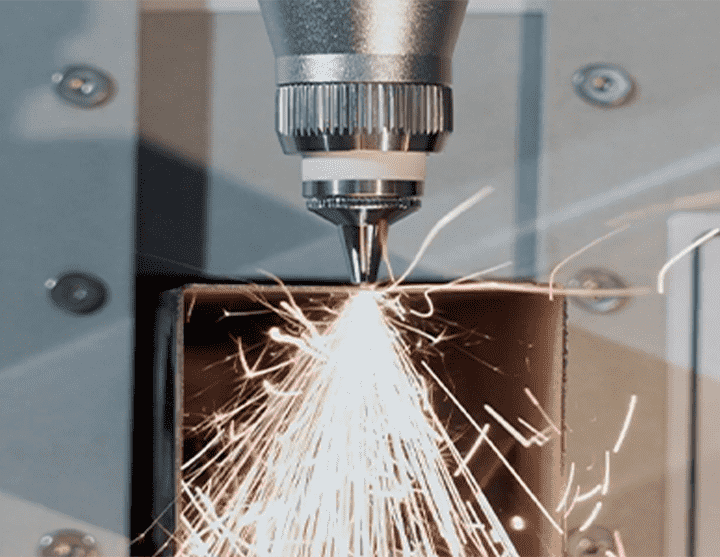

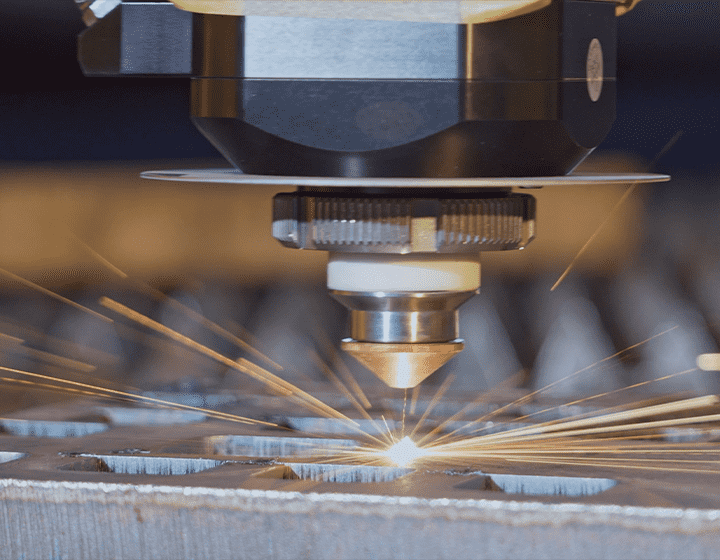

A fiber laser cutting machine is an advanced tool that uses a high-powered laser beam to cut through materials with extreme precision. Unlike CO₂ lasers, fiber lasers use optical fibers to amplify the laser beam, resulting in greater efficiency, faster speeds, and reduced energy consumption.

◆ How Does It Work?

The core working principle of fiber laser cutting involves:

● A fiber laser source generates a powerful beam.

● The beam is transmitted through fiber optic cables, which enhance efficiency.

● A focusing lens directs the laser onto the material, creating a fine, high-energy cutting point.

● The intense heat vaporizes or melts the material, leaving a clean and precise cut.

☟ The following video will give you a more intuitive understanding of the working principle of the laser cutting machine.

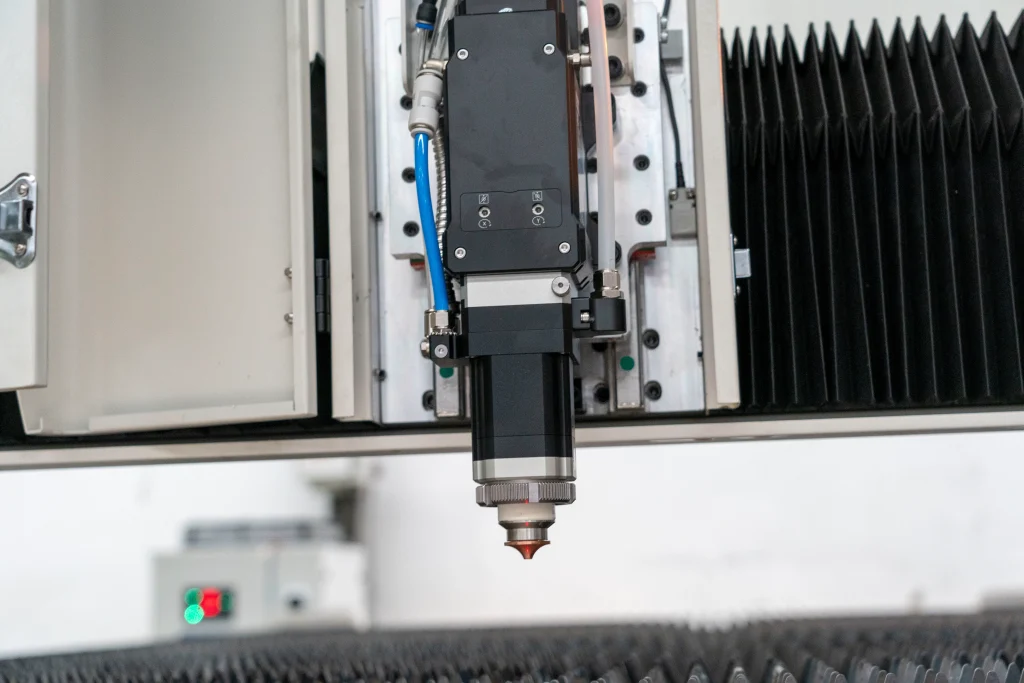

◆ Key Components of a Fiber Laser Cutting Machine

● Fonte a laser – The power generator of the laser beam.

● Cutting Head – Focuses the beam onto the material.

● CNC Control System – Ensures precision cutting via computer-controlled instructions.

● Cooling System – Maintains the machine’s temperature for optimal performance.

2. Why Fiber Laser Cutting Machines Are Ideal for South Africa

South Africa’s industrial sector is booming, with increased demand for high-precision manufacturing solutions. Here’s why fiber laser cutting machines are making waves in the market:

◆ High Efficiency and Speed

Fiber laser cutting is significantly faster than traditional CO₂ laser and plasma cutting methods. The rapid processing speeds increase productivity, reducing manufacturing time and costs.

◆ Unmatched Precision and Quality

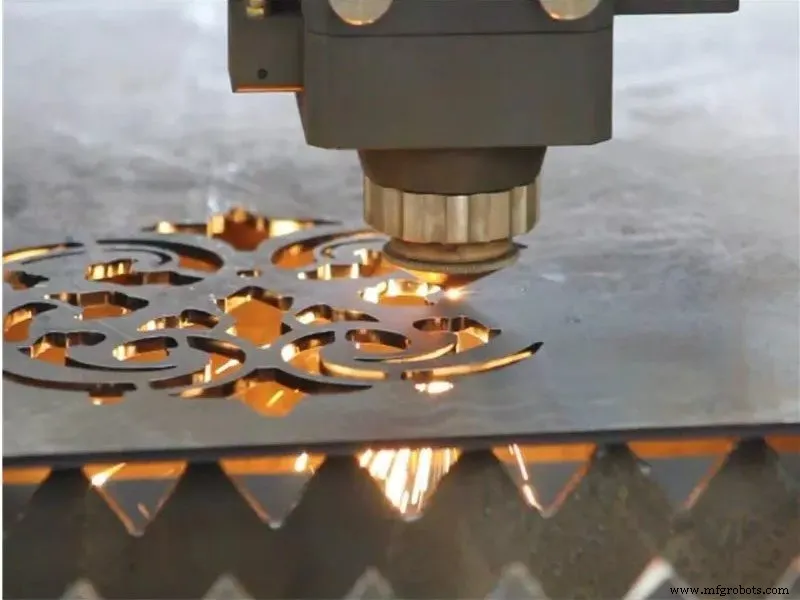

With a focused beam, fiber lasers produce clean, suave, and accurate cuts without excessive heat damage. This precision is crucial for industries requiring intricate designs and fine details.

◆ Cost-Effective and Energy Efficient

Fiber laser machines have a lower operating cost than CO₂ lasers due to:

● Minimal maintenance requirements

● Reduced electricity consumption

● No need for expensive CO₂ gas refills

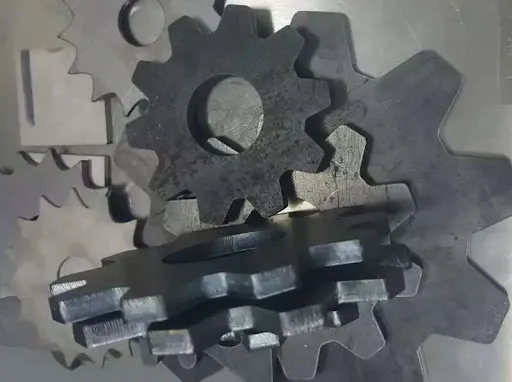

◆ Versatility in Material Cutting

These machines can cut a wide range of materials, Incluindo:

✔ Stainless steel

✔ Carbon steel

✔ Aluminum

✔ Brass

✔ Copper

This versatility makes them invaluable for automotive, aeroespacial, and metal fabrication industries.

3. Applications of Fiber Laser Cutting Machines in South Africa

◆ Manufacturing & Engineering

Precision metal cutting is essential in engineering and manufacturing, ensuring high-quality components for machinery, vehicles, and industrial equipment.

◆ Automotive Industry

From body panels to exhaust systems, fiber lasers ensure seamless fabrication of car components with minimal material waste.

◆ Construction & Infrastructure

Fiber laser cutting allows for precise shaping of metal structures used in buildings, bridges, and infrastructure projects.

◆ Signage & Advertising

Creating high-quality custom signage from metals like stainless steel and aluminum becomes effortless with fiber laser technology.

◆ Jewelry & Artworks

The fine precision of fiber laser cutting enables intricate designs in jewelry-making and artistic metalwork.

4. Choosing the Best Fiber Laser Cutting Machine in South Africa

If you’re looking to invest in a fiber laser cutting machine in South Africa, here are key factors to consider:

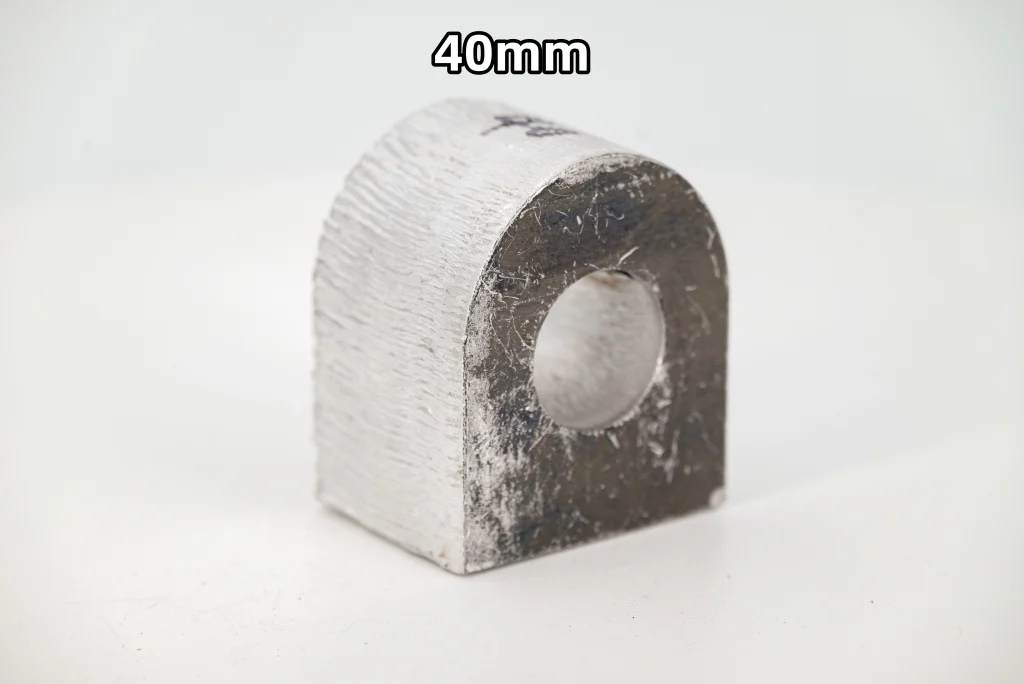

◆ Laser Power Output

Higher wattage enables cutting thicker materials. Standard options range from 1000W to 6000W, depending on industrial needs.

◆ Cutting Bed Size

Larger bed sizes allow for processing bigger workpieces, improving efficiency.

◆ Software & Recursos de automação

Advanced CNC systems improve precision and automation, reducing human error.

◆ Maintenance & Durability

Look for machines with minimal maintenance requirements and durable components for long-term efficiency.

◆ Manufacturer Support & Garantia

Choose a reliable supplier that offers after-sales support, treinamento, and spare parts availability.

5. O futuro do corte a laser de fibra na África do Sul

With advancements in AI integration, automation, and IoT connectivity, fiber laser cutting is set to become even more powerful and efficient. Smart cutting technology, manutenção preditiva, and energy-efficient solutions are shaping the future of industrial manufacturing in South Africa.

Elevate Your Business with Fiber Laser Cutting Machines

Saber mais☆ Final Thoughts: Elevate Your Business with Fiber Laser Cutting Machines

Investing in a fiber laser cutting machine in South Africa is a game-changer for businesses seeking precision, eficiência, and cost-effectiveness. Whether you’re in metal fabrication, construção, or manufacturing, this cutting-edge technology can significantly enhance productivity while reducing operational expenses.

If you’re considering adopting fiber laser cutting technology, now is the time to explore the best options and transform your production processes for a more competitive edge.

Would you like expert guidance on choosing the right machine? Contact us today to learn more!

Notícias principais

-

4000Guia da máquina de corte a laser W | Fundamentos09 dezembro 2025

4000Guia da máquina de corte a laser W | Fundamentos09 dezembro 2025 -

Máquina de corte de metal a laser de fibra para venda05 dezembro 2025

Máquina de corte de metal a laser de fibra para venda05 dezembro 2025 -

4000 Watt Laser | Poder de corte industrial02 dezembro 2025

4000 Watt Laser | Poder de corte industrial02 dezembro 2025 -

6 corte a laser kw | Guia de precisão industrial28 novembro 2025

6 corte a laser kw | Guia de precisão industrial28 novembro 2025 -

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025

Categorias de produtos

- Cortador a laser de metal

- Máquina de solda a laser

- Máquina de limpeza a laser

- Máquina marcadora a laser

- Máquina de freio de imprensa