Notícias

Fabricantes de máquinas a laser de fibra industrial

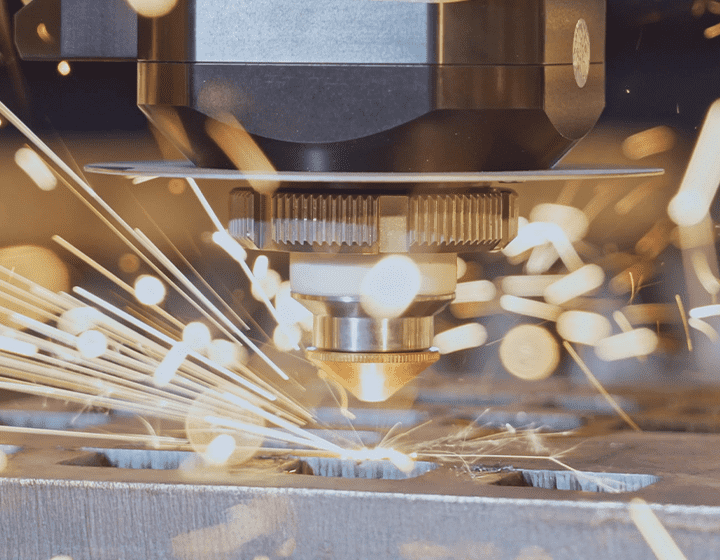

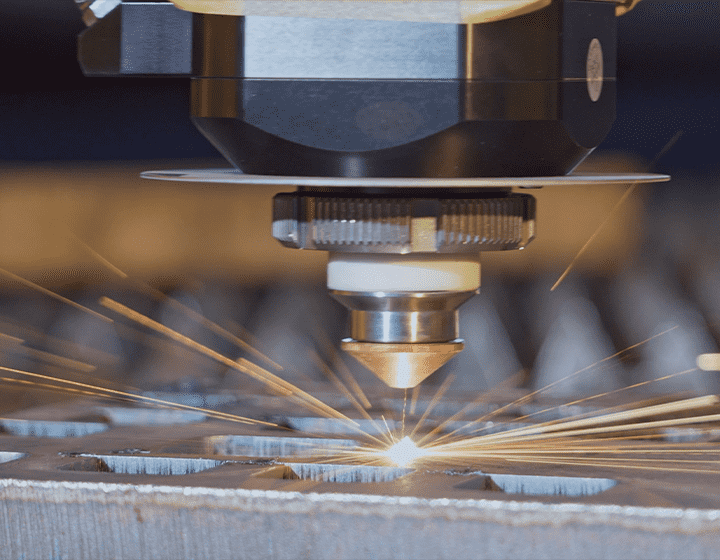

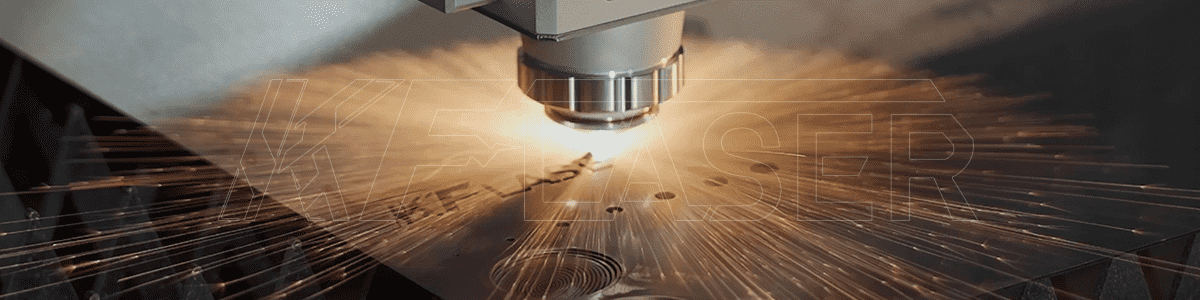

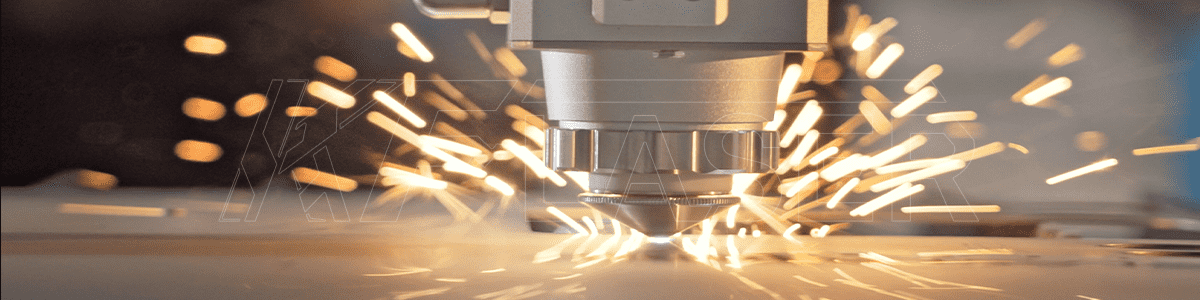

Industrial Fiber laser machine manufacturers ignite industrial revolutions where light conquers steel, photons outpace plasma, and precision defies physics. Imagine slicing through armored plating like warm butter while etching microscopic patterns thinner than spider silk – this is the reality crafted by visionary engineering teams worldwide. These masters of photonic innovation don’t just build equipment; they architect the future of aerospace, Automotivo, and medical manufacturing through beams of concentrated light.

The Photonic Arms Race

Leading Industrial fiber laser machine manufacturers wage silent wars in laboratories and factories, where breakthroughs emerge through three converging revolutions:

Quantum-Leap Beam Quality

Next-generation resonators now achieve M²<1.1 beam quality, concentrating energy with unprecedented accuracy. This allows automotive plants to cut high-strength boron steel at 40 meters/minute while reducing heat zones by 93% compared to legacy systems.

Self-Healing Optical Networks

Embedded nano-sensors detect micro-fractures in fiber delivery systems before failures occur. When a flaw appears, automated laser welding repairs the pathway during scheduled tool changes, eliminating unplanned downtime.

Climate-Adaptive Cooling

Intelligent thermal regulators adjust cooling parameters based on factory humidity and ambient temperature readings. In Singaporean electronics plants, this innovation cut energy waste by 28% despite tropical conditions that crippled conventional chillers.

Industry analysts confirm facilities using these systems achieve 99.1% operational uptime – a previously unthinkable benchmark.

Manufacturing DNA Analysis

Distinguishing exceptional Industrial fiber laser machine manufacturers requires examining their technical genetics:

Capability | Standard Offerings | Industry-Leading Benchmarks |

Power Stability | ±2% fluctuation | ±0.5% through full duty cycles |

Versatilidade material | Steel/aluminum | Copper/brass/titanium composites |

Cutting Accuracy | ±0,1 mm | ±0,02mm (medical device grade) |

Smart Integration | Basic IoT monitoring | Predictive maintenance AI |

Eficiência Energética | 0.8kW/kg cut | 0.35kW/kg with hybrid recovery |

Beware the “wattage trap” – a 20kW system with poor beam shaping delivers inferior results to a precision-tuned 6kW machine.

Behind the Factory Walls

Exceptional Industrial fiber laser machine manufacturers distinguish themselves through unseen innovations:

Diode Development Labs

- Quantum-dot laser stacks lasting 60,000+ horas

- Wavelength-stabilized modules for copper processing

- Fail-safe redundancy in power delivery systems

Dynamic Assembly Protocols

- Vibration-dampened production floors

- Cleanroom optical alignment stations

- Real-time spectral analysis during burn-in testing

Global Supply Mastery

- Secured rare-earth element pipelines

- Dual-sourcing for critical components

- Regional service hubs with <4hr response pledges

Sector-Specific Engineering

Aerospace Fabrication

- Oxygen-free cutting of titanium alloys

- Adaptive piercing for honeycomb structures

- Cryogenic assist gas systems for inconel

EV Battery Production

- Burr-free copper foil processing

- Ultrafast galvanometer scanning

- Particulate containment for dry cutting

Medical Device Creation

- Bio-compatible cutting environments

- Sub-micron position feedback

- Validated cleanroom integration

Future-Proofing Strategies

Visionary Industrial fiber laser machine manufacturers are pioneering:

Self-Calibrating Machines

Autonomous beam path correction using quantum reference pointsDistributed Manufacturing

Containerized laser cells deployable to construction sitesMultiwavelength Platforms

Switchable 515nm/1070nm/1550nm sources in single unitsClosed-Loop Recycling

Metal vapor recapture systems converting waste into powder

Avoid costly errors with these battle-tested tactics:

Demand Operational Transparency

Require factory access to witness production protocols – 67% of quality variances originate in undocumented processes

Decode Warranty Terminology

“Lifetime” optics coverage often excludes consumables like protective windows

Verify Cybersecurity Frameworks

Manufacturing systems now require IEC 62443-3-3 certification to prevent production ransomware

Insist on Real-World Testing

Submit your most challenging materials:

» Laser-sensitive coated steels

» Thin-gauge copper-nickel composites

» Variable-thickness aerospace assemblies

The most advanced fiber laser machine manufacturers now incorporate digital twin technology, allowing virtual commissioning before equipment ships. As a Tokyo Institute of Technology white paper recently observed: “The new manufacturing paradigm values photon flow over material flow, with laser sources becoming strategic assets rather than mere tools.”

Notícias principais

Categorias de produtos

- Cortador a laser de metal

- Máquina de solda a laser

- Máquina de limpeza a laser

- Máquina marcadora a laser

- Máquina de freio de imprensa