Noticias

La máquina de corte láser más grande: Innovaciones en precisión y eficiencia

En el ámbito de la fabricación moderna, the largest laser cutting machine stands out as a marvel of technological advancement. As industries push for higher precision, faster production speeds, and the ability to work with increasingly complex materials, these cutting-edge machines have become indispensable tools for manufacturers worldwide. Whether you are in aerospace, automotor, or heavy industry, understanding the power and capabilities of the largest laser cutting machine can revolutionize your approach to production.

Ⅰ.What is the Largest Laser Cutting Machine?

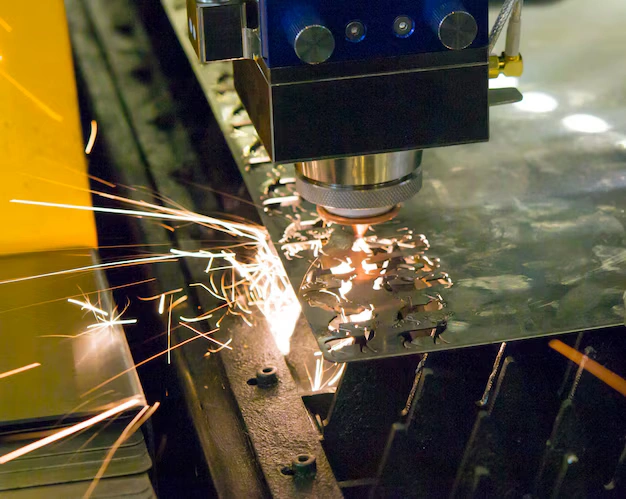

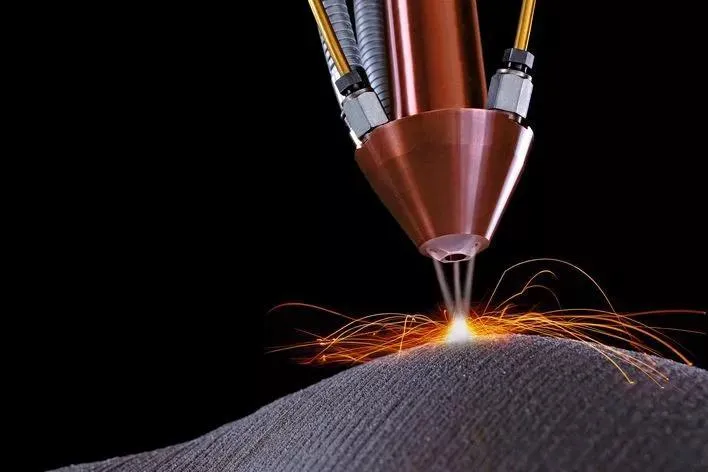

The largest laser cutting machine is an industrial-grade tool designed for cutting large-scale metal sheets with precision and speed. It utilizes high-powered lasers to melt, quemar, or vaporize materials, leaving behind clean edges and intricate designs. Unlike traditional cutting methods that require physical tools to contact the material, the laser beam of the cutting machine does not come into direct contact, allowing for more precise cuts with minimal distortion.

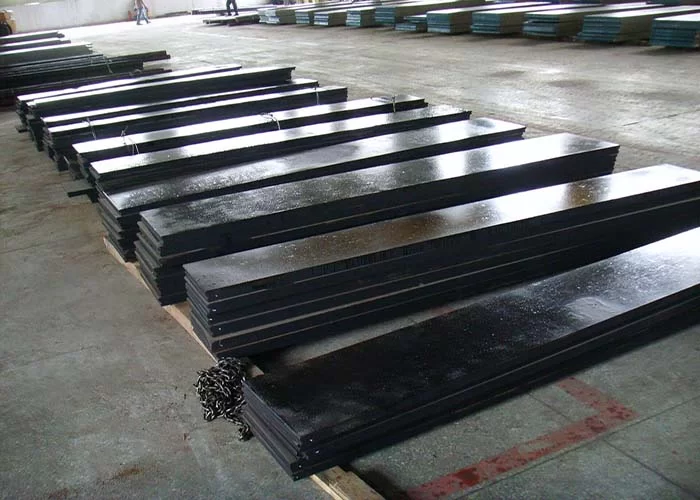

These machines are specifically designed to handle large materials such as steel plates, aluminum sheets, and other heavy-duty metals. The scale of these machines allows manufacturers to create products that would be nearly impossible with smaller, conventional cutting tools.

Ⅱ.Advantages of the Largest Laser Cutting Machine

When it comes to industrial manufacturing, the largest laser cutting machine offers several key advantages that enhance productivity and quality. Let’s explore the benefits that make these machines so indispensable in today’s production processes.

✔Precision and Accuracy

The primary advantage of the largest laser cutting machine lies in its unparalleled precision. Laser cutting uses a highly concentrated beam of light to make cuts, allowing for extremely tight tolerances. This makes it ideal for industries such as aerospace, automotor, y electrónica, where the quality and precision of each part are critical to the end product’s functionality and safety.

✔Ability to Cut Large Materials

One of the biggest advantages of the largest laser cutting machine is its ability to cut large sheets of metal with ease. Traditional cutting machines might struggle with large, heavy-duty materials, but these laser machines handle them effortlessly. Their expansive workbeds can accommodate large plates of steel or aluminum, providing manufacturers with the flexibility to cut larger components without the need for multiple machines or excessive labor.

✔Speed and Efficiency

With advancements in laser technology, the largest laser cutting machine can cut materials faster than traditional methods, reduciendo significativamente el tiempo de producción. Unlike mechanical cutting, which requires a change of tools for different cuts, laser cutting is an automated process that can handle multiple operations with the same setup. This efficiency results in a more streamlined production process and faster turnaround times.

✔Cleaner Cuts and Less Waste

The non-contact nature of laser cutting ensures that there is little to no wear on the cutting head, which means fewer chances for material distortion or degradation. The largest laser cutting machine creates precise, clean cuts that require little to no post-processing, reducing the amount of wasted material and labor needed to finish the workpiece.

Moreover, because the laser beam is so narrow, it produces less material waste, which contributes to the sustainability of manufacturing processes. This reduced waste and increased efficiency not only benefit the environment but also save businesses money.

✔ Flexibility in Design

The largest laser cutting machine offers incredible design flexibility. The ability to cut complex shapes, intricate patterns, and delicate details on a wide range of materials makes laser cutting an ideal choice for custom jobs and one-off prototypes. Whether it’s aerospace components, automotive parts, or large industrial structures, laser cutting allows for the fabrication of precise and customized designs that other cutting methods can’t replicate.

Ⅲ.Applications of the Largest Laser Cutting Machine

Laser cutting technology has many applications across a wide range of industries, and the largest laser cutting machine can be adapted for several specific uses.

Industria aeroespacial

In the aerospace sector, the largest laser cutting machine is invaluable for producing parts with tight tolerances, such as turbine blades, componentes del motor, y componentes estructurales. The precision of laser cutting ensures that even the smallest components are cut with the utmost accuracy, which is vital for the performance and safety of aircraft.

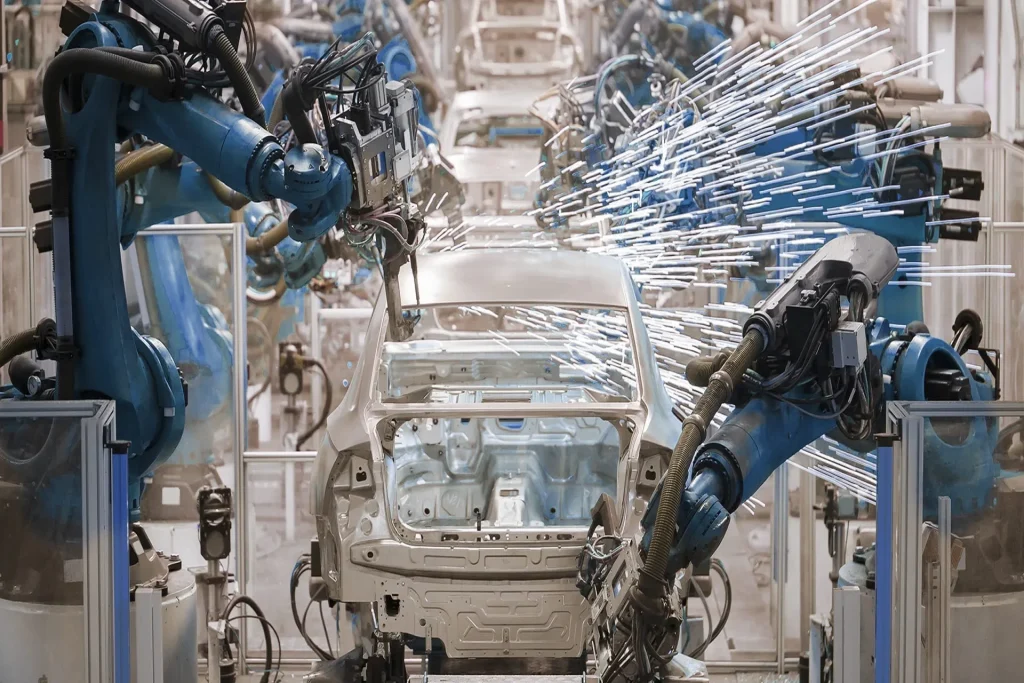

Fabricación de automóviles

The automotive industry relies on laser cutting for the production of both large and small components. From chassis parts to intricate interior components, the largest laser cutting machine is capable of cutting both thin and thick metals used in vehicle manufacturing. Its ability to produce parts quickly and with great accuracy allows automakers to keep up with the demand for high-quality vehicles.

Construction and Heavy Industry

In construction and heavy industry, laser cutting is used to create complex shapes in steel and other materials for structural elements such as beams, columnas, and girders. The largest laser cutting machine can cut through thick steel plates with ease, making it a vital tool in modern construction.

Shipbuilding

Shipbuilding also benefits from laser cutting technology. Large sheets of steel and other metals are commonly used in the construction of ships, and laser cutting provides a highly efficient and accurate way to process these materials. The largest laser cutting machine enables shipbuilders to create precise cuts, ensuring the integrity and strength of the vessel.

Ⅳ.The Future of the Largest Laser Cutting Machines

A medida que avanza la tecnología, so does the capabilities of the largest laser cutting machine. Some key trends and innovations to watch in the future include:

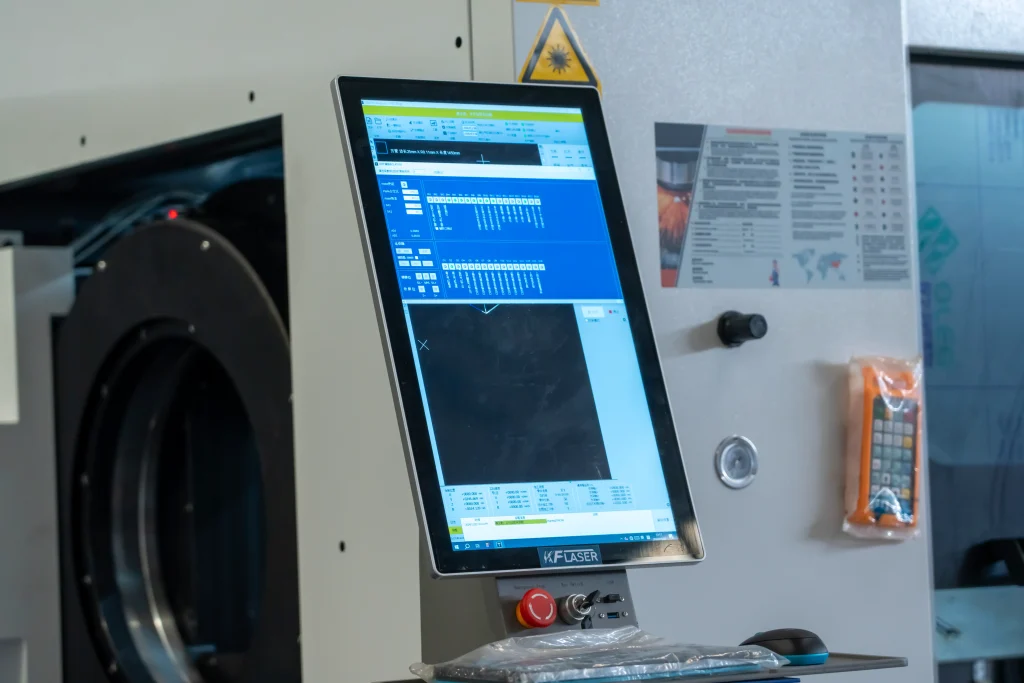

Automation and Integration with AI

As industries continue to automate, the largest laser cutting machine will likely incorporate more advanced artificial intelligence (AI) to enhance its efficiency. AI could optimize cutting paths, improve material utilization, and even adjust settings in real-time for the most efficient production.

Improved Energy Efficiency

The push for more energy-efficient manufacturing processes will also impact laser cutting technology. Newer models of the largest laser cutting machine are being designed to consume less energy while still delivering high-performance cutting, helping businesses reduce their carbon footprint.

Greater Precision with Fiber Lasers

The rise of fiber lasers has already made a significant impact on the laser cutting industry, providing higher beam quality and better energy efficiency. As fiber laser technology continues to improve, expect the largest laser cutting machine to adopt even more advanced laser systems for higher precision and faster cutting speeds.

The largest laser cutting machine is not just a tool—it’s a game changer. By offering unmatched precision, velocidad, y eficiencia, it has become a cornerstone of modern manufacturing across industries. Whether it’s for large-scale industrial applications or intricate aerospace components, the largest laser cutting machine is here to stay, driving innovation and enabling manufacturers to meet the growing demands of the modern world.

Historias destacadas

-

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025 -

4000 Láser de vatios | Poder de corte industrial02 Dic 2025

4000 Láser de vatios | Poder de corte industrial02 Dic 2025 -

6 corte por láser kw | guía de precisión industrial28 Nov 2025

6 corte por láser kw | guía de precisión industrial28 Nov 2025 -

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025 -

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora