Notícias

Placas de metal cortadas a laser: A fusão perfeita de arte e precisão

Prefácio

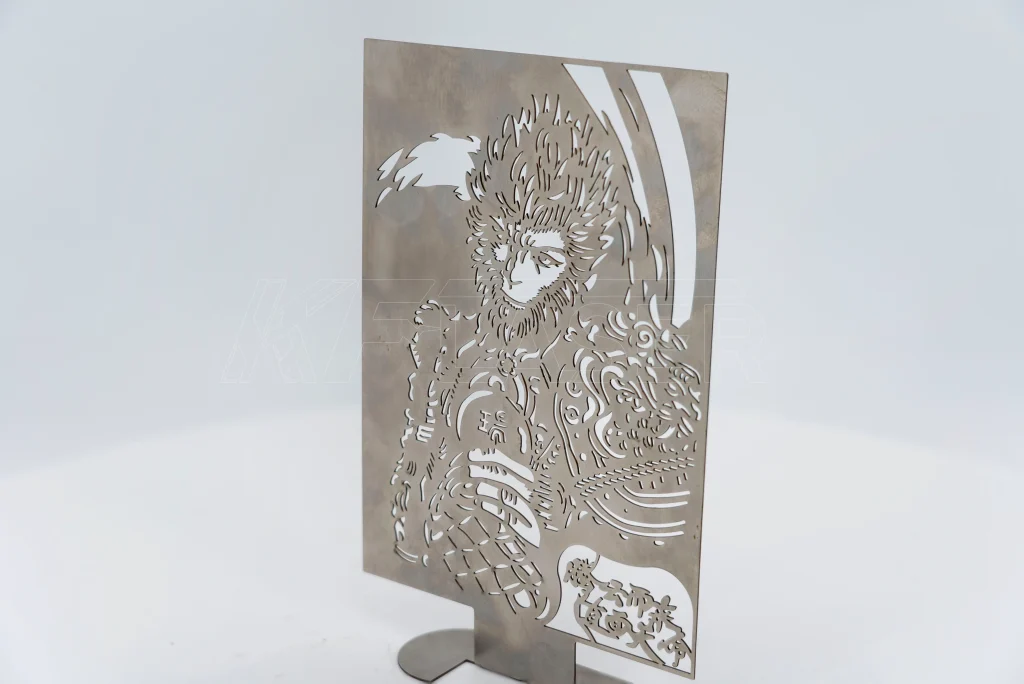

Imagine a sign so precise it looks sculpted by light, its edges flawless and its details mesmerizing. Visualize a piece that isn’t just functional but also a work of art—a sign that embodies elegance, durabilidade, and craftsmanship. This is the magic of laser cut metal signs, a technology-driven solution transforming signage into an expressive and lasting medium. Whether for businesses, homes, or public spaces, these signs are redefining creativity and functionality.

where innovation meets craftsmanship

1.Why Laser Cut Metal Signs Are the Best Choice

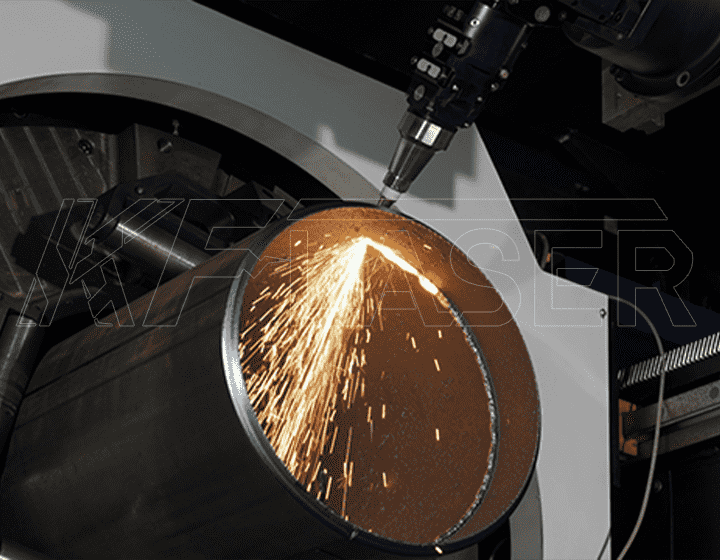

1. Precisão incomparável

Laser cutting offers exceptional accuracy, allowing intricate designs and complex patterns to be cut into metal with micrometer-level precision. From sharp text to detailed logos, laser technology ensures every element is flawlessly executed.

2. Durability That Lasts

Metal signs crafted with laser cutting are built to withstand the test of time. Whether exposed to extreme weather conditions or daily wear, their robustness ensures a long lifespan, making them an excellent investment for any application.

3. Customization at Its Finest

Laser cut metal signs can be tailored to any design, size, or finish. Whether you’re creating an industrial-chic look for a café or an elegant monogram for your home, laser technology brings your vision to life.

4. Versatility Across Industries

From businesses needing eye-catching storefront signs to municipalities installing public wayfinding systems, laser cut metal signs find applications in countless industries, offering both aesthetic appeal and practicality.

2.The Science Behind Laser Cut Metal Signs

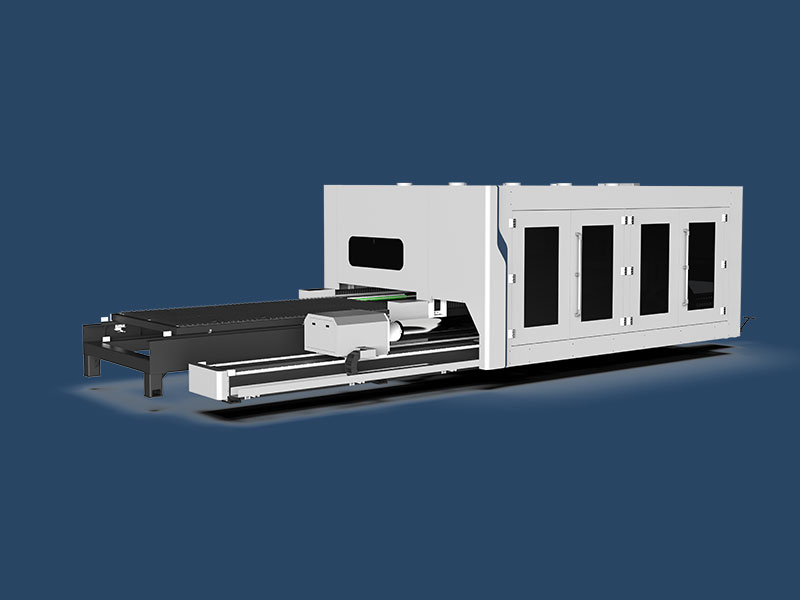

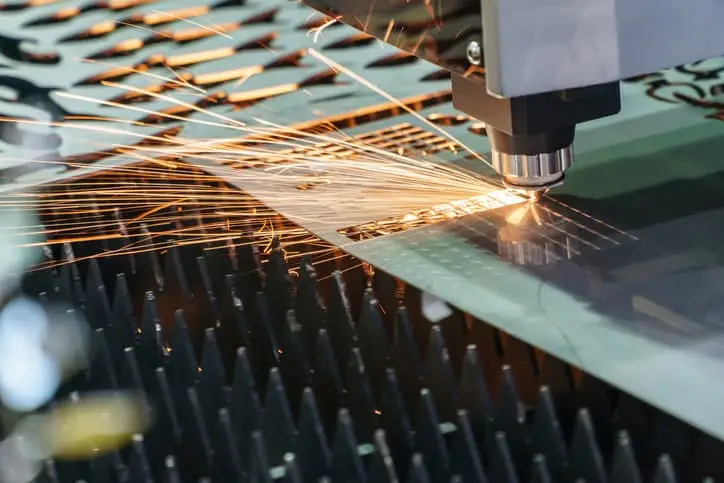

Laser cutting uses a concentrated beam of light to cut through materials with high precision. Here’s how it works:

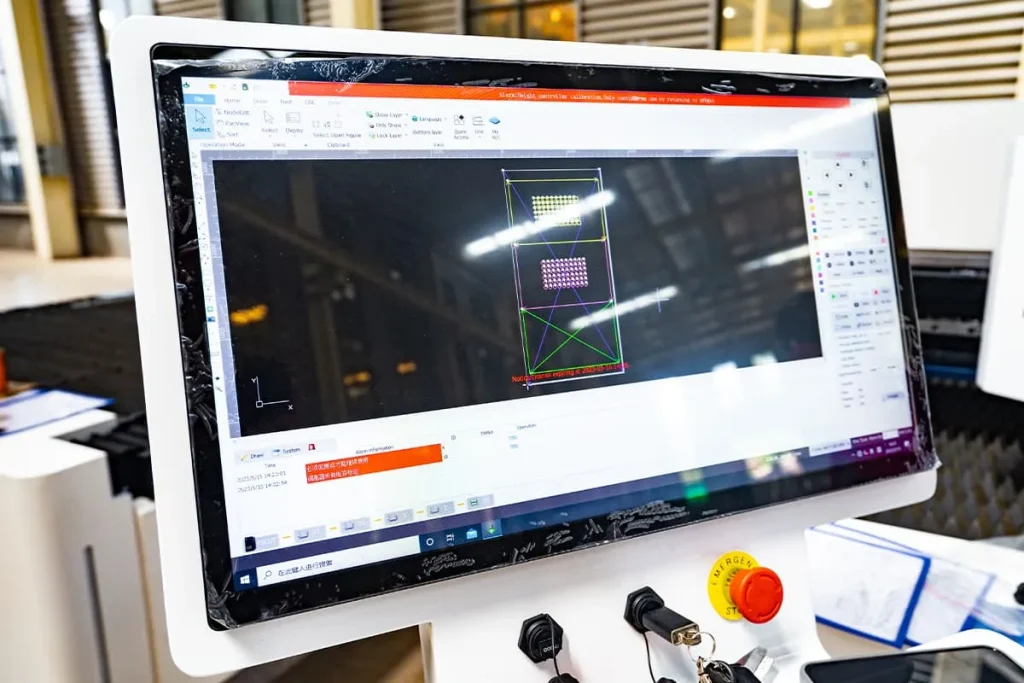

– Heat and Focus: Um feixe de laser, typically guided by CNC (Controle numérico do computador), melts or vaporizes the material along a defined path.

– Assist Gases: Gases like nitrogen or oxygen remove molten material, ensuring clean and polished edges.

– Controlled Automation: The process is entirely automated, ensuring repeatability and accuracy for even the most complex designs.

Metals commonly used for laser cut signs include:

– Aço inoxidável

– Alumínio

– Latão

– Cobre

– Aço suave

Each material brings unique characteristics, such as reflectivity or strength, making it suitable for specific applications.

3.Applications of Laser Cut Metal Signs

1. Business and Commercial Signage

For businesses, first impressions matter. Laser cut metal signs create a professional, polished look that conveys quality and attention to detail. These signs are often used for:

– Storefronts

– Office directories

– Lobby branding

2. Decorative Home Signs

Custom laser cut signs are increasingly popular for personal use. Whether it’s a family name plaque, a garden marker, or decorative wall art, these signs add a touch of sophistication to any space.

3. Wayfinding and Public Signage

Municipalities and large organizations use laser cut signs for wayfinding, ensuring durability and visibility in outdoor environments. These include street signs, park markers, and directional signage.

4. Event and Wedding Décor

Metal signs elevate event spaces with their sleek, elegant appearance. They are often used as wedding backdrops, table markers, or custom monograms.

5. Industrial and Safety Signs

In factories and industrial settings, laser cut metal signs ensure clear, durable safety instructions and hazard markers.

4.Benefits of Choosing Laser Cut Metal Signs

1. Aesthetic Appeal

The precision of laser cutting allows for clean lines, sharp edges, and intricate patterns. This results in a visually stunning product that stands out in any setting.

2. Weather Resistance

Metal signs are highly resistant to weather, UV rays, and rust, making them ideal for outdoor use.

3. Eco-Friendly Solution

Laser cutting minimizes waste by using material efficiently. Adicionalmente, metals like aluminum and stainless steel are recyclable, contributing to sustainable practices.

4. Baixa manutenção

Unlike wood or plastic, metal signs require minimal upkeep. A simple cleaning keeps them looking new for years.

5. Fast Turnaround

Laser cutting processes are automated and efficient, reducing production time and allowing for quick delivery of custom orders.

5.Designing the Perfect Laser Cut Metal Sign

1. Material Selection

Choose a metal that suits your needs:

– Aço inoxidável: Ideal for modern, industrial aesthetics.

– Alumínio: Lightweight and corrosion-resistant for outdoor signs.

– Brass or Copper: Adds a luxurious touch with its natural luster.

2. Finish Options

From brushed metal to powder-coated finishes, the possibilities are endless. Choose a finish that complements your design and enhances durability.

3. Font and Design

Keep your audience in mind when selecting fonts and layouts. Bold, clear fonts work well for outdoor and commercial signs, while decorative scripts suit personalized designs.

4. Mounting and Placement

Consider how and where your sign will be displayed. Wall-mounted signs may require specific brackets, while freestanding signs need durable bases.

6.Laser Cut Metal Signs vs. Traditional Methods

1. Precisão

Traditional methods like plasma cutting can’t achieve the fine details possible with laser cutting. Laser cut signs excel in creating complex patterns and intricate text.

2. Eficiência

Laser cutting reduces production times compared to manual or mechanical cutting methods, especialmente para projetos em larga escala.

3. Quality

The smooth edges and clean cuts produced by laser technology eliminate the need for additional finishing steps, reducing costs and time.

7.How Laser Cutting Enhances Business Branding

In a crowded marketplace, standing out is essential. Laser cut metal signs contribute to strong branding by:

– Creating Recognition: A distinctive, high-quality sign leaves a lasting impression.

– Building Trust: Professionally crafted signs convey reliability and attention to detail.

– Enhancing Visibility: Metal signs are durable and reflective, ensuring visibility day and night.

8.The Future of Laser Cut Metal Signs

1. Smart Integration

With the rise of smart cities, metal signs may incorporate LED lighting or QR codes for interactive functionality.

2. Materiais avançados

Future advancements in metallurgy could introduce new materials that combine strength, flexibilidade, and aesthetic appeal.

3. Customization Trends

À medida que a tecnologia evolui, even more intricate and personalized designs will become possible, pushing the boundaries of creativity.

4. Sustainability Initiatives

Laser cutting will continue to align with eco-friendly manufacturing, emphasizing waste reduction and material recycling.

9.Why KF LASER is the Trusted Choice for Metal Signs

Laser kf offers advanced laser cutting solutions tailored to the unique needs of customers. With state-of-the-art equipment, skilled craftsmanship, and exceptional support, KF LASER ensures each sign meets the highest standards of quality and precision.

10.Conclusão: Transform Your Space with Laser Cut Metal Signs

A laser cut metal sign isn’t just a functional piece—it’s a statement of style, durabilidade, e precisão. Whether you’re branding a business, decorating a home, or enhancing public spaces, this technology offers limitless possibilities. With its perfect balance of artistry and practicality, laser cutting is the ultimate choice for creating signs that leave a lasting impression.

Explore the potential of laser cut metal signs with KF LASER, where innovation meets craftsmanship. Your next masterpiece is just a beam of light away.

Notícias principais

-

Fiber Laser Metal Cutting Machine For Sale05 Dec 2025

Fiber Laser Metal Cutting Machine For Sale05 Dec 2025 -

4000 Watt Laser | Industrial Cutting Power02 Dec 2025

4000 Watt Laser | Industrial Cutting Power02 Dec 2025 -

6 corte a laser kw | Guia de precisão industrial28 novembro 2025

6 corte a laser kw | Guia de precisão industrial28 novembro 2025 -

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025 -

10Corte a laser kW | Precisão & Poder21 novembro 2025

10Corte a laser kW | Precisão & Poder21 novembro 2025

Categorias de produtos

- Cortador a laser de metal

- Máquina de solda a laser

- Máquina de limpeza a laser

- Máquina marcadora a laser

- Máquina de freio de imprensa