Notícias

Máquina de corte a laser eficiente para folha de latão: Aumente seu corte de precisão

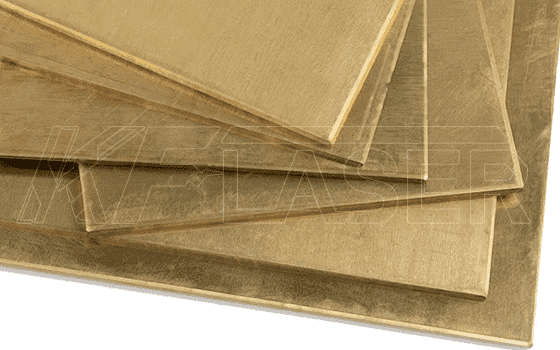

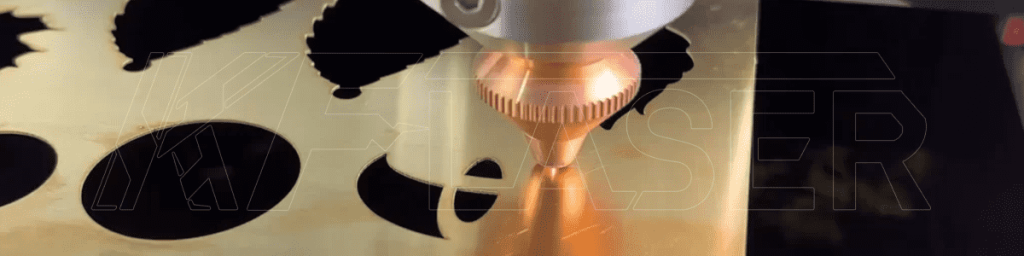

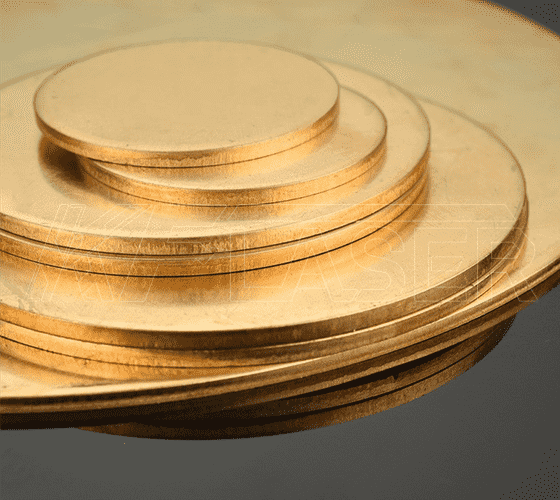

Quando se trata de fabricação de metal, precisão é fundamental, especialmente para materiais complexos como latão. UM máquina de corte a laser para chapa de latão oferece a solução perfeita para obter limpeza, preciso, e cortes eficientes. Se você está envolvido na fabricação, artístico, ou indústrias de design, aproveitar o poder da tecnologia de corte a laser pode revolucionar seu fluxo de trabalho. Mas o que torna estas máquinas tão cruciais para cortar latão? Vamos mergulhar nos detalhes, vantagens, e aplicações de máquinas de corte a laser no processamento de chapas de latão.

O que é uma máquina de corte a laser para chapas de latão?

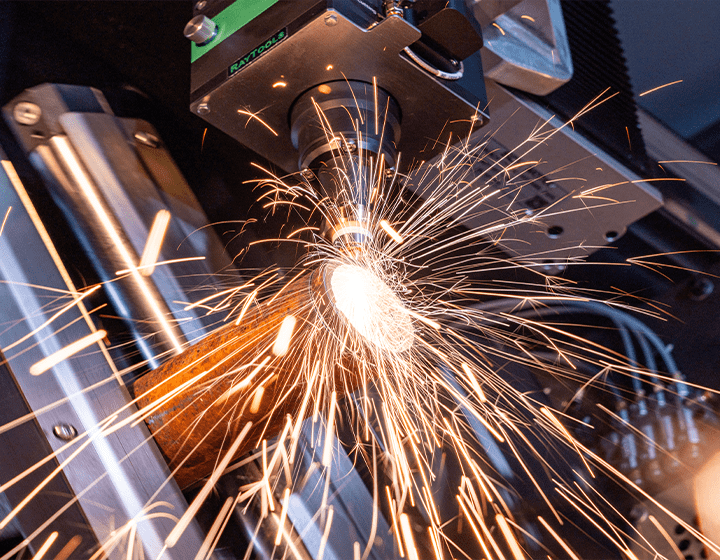

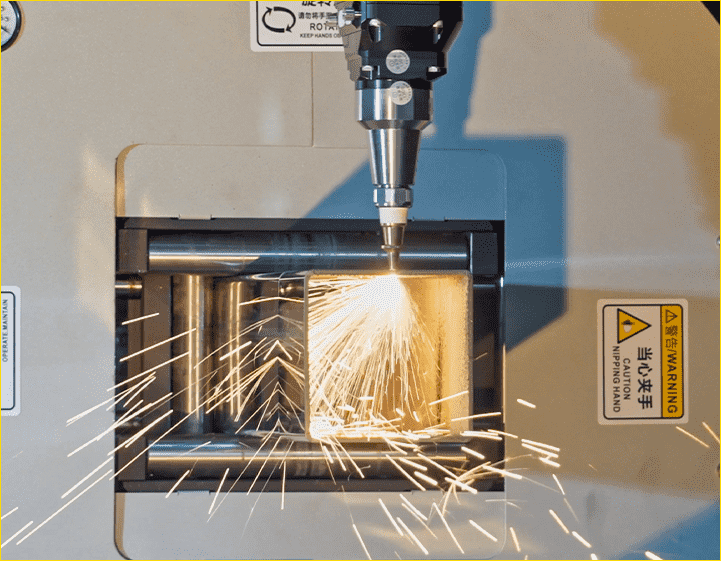

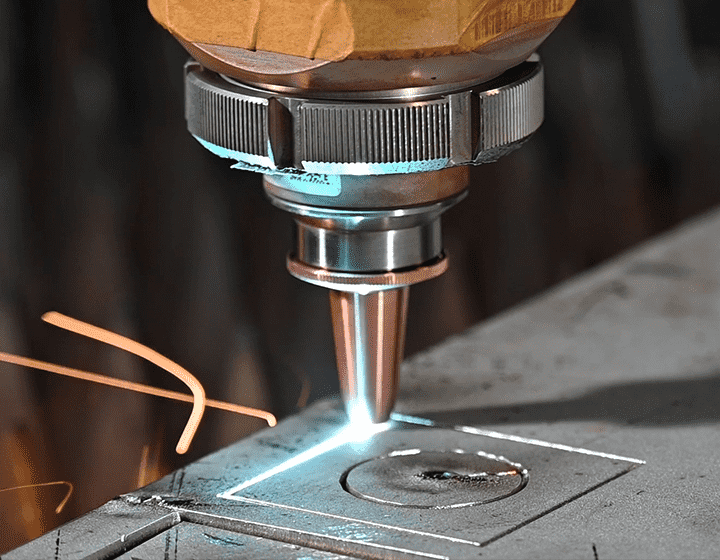

UM máquina de corte a laser para chapa de latão usa um feixe de laser focado para cortar latão com incrível precisão. O calor do laser derrete ou vaporiza o material no ponto de corte, deixando uma borda limpa com distorção mínima de calor. Este método de corte garante que designs complexos e detalhes em pequena escala possam ser replicados perfeitamente, sem comprometer a integridade do material..

Principais benefícios do uso de corte a laser para chapas de latão

1. Precisão e exatidão:

O corte a laser oferece precisão incomparável, especialmente importante ao trabalhar com metais delicados como latão. Até os designs mais complexos, como gravura ou cortes detalhados, pode ser executado com desvio mínimo, garantindo resultados de alta qualidade.

2. Bordas limpas e lisas:

Ao contrário dos métodos de corte tradicionais, o que pode deixar rebarbas ou arestas, o corte a laser produz um acabamento suave, acabamento limpo. Isto é particularmente valioso quando se trabalha com componentes decorativos ou de latão de alta qualidade, onde a estética é crucial.

3. Desperdício de material mínimo:

A precisão do corte a laser permite um encaixe perfeito das peças, o que significa que a quantidade de latão desperdiçada é mínima. Isso é econômico e ecologicamente correto, reducing the overall material consumption in your projects.

4. Corte de alta velocidade:

Laser cutters can cut through brass sheets much faster than conventional methods. This makes them ideal for mass production or jobs with tight deadlines, increasing overall efficiency without sacrificing quality.

5. Flexibilidade no Design:

Laser cutting machines can handle a variety of designs, from simple shapes to complex geometries, with ease. This flexibility enables users to experiment with different patterns, engravings, and customized designs that would otherwise be time-consuming or impossible with other tools.

Applications of Laser Cutting Machines for Brass Sheets

Laser cutting technology is a game-changer in many industries. Some of the most common applications of laser cutting machines for brass sheet incluir:

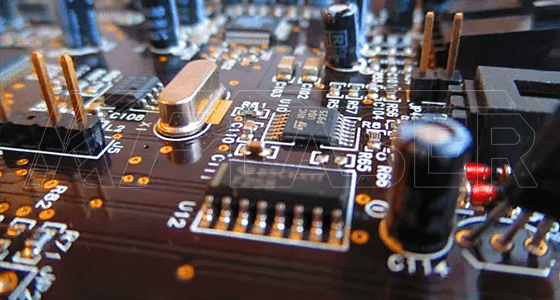

1. Fabricação eletrônica:

Brass is widely used in the production of electronic components, como conectores e dissipadores de calor, devido à sua excelente condutividade e resistência à corrosão. O corte a laser garante a precisão necessária para esses pequenos, peças complexas.

2. Itens Decorativos:

O latão é frequentemente escolhido por seu apelo estético na criação de joias., decoração de casa, e instalações artísticas. O corte a laser fornece aos artistas e designers uma ferramenta para dar vida às suas visões criativas com precisão e detalhes excepcionais.

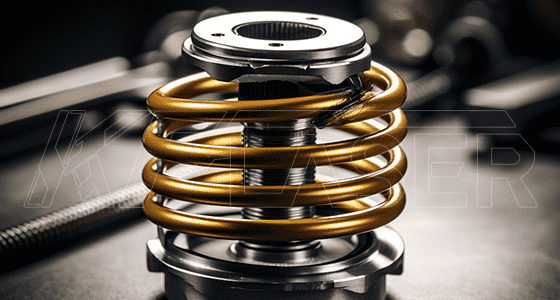

3. Indústria automobilística:

No setor automotivo, o latão é usado por sua durabilidade e resistência à corrosão. O corte a laser ajuda a fabricar peças para a indústria automotiva, como conectores elétricos, Juntas, e acessórios de precisão, com a precisão e eficiência necessárias.

4. Aeroespacial e Defesa:

As máquinas de corte a laser também desempenham um papel significativo nas indústrias aeroespacial e de defesa, onde alta qualidade, peças de precisão são necessárias para sistemas críticos. O latão é frequentemente usado em aplicações militares e aeroespaciais por sua força e resistência ao desgaste, tornando o corte a laser uma parte essencial do processo de produção.

Escolhendo a máquina de corte a laser certa para chapas de latão

Ao selecionar uma máquina de corte a laser para chapa de latão, há vários fatores a serem considerados para garantir que você esteja obtendo o melhor valor e desempenho:

1. Potência Laser:

A potência do laser afeta diretamente sua capacidade de cortar materiais mais espessos. Para latão, normalmente é necessária uma máquina de corte a laser com maior potência, especialmente para folhas mais grossas. Um laser de CO2, por exemplo, é ideal para cortar latão e outros metais não ferrosos.

2. Precisão e qualidade do feixe:

Um feixe de maior qualidade leva a cortes mais precisos. Ao lidar com latão, uma alta qualidade do feixe garante que os cortes sejam precisos, reduzindo a necessidade de pós-processamento e retrabalho.

3. Velocidade de corte:

Embora a velocidade seja importante, não deve acontecer em detrimento da qualidade. Uma máquina que oferece velocidades ajustáveis permitirá adaptar o processo de corte dependendo da espessura e complexidade da chapa de latão.

4. Compatibilidade de software:

Procure uma máquina de corte a laser que suporte software moderno para design e controle. Isso permitirá que você integre facilmente projetos, controlar os parâmetros de corte, e otimizar o processo de corte para eficiência.

Por que escolher o corte a laser para latão em vez dos métodos tradicionais?

Em comparação com métodos tradicionais, como perfuração, corte por jato de água, ou serrar, o corte a laser oferece muito mais precisão, velocidade, e versatilidade. Outros métodos podem exigir etapas adicionais de acabamento ou resultar em mais desperdício, o que pode aumentar custos e tempos de produção. As máquinas de corte a laser para latão oferecem uma limpeza, solução mais eficiente, especialmente ao lidar com cortes detalhados ou intrincados.

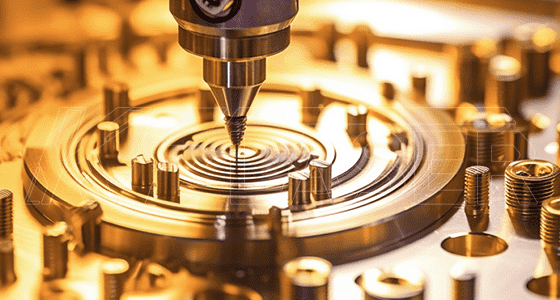

Compreendendo os componentes da máquina de corte a laser

UM máquina de corte a laser para chapa de latão normalmente consiste em vários componentes principais:

Fonte a laser: Isso gera o feixe de laser. Para latão, um laser de CO2 de alta potência é comumente usado devido à sua eficiência no corte de metais não ferrosos.

Cabeça Laser: A cabeça do laser foca o feixe de laser na superfície de latão. Controla a intensidade e o posicionamento do feixe para um corte preciso.

Sistema de movimento: Este sistema move a cabeça do laser ao longo do X, S, e eixos Z, permitindo que a máquina corte ao longo de qualquer caminho desejado.

Sistema de resfriamento: O latão requer resfriamento significativo durante o processo de corte para evitar distorção. Um sistema de resfriamento robusto garante que o laser permaneça na temperatura correta e evite superaquecimento.

Conclusão

O uso de um máquina de corte a laser para chapa de latão é sem dúvida um divisor de águas na metalurgia moderna, oferecendo inúmeras vantagens sobre os métodos de corte tradicionais. Com sua capacidade de criar cortes precisos, minimizar o desperdício de materiais, e trabalhar com designs complexos, o corte a laser está se tornando rapidamente a escolha preferida para muitas indústrias. Selecionando a máquina de corte a laser certa para seus projetos de chapas de latão, você pode garantir que suas operações sejam econômicas e de alta qualidade, entregando sempre os resultados exatos que você precisa.

Pensamentos finais

O corte a laser para latão provou ser uma ferramenta inestimável em vários setores. Sua capacidade de produzir designs complexos, alta precisão, e o desperdício mínimo tornou-o uma escolha preferida tanto para fabricantes de grande escala como para pequenos artesãos. À medida que a tecnologia continua a avançar, o corte a laser só se tornará mais poderoso e acessível, proporcionando novas oportunidades para empresas e designers explorarem. Se você está pensando em investir em uma máquina de corte a laser para chapas de latão, certifique-se de escolher um que ofereça as especificações corretas para atender às suas necessidades e aplicações específicas.

Notícias principais

Categorias de produtos

- Cortador a laser de metal

- Máquina de solda a laser

- Máquina de limpeza a laser

- Máquina marcadora a laser

- Máquina de freio de imprensa