Notícias

Corte a laser de alumínio: Precision and Benefits for Your Projects

Aluminium is one of the most versatile and widely used materials in industries such as automotive, aeroespacial, arquitetura, e fabricação. Due to its lightweight nature, resistência à corrosão, and excellent strength-to-weight ratio, aluminium is ideal for a range of applications. One of the most effective and popular methods for cutting aluminium is corte a laser. Neste artigo, we’ll explore how aluminium laser cutting works, its benefits, and why it’s the go-to choice for precision cutting in various industries.

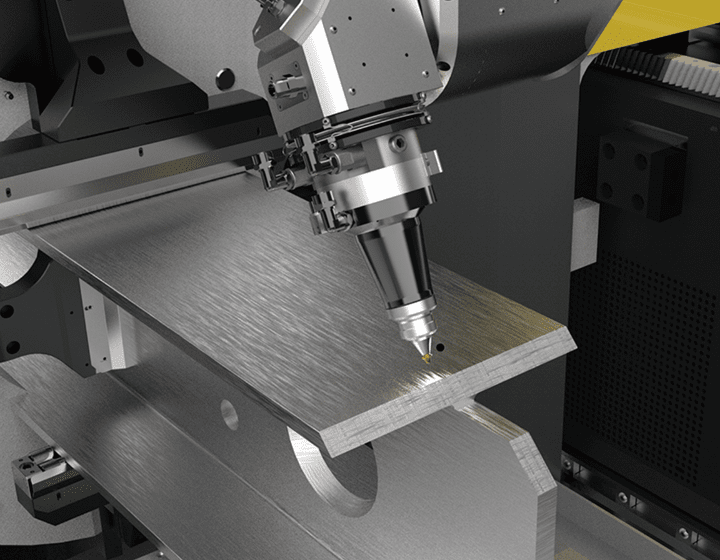

What is Aluminium Laser Cutting?

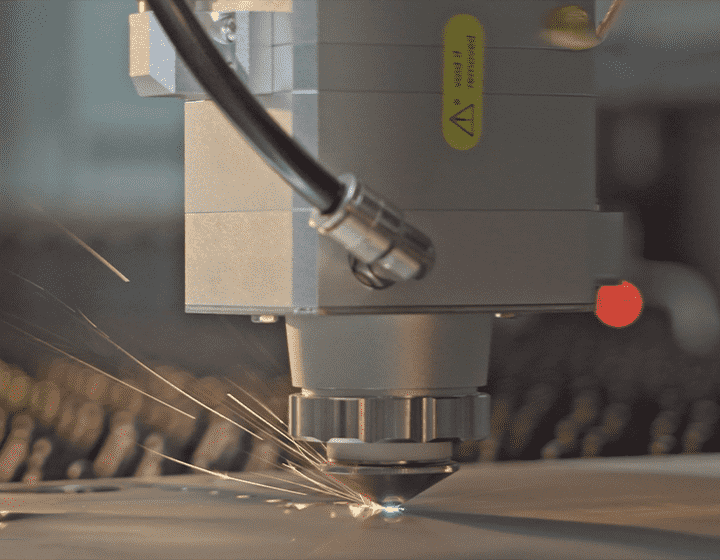

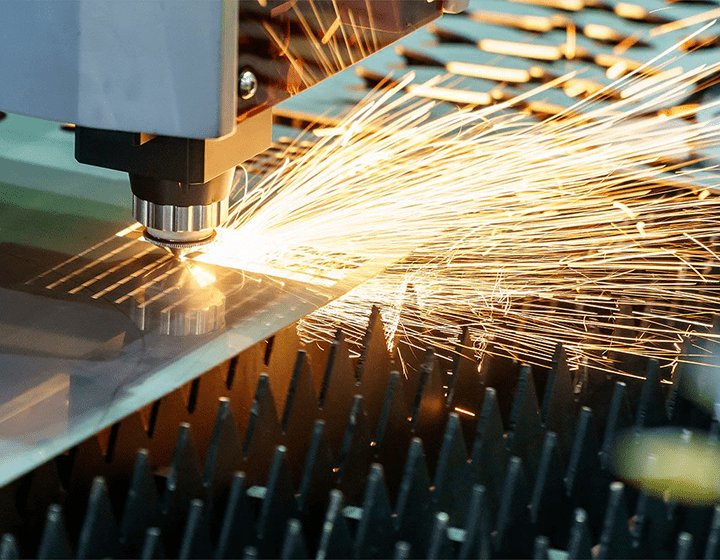

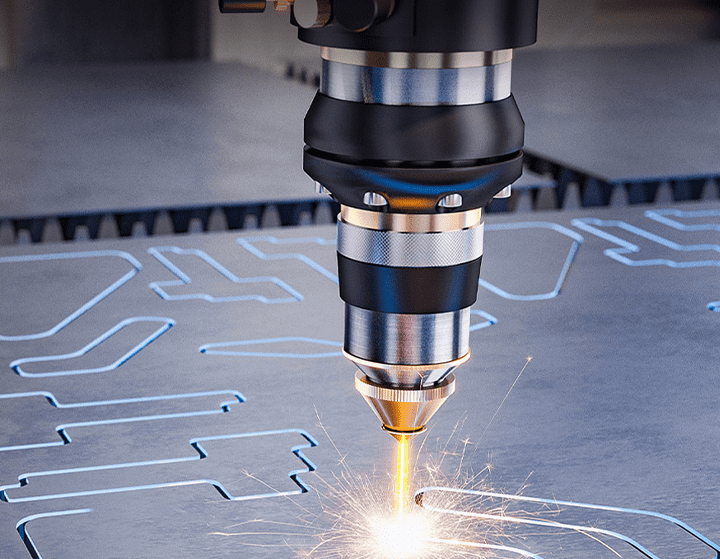

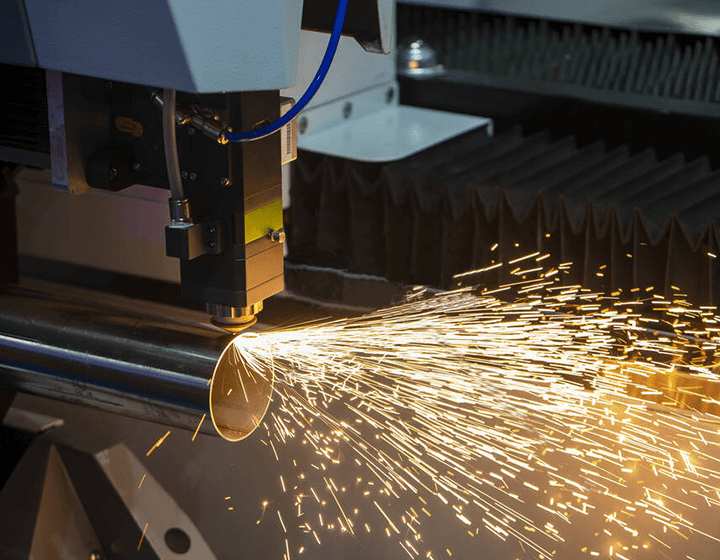

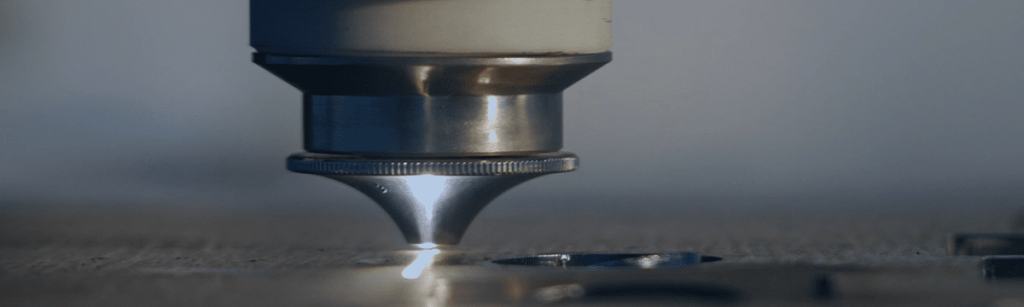

Aluminium laser cutting is a process that uses a high-powered laser beam to cut or engrave aluminium with high precision. The laser cutting machine uses a focused laser beam directed onto the aluminium sheet, melting, burning, or vaporizing the material. This results in clean, sharp cuts with minimal heat-affected zones (HAZ), ensuring high accuracy and excellent finish quality.

The process can be done using different types of lasers, including CO2 lasers and fiber lasers, depending on the thickness and type of aluminium being cut. The cutting process is controlled by CNC (controle numérico de computador) software, which allows for intricate and complex shapes to be cut quickly and precisely.

Benefits of Aluminium Laser Cutting

1. Precisão e exatidão

- One of the most significant advantages of aluminium laser cutting is its precision. Laser cutting machines can achieve incredibly fine details, sharp edges, and tight tolerances, making them ideal for applications that require high levels of accuracy. Whether you’re working with intricate designs or large-scale industrial components, laser cutting ensures clean, repeatable cuts every time.

2. Resíduos de material reduzido

- Laser cutting is an efficient process that optimizes material usage. The focused laser beam creates narrow kerfs (cutting widths), which means there’s less material waste compared to traditional cutting methods like sawing or punching. Adicionalmente, laser cutting allows for nesting software, which maximizes the use of the aluminium sheet by efficiently planning the cut patterns.

3. Versatilidade

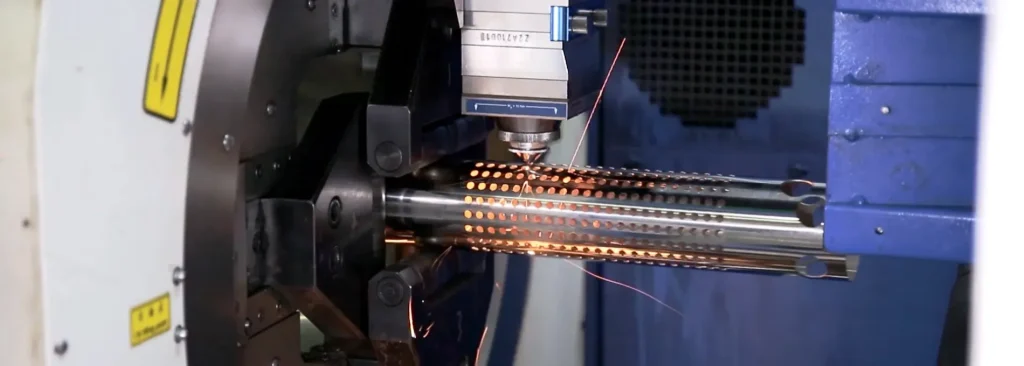

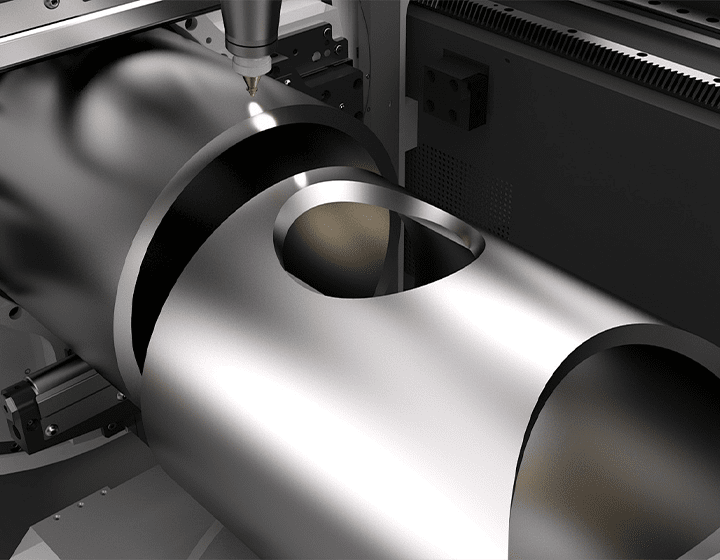

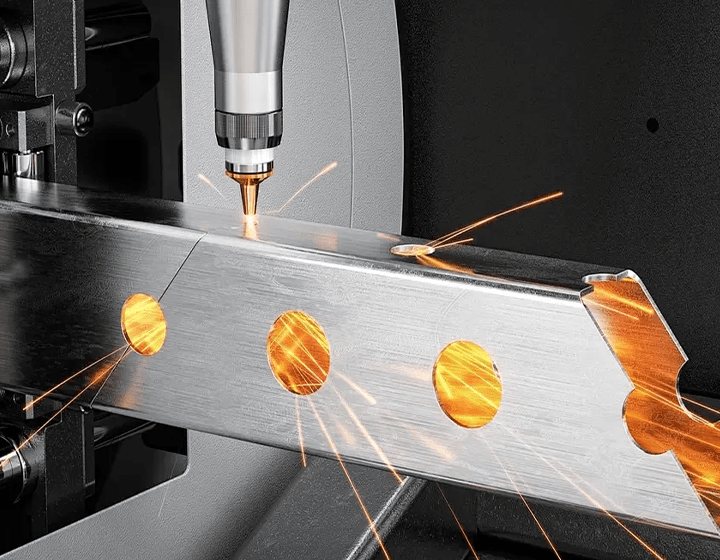

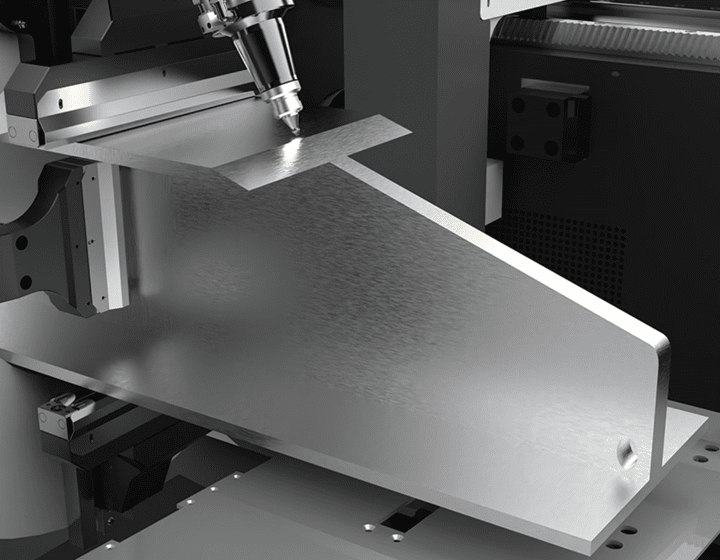

- Aluminium laser cutting is versatile and can be applied to a wide range of projects, from thin sheets to thicker aluminium plates. Laser cutting is suitable for cutting complex shapes, such as circular holes, curves, and detailed designs. The process can also handle varying thicknesses of aluminium, making it an adaptable option for many industries.

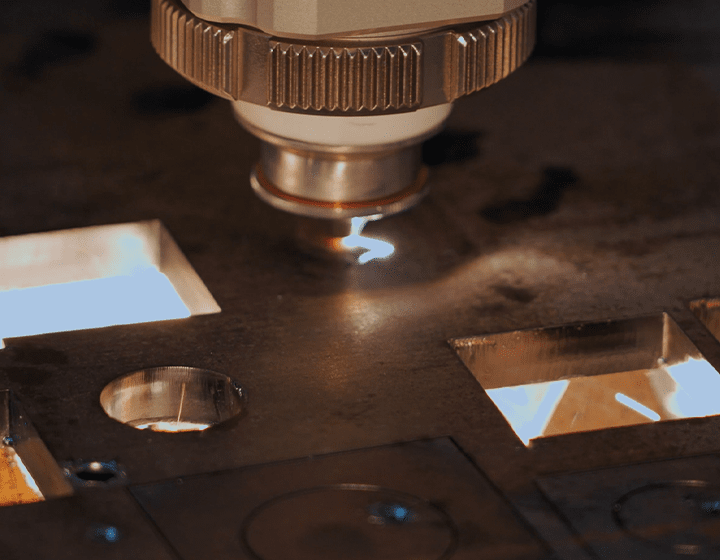

4. Minimal Heat-Affected Zone (HAZ)

- Ao contrário dos métodos de corte tradicionais, laser cutting produces very little heat, resulting in a minimal heat-affected zone (HAZ). This is particularly important for aluminium, as it is sensitive to heat and can warp or lose its structural integrity if overheated. The minimal HAZ ensures that the cut edges remain straight, and the material’s strength is preserved.

5. Alta velocidade de corte

- O corte a laser é um processo rápido e eficiente, especially for applications that require high throughput. The laser beam can cut through aluminium quickly, reducing production time and improving overall efficiency. This makes it ideal for both prototyping and large-scale production runs.

6. Limpar, Bordas suaves

- Laser-cut aluminium parts typically have smooth, clean edges that require little to no post-processing. The precision of the laser ensures that the edges are free from burrs, and the surface finish is often ideal for most applications, reducing the need for additional finishing processes.

Applications of Aluminium Laser Cutting

Aluminium laser cutting is used in a wide variety of industries for various applications. Some of the most common include:

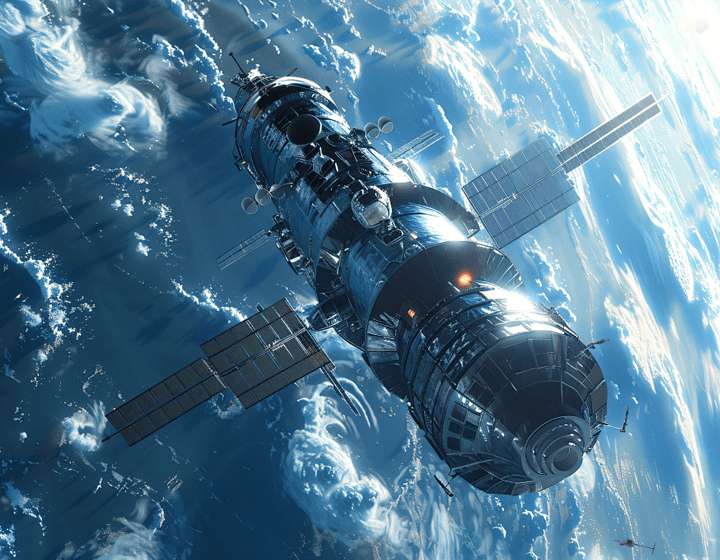

1. Automotive and Aerospace

- In the automotive and aerospace industries, laser cutting is used for producing lightweight, high-strength components. Aluminium is commonly used in these industries because of its excellent strength-to-weight ratio. Laser cutting allows for the precise cutting of complex parts such as engine components, colchetes, and panels.

2. Projeto Arquitetônico

- Laser-cut aluminium is increasingly used in architectural design, both for structural and decorative purposes. Aluminium panels with intricate patterns are often used in facades, window coverings, and interior elements, creating visually stunning effects. Laser cutting allows architects to experiment with unique shapes and designs while maintaining structural integrity.

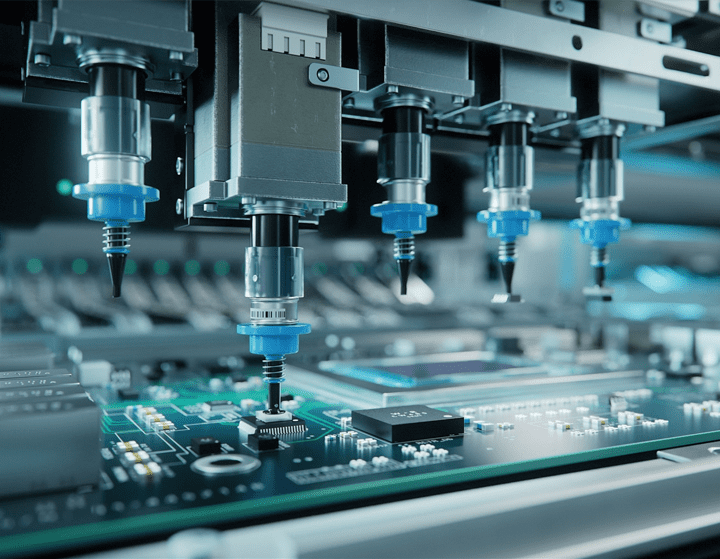

3. Eletrônicos e Componentes Elétricos

- Na indústria eletrônica, aluminium laser cutting is used for manufacturing components like heat sinks, gabinetes, and mounting plates. The precision of the laser ensures that components fit perfectly and that the aluminium material retains its optimal heat dissipation properties.

4. Signage and Branding

- Laser cutting is a popular choice for creating custom signage and branding materials. Aluminium is a durable and weather-resistant material, making it ideal for outdoor signs and displays. Laser cutting allows businesses to create logos, texto, and intricate designs with high precision.

5. Custom Fabrication and Prototyping

- For custom fabrication and prototyping, aluminium laser cutting provides a fast and cost-effective way to produce detailed prototypes or small batches of parts. The ability to cut intricate shapes quickly and accurately makes it a popular choice for manufacturers looking to test designs or produce limited runs.

Types of Lasers Used for Aluminium Cutting

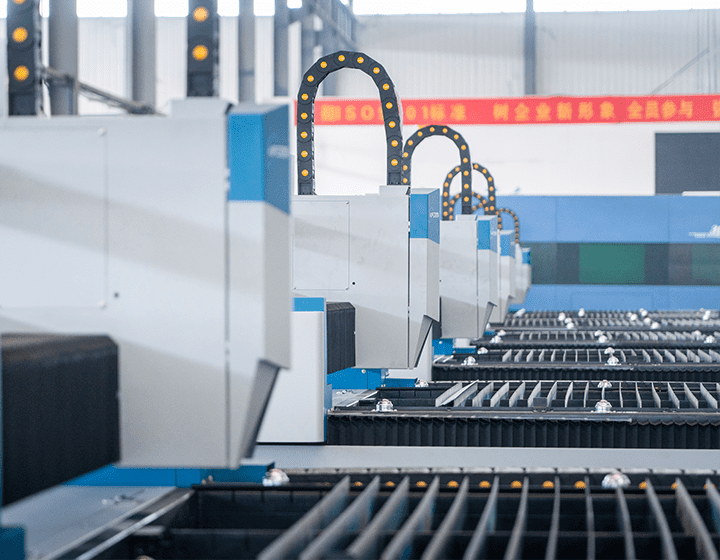

When choosing a laser cutting machine for aluminium, the two most common types of lasers are Lasers de CO2 e lasers de fibra. Each type has its advantages, and the choice depends on factors like material thickness, velocidade de corte, e eficiência energética.

1. Lasers de CO2

CO2 lasers are widely used for cutting aluminium, especialmente para materiais mais finos. They are highly efficient and cost-effective, making them ideal for general-purpose cutting. CO2 lasers are known for producing high-quality cuts on various materials, incluindo metais, plásticos, e madeira.

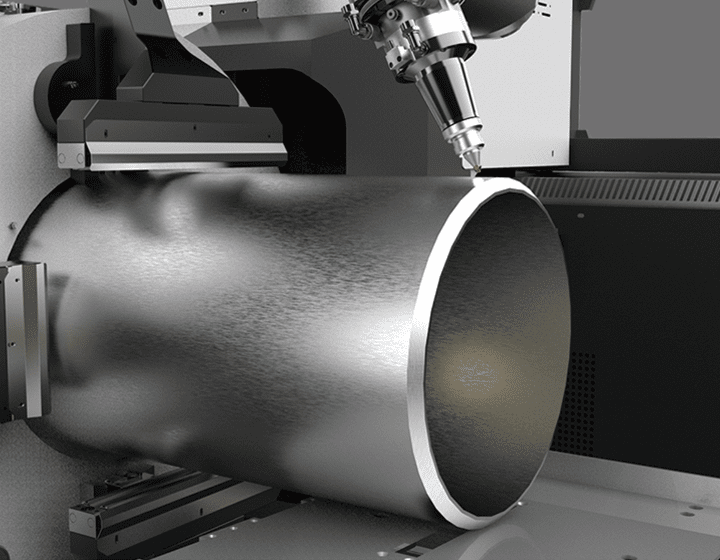

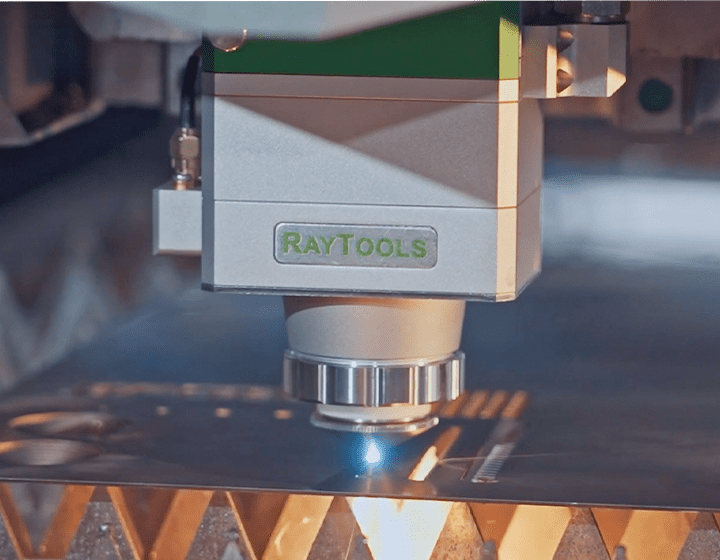

2. Lasers de fibra

Fiber lasers are more commonly used for cutting thicker materials and offer several advantages over CO2 lasers. They provide higher power density, allowing for faster cutting speeds and greater precision, especially on thicker aluminium sheets. Fiber lasers are also more energy-efficient and have a longer lifespan than CO2 lasers.

Key Considerations for Aluminium Laser Cutting

While aluminium laser cutting offers many benefits, there are a few factors to keep in mind:

- Thickness of the Material: Laser cutting machines have varying capabilities when it comes to material thickness. Thicker aluminium requires more power and may need a fiber laser for efficient cutting.

Tipo de material: Different grades of aluminium may require different settings, so it’s important to use the appropriate parameters for your material.

Custo: While laser cutting is an efficient process, the cost of the machine, as well as maintenance and operational costs, should be considered for large-scale production.

Post-processing: In some cases, post-processing steps may be required, such as deburring or polishing, depending on the quality of the cut.

Conclusão

Aluminium laser cutting is a highly effective and precise method for creating custom parts, componentes, and designs. With its many benefits, incluindo alta precisão, minimal waste, and fast cutting speeds, it has become the go-to solution for a variety of industries. Esteja você no setor automotivo, aeroespacial, or design, using laser cutting for aluminium allows you to achieve high-quality results and optimize your production process.

By understanding the different types of lasers and choosing the right machine for your needs, you can maximize the benefits of this cutting-edge technology for your next aluminium project.

This guide offers a comprehensive look at the aluminium laser cutting processo, suas vantagens, and applications. Whether you’re a professional manufacturer or a hobbyist, laser cutting offers the precision and efficiency needed for a wide range of aluminium projects.

Notícias principais

-

6 kw laser cutting | Industrial precision guide28 novembro 2025

6 kw laser cutting | Industrial precision guide28 novembro 2025 -

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025 -

10Corte a laser kW | Precisão & Poder21 novembro 2025

10Corte a laser kW | Precisão & Poder21 novembro 2025 -

4kw de espessura de corte a laser | Capacidade máxima de material18 novembro 2025

4kw de espessura de corte a laser | Capacidade máxima de material18 novembro 2025 -

Máquina de corte de chapa metálica para venda: Ultimate Buyer's Guide14 novembro 2025

Máquina de corte de chapa metálica para venda: Ultimate Buyer's Guide14 novembro 2025

Categorias de produtos

- Cortador a laser de metal

- Máquina de solda a laser

- Máquina de limpeza a laser

- Máquina marcadora a laser

- Máquina de freio de imprensa