Notícias

CNC Fiber Laser Cutting Machine: Precisão, Eficiência, and Versatility for Modern Manufacturing

The rise of CNC fiber laser cutting machines has revolutionized the manufacturing industry by combining the power of laser technology with the precision of computer numerical control (CNC). This advanced machinery offers high-quality cutting performance for a wide range of materials, incluindo metais, plásticos, e mais. Neste artigo, we’ll delve into how CNC fiber laser cutting machines work, seus benefícios, and why they are the preferred choice for modern manufacturing applications.

What is a CNC Fiber Laser Cutting Machine?

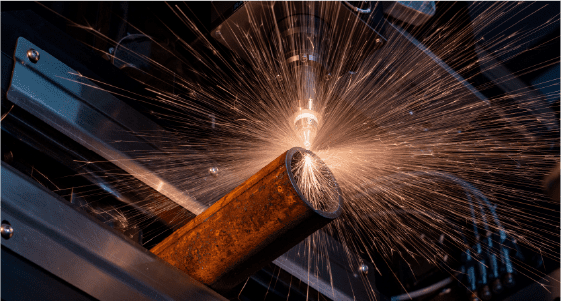

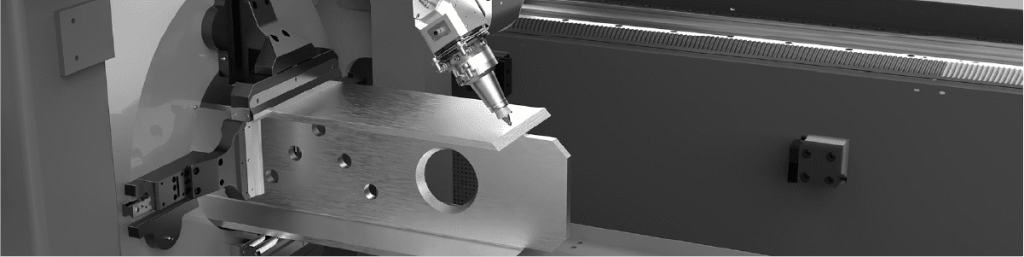

UM CNC fiber laser cutting machine is an automated system that uses a high-powered laser beam to cut through various materials with exceptional accuracy and speed. The machine integrates CNC technology, which allows for precise control of the cutting path, ensuring high-quality results for complex designs and shapes.

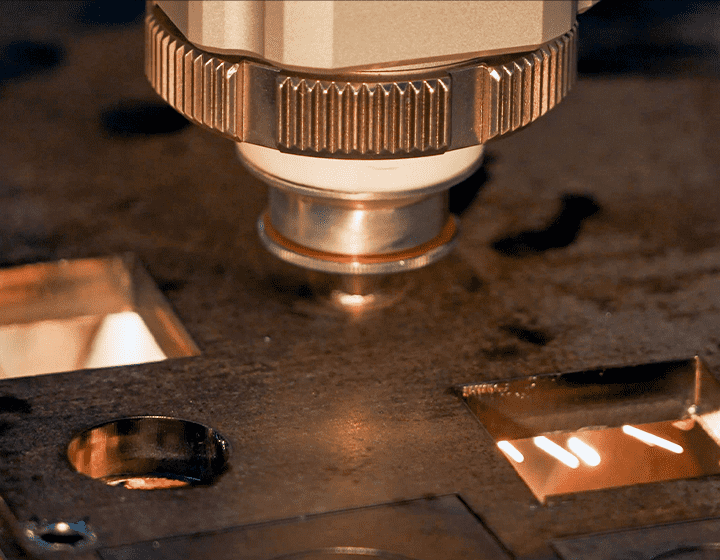

O “fibra” in the name refers to the type of laser used – lasers de fibra, which are made from a solid fiber-optic material that generates a high-intensity laser beam. Compared to traditional CO2 lasers, fiber lasers have a smaller wavelength, which improves the cutting speed and precision, especially when working with reflective materials like stainless steel, aluminium, e cobre.

How Does a CNC Fiber Laser Cutting Machine Work?

The operation of a CNC fiber laser cutting machine involves several steps:

Geração a laser: The fiber laser generator produces a laser beam that is directed through fiber-optic cables to the cutting head.

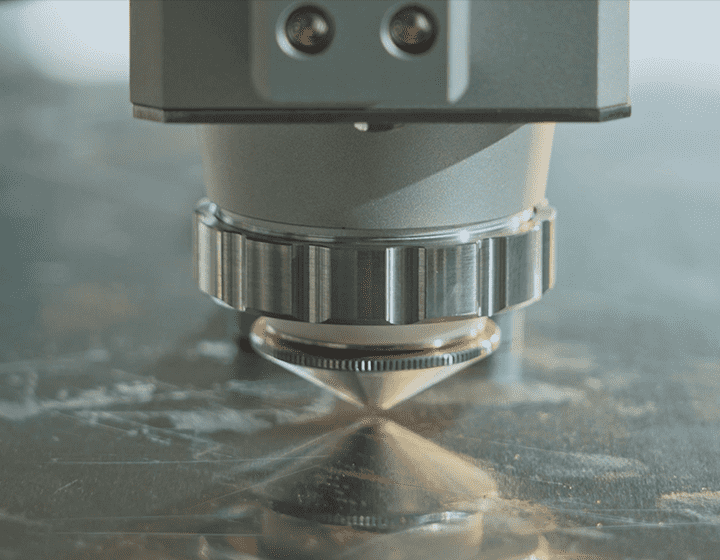

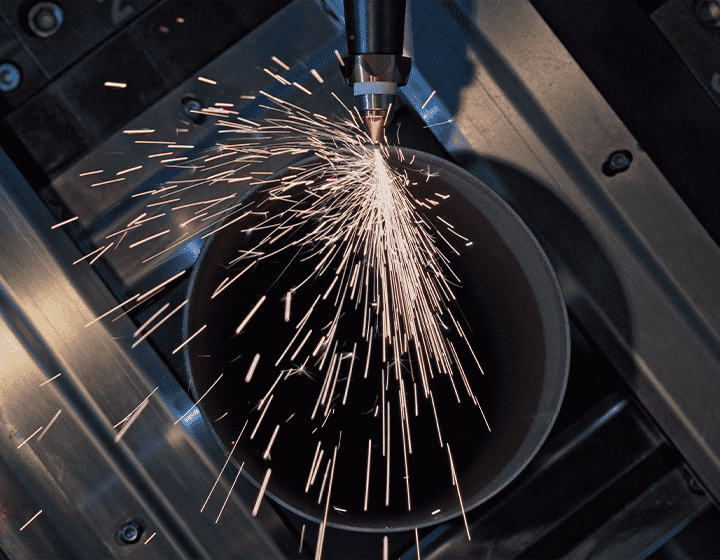

Focus and Cutting: The focused laser beam is directed onto the material’s surface, onde derrete, queimaduras, or vaporizes the material along the cutting path.

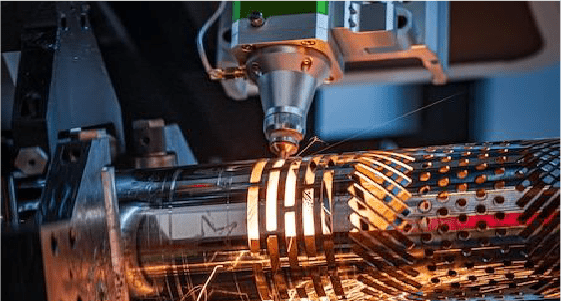

Controle do CNC: O Sistema CNC precisely controls the movement of the cutting head along a programmed path, which is based on a CAD (computer-aided design) file or other 3D models. This ensures high accuracy and repeatability in the cutting process.

Auxiliar gás: In some cases, um gás de assistência (como oxigênio, azoto, ou ar) is blown through the nozzle to help remove the molten material from the cut, resulting in a cleaner edge.

The combination of fiber laser technology and CNC precision control allows for intricate, high-speed cutting of materials with minimal heat-affected zones (HAZ), which is ideal for materials that are sensitive to heat.

Benefits of CNC Fiber Laser Cutting Machines

1. Alta Precisão e Exatidão

One of the standout features of CNC fiber laser cutting machines is their ability to produce highly accurate cuts with extremely tight tolerances. CNC systems allow the machine to follow precise cutting paths, ensuring that even the most intricate designs are replicated with consistency. Whether you’re cutting simple shapes or complex geometries, the precision of a CNC fiber laser cutting machine ensures clean and flawless results.

2. Velocidade e eficiência

Compared to traditional cutting methods, CNC fiber laser cutting machines offer significantly higher cutting speeds. Fiber lasers can cut through metals at high speeds, reducing production times and improving overall efficiency. This makes them particularly suitable for industries that require quick turnaround times or high-volume production.

3. Low Operating Costs

Fiber lasers are known for their energy efficiency, as they use less power compared to CO2 lasers and other cutting technologies. Adicionalmente, the reduced wear and tear on the machine components result in lower maintenance costs over time. The reduced energy consumption and maintenance requirements make CNC fiber laser cutting machines a cost-effective solution for both small businesses and large manufacturers.

4. Versatility in Material Processing

A major advantage of CNC fiber laser cutting machines is their versatility in cutting a wide range of materials, incluindo metais (aço, aço inoxidável, aluminium, cobre, latão, etc.), plásticos, madeira, e mais. The ability to switch between materials without needing to change tools or setups makes fiber lasers highly adaptable to different production needs.

5. Minimal Heat-Affected Zone (HAZ)

The fiber laser cutting process generates very little heat, which results in a minimal heat-affected zone (HAZ). This is crucial for maintaining the integrity of the material being cut. In applications where precision and material quality are important, such as in aerospace and automotive industries, minimizing HAZ ensures that the material does not warp or degrade during cutting.

6. Low Maintenance and Durability

CNC fiber laser cutting machines are known for their durability and low maintenance requirements. The fiber laser source has a longer lifespan compared to traditional CO2 lasers and does not require regular maintenance like mirror alignment or lens cleaning. This reduces the overall operating cost and downtime, making fiber lasers a reliable choice for continuous production.

Applications of CNC Fiber Laser Cutting Machines

The versatility and precision of CNC fiber laser cutting machines make them applicable in a wide variety of industries. Algumas das aplicações mais comuns incluem:

1. Fabricação de metal

In metal fabrication, CNC fiber laser cutting machines are used to cut various metals, incluindo aço carbono, aço inoxidável, and aluminium. The high precision of these machines is ideal for manufacturing components with intricate designs and tight tolerances.

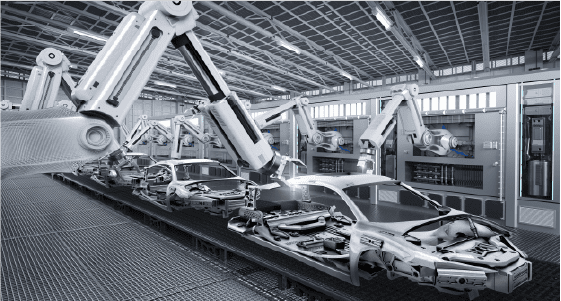

2. Indústria automobilística

The automotive industry benefits from the high-speed cutting capabilities of CNC fiber laser cutting machines. They are used to cut parts for vehicles, such as chassis components, sistemas de escape, e painéis da carroceria. The ability to cut complex shapes and patterns with minimal waste makes fiber lasers a go-to solution for automotive manufacturers.

3. Aeroespacial e aviação

In the aerospace sector, where safety and precision are paramount, CNC fiber laser cutting machines are employed to manufacture high-precision parts for aircraft. The minimal heat-affected zone (HAZ) ensures that the components retain their strength and integrity, which is critical for aerospace applications.

4. Sinalização e Painéis Decorativos

CNC fiber laser cutting machines are widely used for producing custom signs and decorative panels. The ability to cut through a variety of materials, such as stainless steel, acrílico, e madeira, with intricate designs, makes them ideal for creating visually appealing signs, logotipos, e elementos decorativos.

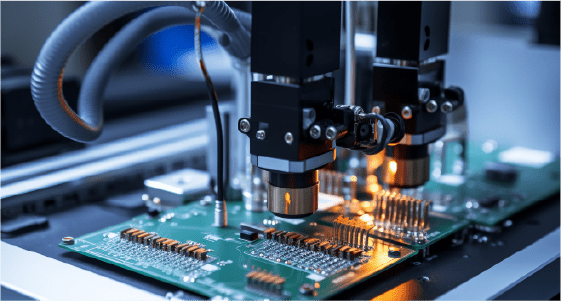

5. Fabricação eletrônica

In electronics, CNC fiber laser cutting machines are used to cut circuit boards, gabinetes, and heat sinks with high precision. The accuracy of the cuts ensures that electronic components fit perfectly and are not damaged during the cutting process.

6. Custom Metal Works

For custom metal fabrication, such as creating prototypes or low-volume production runs, CNC fiber laser cutting machines provide the flexibility and precision needed to manufacture complex designs with minimal material waste.

Conclusão

CNC fiber laser cutting machines are an essential tool for modern manufacturing, oferecendo precisão incomparável, velocidade, e versatilidade. Their ability to cut a wide range of materials with high accuracy and minimal heat distortion makes them invaluable across industries such as metal fabrication, Automotivo, aeroespacial, and signage. By integrating tecnologia laser de fibra with CNC control, these machines deliver high-quality cuts and are cost-effective in the long run.

As manufacturers continue to seek ways to improve production efficiency, reduzir o desperdício, and maintain high-quality standards, CNC fiber laser cutting machines will remain a top choice for precision cutting and custom fabrication. Investing in this advanced technology ensures that businesses can stay competitive in an increasingly demanding marketplace.

This comprehensive guide highlights the capabilities, vantagens, and applications of CNC fiber laser cutting machines, making it a valuable resource for anyone looking to understand the role of this technology in modern manufacturing.

Notícias principais

-

6 kw laser cutting | Industrial precision guide28 novembro 2025

6 kw laser cutting | Industrial precision guide28 novembro 2025 -

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025 -

10Corte a laser kW | Precisão & Poder21 novembro 2025

10Corte a laser kW | Precisão & Poder21 novembro 2025 -

4kw de espessura de corte a laser | Capacidade máxima de material18 novembro 2025

4kw de espessura de corte a laser | Capacidade máxima de material18 novembro 2025 -

Máquina de corte de chapa metálica para venda: Ultimate Buyer's Guide14 novembro 2025

Máquina de corte de chapa metálica para venda: Ultimate Buyer's Guide14 novembro 2025

Categorias de produtos

- Cortador a laser de metal

- Máquina de solda a laser

- Máquina de limpeza a laser

- Máquina marcadora a laser

- Máquina de freio de imprensa