Notícias

Máquina de corte a laser para chapa metal: Precisão e eficiência na fabricação

In the modern manufacturing world, laser cutting machines for sheet metal have transformed the way industries approach metal fabrication. From automotive parts to aerospace components, O corte a laser oferece precisão incomparável, eficiência, e versatilidade. Whether you’re cutting thin sheets or intricate designs, this technology ensures high-quality results with minimal material waste.

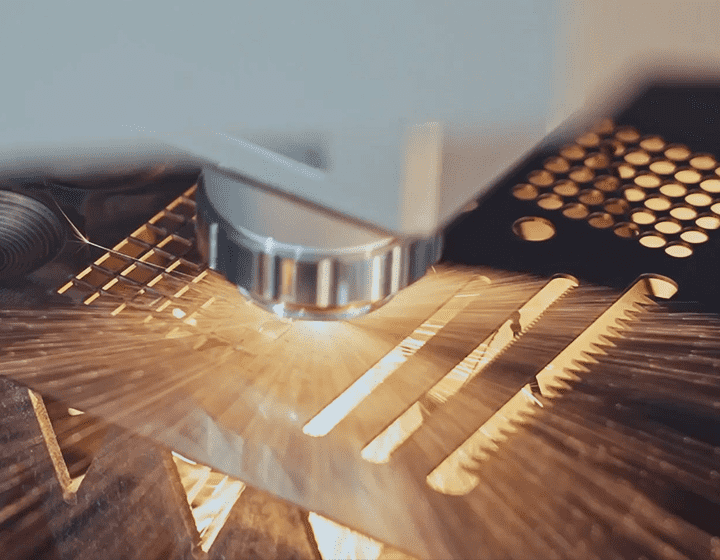

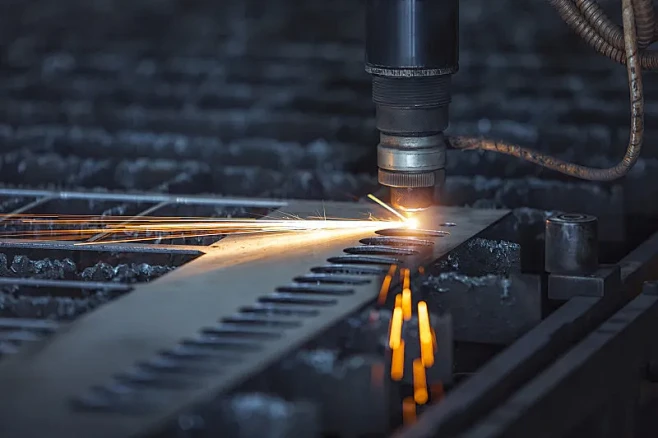

Laser cutting machines use a concentrated laser beam to cut through metals, delivering smoother cuts than traditional methods while reducing the time required for production. This technology is not only faster but also far more accurate, making it an invaluable tool in industries requiring complex and precise cuts.

1.How Does a Máquina de corte a laser para chapa metal Trabalhar?

A laser cutting machine utilizes a high-powered laser beam focused on the material to be cut. The beam is directed onto the metal sheet, onde derrete, queimaduras, or vaporizes the material along the cutting path. The laser’s focused nature allows it to cut intricate shapes and designs with high precision, minimizing material distortion and waste.

The machine operates using a computer numerical control (CNC) sistema, which ensures that each cut is made according to pre-programmed designs. This system provides the ability to perform complex cuts that are difficult or impossible to achieve with traditional mechanical cutting methods.

2.Advantages of Laser Cutting for Sheet Metal

Precisão e exatidão incomparáveis

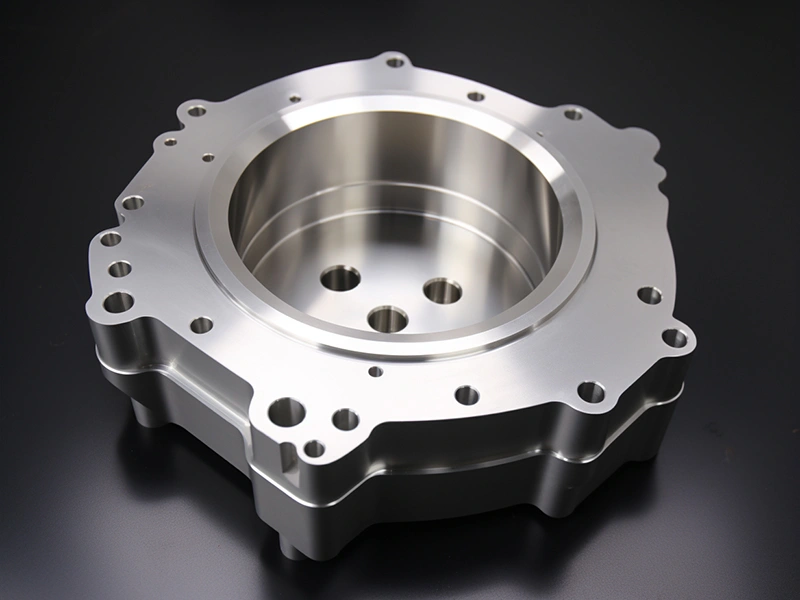

One of the primary reasons manufacturers turn to laser cutting machines for sheet metal is their ability to deliver highly precise cuts. Laser cutting technology can achieve tight tolerances, ensuring that even the most intricate designs are executed with accuracy. This precision is crucial in industries like aerospace and medical device manufacturing, where even the smallest errors can lead to costly defects.

Faster Turnaround Times

Laser cutting machines operate at impressive speeds. The process is faster than traditional cutting methods such as water jet or mechanical cutting, allowing manufacturers to complete more jobs in less time. The reduced processing time can significantly increase production capacity and reduce overall project timelines.

Minimal Waste and Cost Efficiency

Laser cutting minimizes waste by creating narrow, precise cuts that require less material. This is particularly beneficial for industries looking to reduce material costs, as the accuracy of the cut ensures that less scrap is produced during the cutting process. Adicionalmente, since laser cutting machines are highly automated, they reduce the need for manual labor and increase overall cost efficiency.

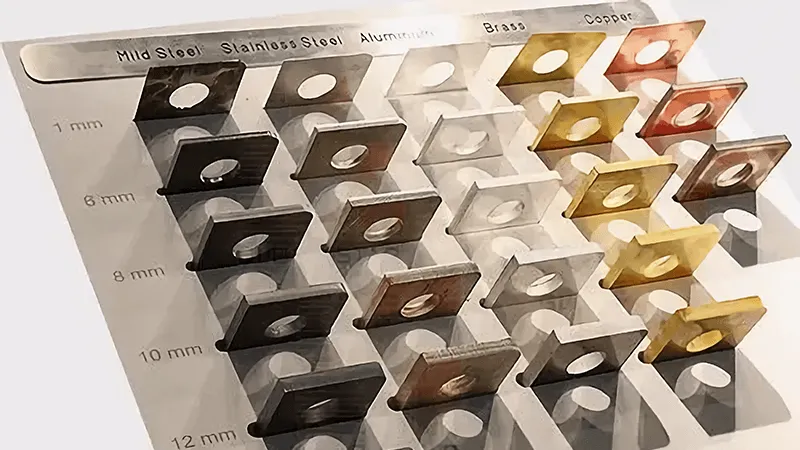

Versatility in Material Handling

Laser cutting machines are capable of cutting a wide range of materials beyond just sheet metal. They can handle stainless steel, alumínio, latão, cobre, and many other metals with ease. The flexibility to switch between different materials without the need for significant setup changes makes laser cutting an ideal solution for manufacturers working with diverse materials and products.

Cleaner Cuts and Better Finishing

Laser cutting is known for its ability to produce smooth, Bordas limpas, eliminating the need for additional post-processing or finishing. A zona afetada pelo calor (HAZ) is minimal, which reduces the risk of material warping and ensures a high-quality finish. This feature is particularly useful for industries that require clean, sharp edges for both functional and aesthetic purposes.

3.Applications of Laser Cutting Machines for Sheet Metal

Indústria automobilística

Na indústria automotiva, laser cutting machines for sheet metal are used to create everything from car body parts to engine components. The precision of laser cutting allows manufacturers to produce complex shapes and intricate designs required for modern vehicles. Whether cutting structural components or decorative features, laser cutting ensures that parts are produced with the highest level of accuracy and consistency.

Fabricação aeroespacial

Aerospace components require exceptional accuracy and strength. Laser cutting machines are used extensively in the aerospace industry to cut high-strength alloys, alumínio, and other materials used in aircraft manufacturing. These machines can create parts with tight tolerances, essential for meeting the stringent quality standards of the aerospace sector.

Metal Fabrication and Construction

Laser cutting for sheet metal has become the backbone of metal fabrication in construction and structural engineering. Builders and fabricators rely on laser cutting machines to produce custom-sized metal parts for structures, bridges, and industrial equipment. The ability to produce precise cuts quickly and efficiently makes laser cutting indispensable in the metalworking industry.

Eletrônicos e Componentes Elétricos

Na indústria eletrônica, laser cutting machines are employed to fabricate intricate parts such as heat sinks, placas de circuito, and housing components. The precision of laser cutting ensures that these delicate parts meet the required performance standards while maintaining aesthetic quality.

4.Why Choose a Laser Cutting Machine for Sheet Metal?

Maior eficiência

Laser cutting technology offers significantly faster processing times compared to traditional methods, reducing production cycles and improving overall efficiency. The ability to make precise cuts in a variety of materials without the need for manual adjustments makes laser cutting a highly efficient option for manufacturers.

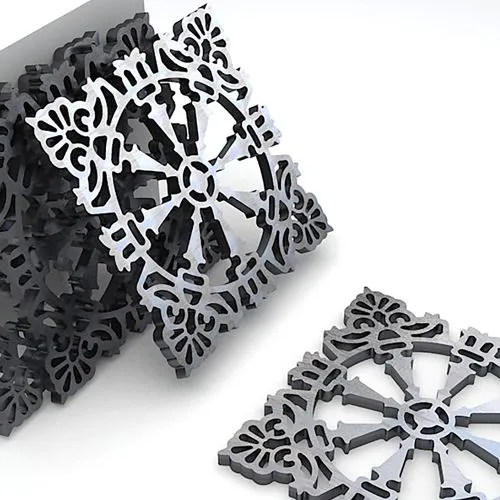

Capacidades de design aprimoradas

Laser cutting enables manufacturers to create more complex designs and shapes that were once impossible or extremely costly to produce with other methods. The CNC control system allows for detailed customization, opening up new possibilities for product development and design.

Reduced Material Costs

By reducing waste and maximizing the material usage, laser cutting machines offer significant savings on material costs. The ability to cut metal with high precision ensures that the maximum amount of material is used efficiently, which can have a substantial impact on long-term cost savings.

Greater Reliability and Consistency

Laser cutting machines are designed to operate autonomously with minimal human intervention, leading to fewer mistakes and a more consistent output. This level of reliability ensures that manufacturers can meet high-quality standards consistently without worrying about human error.

5.Future Trends in Laser Cutting for Sheet Metal

À medida que a tecnologia continua a evoluir, the capabilities of laser cutting machines are expected to expand even further. Innovations in laser technology, such as fiber lasers and hybrid machines, are already improving efficiency and cutting speed. Adicionalmente, the integration of artificial intelligence (IA) and machine learning into laser cutting systems will allow for smarter, more adaptive cutting processes, optimizing performance and reducing downtime.

Laser cutting machines for sheet metal are revolutionizing the manufacturing process. Offering precision, eficiência, e versatilidade, these machines are helping industries across the globe meet the increasing demands for high-quality, intricate metal parts. Whether you’re looking to reduce production time, minimize waste, or create complex designs, a laser cutting machine could be the perfect solution for your needs.

Notícias principais

-

Fiber Laser Metal Cutting Machine For Sale05 Dec 2025

Fiber Laser Metal Cutting Machine For Sale05 Dec 2025 -

4000 Watt Laser | Industrial Cutting Power02 Dec 2025

4000 Watt Laser | Industrial Cutting Power02 Dec 2025 -

6 corte a laser kw | Guia de precisão industrial28 novembro 2025

6 corte a laser kw | Guia de precisão industrial28 novembro 2025 -

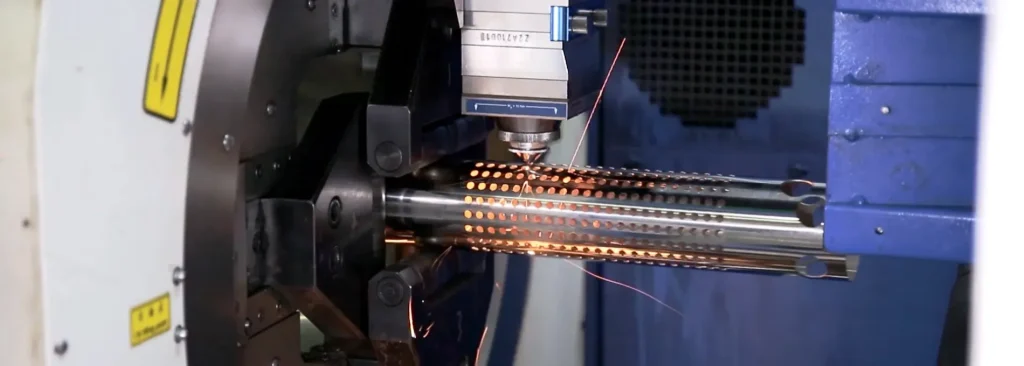

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025 -

10Corte a laser kW | Precisão & Poder21 novembro 2025

10Corte a laser kW | Precisão & Poder21 novembro 2025

Categorias de produtos

- Cortador a laser de metal

- Máquina de solda a laser

- Máquina de limpeza a laser

- Máquina marcadora a laser

- Máquina de freio de imprensa