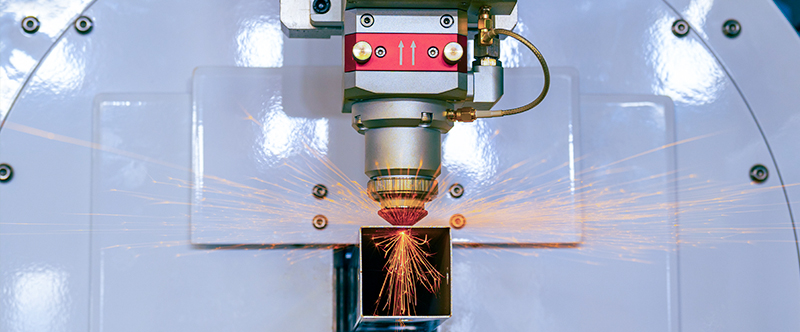

Ao procurar por um confiável e econômico Máquina de corte a laser, uma das primeiras considerações é o preço da máquina de corte a laser. O preço de uma máquina de corte a laser pode variar significativamente com base em vários fatores, incluindo o tipo de laser, a potência da máquina, sua precisão, e o tamanho da máquina. Compreender esses elementos pode ajudá-lo a tomar uma decisão informada ao comprar uma máquina de corte a laser que atenda às suas necessidades e ao mesmo tempo permanecer dentro do seu orçamento..

O preço da máquina de corte a laser é influenciado por vários fatores principais:

1.Tipo de Laser:

Existem vários tipos de lasers usados em máquinas de corte, incluindo lasers de CO2, lasers de fibra, Nd:Lasers yag, e lasers de diodo. Cada tipo possui características diferentes que afetam o desempenho da máquina e, consequentemente, seu preço. Por exemplo, lasers de fibra são geralmente mais caros que os lasers de CO2 devido à sua maior eficiência, vida útil mais longa, e precisão de corte superior.

2.Saída de energia:

A potência do laser afeta significativamente o preço da máquina de corte a laser. Maior potência significa que a máquina pode cortar materiais mais espessos com mais eficiência e rapidez. No entanto, isso também aumenta o custo da máquina. Cortadores a laser com maior potência são geralmente mais caros devido à tecnologia avançada necessária para gerar e manter altos níveis de potência.

3.Tamanho da máquina:

O tamanho da máquina de corte a laser também desempenha um papel crucial na determinação do seu preço. Máquinas maiores, capaz de lidar com folhas maiores de material, tendem a ser mais caros devido aos materiais e tecnologia adicionais necessários para construí-los e operá-los. Além disso, máquinas maiores geralmente têm capacidades aprimoradas, como movimento multieixo ou bases de corte maiores, que aumentam seu custo geral.

4.Precisão e exatidão:

A precisão e exatidão da máquina de corte a laser são vitais, especialmente para indústrias que exigem designs complexos e acabamentos de alta qualidade. Máquinas com maior precisão geralmente vêm com recursos avançados, como pontos de laser menores, melhores sistemas de focagem, e controle de movimento superior, que aumentam seu preço.

5.Custos de manutenção:

Embora o preço de compra inicial seja um fator significativo, os custos de manutenção a longo prazo também devem ser considerados. Lasers de fibra, por exemplo, tendem a ter custos de manutenção mais baixos em comparação com os lasers de CO2 porque possuem menos peças móveis e não requerem calibração frequente ou substituição de componentes ópticos.

Embora o preço da máquina de corte a laser possa ser um investimento significativo, as vantagens de possuir uma máquina de alta qualidade muitas vezes superam os custos. Aqui estão alguns dos principais benefícios:

1. Eficiência aprimorada:

Máquinas de corte a laser de alta qualidade são projetadas para maximizar a eficiência. Eles podem cortar materiais com mais rapidez e precisão do que os modelos de baixo custo, o que se traduz em aumento de produtividade e redução do tempo de produção. Essa eficiência pode levar a economias de custos significativas no longo prazo, tornando o investimento inicial mais justificável.

2.Corte de precisão:

A precisão oferecida pelas máquinas avançadas de corte a laser é incomparável a outros métodos de corte. Esta precisão é crucial para indústrias como a aeroespacial, Automotivo, e eletrônica, onde mesmo o menor desvio pode resultar em erros dispendiosos. Investir em uma máquina de corte a laser de alta qualidade garante que seus cortes sejam sempre precisos e consistentes.

3. Versatilidade:

Uma máquina de corte a laser versátil pode lidar com uma ampla variedade de materiais, incluindo metais, plásticos, vidro, e cerâmica. Essa versatilidade o torna uma ferramenta valiosa em vários setores, da fabricação e construção à arte e design. Ao escolher uma máquina que pode cortar vários materiais, você pode diversificar suas capacidades de produção e assumir uma gama mais ampla de projetos.

4. Custos operacionais mais baixos:

Embora as máquinas de corte a laser de alta qualidade tenham um custo inicial mais alto, eles geralmente têm custos operacionais mais baixos. Lasers de fibra, por exemplo, são mais eficientes em termos energéticos do que os lasers de CO2, o que pode resultar em contas de eletricidade mais baixas ao longo do tempo. Adicionalmente, sua durabilidade significa menos tempo de inatividade e menos peças de reposição, reduzindo ainda mais as despesas de longo prazo.

5. Segurança aprimorada:

A segurança é uma preocupação crítica em qualquer ambiente de produção. Máquinas de corte a laser de alta qualidade estão equipadas com recursos avançados de segurança, como feixes de laser fechados e sistemas de desligamento automático, para proteger os operadores e reduzir o risco de acidentes. Investir em uma máquina com essas características garante um ambiente de trabalho mais seguro, que pode evitar lesões dispendiosas no local de trabalho e responsabilidades legais.

Embora o preço da máquina de corte a laser seja uma consideração importante, também é essencial considerar o valor da máquina a longo prazo. Isto inclui não apenas o custo inicial, mas também a eficiência da máquina, durabilidade, e potencial de economia de custos ao longo do tempo.

1.Retorno do Investimento (ROI):

Uma máquina de corte a laser de alta qualidade pode proporcionar um retorno substancial do investimento, melhorando a eficiência da produção e reduzindo os custos operacionais. As empresas podem recuperar o custo inicial da máquina através do aumento da produtividade, menores despesas de manutenção, e a capacidade de assumir projetos mais complexos.

2. Durabilidade e vida útil:

A durabilidade de uma máquina de corte a laser é um fator chave no seu valor geral. Máquinas construídas com componentes de alta qualidade e tecnologia avançada tendem a ter vida útil mais longa, o que significa que podem operar com eficiência por muitos anos sem a necessidade de reparos ou substituições frequentes. Esta durabilidade contribui para um menor custo total de propriedade.

3. Flexibilidade para necessidades futuras:

Investir em uma máquina de corte a laser versátil e poderosa permite que sua empresa se adapte às novas demandas do mercado. À medida que surgem novos materiais e técnicas de corte, ter uma máquina capaz de lidar com essas inovações garante que seu negócio continue competitivo. Essa flexibilidade pode levar a novas oportunidades e fluxos de receita.

Escolher a máquina de corte a laser certa envolve equilibrar seu orçamento com as necessidades do seu negócio. Aqui estão algumas dicas para ajudá-lo a tomar a melhor decisão:

1.Avalie suas necessidades de corte:

Comece avaliando os tipos de materiais que você precisa cortar e as espessuras com as quais trabalhará. Isso o ajudará a determinar a potência necessária e o tipo de laser para sua máquina. Por exemplo, se você corta metais grossos com frequência, você pode precisar de um laser de fibra de alta potência.

2. Considere o custo total de propriedade:

Vá além do preço inicial da máquina de corte a laser e considere o custo total de propriedade. Isto inclui manutenção, consumo de energia, e o custo de consumíveis como lentes e bicos. Uma máquina com um custo inicial mais alto, mas com despesas operacionais mais baixas, pode ser mais econômica no longo prazo.

3. Avalie os recursos da máquina:

Considere os recursos oferecidos por diferentes máquinas de corte a laser, como recursos de automação, integração de software, e recursos de segurança. Isso pode impactar significativamente sua produtividade e facilidade de uso. Escolha uma máquina que ofereça a melhor combinação de recursos para suas aplicações específicas.

4.Pesquise a reputação do fabricante:

A reputação do fabricante também é crucial. Procure fabricantes com histórico de produção confiável, máquinas de alta qualidade e oferecendo excelente suporte ao cliente. Um fabricante respeitável fornecerá o treinamento necessário, manutenção, e suporte técnico para garantir que sua máquina opere com desempenho máximo.

5. Plano para Expansão Futura:

Se você prevê que seu negócio crescerá ou se expandirá para novos mercados, escolha uma máquina de corte a laser que possa ser dimensionada de acordo com suas necessidades. Isso pode significar selecionar uma máquina com uma base de corte maior ou maior potência do que você precisa atualmente, permitindo que você assuma projetos maiores no futuro.

A automação está se tornando cada vez mais um fator crítico na fabricação moderna, e pode desempenhar um papel significativo na redução do preço da máquina de corte a laser, melhorando a eficiência e reduzindo os custos trabalhistas.

1. Sistemas automatizados de carga e descarga:

Algumas máquinas de corte a laser vêm com sistemas automatizados de carga e descarga que reduzem a necessidade de trabalho manual. Esses sistemas podem aumentar significativamente a produtividade, permitindo que a máquina opere continuamente com o mínimo de intervenção humana.. Ao longo do tempo, a redução nos custos trabalhistas pode compensar o investimento inicial nos recursos de automação.

2. Integração com Software CAD/CAM:

Máquinas avançadas de corte a laser geralmente se integram ao software CAD/CAM, que agiliza o processo de design e produção. Esta integração reduz o tempo necessário para programar a máquina e minimiza o risco de erros, levando a tempos de produção mais rápidos e custos mais baixos.

3. Monitoramento e diagnóstico remoto:

Algumas máquinas de corte a laser oferecem monitoramento e diagnóstico remotos, permitindo que os operadores monitorem o desempenho da máquina e detectem possíveis problemas antes que se tornem problemas graves. Esse recurso pode reduzir o tempo de inatividade e os custos de manutenção, contribuindo para um menor custo geral de propriedade.

4. Manutenção Preditiva:

A manutenção preditiva usa análise de dados para prever quando uma máquina provavelmente precisará de manutenção, permitindo que as operadoras resolvam os problemas antes que eles levem a avarias dispendiosas. A implementação da manutenção preditiva pode prolongar a vida útil da máquina e reduzir a necessidade de reparos caros.

O preço da máquina de corte a laser é um fator importante na hora de selecionar a máquina certa para o seu negócio, mas é crucial considerar o custo total de propriedade, incluindo custos operacionais, manutenção, e potencial para crescimento futuro. Investindo em uma máquina de corte a laser de alta qualidade, você pode melhorar sua eficiência de produção, reduzir custos, e melhore a qualidade dos seus produtos.

Ao avaliar diferentes máquinas, concentre-se nas necessidades específicas do seu negócio, a reputação do fabricante, e o valor a longo prazo da máquina. Recursos de automação, como sistemas automatizados de carga e descarga e integração com software CAD/CAM, também pode desempenhar um papel significativo na redução de custos e na melhoria da produtividade.

Em última análise, escolher a máquina de corte a laser certa é encontrar o equilíbrio entre custo e funcionalidade, garantindo que você faça um investimento que terá retorno no longo prazo.