Noticias

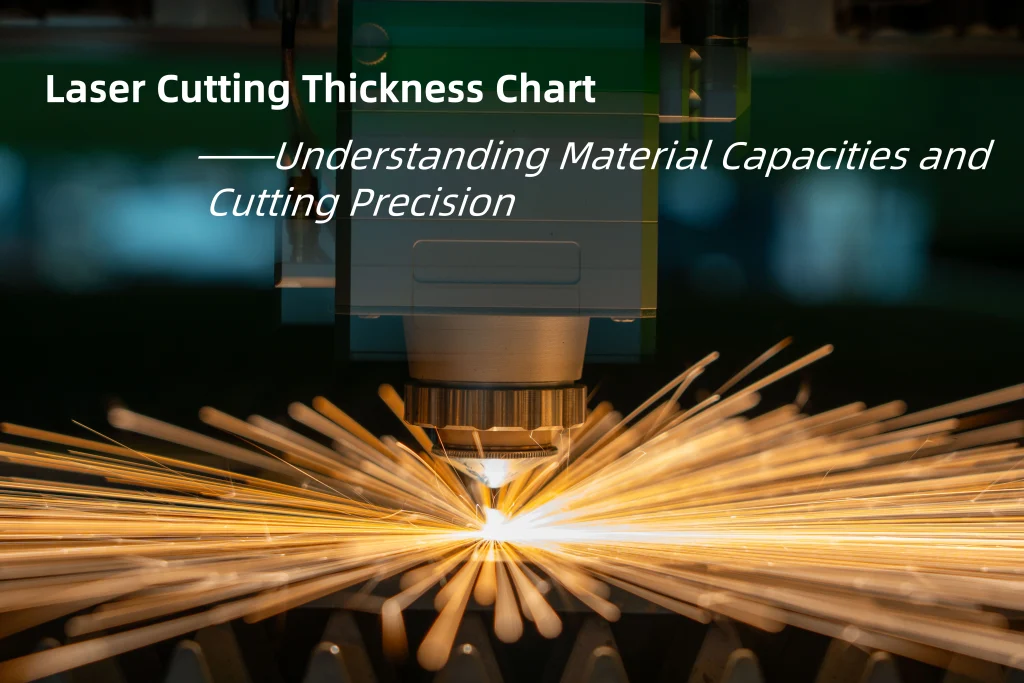

Gráfico de grosor de corte láser: Comprender las capacidades materiales y la precisión de corte

Introducción: Cómo maneja la tecnología de corte por láser el espesor del material

cuando se trata de tabla de espesor de corte por láser, Comprender la relación entre el espesor del material y la tecnología de corte es clave para optimizar la producción.. Ya sea que esté trabajando con acero, aluminio, u otros materiales, Saber cómo los diferentes espesores afectan su proceso de corte por láser es crucial para lograr precisión., reduciendo el desperdicio, y manteniendo la eficiencia.

El corte por láser ha revolucionado la industria manufacturera al ofrecer capacidades de corte de alta precisión., pero cada material viene con su propio conjunto de desafíos. con el derecho máquina de corte por láser y una comprensión de límites de espesor del material, puede garantizar resultados de alta calidad y optimizar sus operaciones.

En este artículo, exploraremos cómo tecnología de corte por láser trabaja con diferentes espesores de material, y brindarle una completa tabla de espesor de corte por láser para guiar tu próximo proyecto.

1. Qué es Corte por láser?

◆ Cómo funciona el corte por láser

El corte por láser es una tecnología utilizada para cortar o grabar materiales mediante un rayo láser.. El proceso consiste en enfocar un láser de alta potencia sobre la superficie de un material., donde se derrite el calor del láser, quemaduras, o vaporiza el material. Este proceso es muy preciso y capaz de crear cortes precisos incluso en geometrías complejas.

El corte por láser suele estar controlado por programas CNC, permitiendo la precisión y la capacidad de hacer cortes intrincados. El sistema puede ajustar la potencia del láser., velocidad, y enfoque para adaptarse a diferentes tipos y espesores de materiales.

2. Gráfico de grosor de corte láser: La clave para comprender las limitaciones materiales

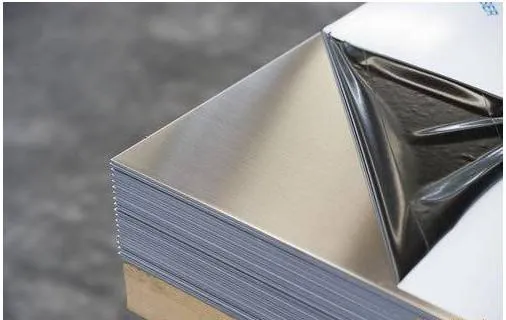

◆ Tabla de espesores de acero para corte por láser

El acero es uno de los materiales más comúnmente cortados mediante tecnología láser.. A continuación se muestra una guía general para corte por láser de acero, basado en niveles de potencia de máquina comunes:

| Tipo de material | espesor | ilustrar |

| Hojas de acero delgadas | (0.5 milímetros – 3 milímetros) | El corte por láser puede manejar estos espesores fácilmente con 1000W a 2000W láseres, proporcionando precisión, Cortes limpios con zonas mínimas afectadas por el calor.. |

| Placas de acero medianas | (4 milímetros – 12 milímetros) | Para este rango de espesor, 2000W a 4000W Por lo general, se requieren láseres para mantener la precisión al cortar el material más grueso.. |

| Placas de acero gruesas | (13 milímetros – 20 milímetros) | Láseres de mayor potencia, como 4000en esto 6000W., Son ideales para cortar placas de acero gruesas., ofreciendo una penetración más profunda y velocidades de corte más rápidas. |

◆ Tabla de espesores de aluminio para corte por láser

El aluminio es más ligero y reflectante que el acero., lo que afecta la forma en que interactúa con el corte por láser. A continuación se muestra una guía básica para corte por láser de aluminio:

| Tipo de material | espesor | ilustrar |

| Hojas delgadas de aluminio | 0.5 milímetros – 3 milímetros | 1000Láseres de W a 2000W Funciona bien para cortar aluminio fino con alta precisión y mínima distorsión.. |

| Placas de aluminio medianas | (4 milímetros – 8 milímetros) | Para aluminio más grueso, 2000W a 4000W láseres son necesarios para lograr cortes de alta calidad. |

| Placas de aluminio gruesas | (9 milímetros – 15 milímetros) | Para cortar placas de aluminio gruesas, 4000W. o láseres más potentes son necesarios para manejar la mayor reflectividad del material.. |

◆ Tabla de espesores de acero inoxidable para corte por láser

El acero inoxidable es un material popular debido a su fuerza y resistencia a la corrosión.. Aquí tienes una guía para corte por láser de acero inoxidable:

| Tipo de material | espesor | ilustrar |

| Acero inoxidable fino | (0.5 milímetros – 3 milímetros) | 1000Láseres de W a 2000W Puede cortar fácilmente acero inoxidable fino con precisión.. |

| Acero inoxidable mediano | (4 milímetros – 8 milímetros) | Para acero inoxidable de espesor medio, 2000Láseres de W a 4000W se utilizan habitualmente para garantizar una limpieza, corte suave. |

| Acero inoxidable grueso | (9 milímetros – 20 milímetros) | Cortar acero inoxidable grueso requiere 4000Láseres de W a 6000W para una penetración adecuada y bordes de alta calidad. |

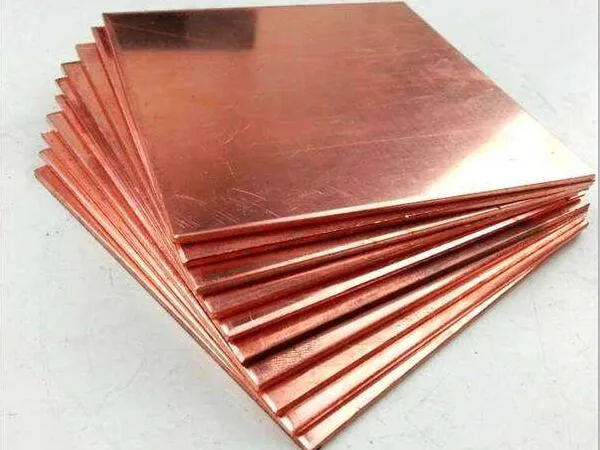

◆ Corte por láser de otros materiales (Plástico, Madera, Cobre, etc.)

La tecnología de corte por láser también se puede utilizar para una variedad de materiales no metálicos.. Así es como se aplica a algunos de ellos.:

| Tipo de material | espesor | ilustrar |

| Plástico | (1 milímetros – 10 milímetros) | Para cortar plastico, 500Láseres de W a 1000W suelen ser suficientes, dependiendo del material y de la velocidad de corte deseada. |

| Madera | (3 milímetros – 15 milímetros) | Láser de CO2 Se utilizan a menudo para cortar madera., y 1000Láseres de W a 3000W Son adecuados para la mayoría de aplicaciones de carpintería.. |

| Cobre | (0.5 milímetros – 6 milímetros) | Cobre, debido a su alta reflectividad, es difícil de cortar. 3000Láseres de W a 5000W Se utilizan normalmente para aplicaciones de corte de cobre.. |

3. Factores que afectan el espesor del corte por láser

◆ Potencia del láser y espesor del material

La potencia del láser influye directamente en la espesor del material que puede cortar eficazmente. Se necesitan láseres de mayor potencia para materiales más gruesos, mientras que los materiales más delgados requieren menos energía. Comprender esta relación es esencial a la hora de seleccionar la máquina correcta para su proyecto..

◆ Tipo de material

El material que se corta también influye significativamente en el proceso de corte por láser.. Materiales como aluminio, cobre, y acero inoxidable requieren diferentes configuraciones de láser debido a su diferente reflectividad, conductividad térmica, y puntos de fusión. Cada tipo de material tiene su óptimo potencia láser y velocidad de corte.

◆ Velocidad y precisión de corte

Para materiales más gruesos, velocidades de corte más lentas puede ser necesario para garantizar la precisión. Sin embargo, esto también puede aumentar zonas afectadas por el calor, que puede afectar la calidad general del corte. Para materiales más delgados, Se pueden utilizar velocidades de corte más rápidas manteniendo la precisión..

4. Cómo elegir la máquina de corte por láser adecuada para sus necesidades

◆ Evalúe sus necesidades materiales

Antes de comprar un máquina de corte por láser, determine los tipos de materiales que cortará y sus respectivos espesores. Esto le ayudará a elegir el correcto potencia láser y capacidad de corte.

◆ Considere la velocidad y precisión de corte

Elija una máquina que equilibre velocidad de corte con precisión. Para industrias que requieren corte de alta velocidad sin sacrificar la calidad, asegúrese de que la máquina que seleccione ofrezca la adecuada configuración de energía para los materiales y espesores involucrados.

◆ Busque funciones avanzadas

Las máquinas de corte por láser modernas vienen con características avanzadas como alimentación automática de material, Optimización impulsada por IA, y monitoreo en tiempo real, todo lo cual puede mejorar su eficiencia y reducir la probabilidad de errores.

Al comprender el tabla de espesor de corte por láser, usted puede tomar decisiones informadas sobre qué máquina de corte por láser elegir para tu negocio. Ya sea que estés cortando acero, aluminio, u otros materiales, Conocer los límites de su equipo y seleccionar la máquina adecuada para sus requisitos de corte específicos lo ayudará a lograr resultados de la más alta calidad..

Historias destacadas

-

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025

Fiber Laser Metal Cutting Machine For Sale05 Dic 2025 -

4000 Láser de vatios | Poder de corte industrial02 Dic 2025

4000 Láser de vatios | Poder de corte industrial02 Dic 2025 -

6 corte por láser kw | guía de precisión industrial28 Nov 2025

6 corte por láser kw | guía de precisión industrial28 Nov 2025 -

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025

Revolucionando la industria con la máquina cortadora láser de tubos de acero25 Nov 2025 -

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

10Corte por láser en kW | Precisión & Fuerza21 Nov 2025

Categorías de productos

- Cortador láser de metales

- Máquina soldadora láser

- Máquina limpiadora láser

- Máquina marcadora láser

- Prensa plegadora