News

Understanding Laser Tube 1000W: Key Features and Benefits

Laser tube 1000W technology is not just a leap forward in cutting precision; it is a game changer in industries ranging from manufacturing to design and medical fields. Imagine being able to cut through thick materials with ease, achieve unparalleled accuracy, and reduce production time—this is the power of a high-performance 1000W laser tube.

But what exactly makes these laser tubes stand out? Why is their demand surging across industries, and what are their benefits? In this comprehensive guide, we’ll dive deep into the technology behind laser tubes, how they are revolutionizing industries, and how they deliver superior performance over traditional cutting methods.

What Is a Laser Tube 1000W?

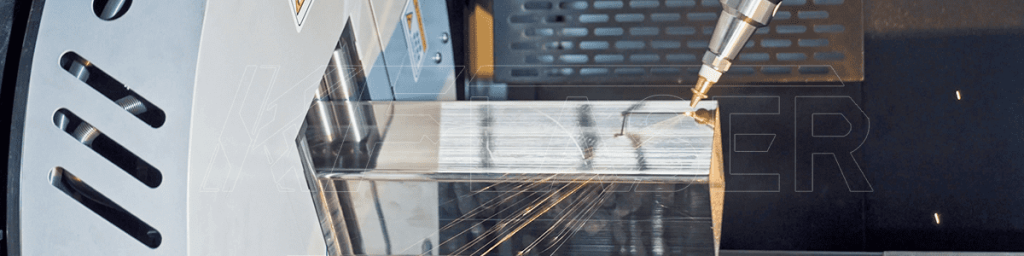

A laser tube 1000W is a high-powered laser device used for cutting, engraving, and marking various materials such as metals, plastics, ceramics, and more. The key feature of a 1000W laser tube is its power output of 1000 watts, which enables it to cut through tougher and thicker materials more effectively than lower-powered lasers.

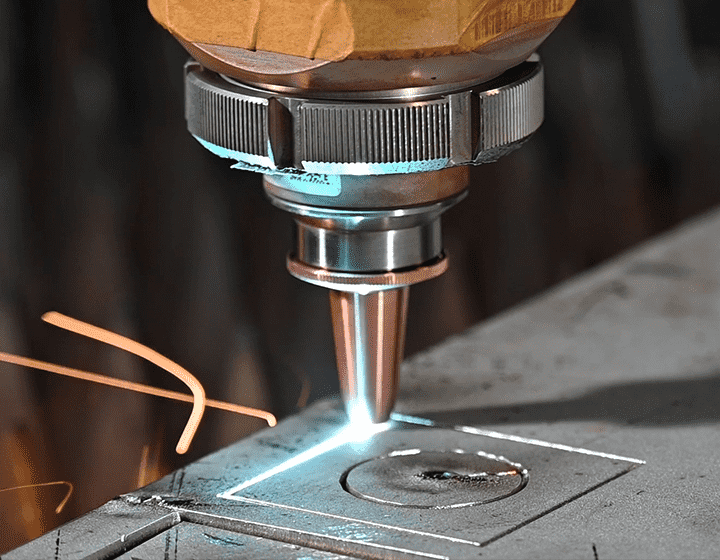

Laser tubes work by focusing laser light into a thin beam. This focused energy can melt, vaporize, or burn away the material in a controlled and precise manner. The power of a 1000W laser tube allows it to cut with high speed and accuracy, making it ideal for applications where both quality and efficiency are paramount.

Key Features of Laser Tube 1000W

High Power Output:

The 1000W power rating ensures that the laser can cut through thick materials quickly and with minimal distortion. Whether it’s stainless steel, acrylic, or wood, a 1000W laser tube can handle a wide range of materials, reducing downtime and increasing production speed.

Precision and Accuracy:

Laser tubes are known for their high precision. The energy is concentrated in a very narrow beam, which allows for extremely fine cuts. Whether you are working with intricate designs or precise measurements, the accuracy provided by a 1000W laser tube is unmatched.

Durability and Longevity:

These tubes are designed to be durable and reliable. With proper maintenance, a 1000W laser tube can last for several years, offering long-term value and consistent performance.

Low Maintenance:

One of the major advantages of using a laser tube 1000W is its relatively low maintenance. Unlike mechanical cutting tools, which can wear down over time, laser tubes require minimal mechanical parts, leading to fewer breakdowns and a lower cost of ownership.

Applications of Laser Tube 1000W

Laser tubes with a power rating of 1000W are incredibly versatile. They are used in a wide variety of industries for different purposes. Here are some of the most common applications:

Metal Fabrication:

The 1000W laser tube is a popular choice for cutting through metals like stainless steel, aluminum, and titanium. It’s used in industries such as automotive manufacturing, aerospace, and construction, where precise and clean cuts are crucial.

Signage and Advertising:

Laser tubes are widely used in the signage industry to create detailed, high-quality signs. The ability to cut complex shapes and logos from various materials, such as acrylic and wood, makes laser tubes ideal for this purpose.

Textile and Leather Cutting:

Laser cutting is often preferred in the textile and leather industries because it offers cleaner edges and more intricate cuts than traditional methods. A 1000W laser tube can efficiently cut through thicker materials, providing high-quality results.

Medical Devices and Equipment:

The precision of laser tubes makes them ideal for the medical industry, where strict tolerances are required. From cutting through surgical instruments to engraving vital information on medical devices, laser tubes have proven indispensable.

Advantages of Using a Laser Tube 1000W

Efficiency and Speed:

With a higher power output, the 1000W laser tube cuts materials faster than its lower-powered counterparts. This leads to reduced production times and improved overall efficiency, which is critical for industries that require rapid turnaround times.

Reduced Material Waste:

Precision cutting means there is less material waste compared to traditional cutting methods. The ability to make exact cuts minimizes scrap material, which can be both cost-saving and environmentally friendly.

Minimal Heat Affected Zone (HAZ):

Unlike conventional cutting methods that create a large heat-affected zone, laser tubes have a very narrow HAZ. This ensures that there is minimal distortion and that the surrounding material remains intact, preserving the quality of the cut.

Versatility:

Laser tubes are incredibly versatile. They can cut through a wide range of materials, from metals to plastics, making them suitable for a variety of industries. Whether you are working with thick or thin materials, a 1000W laser tube can handle it all.

How Does a 1000W Laser Tube Work?

A laser tube works by converting electrical energy into a high-powered light beam, which is then focused onto the material to be cut. The light beam is typically generated by a gas-filled tube, such as CO2, and it is amplified to produce the necessary power.

When the focused beam strikes the material, it melts or vaporizes it, allowing for clean cuts. The cutting process is highly controlled, ensuring that each cut is precise and consistent. The key difference between a 1000W laser tube and lower-powered options is the amount of power being delivered to the material. With more power, the laser tube can cut through thicker materials more efficiently.

The Future of Laser Tube Technology

As industries continue to demand greater efficiency and precision, the technology behind laser tubes, including the 1000W models, will continue to evolve. Innovations in laser technology are expected to lead to even more powerful and efficient lasers that can handle even more challenging materials. We may see advancements in cooling systems, beam quality, and automation, all of which will enhance the capabilities of laser tubes.

Why Invest in a Laser Tube 1000W?

Investing in a 1000W laser tube is an investment in efficiency, precision, and reliability. Whether you are in manufacturing, medical device production, or any other industry that requires accurate cutting, a 1000W laser tube will provide you with a significant edge. The advantages it offers, from faster cutting speeds to minimal maintenance, make it an invaluable tool for businesses looking to stay ahead of the competition.

By incorporating this technology into your operations, you can achieve higher-quality products, reduce production time, and ultimately increase profitability. The 1000W laser tube is a powerful tool that delivers significant benefits in a wide range of industries.

By leveraging the benefits of laser tube 1000W technology, industries can optimize their production processes and achieve remarkable results. Whether cutting thick metals or delicate materials, these tubes represent the future of precision manufacturing. As demand for faster, cleaner, and more accurate cuts grows, laser tube technology is set to be at the forefront of industrial innovation.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine