News

Discover the Power of a Laser That Can Cut Through Steel – Precision and Strength

When we think about cutting through one of the toughest materials known to man—steel—most people wouldn’t consider the possibility of doing so with a laser. But the advent of powerful lasers that can cut through steel has made this a reality. In industries like manufacturing, aerospace, and automotive production, these lasers are becoming indispensable tools. But how exactly do they work, and why are they so effective?

The Technology Behind Laser Cutting Steel

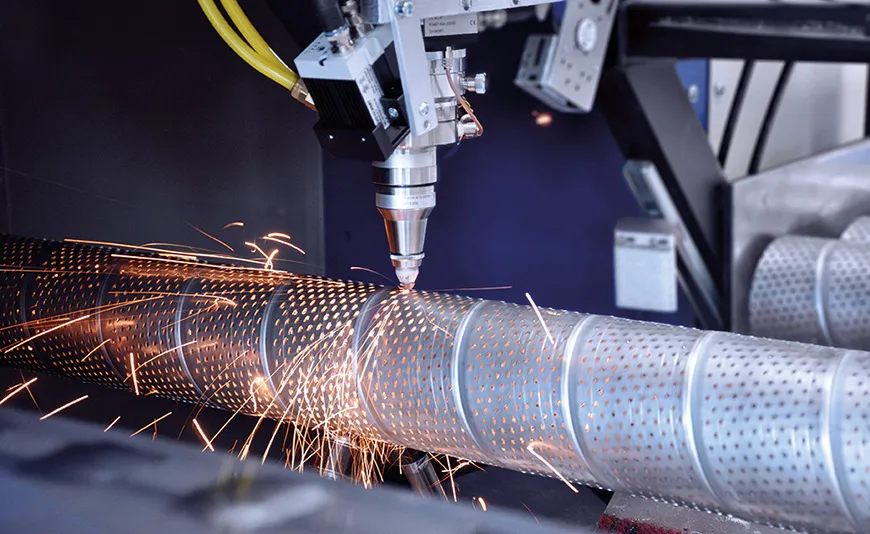

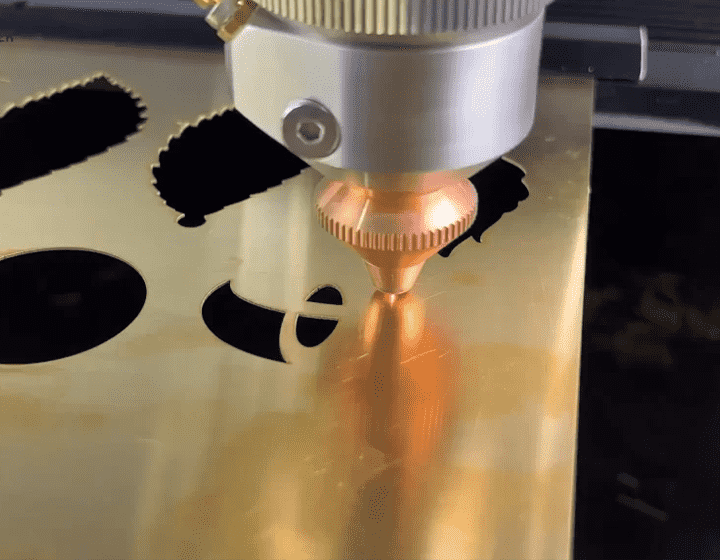

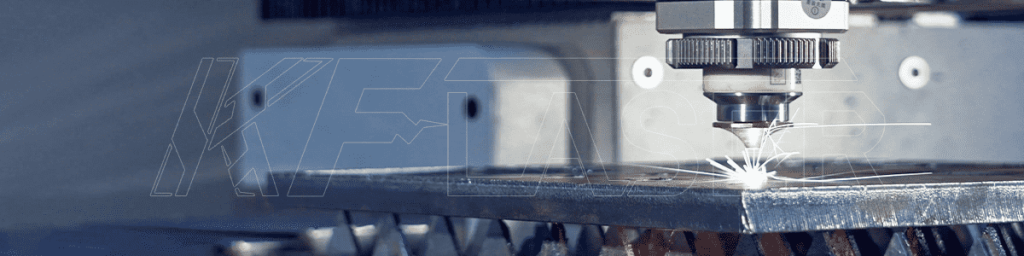

A laser that can cut through steel uses a process known as laser cutting. This technology focuses a high-powered laser beam onto the surface of the steel, where it generates enough heat to melt, burn, or vaporize the material. The beam is typically directed through a high-precision nozzle, often assisted by gases like oxygen or nitrogen to assist the cutting process. What makes this method so precise is the laser’s ability to focus on a very narrow area, making the cut highly accurate with minimal material distortion.

Unlike traditional cutting methods, lasers can achieve cuts that are much finer and cleaner, which can save both time and money. Not only can the laser cut steel at high speeds, but it can also do so with a level of precision that manual cutting tools cannot match.

Types of Lasers That Can Cut Through Steel

Not all lasers are created equal, and different types are used depending on the thickness of the steel and the specific requirements of the task. The most common lasers used for cutting steel include:

CO2 Lasers:

Carbon dioxide lasers are a popular choice for cutting steel. These lasers use a gas mix that is excited to produce a high-powered beam. They work well for cutting thick materials and offer high precision, but they require high maintenance compared to other options.

Fiber Lasers:

Fiber lasers are newer on the market but have rapidly gained popularity for steel cutting due to their efficiency. These lasers are smaller, more compact, and more energy-efficient than CO2 lasers. They also require less maintenance and provide better cutting speed.

Nd:YAG Lasers:

Neodymium-doped yttrium aluminum garnet (Nd:YAG) lasers are another choice for cutting steel. They are used for more specialized applications and tend to be more expensive, but they provide excellent precision and versatility.

Advantages of Laser Cutting Steel

Laser cutting steel provides several benefits over traditional cutting methods:

Precision: Lasers can cut steel with incredibly tight tolerances, allowing for detailed patterns and shapes.

Efficiency: Laser cutting is faster and more efficient, meaning less material is wasted, and less energy is consumed.

Minimal Heat-Affected Zone: Unlike other cutting methods that can deform the steel around the cut, laser cutting minimizes the heat affected zone (HAZ), which results in more accurate cuts with better material properties.

Versatility: A laser that can cut through steel is not limited to just one type of metal. Many lasers can cut through a variety of materials, making them highly versatile tools for different applications.

Industrial Applications of Laser Cutting Steel

Lasers that can cut through steel are used in a variety of industries. Some of the key areas where laser cutting is widely adopted include:

Automotive Manufacturing:

In the automotive industry, lasers are used to cut steel sheets into various shapes for body parts. These cuts are crucial for assembling everything from frames to doors to exhaust systems.

Aerospace:

The aerospace industry relies on precise cuts to fabricate components for airplanes and spacecraft. Laser cutting provides the necessary precision to meet the strict requirements for safety and performance.

Construction:

Steel cutting lasers are used in construction to fabricate structural elements such as beams and columns. The ability to cut these elements quickly and accurately saves both time and money on-site.

Metal Fabrication:

From structural beams to decorative designs, laser cutting is used in the fabrication of a wide range of metal products, ensuring that each piece is cut to exact specifications.

Challenges and Limitations of Laser Cutting Steel

While laser cutting offers many advantages, it also has some challenges and limitations. For instance, the initial cost of laser cutting equipment can be quite high. Additionally, lasers have limitations when it comes to cutting very thick steel, as the laser’s energy becomes less effective at greater thicknesses.

Moreover, although laser cutting produces a clean edge, it may not be suitable for materials that are reflective, such as aluminum, unless special techniques are employed.

Conclusion

The laser that can cut through steel is a game-changer in multiple industries. Its unparalleled precision, efficiency, and versatility make it the tool of choice for manufacturers, engineers, and fabricators. Whether you’re working in automotive, aerospace, construction, or general metal fabrication, understanding the power of laser cutting technology can help you unlock new possibilities for your business.

Laser cutting is no longer a futuristic concept—it’s a present-day reality, and it’s revolutionizing the way we approach manufacturing, design, and fabrication. If you’re looking to enhance your production capabilities, adopting this advanced technology could be the key to unlocking greater productivity and innovation.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine