In today’s fast-paced manufacturing environment, precisión, eficiencia, and flexibility are crucial factors for success. Metal CNC laser cutting machines have become integral tools for businesses looking to meet these demands. These advanced machines combine the power of laser cutting with the accuracy of Computer Numerical Control (CNC) tecnología, revolutionizing the way metal parts are produced.

Whether you’re in the automotive, aeroespacial, electrónica, or architectural industries, CNC laser cutting machines are changing the landscape of metal fabrication. This article will delve into the features, beneficios, and applications of these machines, as well as factors to consider when selecting the right system for your needs.

A metal CNC laser cutting machine combines two cutting-edge technologies: laser cutting and CNC automation.

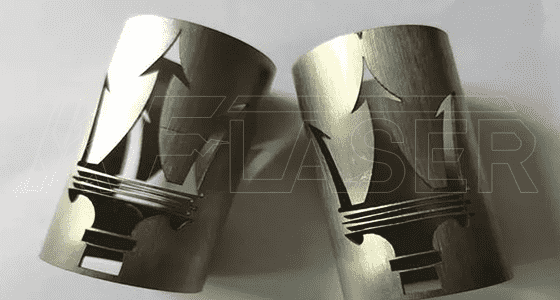

Laser cutting uses a high-powered laser beam to melt, quemar, or vaporize the material along the cut path. This allows for precise, intricate cuts with minimal heat distortion.

CNC (Control numérico por computadora) refers to the automated control of machine tools via a computer system. CNC systems enable high-speed and highly accurate control of the laser’s movements, allowing for repeatable precision and faster production.

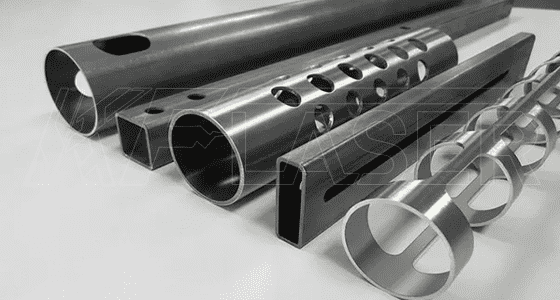

Juntos, these systems enable manufacturers to cut metal sheets, plates, and tubes with a high level of detail and speed. CNC laser cutting machines can cut a wide variety of metals, incluyendo acero inoxidable, aluminio, titanio, y acero al carbono.

Metal CNC laser cutting machines offer a host of benefits over traditional cutting methods. Here’s why many industries are investing in these advanced systems.

One of the most significant advantages of CNC laser cutting is its ability to achieve high precision. With the help of advanced software and CNC programming, these machines can cut with tolerances as tight as ±0.1mm. This level of accuracy is especially crucial in industries like aerospace and electronics, where even minor deviations can lead to expensive defects or safety concerns.

Laser cutting produces smooth, clean cuts with minimal burrs or distortion. Since the heat-affected zone (Cría) is small, there’s little to no warping of the material, which results in a cleaner finish and reduced need for post-processing. Además, laser cutting is highly efficient in terms of material usage, as the narrow cutting path minimizes waste, making it an eco-friendly and cost-effective option.

CNC laser cutting machines are incredibly versatile and can cut a variety of metals, incluyendo acero inoxidable, aluminio, latón, cobre, y acero al carbono. These systems are also effective for cutting materials of varying thicknesses, desde láminas finas hasta placas más gruesas, making them suitable for a wide range of applications.

A diferencia de los métodos de corte tradicionales, which may require multiple steps or tool changes, CNC laser cutting is highly automated and can run continuously with little downtime. The high-speed capabilities of CNC laser machines mean that production times are reduced, mejorando la eficiencia general. This is particularly beneficial for large production runs or when quick turnaround times are essential.

CNC laser cutting systems require less manual intervention than traditional methods, making them more efficient in terms of labor costs. Operators mainly need to program the machine and monitor the process, significantly reducing the need for skilled labor. This also lowers the potential for human error, contributing to overall process consistency.

Metal CNC laser cutting machines come in various types, each suited to different applications and materials. Here’s a breakdown of the most common systems:

Fiber lasers have gained immense popularity in recent years due to their efficiency and superior cutting quality. These systems use a fiber optic cable to generate the laser beam, which is then focused onto the material. Fiber lasers are particularly effective for cutting thin to medium-thick metals, such as stainless steel and aluminum, with high speed and precision. They are energy-efficient and have lower operating costs compared to traditional CO2 lasers.

CO2 laser cutting machines are one of the oldest and most commonly used laser technologies. These systems generate a laser beam using a CO2 gas mixture, which is then amplified and directed onto the material. CO2 lasers are ideal for cutting thick metals and non-ferrous materials, such as brass and copper. While they are not as fast or energy-efficient as fiber lasers, they remain a reliable option for many applications.

Hybrid systems combine both fiber and CO2 laser technologies, allowing manufacturers to leverage the benefits of both. These machines can be especially beneficial for cutting a variety of metal types and thicknesses without the need for multiple machines.

CNC laser cutting machines are widely used across a variety of industries due to their versatility, precisión, y velocidad. Aquí hay algunas aplicaciones comunes.:

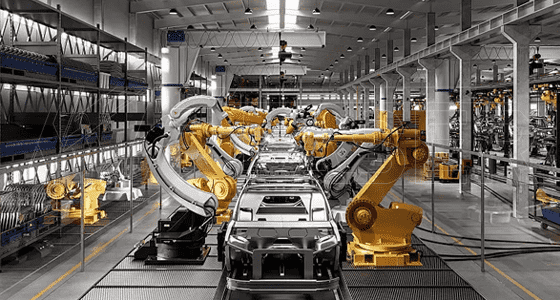

Laser cutting is essential in automotive manufacturing, where precision and speed are critical. CNC laser machines are used to cut car body parts, paréntesis, y componentes estructurales. The high accuracy of the cuts ensures that the parts fit together seamlessly, meeting the stringent requirements for safety and performance.

En la industria aeroespacial, parts must be lightweight, durable, y preciso. CNC laser cutting machines help produce complex parts for aircraft, such as fuselage panels, wing components, and turbine blades, ensuring they meet the strict tolerances required for performance and safety.

CNC laser cutting is used to create intricate designs for metal panels, gates, facades, and structural components in the construction and architecture sectors. The ability to produce custom patterns with high precision makes laser cutting ideal for creating aesthetically pleasing yet functional pieces.

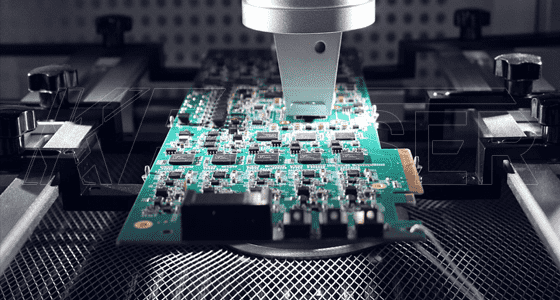

In the electronics industry, laser cutting machines are used to produce circuit boards, conectores, and components for devices like smartphones, computers, and medical equipment. The ability to cut fine, intricate patterns in metal ensures the quality and reliability of these critical components.

Metal CNC laser cutting machines are commonly used in general metalworking and fabrication. These machines allow manufacturers to produce custom metal parts for various applications, including machinery, equipment, y elementos decorativos. Laser cutting provides high precision and minimal waste, which is especially important when working with high-value metals.

Selecting the right CNC laser cutting machine for your needs involves several key factors:

Different machines are better suited for specific materials and thicknesses. Fiber lasers are typically more efficient for cutting thinner metals, mientras que los láseres de CO2 son mejores para materiales más gruesos. Be sure to choose a machine that can handle the specific materials and thicknesses you plan to cut.

If high-speed production is essential for your business, consider the cutting speed of the machine. Fiber laser machines are typically faster than CO2 lasers, particularly for thinner materials, so they may be a better fit for fast-paced manufacturing environments.

The level of precision required for your applications is another crucial consideration. CNC laser cutting machines can achieve extremely tight tolerances, but some systems may offer better performance depending on the material and thickness.

While the initial investment in CNC laser cutting machines can be significant, their long-term operating costs are usually lower than traditional methods due to minimal material waste, reduced labor requirements, and faster production speeds. Always consider factors like energy consumption and maintenance when calculating the total cost of ownership.

Look for CNC laser cutting systems that offer advanced features such as automation, multi-axis cutting, e integración con software CAD/CAM. These features can improve efficiency, reduce downtime, and allow for more complex designs and cuts.

la demanda de metal CNC laser cutting machines is expected to continue growing, driven by advancements in laser technology, automation, and material science. As industries push for greater efficiency, precisión, y versatilidad, laser cutting technology will remain a vital tool in modern manufacturing.

By investing in the right CNC laser cutting system, manufacturers can ensure high-quality production, reduce material waste, and streamline their operations, helping them stay competitive in a rapidly changing market.