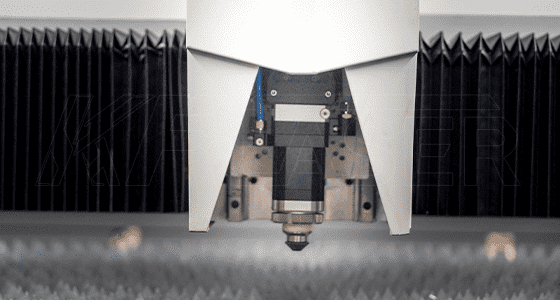

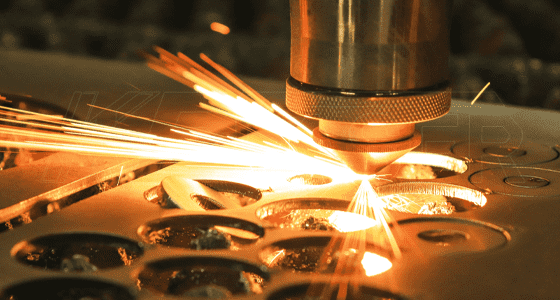

La tecnología de corte por láser se ha vuelto indispensable para industrias donde la precisión y la velocidad son primordiales. Entre los muchos tipos de máquinas de corte por láser disponibles, máquinas de corte por láser de metales han ganado una tracción significativa debido a su capacidad para cortar una variedad de metales con una precisión incomparable. Ya sea que esté involucrado en la fabricación aeroespacial, producción automotriz, o aplicaciones industriales, Comprender la tecnología y sus beneficios es crucial para optimizar sus procesos de producción..

A máquina de corte por láser de metales es un tipo de CNC (Control numérico por computadora) Máquina que utiliza rayos láser de alta potencia para cortar materiales metálicos.. Esta tecnología utiliza un rayo láser enfocado, típicamente un láser de fibra o Láser de CO2, derretirse, quemar, o vaporizar el material. El proceso garantiza una fluidez, cortes precisos con mínima distorsión, haciéndolo ideal para formas complejas y diseños intrincados.

Las máquinas de corte por láser de metales se utilizan comúnmente para cortar metales como el acero., acero inoxidable, aluminio, latón, cobre, y titanio, ofreciendo una calidad de corte superior en comparación con los métodos de corte mecánico tradicionales.

Al seleccionar una máquina de corte por láser de metal, Es esencial comprender las características críticas que diferencian estas máquinas.. Estas características no sólo mejoran el rendimiento sino que también garantizan la longevidad y eficiencia de la máquina en entornos industriales..

La distinción más significativa en las máquinas de corte por láser de metales radica en el tipo de láser utilizado.:

Láser de fibra: Conocidos por su eficiencia energética superior, velocidades de corte más rápidas, y capacidad para cortar metales más gruesos, Los láseres de fibra son ideales para aplicaciones de alta precisión y gran volumen..

Láser de CO2: Si bien los láseres de CO2 son menos eficientes que los láseres de fibra, Siguen siendo eficaces para cortar una amplia gama de metales., láminas de material especialmente delgadas.

Las máquinas de corte por láser de metales son conocidas por su precisión y velocidad.. Con control CNC avanzado, Estas máquinas pueden cortar formas complejas con un mínimo desperdicio de material y tolerancias estrictas.. La velocidad de corte depende del tipo de material., espesor, y potencia del láser, pero en general, Las cortadoras láser ofrecen velocidades de corte más rápidas en comparación con los métodos mecánicos tradicionales..

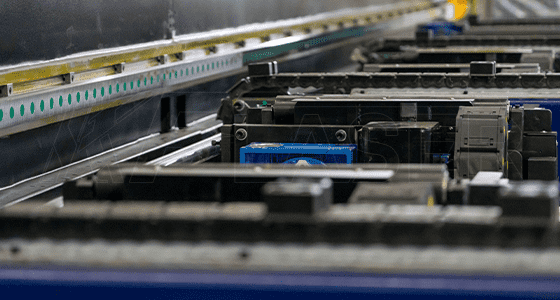

Muchos modernos máquinas de corte por láser de metales vienen con funciones automatizadas como sistemas de carga/descarga de material, optimización de la ruta de corte, y diagnóstico remoto. Estas características aumentan la eficiencia operativa y reducen la probabilidad de error humano durante el proceso de producción..

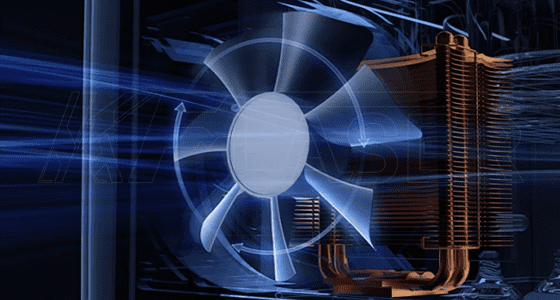

El proceso de corte genera una cantidad considerable de calor., por eso es eficiente sistemas de enfriamiento son cruciales. La mayoría de las cortadoras láser de metal vienen con mecanismos de enfriamiento integrados para regular la temperatura y evitar el sobrecalentamiento.. Además, un efectivo sistema de escape Es necesario eliminar los gases y humos generados durante el corte., garantizar un entorno de trabajo seguro.

la demanda de máquinas de corte por láser de metales ha aumentado debido a los múltiples beneficios que ofrecen sobre los métodos de corte convencionales.. Estas son las principales ventajas.:

El corte por láser proporciona un nivel de precisión que es difícil de lograr con los métodos de corte mecánico tradicionales.. El rayo láser enfocado produce imágenes nítidas., Bordes limpios con zonas mínimas afectadas por el calor. (Cría), asegurando que incluso los diseños más complejos se ejecuten perfectamente.

Una de las ventajas más importantes de las máquinas de corte por láser de metales es su versatilidad. Estas máquinas pueden manejar varios metales., incluyendo acero inoxidable, aluminio, latón, y acero al carbono. Además, Se pueden utilizar para cortar láminas finas o gruesas., haciéndolos adecuados para una amplia gama de aplicaciones en múltiples industrias.

El corte láser es un proceso sin contacto, lo que significa que hay un desgaste mínimo en la máquina, y el material permanece intacto sin deformarse. Esta característica sin contacto también reduce el desperdicio de material porque el láser puede seguir trayectorias de corte muy estrechas., dejando poca o ninguna chatarra.

El corte por láser es más rápido que los métodos de corte tradicionales. El proceso de corte de alta velocidad reduce el tiempo del ciclo., lo que lo convierte en una opción ideal para los fabricantes que necesitan satisfacer demandas de producción de gran volumen. Con opciones avanzadas de automatización, las empresas pueden lograr una eficiencia de producción aún mayor.

Porque el corte por láser produce bordes lisos, la necesidad de posprocesamiento, como desbarbar o pulir, a menudo se minimiza. Esto reduce los costos de mano de obra y acelera el proceso de producción general..

La tecnología de corte por láser de metales se utiliza en diversas industrias donde la precisión, velocidad, y la calidad son cruciales. Aquí hay algunas aplicaciones comunes.:

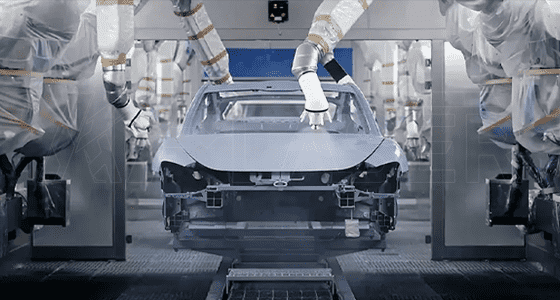

El sector del automóvil requiere un corte preciso de piezas de chapa para carrocerías, sistemas de escape, y piezas del motor. Las máquinas de corte por láser brindan la precisión y velocidad necesarias para cumplir con las estrictas tolerancias en la producción de componentes automotrices..

La fabricación aeroespacial implica trabajar con materiales como el titanio., aluminio, y acero. Estos metales requieren cortes complejos y alta precisión., haciendo máquinas de corte por láser de metales la opción ideal para cortar componentes de aviones como soportes, paneles, y piezas estructurales.

El corte por láser también se utiliza ampliamente en el construcción y arquitectura industrias para crear diseños complejos en metales para fachadas de edificios, barandillas, y elementos decorativos. La capacidad de cortar patrones complejos con alta precisión permite a los diseñadores superar los límites creativos..

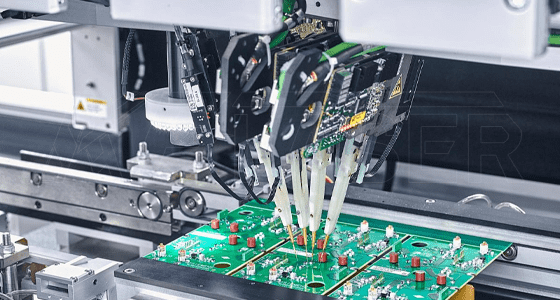

El corte por láser se utiliza para cortar piezas metálicas utilizadas en dispositivos electrónicos., incluyendo conectores, placas de circuito, y viviendas. La precisión y velocidad del corte por láser garantizan que estos componentes cumplan con los estándares requeridos de funcionalidad y rendimiento..

en el sector industrial, Las máquinas de corte por láser de metal se utilizan para fabricar piezas para maquinaria., herramientas, y equipo. Su capacidad para manejar láminas de metal gruesas manteniendo tolerancias estrictas es especialmente valiosa en la producción de piezas que requieren durabilidad y resistencia..

Al decidir por la derecha máquina de corte por láser de metales para tu negocio, hay que tener en cuenta varios factores. Estos incluyen:

Compatibilidad de materiales: Asegúrese de que la máquina pueda manejar los tipos de metales que planea cortar.. Algunas máquinas funcionan mejor con ciertos metales, por lo que es posible que tengas que elegir uno según los materiales con los que estás trabajando.

Potencia y velocidad de la máquina: Las máquinas vienen con diferentes potencias, normalmente oscila entre 500W y 15kW. Las potencias más altas permiten un corte más rápido de materiales más gruesos, pero puede no ser necesario para metales de calibre más ligero..

Integración de software: La máquina de corte debe ser compatible con el software que utiliza para diseñar sus piezas.. Una buena integración garantiza una comunicación perfecta entre el software de diseño y la máquina de corte., Reducir errores y mejorar la productividad..

Mantenimiento y soporte: Como cualquier máquina industrial, Las máquinas de corte por láser de metal requieren un mantenimiento regular.. Elija un fabricante que ofrezca un sólido soporte posventa, capacitación, y servicios de mantenimiento.

Presupuesto: Finalmente, Equilibre las capacidades deseadas de su máquina con su presupuesto.. Las máquinas de corte por láser tienen diferentes precios según su potencia., características, y marca. Asegúrese de que la máquina que elija ofrezca el mejor valor por su inversión.

A medida que las industrias continúan evolucionando, la demanda de avanzada máquinas de corte por láser de metales probablemente aumentará. Nuevas tecnologías, como Sistemas de corte impulsados por IA y corte por láser multimaterial, Se espera que impulsen la innovación en el campo., mejorando aún más la precisión, eficiencia, y automatización. Estos avances prometen hacer que el corte por láser sea aún más versátil, eficiente, y asequible para fabricantes de todo el mundo.

Al adoptar estas innovaciones, Las empresas pueden seguir siendo competitivas y seguir satisfaciendo las demandas cada vez mayores de la fabricación moderna..