Notícias

Laser de corte de tubo: Revolucionando a precisão na fabricação tubular

★Imagine a machine so precise it slices through metal pipes as if they were paper, shaping them into intricate forms with unmatched accuracy. Envision a tool that doesn’t just cut but also streamlines production, reduces waste, and brings efficiency to the forefront. This isn’t science fiction—it’s the power of pipe cutting laser technology, an innovation that has transformed industries reliant on tubular fabrication.

From construction to automotive, furniture to aerospace, pipe cutting lasers are the backbone of modern manufacturing, delivering precision and versatility at an unprecedented scale.

1.What is Pipe Cutting Laser Technology?

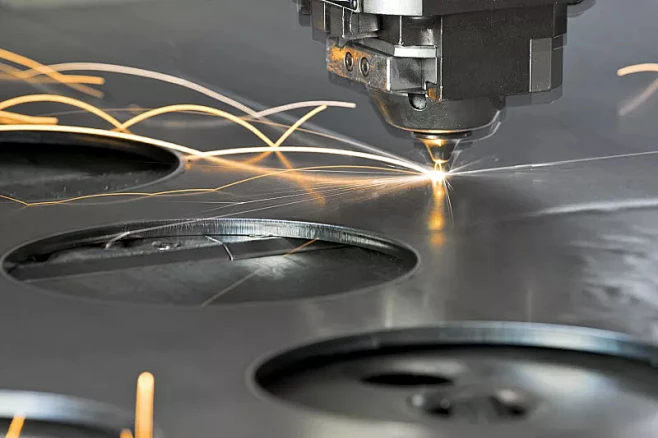

Pipe cutting laser technology uses a highly focused laser beam to cut, forma, or engrave metal pipes and tubes. Unlike traditional mechanical methods, this process is non-contact, ensuring clean cuts, minimal distortion, and exceptional repeatability.

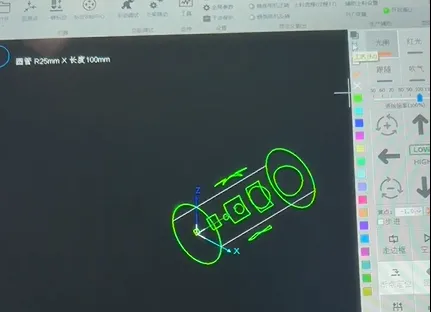

The system typically involves:

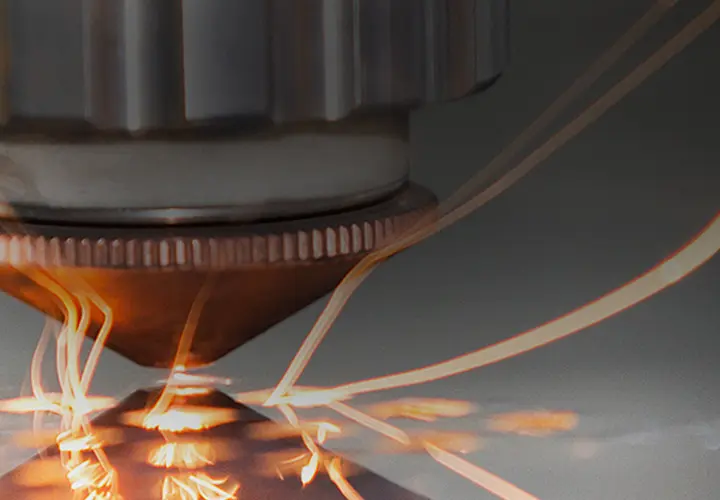

– A Laser Source: Generates the intense beam of light.

– Cutting Head with Rotation Capability: Ensures precise movement around cylindrical shapes.

– Assist Gases: Helps clear molten material and improve edge quality.

– Software de controle: Guides the cutting process with CAD-based designs.

This combination of advanced components enables pipe cutting lasers to handle complex geometries, multiple materials, and various wall thicknesses.

2.The Advantages of Using a Pipe Cutting Laser

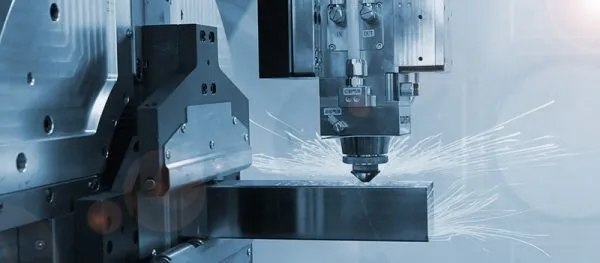

1. Precision That Shapes the Future

Pipe cutting laser machines are synonymous with accuracy. They can achieve tight tolerances, ensuring that every cut aligns perfectly with design specifications. Este nível de precisão é crucial para indústrias como aeroespacial, where even the smallest deviations can compromise safety and performance.

2. Speed Without Sacrificing Quality

Time is a critical factor in manufacturing. Pipe cutting lasers deliver unparalleled cutting speeds, reducing production times significantly. High-speed processing doesn’t compromise on quality, making it possible to meet tight deadlines without sacrificing precision.

3. Complex Designs Made Simple

With the ability to cut intricate patterns, chamfers, notches, and custom openings, laser technology excels at creating complex geometries. Designers have the freedom to innovate without the constraints of traditional methods.

4. Versatility Across Materials

Pipe cutting lasers are compatible with a wide range of materials, Incluindo:

– Aço inoxidável

– Aço carbono

– Alumínio

– Cobre

– Latão

This versatility makes them indispensable across diverse industries.

5. Desperdício mínimo, Maximum Efficiency

Laser technology optimizes material usage by delivering precise cuts. The clean edges and minimal distortion reduce the need for additional finishing processes, saving both time and resources.

6. Automation and Scalability

Pipe cutting lasers integrate seamlessly with automation systems, enabling batch processing and consistent quality. Their scalability makes them suitable for small workshops and large-scale industrial facilities alike.

3.Applications of Pipe Cutting Laser Technology

1. Construção e infraestrutura

Pipe cutting lasers are extensively used in structural applications, producing steel frameworks, support beams, and piping systems. Their ability to handle large diameters and thick walls ensures robust and reliable components.

2. Automotive and Aerospace

From roll cages to exhaust systems, laser-cut pipes are integral to lightweight, high-performance designs in the automotive and aerospace sectors. The precision of laser technology meets the stringent demands of these industries.

3. Furniture and Design

Innovative furniture designs often rely on tubular structures. Laser cutting enables the creation of unique patterns and shapes, elevating aesthetic appeal while maintaining structural integrity.

4. Energy and Utilities

In energy production, laser technology is used to fabricate piping for oil, gas, and renewable energy projects. The precise cuts ensure efficient flow and reliable performance in critical applications.

5. Equipamento Médico

The medical industry uses laser-cut pipes in surgical instruments, implantes, and diagnostic tools. Precision and cleanliness are paramount, and laser technology delivers on both fronts.

6. Shipbuilding and Marine

Pipe cutting lasers are essential in constructing marine vessels, creating pipes and components that resist corrosion and perform under extreme conditions.

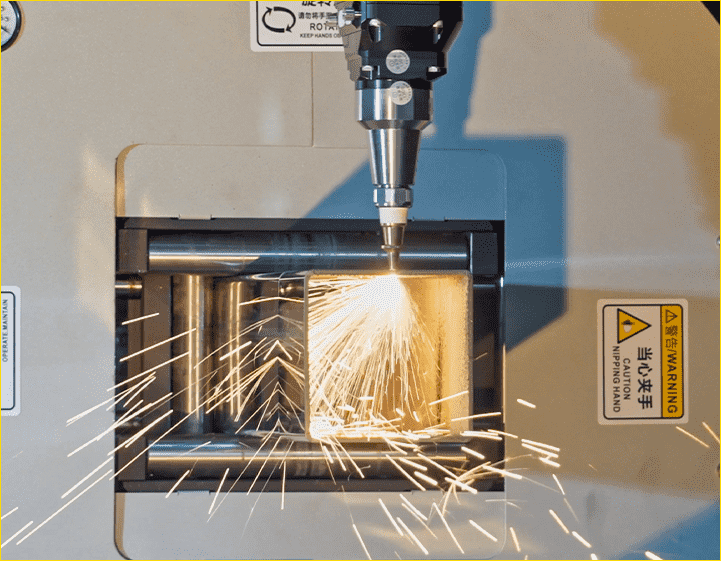

4.How Pipe Cutting Laser Technology Works

1. Design and Programming

The process begins with a CAD design that outlines the required cuts and patterns. The design is uploaded to the machine’s software, which guides the cutting path.

2. Configuração de materiais

The pipe or tube is securely positioned on a rotating chuck, allowing the laser head to move around its circumference.

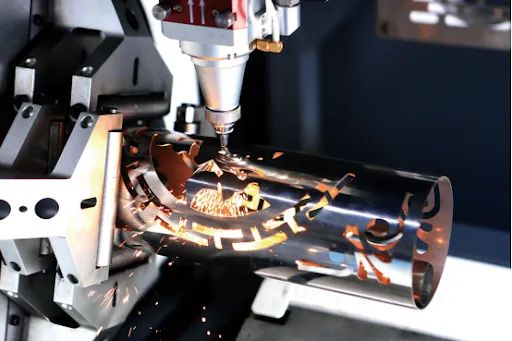

3. Corte a laser

The laser beam focuses on the material, heating and vaporizing it to create precise cuts. Assist gases clear molten material and enhance edge quality.

4. Controle de qualidade

Once the cutting is complete, the piece undergoes inspection to ensure it meets specifications. The clean edges and precision often eliminate the need for post-processing.

☟ The following is a video of cutting a carbon steel round tube with a diameter of 280mm and a thickness of 4mm.

5.Fibra versus. Lasers de CO2: Which is Best for Pipe Cutting?

- Lasers de fibra

Fiber lasers are ideal for cutting reflective metals like aluminum and copper. They are more energy-efficient and deliver higher cutting speeds, making them a popular choice for industrial applications.

- Lasers de CO2

CO2 lasers excel at cutting non-metal materials but are also effective for thicker metal pipes. They are often used in applications requiring smooth finishes.

6.Choosing the Right Pipe Cutting Laser

1. Compatibilidade de materiais

Ensure the machine can handle the materials you frequently work with, including their thickness and reflectivity.

2. Diameter and Length Capabilities

Consider the range of pipe sizes the machine can accommodate. Larger projects may require machines with extended cutting beds and higher power outputs.

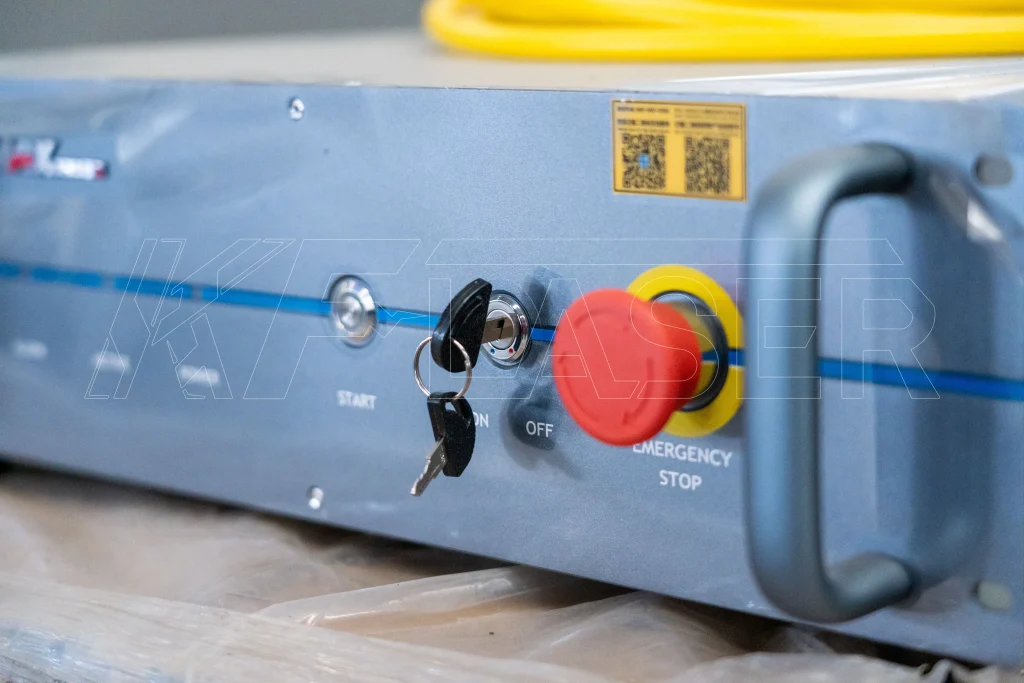

3. Software e Automação

Look for machines with intuitive software and automation features that simplify operation and increase efficiency.

4. Manutenção e Suporte

Partner with a trusted provider like Laser kf for reliable customer support and minimal downtime.

7.The Future of Pipe Cutting Laser Technology

1. Sistemas orientados a IA

Artificial Intelligence will enable real-time adjustments, manutenção preditiva, and smarter automation, further enhancing efficiency.

2. Expanded Material Options

Advancements in laser technology will enable cutting of more exotic materials and composites.

3. Portability

Compact and portable laser systems will empower small businesses and remote projects without sacrificing precision.

4. Hybrid Machines

Combining laser cutting with other fabrication methods, such as 3D printing or engraving, will offer multi-functional solutions

8.Why Choose KF LASER for Pipe Cutting?

Laser kf has established itself as a leader in laser cutting technology. Their pipe cutting systems combine precision, velocidade, e versatilidade, empowering businesses to achieve their goals efficiently. With advanced features, user-friendly interfaces, and robust support, KF LASER is the trusted choice for industries worldwide.

*Conclusão: Elevate Your Fabrication Process

Pipe cutting laser technology isn’t just a tool—it’s a revolution in how industries approach tubular fabrication. Its precision, velocidade, and versatility open up endless possibilities, from creating robust infrastructure to designing intricate furniture.

Com laser KF, you can unlock the full potential of laser technology. Whether you’re building skyscrapers or crafting bespoke designs, pipe cutting lasers will help you achieve excellence. Step into the future of manufacturing, where light shapes the world. The possibilities are limitless—embrace them today.

Notícias principais

-

Fiber Laser Metal Cutting Machine For Sale05 Dec 2025

Fiber Laser Metal Cutting Machine For Sale05 Dec 2025 -

4000 Watt Laser | Industrial Cutting Power02 Dec 2025

4000 Watt Laser | Industrial Cutting Power02 Dec 2025 -

6 corte a laser kw | Guia de precisão industrial28 novembro 2025

6 corte a laser kw | Guia de precisão industrial28 novembro 2025 -

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025

Revolucionando a indústria com máquina de corte a laser para tubos de aço25 novembro 2025 -

10Corte a laser kW | Precisão & Poder21 novembro 2025

10Corte a laser kW | Precisão & Poder21 novembro 2025

Categorias de produtos

- Cortador a laser de metal

- Máquina de solda a laser

- Máquina de limpeza a laser

- Máquina marcadora a laser

- Máquina de freio de imprensa