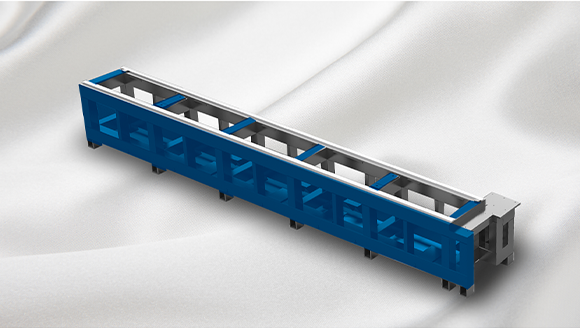

Modelo de máquina | TS62 seris | TS72 series | TS82 serie |

Área de trabajo | 6000milímetros&20-220milímetros | 7000milímetros&20-220milímetros | 8000milímetros&20-220milímetros |

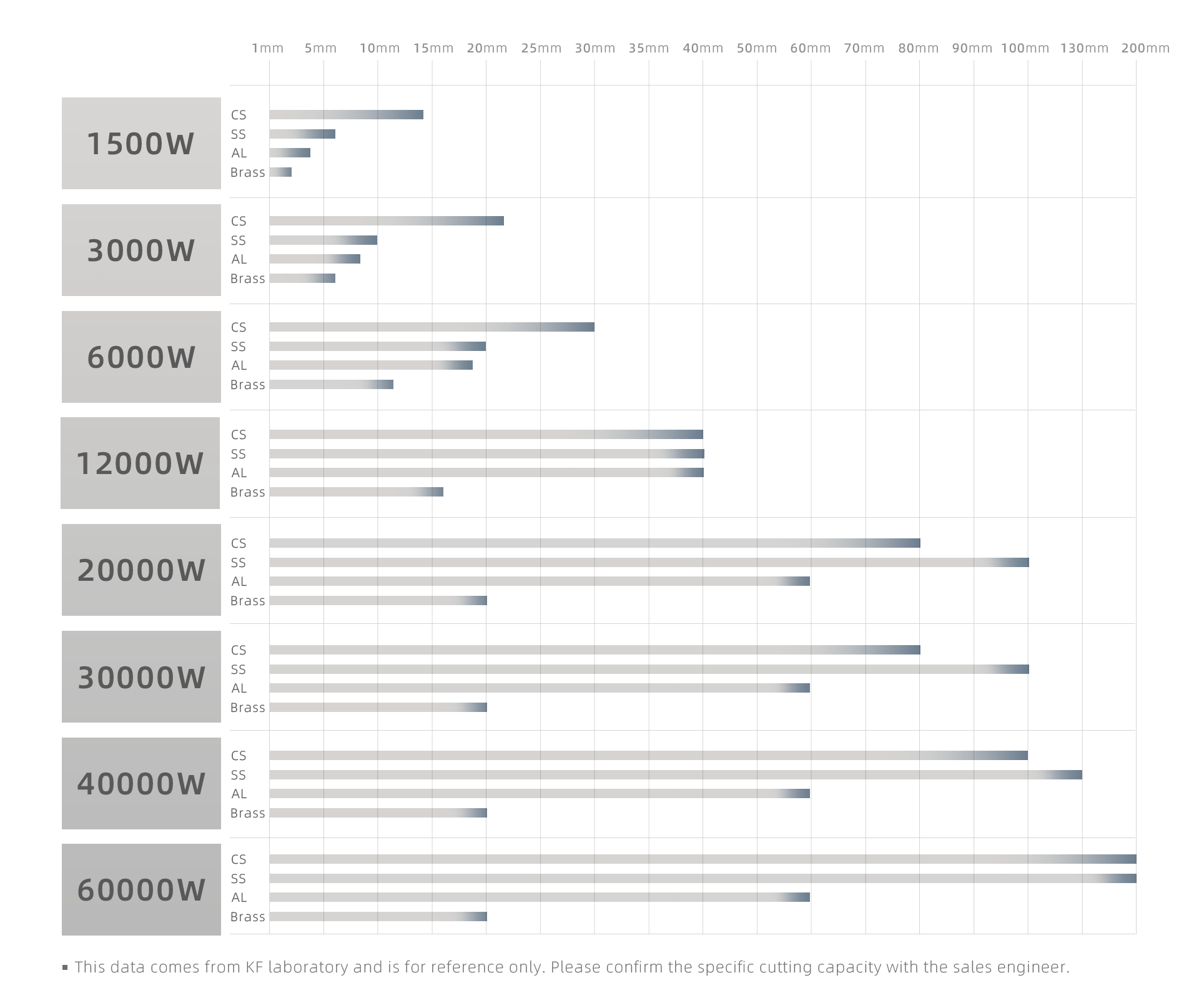

Potencia del láser | 1-6kilovatios | 1-6kilovatios | 1-6kilovatios |

Dimensión | 11230*2021*2133milímetros | 12000*2021*2136milímetros | 13000*2021*2139milímetros |

Peso | 2500kilos | 4000kilos | 7500kilos |

Velocidad máxima de funcionamiento en ralentí(m/min) | 100m/min-120m/min | ||

Aceleración máxima en ralentí(GRAMO) | 1.0GRAMO | ||

Precisión de posicionamiento del eje X/Y/mm | ±0,05 mm | ||

Precisión de posicionamiento repetido/mm | ±0,03 mm | ||

Precisión de corte/mm | ≤0,1 mm | ||

Voltaje de trabajo | 380V,trifásico /50Hz-60Hz | ||

Formatos de imagen soportados | LXD/.DXF/.PLT/.AI/.Gerber/.DWG | ||

A: Para recomendarle el modelo de máquina más adecuado, solo díganos la información a continuación

1)cual es tu materia

2)El tamaño del material

3)El espesor del material

4)Cortadora láser de fibra para metal.

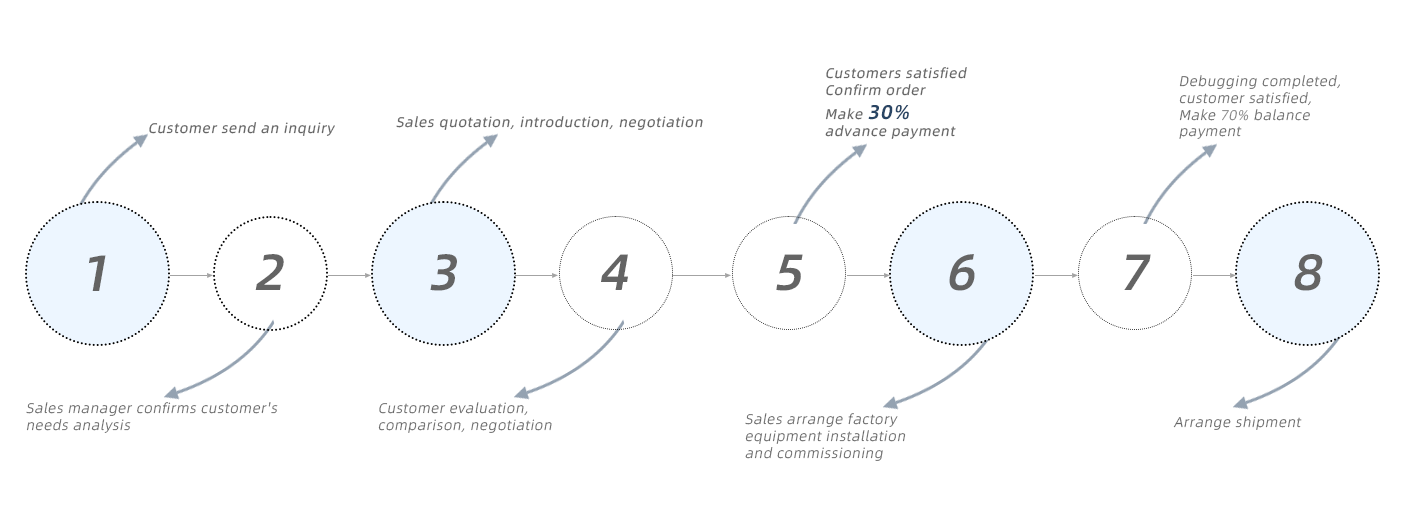

A:1)Garantía comercial de Alibaba/TT/West Union/Payple/LC/Cash, etc..

2)Empezamos a fabricar máquinas estandarizadas después de recibir 30% del pago, Inspeccionar las máquinas una vez finalizadas., y finalmente recoger el 70% saldo antes del envío.

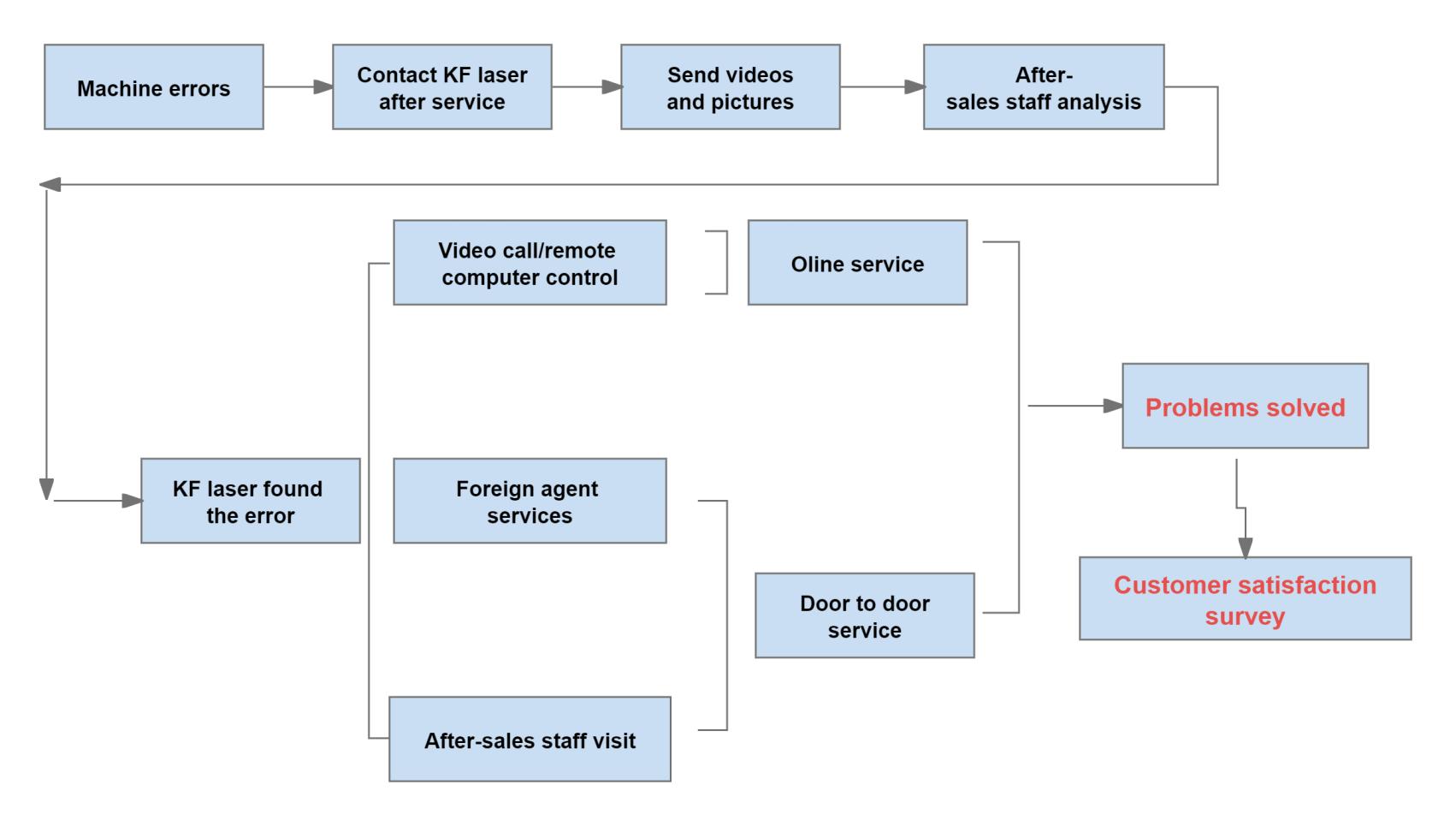

A:1)Ofrecemos formación gratuita en nuestra fábrica.

2)Ofrecemos servicio postventa en línea gratuito.

3)Contamos con instrucciones completas de instalación y videotutoriales.

4)Los cargos por servicio puerta a puerta se basan en la región y el modelo de avión.

5)Proporcionar garantía de tres años., excepto piezas consumibles, reemplazo directo por daño no humano

1):Limpiar la lente óptica.: Limpie la lente óptica con regularidad para mantener la calidad del haz..

2):Comprobar el suministro de gas: Asegúrese de que el sistema de suministro de gas sea normal para evitar que la calidad del corte se vea afectada..

3):Lubricar las piezas móviles.: Lubrique los rieles guía y el tornillo de avance con regularidad para garantizar el buen funcionamiento de las piezas móviles..

4):Reemplace el agua purificada del enfriador cada mes. Si hace bajo cero en invierno, recuerda agregar anticongelante.

Fiber Laser Cutter for Metal: The Ultimate Tool for Precision and Efficiency

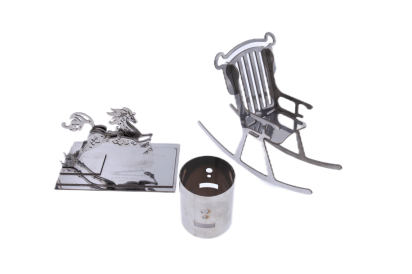

A fiber laser cutter for metal is a revolutionary tool in the manufacturing and fabrication industries. It leverages advanced laser technology to deliver high precision, velocidad, y eficiencia, transforming how metal cutting is performed. This comprehensive guide will explore the workings, aplicaciones, and advantages of fiber laser cutters for metal, ensuring you understand why they are indispensable in modern manufacturing.(Cortadora láser de fibra para metal.)

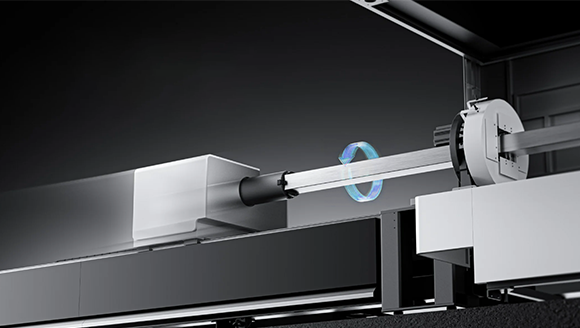

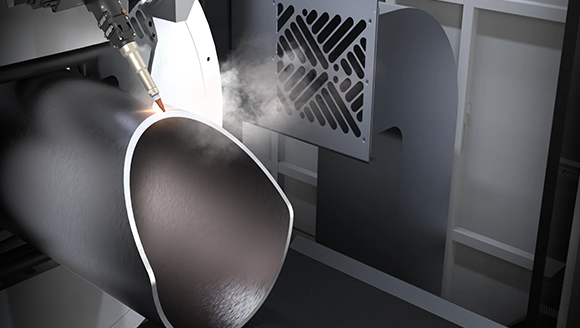

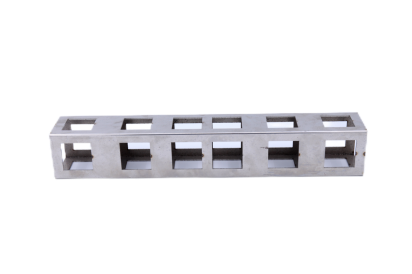

A fiber laser cutter for metal utilizes a highly focused laser beam to melt and cut through metal materials. This process is facilitated by the use of optical fibers as the gain medium, which amplifies the light and directs it to the cutting head. The concentrated laser beam is then used to cut through various metals with incredible precision and speed.

The operation of a fiber laser cutter for metal begins with a laser diode emitting light, which is then sent through a fiber optic cable to be amplified. This amplified laser beam, with its high intensity, strikes the metal surface, where it is absorbed and converted into heat. This heat melts the metal, and a high-speed airflow blows away the molten material, creating a precise cut.

Fiber laser cutters for metal are used in various industries due to their precision and efficiency. Some key applications include:

When choosing the best fiber laser cutter for metal, Se deben considerar varias características para garantizar que satisfaga sus necesidades específicas.:

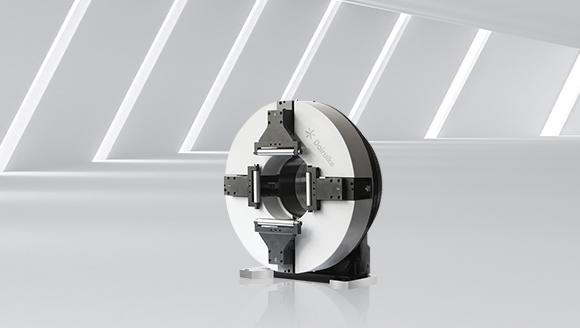

Fiber laser cutters for metal come in various configurations, each suited to specific applications:

Proper maintenance and operation are crucial for ensuring the long-term performance of fiber laser cutters for metal:

The future of fiber laser cutters for metal is bright, with ongoing advancements promising even greater capabilities:

Fiber laser cutters for metal are indispensable tools in modern manufacturing, ofreciendo una precisión incomparable, velocidad, y versatilidad. From automotive and aerospace to electronics and jewelry making, these machines are revolutionizing how metal cutting is performed. Entendiendo las características clave, aplicaciones, and maintenance tips, you can select the best fiber laser cutter for your needs and stay ahead in the competitive world of metal fabrication. A medida que la tecnología continúa avanzando, the potential of fiber laser cutting will only grow, making it an essential investment for any business involved in metalworking.

Envía tu consulta / evaluación para nosotros. Cualquier cosa nos necesita ,por favor no dude en contactarnos aquí! lo mantendremos en secreto para ti !