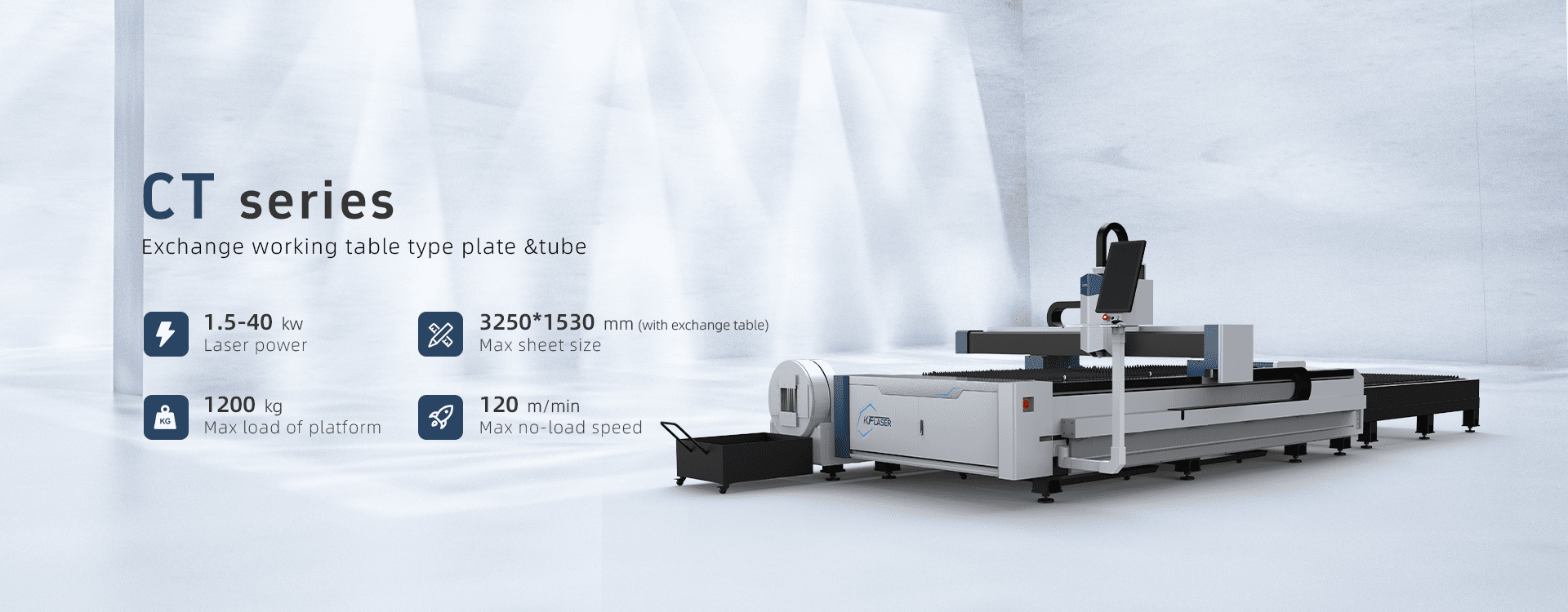

La serie CT combina eficiencia y versatilidad, y es adecuado para necesidades de procesamiento de metales por lotes y de múltiples categorías..

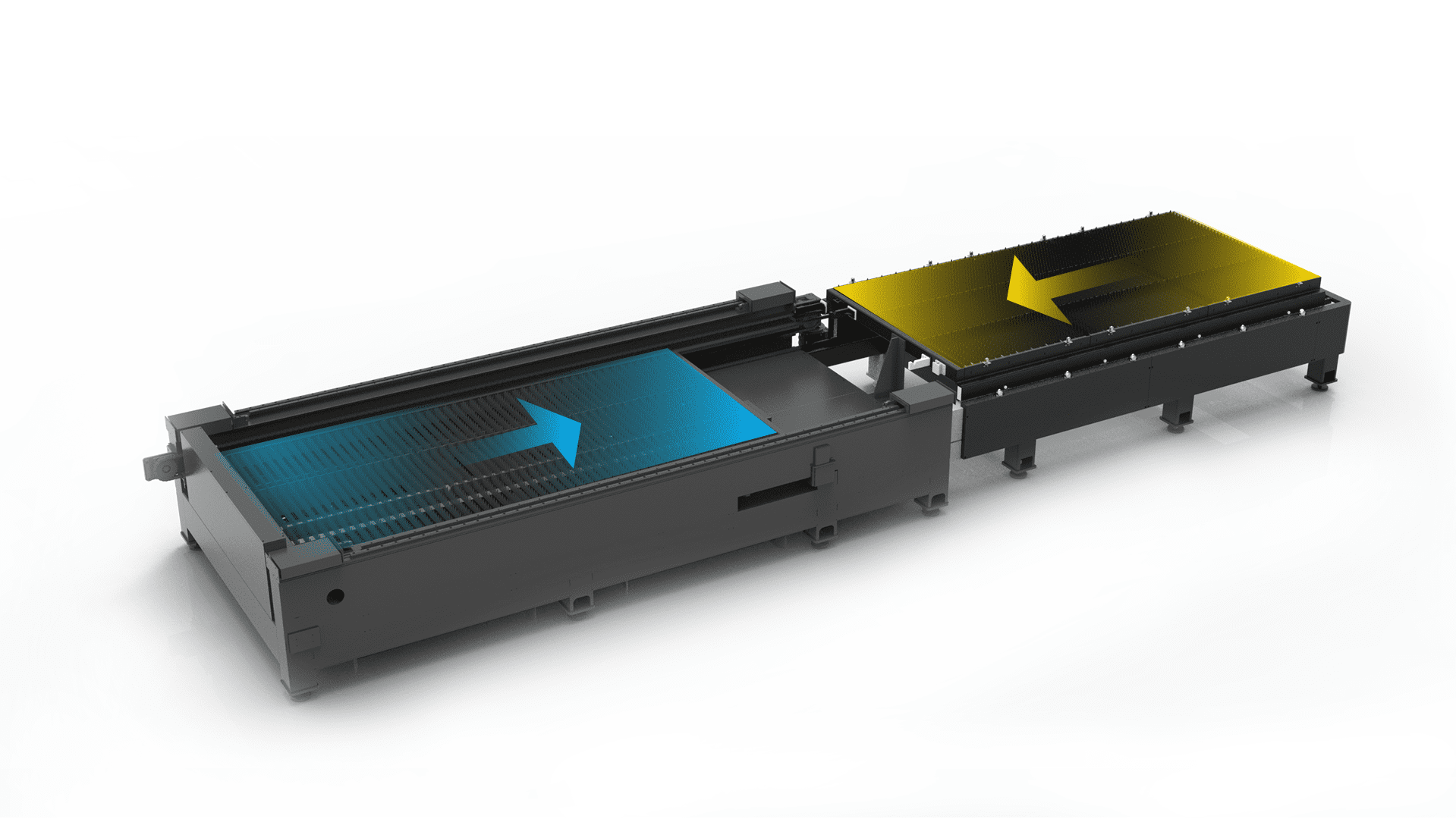

Está equipado con una mesa de trabajo de intercambio de gran tamaño que puede cargar materiales mientras corta..

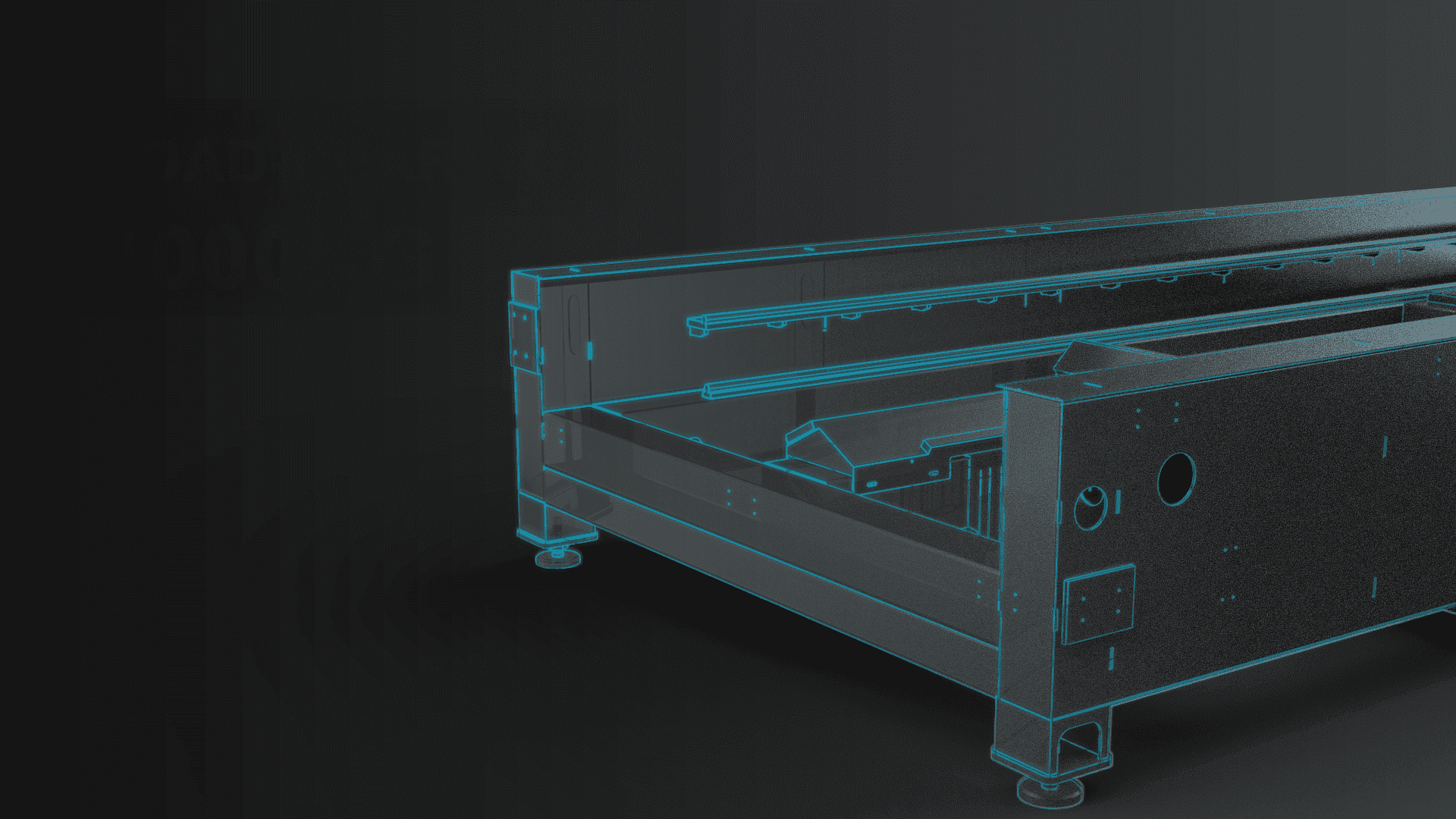

El marco de la cama se suelde con tubos cuadrados gruesos y se refuerza internamente para mejorar la resistencia estructural y la resistencia a la tracción. Somenta un tratamiento de recocido de alta temperatura y envejecimiento natural para eliminar el estrés de soldadura, prevenir la deformación, reducir las vibraciones, y garantizar una excelente precisión de corte.

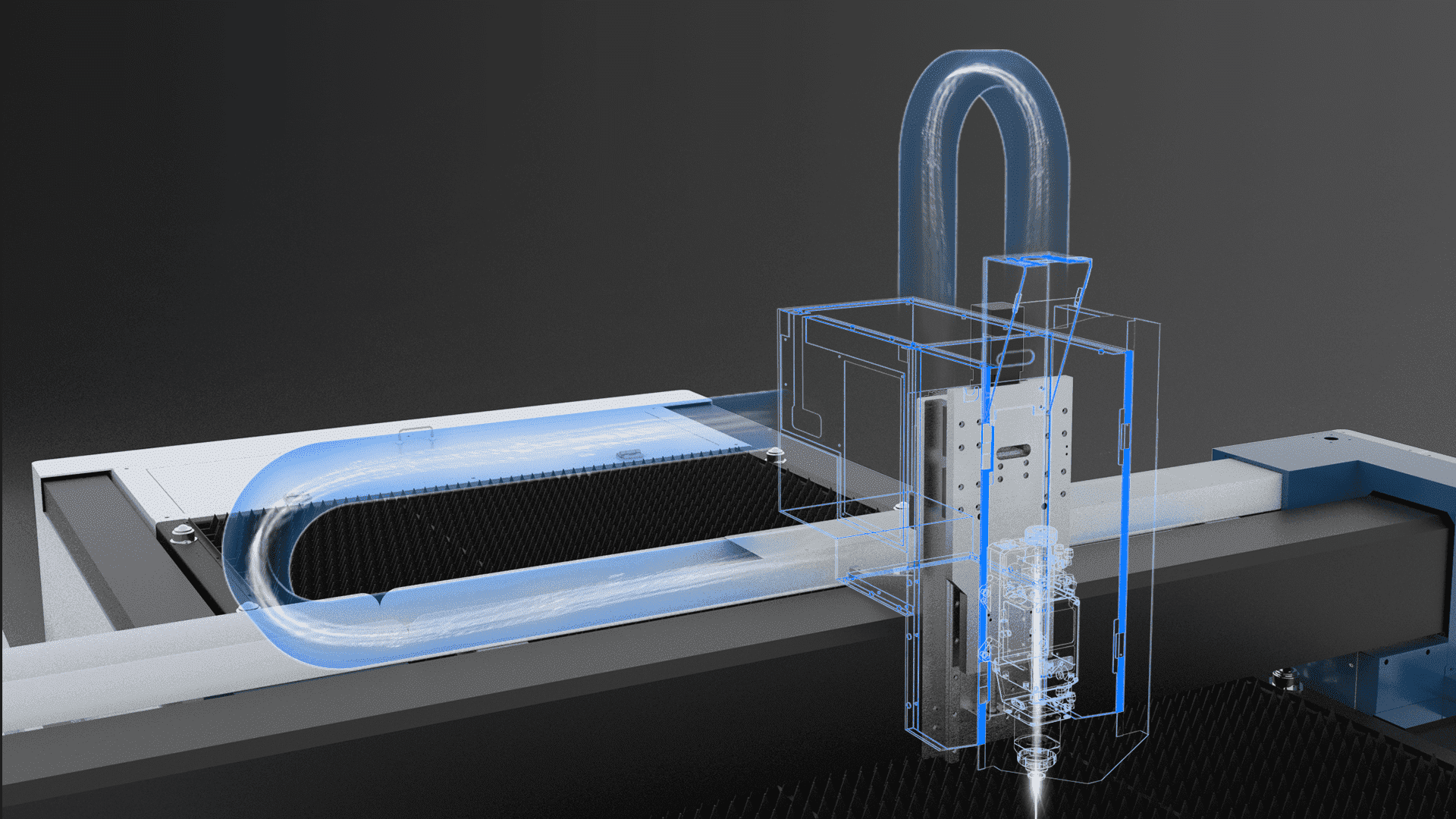

Si concede gran importancia a la protección del medio ambiente, esta máquina es una opción ideal para su negocio. Dispone de múltiples zonas de eliminación automática de polvo., Y la salida de aire cambia automáticamente según la posición del cabezal láser., con eliminación precisa del polvo, que puede eliminar de manera transparente y eficiente el polvo y el humo generados durante el proceso de corte, satisfacer sus necesidades de producción ecológica.

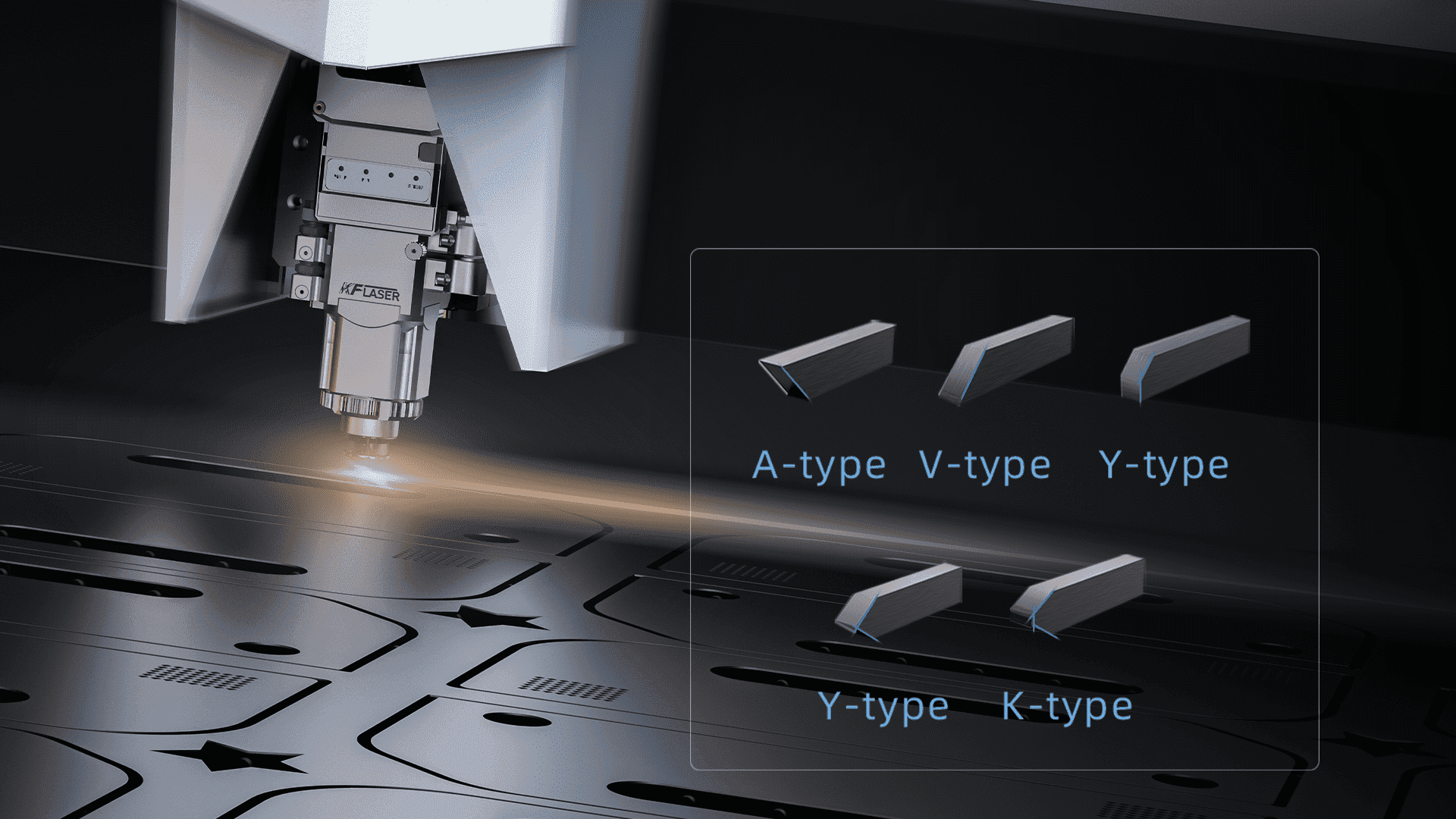

El cabezal de corte de alta potencia de la serie Boci BLT6 puede lograr un corte preciso y estable, Satisfacer necesidades complejas y garantizar resultados de corte de alta calidad.. Incluye un eficiente sistema de refrigeración por agua para prolongar la vida útil y un funcionamiento estable.. Adopta un diseño multifuncional con funciones de mejora de la seguridad, como la evitación inteligente de obstáculos., protección contra colisiones, alarma de subtensión, Monitoreo de circuito cerrado y perforación inteligente., que puede ajustar automáticamente los parámetros de corte para diferentes materiales.

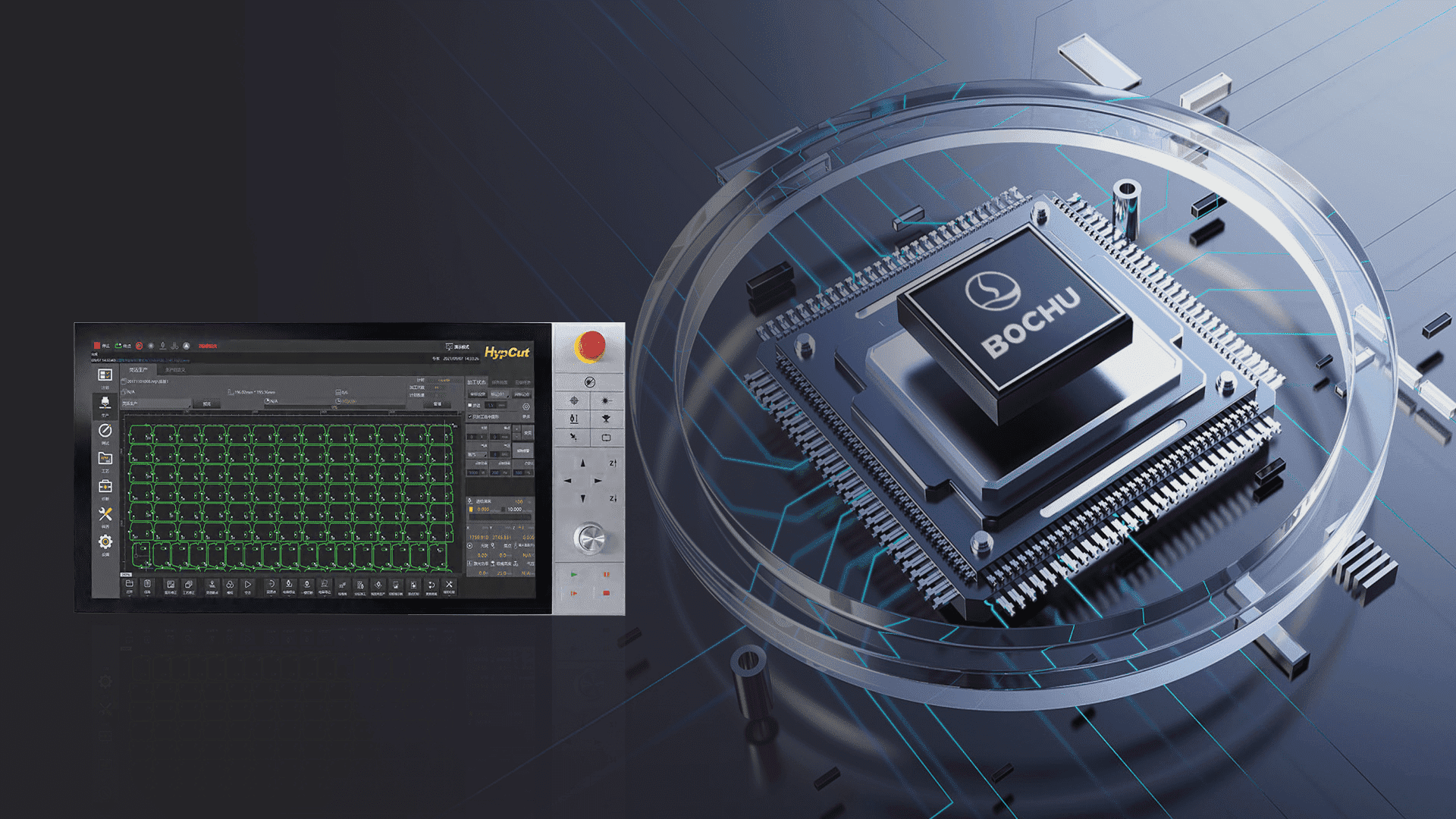

El sistema de control avanzado BOCHU diseñado específicamente para la máquina de corte láser integrada de tubo de placa tiene soporte de corte multifuncional, control de movimiento de alta precisión, Interfaz fácil de usar y capacidades de monitoreo y ajuste en tiempo real. Su función de automatización y estabilidad garantizan una producción eficiente y una calidad de corte, y es adecuado para todo tipo de necesidades de procesamiento de metales, y es una opción ideal para mejorar la eficiencia de producción y la precisión de la reducción.

El eje z usa transmisión de tornillo de bola tbi, Los dos lados del cuerpo de la máquina están equipados con bastidores yyc y rieles guías de Taiwan Hiwin, y el haz está fundiendo aluminio de aviación. Está equipado con motores eléctricos y reductores japoneses yaskawa, torque alto, ruido bajo, y la precisión de posicionamiento de la máquina herramienta puede alcanzar 0.02 mm.

| Modelo de máquina | Serie CT3 | Serie CT4 | Serie CT6 |

| Área de trabajo | 3050*1530milímetros | 4100*2050milímetros | 6100*2550milímetros |

| Potencia del láser | 1-12kilovatios | 1-20kilovatios | 1-20kilovatios |

| Dimensión | 8500*3500*2115milímetros | 10500*4000*2115milímetros | 14500*4500*2115milímetros |

| Tamaño de la tubería de procesamiento | 6m φ20-220 mm / □ 20-220 | ||

| Peso | 7000kilos | 13500kilos | 17000kilos |

| Velocidad máxima de funcionamiento en ralentí(m/min) | 100m/min-120m/min | ||

| Aceleración máxima en ralentí(GRAMO) | 1.0G/1,2G/1,5G | ||

| Precisión de posicionamiento del eje X/Y/mm | ±0,05 mm | ||

| Precisión de posicionamiento repetido/mm | ±0,03 mm | ||

| Precisión de corte/mm | ≤0,1 mm | ||

| Voltaje de trabajo | 380V,trifásico /50Hz-60Hz | ||

| Formatos de imagen soportados | LXD/.DXF/.PLT/.AI/.Gerber/.DWG | ||

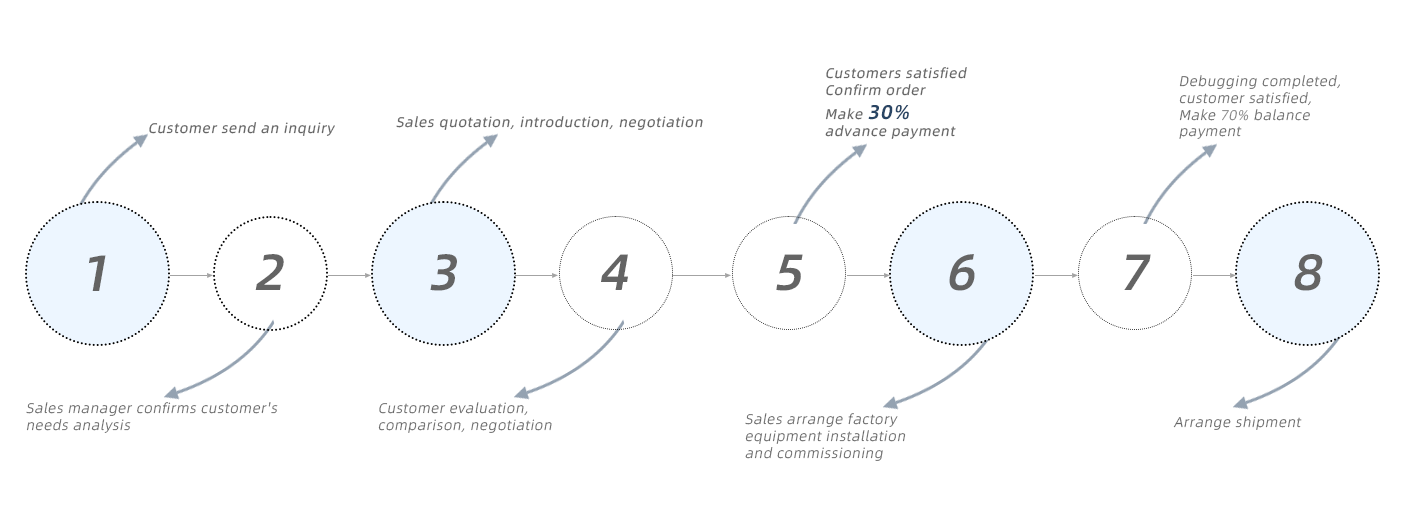

A: Para recomendarle el modelo de máquina más adecuado, solo díganos la información a continuación

1)cual es tu materia

2)El tamaño del material

3)El espesor del material

A:1)Garantía comercial de Alibaba/TT/West Union/Payple/LC/Cash, etc..

2)Empezamos a fabricar máquinas estandarizadas después de recibir 30% del pago, Inspeccionar las máquinas una vez finalizadas., y finalmente recoger el 70% saldo antes del envío.

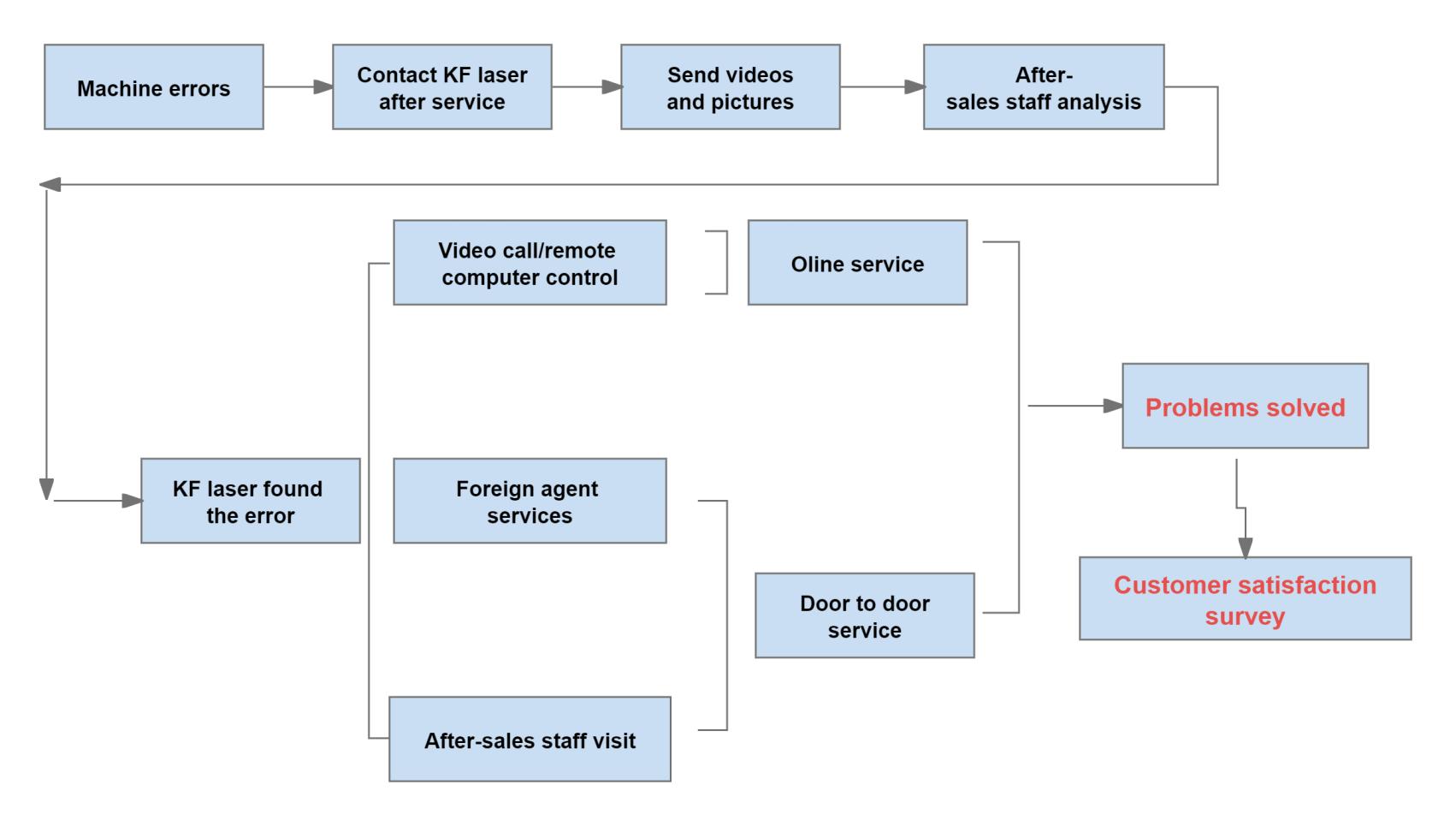

A:1)Ofrecemos formación gratuita en nuestra fábrica.

2)Ofrecemos servicio postventa en línea gratuito.

3)Contamos con instrucciones completas de instalación y videotutoriales.

4)Los cargos por servicio puerta a puerta se basan en la región y el modelo de avión.

5)Proporcionar garantía de tres años., excepto piezas consumibles, reemplazo directo por daño no humano

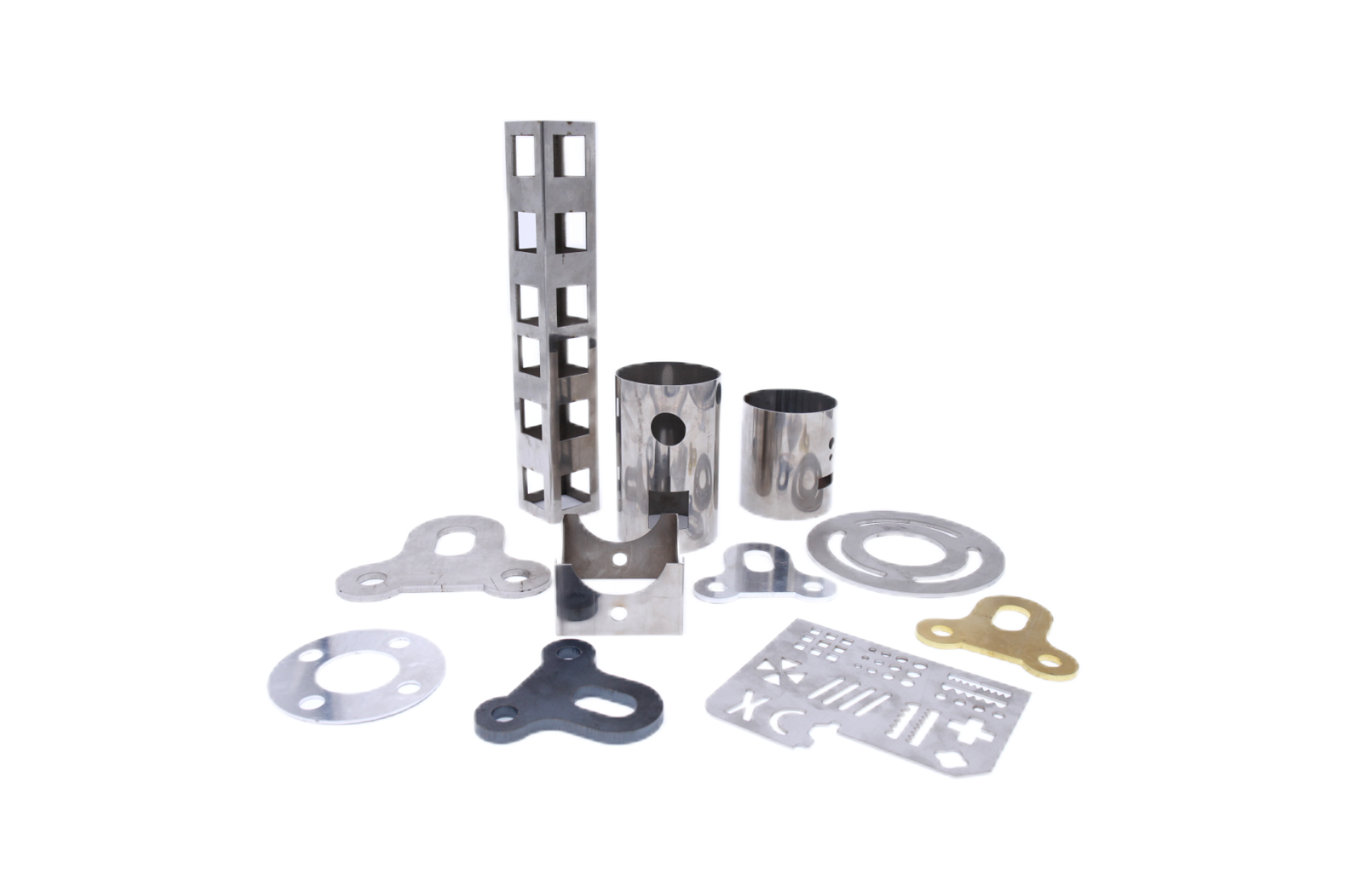

El cortador láser industrial se ha convertido en una herramienta esencial en la fabricación moderna, ofreciendo una precisión incomparable, eficiencia, y versatilidad. Esta guía completa explorará los diversos aspectos de los cortadores láser industriales, sus ventajas, aplicaciones, y características clave a considerar al invertir en uno.

Un cortador láser industrial es una máquina sofisticada que utiliza haces láser de alta potencia para cortar, grabar, o marcar materiales. El haz láser se genera dentro de un resonador y se dirige al material con espejos o fibra óptica. Este rayo de luz enfocado puede derretirse, quemar, o vaporizar el material, Creación de cortes precisos y diseños intrincados con desechos mínimos.

Al buscar un cortador láser industrial, Considere las siguientes características para asegurarse de elegir una máquina que satisfaga sus necesidades específicas:

Los cortadores láser industriales se utilizan en varias industrias debido a su precisión y eficiencia. Algunas aplicaciones comunes incluyen:

Al invertir en un cortador láser industrial, Tenga en cuenta las siguientes consideraciones:

El mantenimiento adecuado de su cortador láser industrial es crucial para garantizar su longevidad y rendimiento óptimo. Aquí hay algunos consejos de mantenimiento para mantener su máquina en las mejores condiciones:

Un cortador láser industrial ofrece numerosas ventajas para la fabricación de metales, incluyendo alta precisión, velocidad, y versatilidad. Considerando características clave, Comprender las aplicaciones, y siguiendo las prácticas de mantenimiento adecuadas, Puede tomar una decisión informada y elegir el mejor cortador láser industrial para sus necesidades. Invertir en un cortador láser industrial de alta calidad mejorará sus capacidades de producción, mejorar la eficiencia, y asegurar consistente, Resultados de alta calidad en sus proyectos de fabricación.