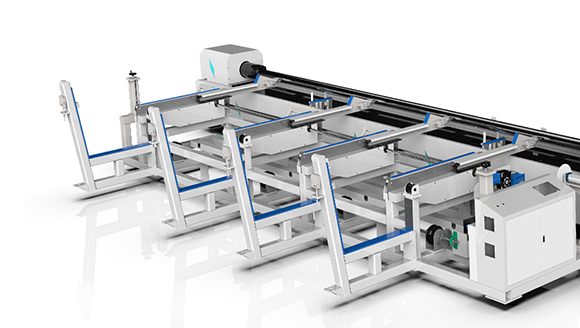

Modelo | THA62 |

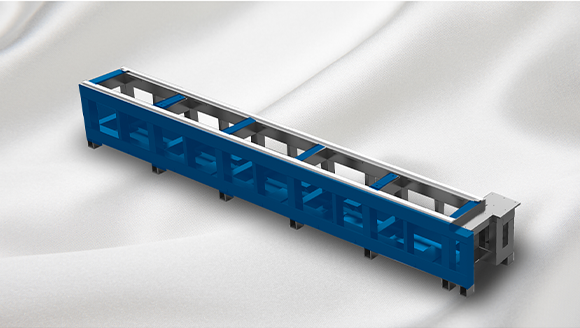

Maximum processing length | 6000milímetros |

unloading length | 3000milímetros |

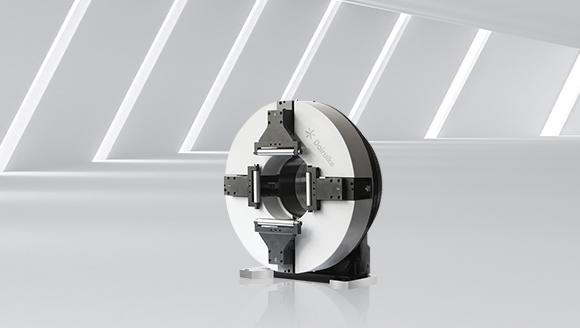

Processing pipe size | Φ10-220mm □10-220mm |

Dimensión (L*W*H) | 11230*2030*2140milímetros |

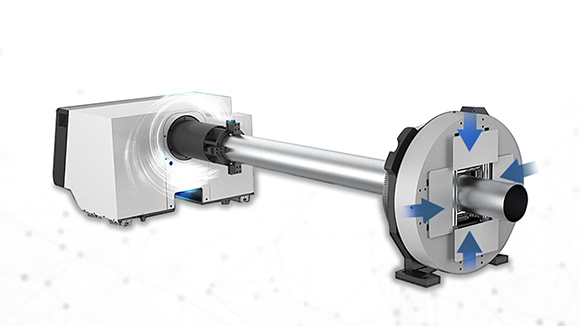

Power support | 1500-6000W. |

Chuck weighing | 200kg |

chuck rotation speed | 100r/min |

Maximum Idle Running Velocidad | 100m/min |

Aceleración máxima en ralentí | 1.0GRAMO |

Positioning accuracy | ±0,02 mm |

Repeat positioning accuracy | ±0,01 mm |

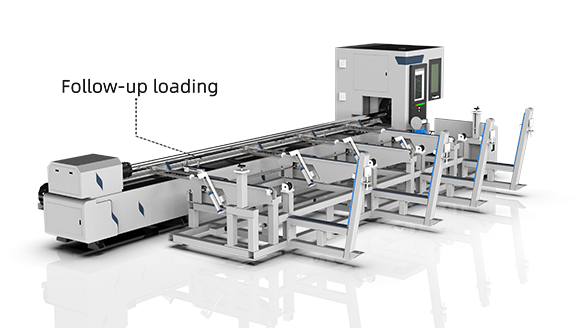

Support device | Follow-up |

Feeding device (optional) | Semi-automatic/Fully automatic feeding |

A: Para recomendarle el modelo de máquina más adecuado, solo díganos la información a continuación

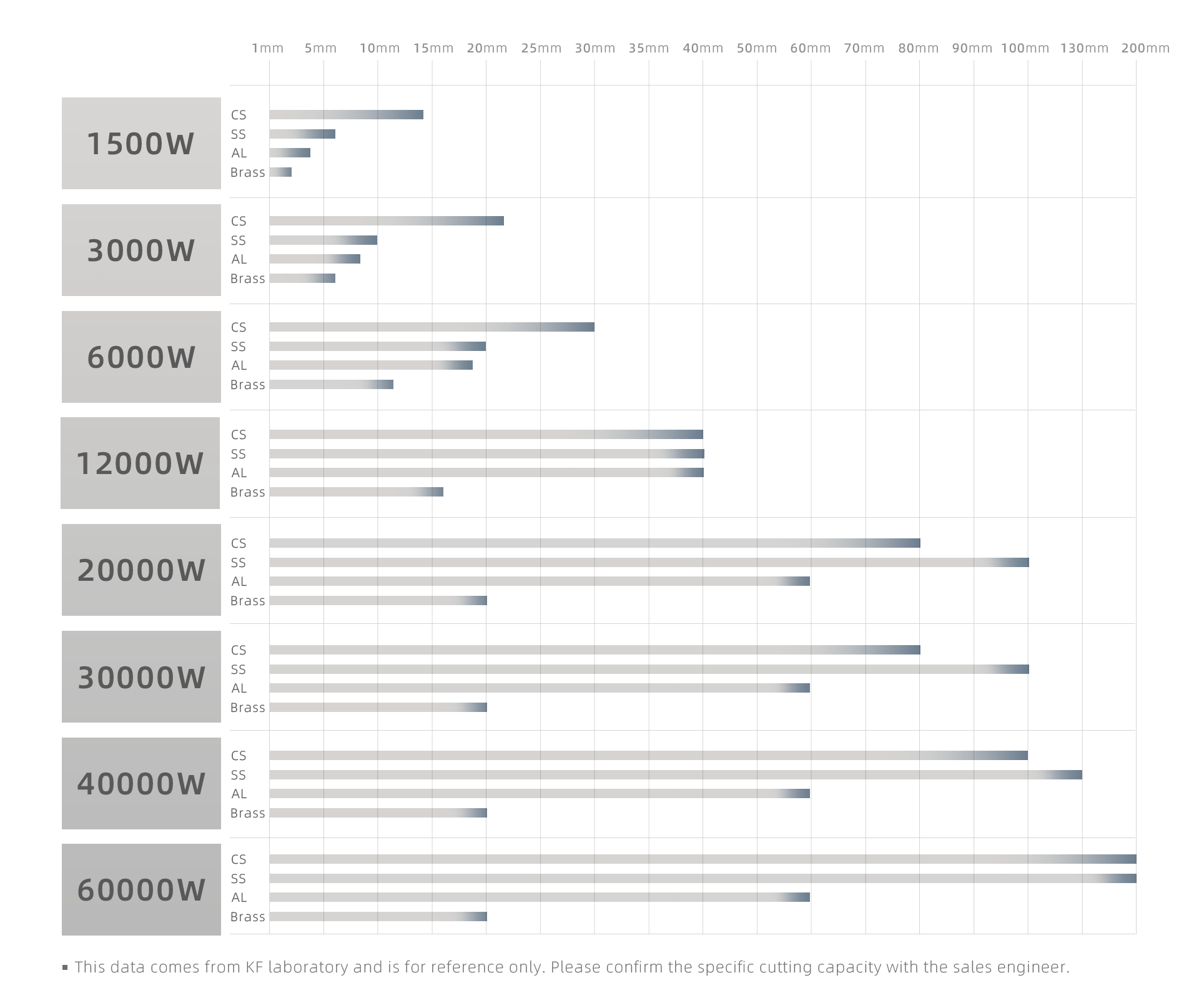

1)cual es tu materia

2)El tamaño del material

3)El espesor del material

4)Cortadora láser de fibra para metal.

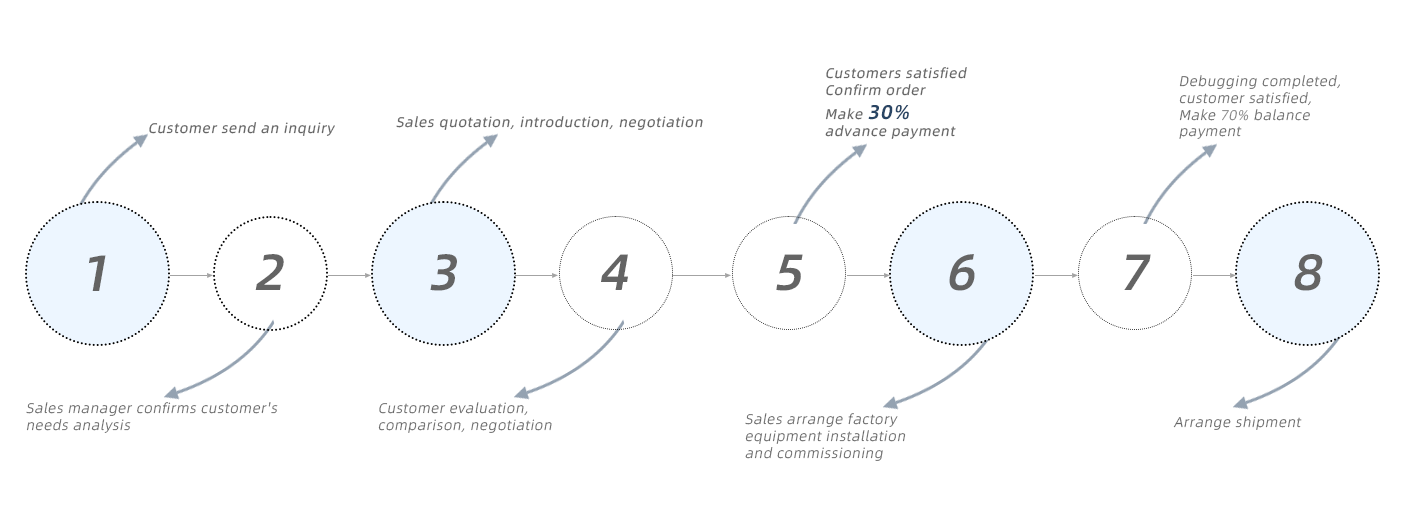

A:1)Garantía comercial de Alibaba/TT/West Union/Payple/LC/Cash, etc..

2)Empezamos a fabricar máquinas estandarizadas después de recibir 30% del pago, Inspeccionar las máquinas una vez finalizadas., y finalmente recoger el 70% saldo antes del envío.

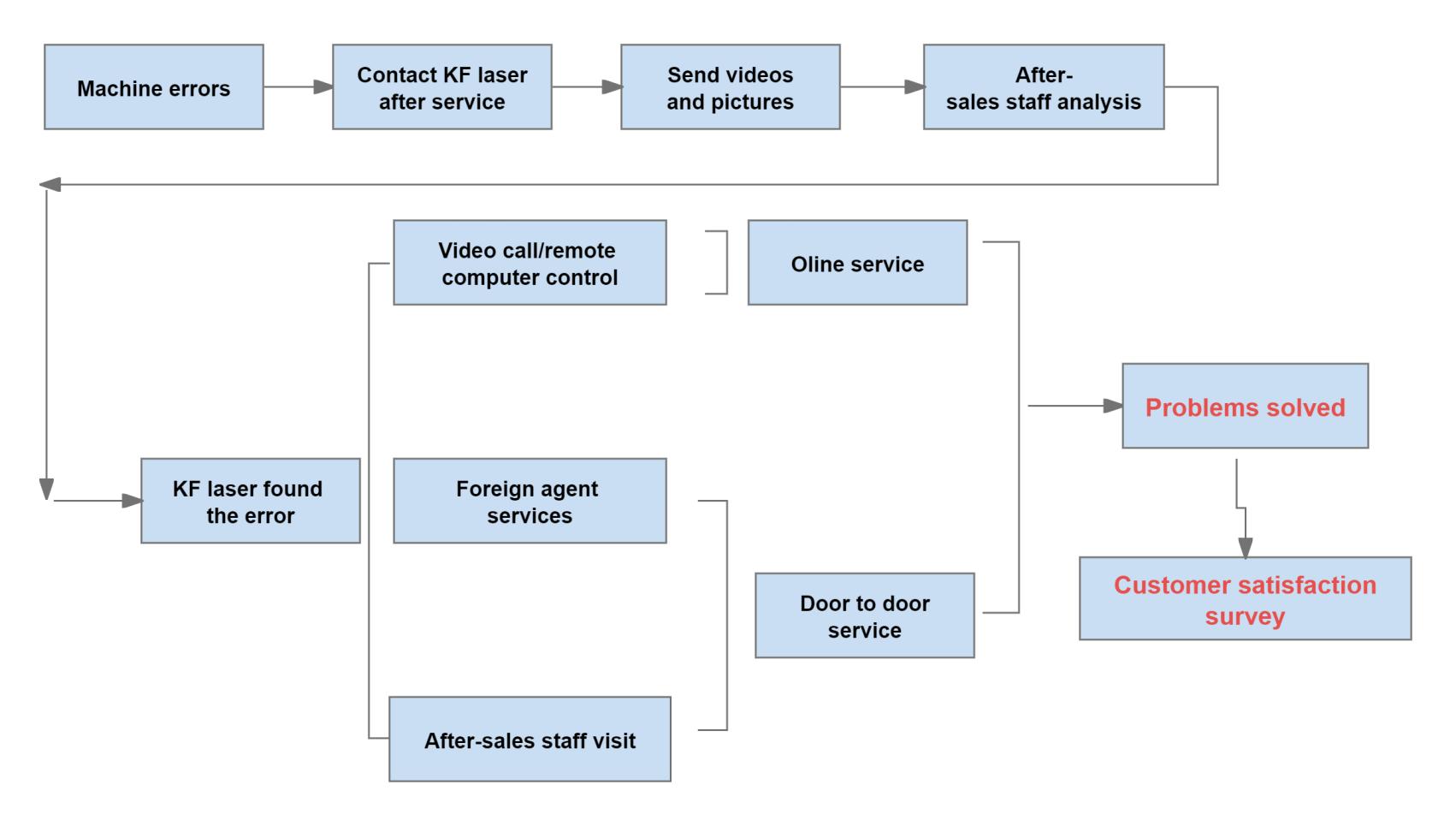

A:1)Ofrecemos formación gratuita en nuestra fábrica.

2)Ofrecemos servicio postventa en línea gratuito.

3)Contamos con instrucciones completas de instalación y videotutoriales.

4)Los cargos por servicio puerta a puerta se basan en la región y el modelo de avión.

5)Proporcionar garantía de tres años., excepto piezas consumibles, reemplazo directo por daño no humano

1):Limpiar la lente óptica.: Limpie la lente óptica con regularidad para mantener la calidad del haz..

2):Comprobar el suministro de gas: Asegúrese de que el sistema de suministro de gas sea normal para evitar que la calidad del corte se vea afectada..

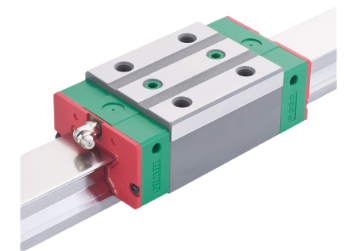

3):Lubricar las piezas móviles.: Lubrique los rieles guía y el tornillo de avance con regularidad para garantizar el buen funcionamiento de las piezas móviles..

4):Reemplace el agua purificada del enfriador cada mes. Si hace bajo cero en invierno, recuerda agregar anticongelante.

A laser cutter for aluminum is a powerful and versatile tool used in various industries for precise and efficient cutting of aluminum sheets and plates. This comprehensive guide will cover the key aspects of laser cutting aluminum, including its advantages, challenges, and factors to consider when choosing a laser cutter for aluminum.

A laser cutter for aluminum is a machine that uses a focused laser beam to cut or engrave aluminum. This process involves directing the laser beam onto the surface of the aluminum, which melts or vaporizes the material, creating a clean and precise cut. The laser beam is typically guided by computer numerical control (CNC) sistemas, allowing for intricate designs and high precision.

Laser cutting aluminum is used across various industries due to its precision and efficiency. Las aplicaciones comunes incluyen:

Proper maintenance is crucial for ensuring the longevity and optimal performance of your laser cutter for aluminum. Here are some maintenance tips:

A laser cutter for aluminum offers numerous advantages for metal fabrication, incluyendo alta precisión, velocidad, y versatilidad. By considering key features, understanding the applications, and following proper maintenance practices, you can make an informed decision and choose the best laser cutter for aluminum for your needs. Investing in a high-quality laser cutter will enhance your production capabilities, improve efficiency, and ensure consistent, high-quality results in your manufacturing projects.

Envía tu consulta / evaluación para nosotros. Cualquier cosa nos necesita ,por favor no dude en contactarnos aquí! lo mantendremos en secreto para ti !