News

What Influences Sheet Metal Laser Cutting Cost?

When considering the adoption of sheet metal laser cutting, one of the most critical aspects to examine is the associated cost. It’s not just about buying the machine or paying for the service; multiple factors come into play that can significantly affect the overall expenditure. Whether you’re a small business owner or a large manufacturing plant, understanding these factors can help you make informed decisions that optimize your budget while maintaining quality.

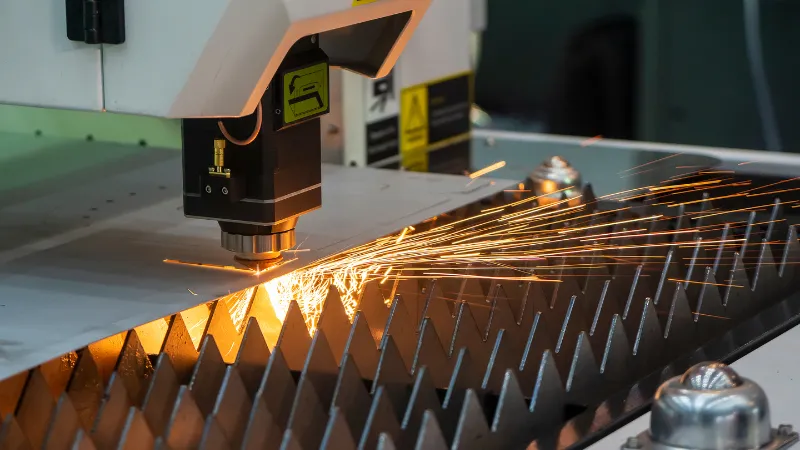

Laser cutting technology has revolutionized the manufacturing sector, especially when it comes to working with sheet metal. However, the price tag for this precision machining process can vary widely depending on several elements. This article delves deep into those influencing factors and offers practical advice on how to manage and reduce sheet metal laser cutting cost without compromising on results.

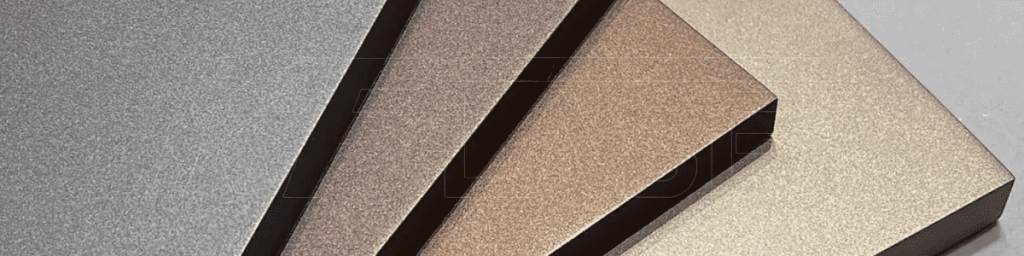

1. The Role of Material Thickness and Type

One of the primary determinants of sheet metal laser cutting cost is the type of material being used and its thickness. Thicker materials naturally require more power and time to cut, which directly increases the cost of the process. Similarly, materials like stainless steel or titanium may cost more to cut compared to regular carbon steel due to their density and hardness. The type of material also dictates the cutting speed, which can either increase or decrease the total project cost.

For businesses looking to keep costs down, it’s crucial to choose the right material for the job. Lighter materials such as aluminum or mild steel might be more affordable, but they may not always meet the necessary strength requirements. The trick lies in balancing material selection with project needs.

2. Machine and Technology Choice

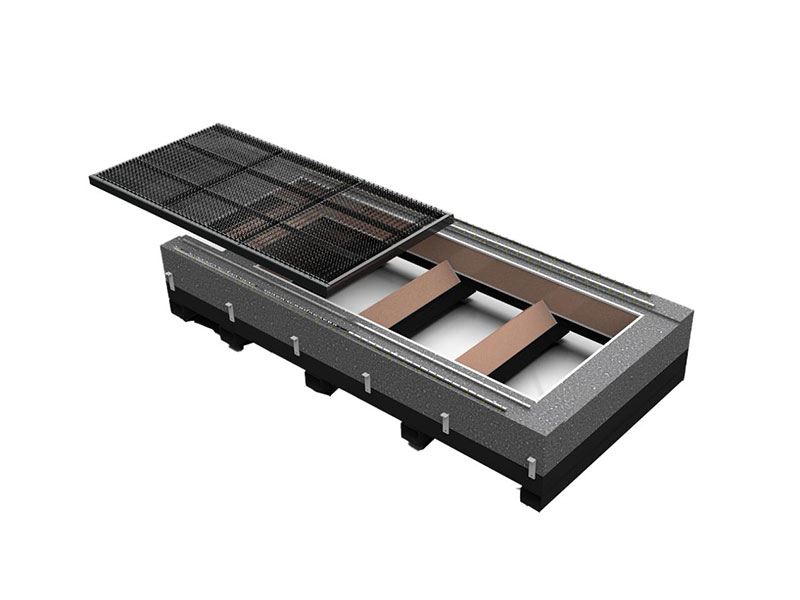

The type of laser cutting machine used plays a significant role in the cost structure. High-power laser cutters tend to be more expensive to operate, but they can handle thicker materials more efficiently. Conversely, lower-powered machines may be less expensive in the short term, but they could increase cutting time on thicker sheets, which leads to higher costs.

Additionally, newer technology with advanced features, such as fiber lasers or CO2 lasers, often come with premium costs but can offer faster cutting speeds, better precision, and reduced energy consumption. Depending on your project’s complexity and volume, choosing the right machine can lead to substantial cost savings in the long run.

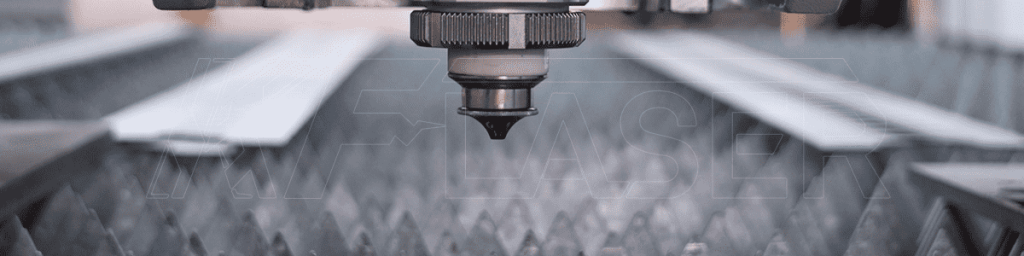

3. Cutting Speed and Time

The speed at which the laser cuts the sheet metal is another significant cost factor. Faster cutting speeds will obviously reduce the time it takes to complete a project, which can lower labor and operational costs. However, achieving optimal cutting speed is a balance — too fast, and you risk compromising the quality of the cuts; too slow, and you increase overall expenses.

Optimizing cutting parameters — such as feed rate, laser power, and assist gas pressure — can help improve speed without sacrificing precision. Efficient scheduling and minimizing downtime during cutting operations are other ways to ensure the cost-effectiveness of laser cutting services.

4. Labor Costs and Operator Expertise

While laser cutting is often automated, operator expertise still plays a critical role in determining the cost of the job. Skilled technicians are required to set up and manage the laser cutting machines, especially when dealing with complex designs. The more intricate the design or the material, the higher the labor costs.

Training costs and hiring skilled professionals can significantly increase the upfront cost. However, their experience can also help reduce mistakes and improve machine efficiency, leading to long-term savings by preventing material wastage and ensuring faster turnaround times.

5. Volume and Production Runs

The quantity of items being produced is a key consideration when estimating laser cutting costs. Generally, the more you produce, the more cost-effective the process becomes, as you can distribute setup and overhead costs across a higher volume. For small batches, the cost per piece will naturally be higher due to the fixed costs involved in setting up the machinery.

Businesses looking to reduce costs on larger runs should take advantage of economies of scale. It may make sense to run larger production orders in one go to maximize cost savings.

6. Post-Processing and Finishing

Once the laser cutting process is complete, post-processing and finishing steps such as deburring, cleaning, and coating can add to the overall expense. Depending on the quality of the cut and the material type, additional work might be required to achieve the desired finish. If the project requires high precision or aesthetic value, such as in aerospace or automotive applications, these post-processing steps will significantly increase the final cost.

Ensuring that your design is optimized for minimal post-processing can reduce these additional charges. For example, choosing laser cutting techniques that leave smooth edges or applying automated finishing solutions can lower labor costs and processing time.

7. Environmental and Operational Factors

Finally, environmental factors and operational considerations should not be overlooked. The cost of energy, the location of the service provider, and even the regulatory standards in your area can impact pricing. For example, in areas with high energy costs or strict environmental regulations, the operational cost of running laser cutting machinery may be higher, leading to increased service fees.

8. Choosing the Right Laser Cutting Service Provider

The choice of laser cutting service provider can also influence the final price. While some companies may offer lower prices, their machinery may be outdated or their processes less efficient. Others might use high-end equipment that offers greater precision and faster turnaround times, justifying a higher price tag.

It is essential to find a service provider that not only offers competitive pricing but also maintains high standards of quality. Assessing their reputation, checking reviews, and considering customer feedback will help ensure that you’re getting the best value for your investment.

Conclusion: Maximizing Value from Your Laser Cutting Investment

Understanding the sheet metal laser cutting cost requires an analysis of many factors, from material selection to machine choice, and even post-processing considerations. By carefully evaluating each aspect and optimizing processes, you can control expenses and achieve the best possible results without overspending.

If you’re just starting out, it may be beneficial to consult with industry experts or laser cutting specialists to get tailored advice for your specific needs. With the right knowledge and strategic approach, sheet metal laser cutting can become a cost-effective and efficient part of your business’s production process.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine