News

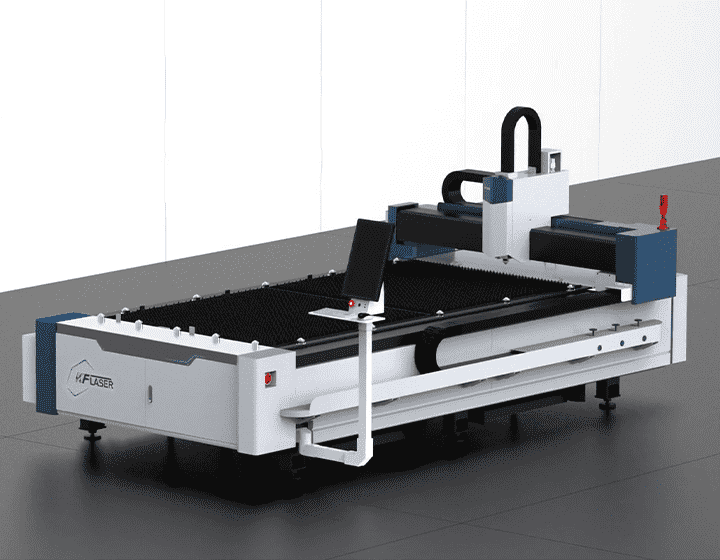

Sheet Metal Laser Cutting Machine Manufacturers | Precision and Efficiency

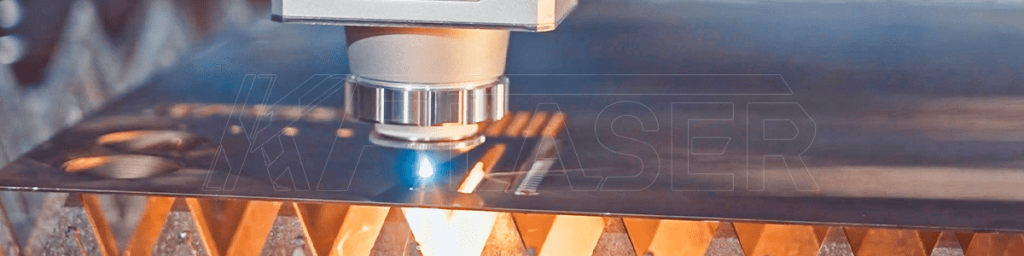

In the dynamic world of manufacturing, the demand for precision and speed is ever-increasing. Sheet metal laser cutting machine manufacturers are leading the charge, revolutionizing the industry with state-of-the-art technology designed to meet the ever-growing need for high-quality, cost-effective manufacturing solutions. Whether it’s creating intricate designs, reducing production time, or improving material efficiency, these machines are setting new standards for what’s possible in metalworking. But how do you choose the right manufacturer? In this article, we’ll explore the key factors to consider when selecting a sheet metal laser cutting machine manufacturer and what makes certain brands stand out from the crowd.

The Rise of Sheet Metal Laser Cutting Technology

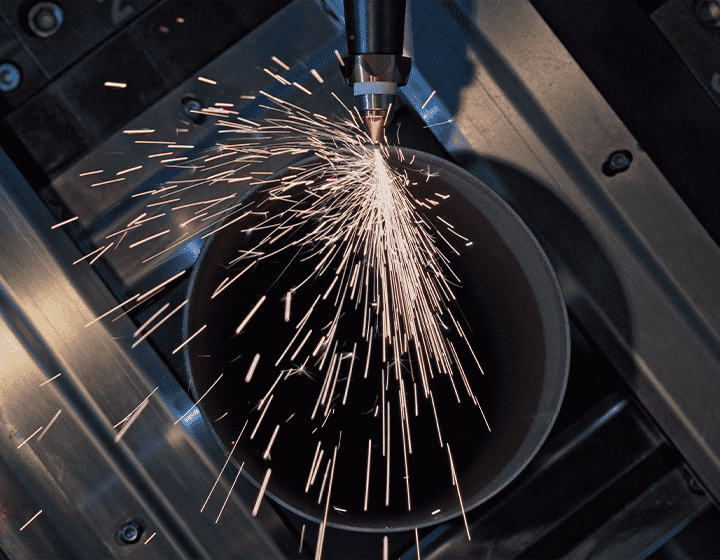

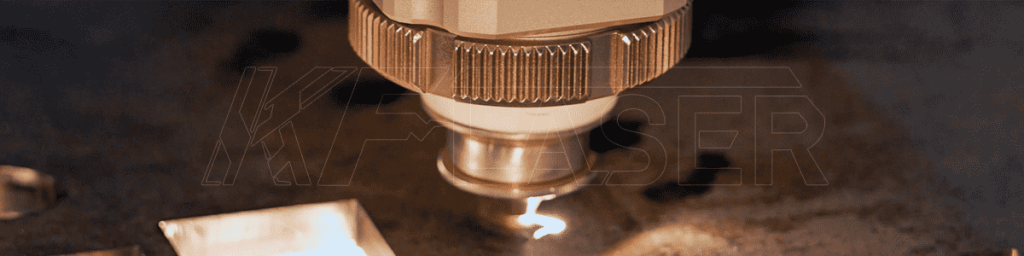

Sheet metal laser cutting machines have become a game-changer in various industries, from automotive to aerospace and beyond. The use of lasers allows for incredibly precise cuts, reducing the material waste that often occurs in traditional cutting methods. This advanced technology not only enhances the quality of the cuts but also increases the overall speed of production, making it more cost-efficient.

Manufacturers that specialize in this cutting-edge technology are pivotal in providing businesses with the tools they need to stay competitive. Sheet metal laser cutting machine manufacturers offer a wide array of machines that differ in size, power, and capability. Whether you’re a small business or a large-scale industrial operation, there’s a machine suited for your needs.

What to Look for in a Sheet Metal Laser Cutting Machine Manufacturers

Precision and Accuracy

The most critical feature in a sheet metal laser cutting machine is precision. The quality of your cuts directly impacts the quality of your end product. Leading manufacturers ensure that their machines offer high levels of accuracy, which is essential when working with sheet metals for industries like automotive, aerospace, and electronics.

Efficiency and Speed

In today’s fast-paced market, time is money. Manufacturers that provide high-speed machines, without compromising the quality of the cut, give businesses a significant advantage. Whether you’re producing large quantities or intricate designs, the ability to speed up production is a must.

Customization Options

Not every manufacturer offers the same features. Some sheet metal laser cutting machine manufacturers allow for a high degree of customization in their machines, whether it’s the size of the cutting area, laser power, or specific features that cater to specialized industries.

Customer Support and Maintenance Services

Another crucial aspect to consider is customer service. A good manufacturer doesn’t just sell the machine; they offer ongoing support, maintenance, and troubleshooting services. This ensures your equipment is always running at its peak, minimizing downtime.

Cost-Effectiveness

While laser cutting machines are a significant investment, the long-term savings in material and labor costs can make them a highly cost-effective solution. Manufacturers offering the best value for money provide high-quality machines that are durable and affordable in the long run.

Top Industries Benefiting from Sheet Metal Laser Cutting Machines

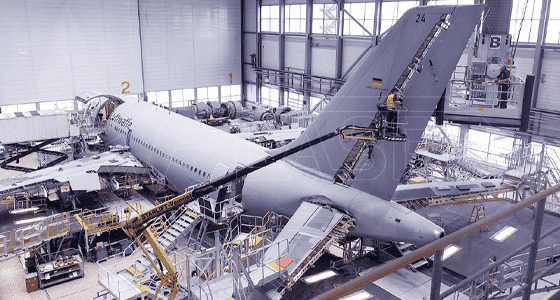

Aerospace:

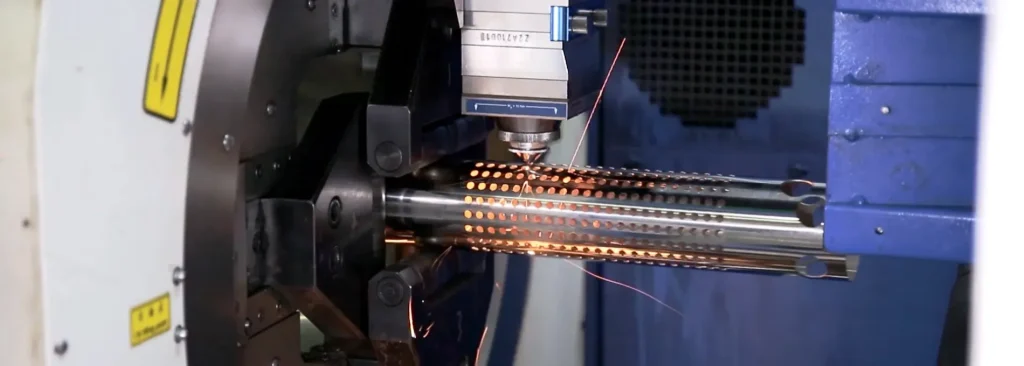

The aerospace industry demands precision cuts that meet strict safety standards. Laser cutting technology allows for the creation of complex parts that are lightweight, durable, and precise. Manufacturers that specialize in this field provide solutions that comply with industry regulations while maintaining efficiency.

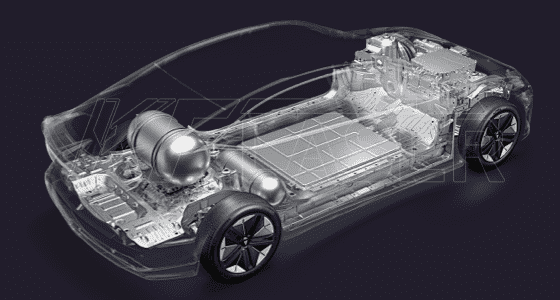

Automotive:

In the automotive industry, sheet metal laser cutting machines are used to produce parts for vehicles with intricate designs, often involving complex geometries. The speed and precision offered by these machines significantly improve production rates while reducing material waste.

Electronics and Appliances:

The electronics industry relies on sheet metal parts for housings, frames, and other components. Laser cutting machines provide the necessary accuracy and efficiency to meet high production demands and tight tolerances.

Key Benefits of Choosing the Right Sheet Metal Laser Cutting Machine Manufacturers

Long-Term Durability and Low Maintenance Costs

Choosing a reputable manufacturer means investing in machines that are built to last. High-quality machines typically come with warranties, and the low maintenance costs ensure that your business’s operations will not be interrupted due to technical failures.

Advanced Laser Technology

Leading manufacturers incorporate the latest in laser technology to provide machines that offer enhanced capabilities. Whether it’s fiber lasers, CO2 lasers, or even newer hybrid models, these innovations provide better cutting capabilities, improved material handling, and increased efficiency.

Flexibility and Scalability

As your business grows, so should your equipment. A good manufacturer offers machines that are scalable, meaning that you can upgrade as your production demands increase. This ensures that your initial investment continues to provide value in the long term.

Energy Efficiency

With the increasing focus on sustainability, energy-efficient machines are becoming a priority for manufacturers. Opting for machines that reduce energy consumption helps lower operating costs while contributing to environmental responsibility.

Emerging Trends in Sheet Metal Laser Cutting

As the sheet metal industry evolves, so too do the technologies that drive it. Manufacturers are continuously innovating to meet the changing needs of the market. Some notable trends include:

Automation: Many sheet metal laser cutting machines now come equipped with automated systems for loading and unloading materials, reducing labor costs and increasing efficiency.

Hybrid Machines: Combining traditional cutting methods with laser technology, hybrid machines are becoming increasingly popular for their versatility and cost-effectiveness.

3D Laser Cutting: Some manufacturers are venturing into the realm of 3D laser cutting, allowing for even more complex parts to be produced with high accuracy.

Conclusion

The sheet metal laser cutting machine manufacturers you choose will have a significant impact on the efficiency and quality of your production process. By selecting the right manufacturer, you ensure that your business stays ahead of the curve in terms of precision, cost-effectiveness, and speed. With the ever-growing demand for high-quality sheet metal components across industries, investing in a reliable and advanced laser cutting machine is an investment in your company’s future success.

By taking the time to research and select a top-tier manufacturer, you can ensure that your operations are optimized for both quality and productivity, paving the way for continued growth and innovation.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine