When it comes to cutting through steel with precision and efficiency, steel laser cutting machines have emerged as one of the most innovative solutions available. Whether you’re working in automotive manufacturing, construcción, or aerospace, laser cutting technology offers a high level of accuracy and speed that traditional methods cannot match. En este artículo, we will dive into how steel laser cutting works, its key benefits, aplicaciones, and why it’s becoming the preferred choice for various industries.

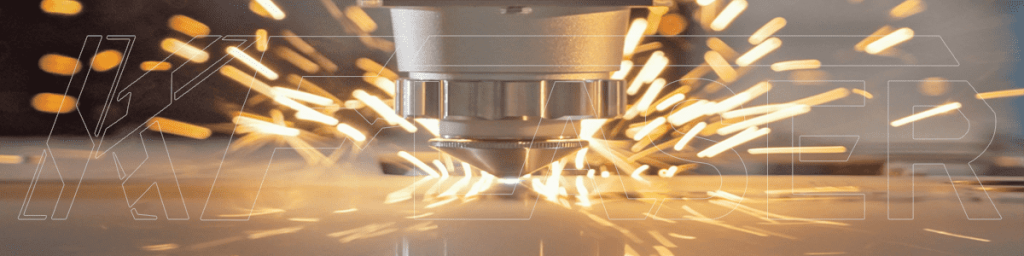

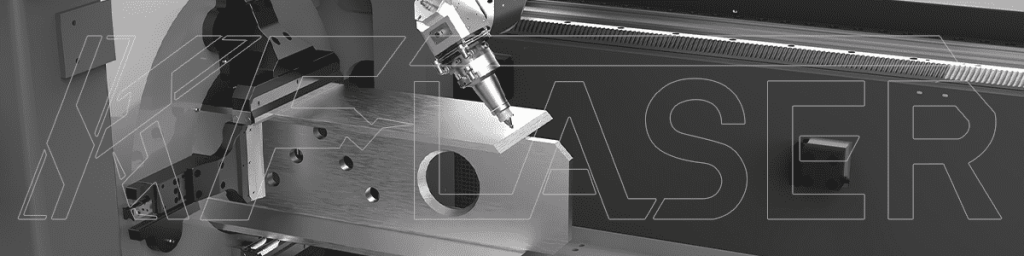

A steel laser cutting machine uses a high-powered laser beam to cut through steel. This method works by focusing a concentrated beam of light on the steel surface, where the energy is absorbed by the material, haciendo que se derrita, quemar, or vaporize along the cutting path. The laser’s high precision ensures that steel sheets, plates, and tubes can be cut with minimal waste and high accuracy.

This cutting method has evolved rapidly over the years, allowing manufacturers to achieve cleaner, faster cuts with less manual intervention. Steel laser cutting machines are commonly used in a variety of industries, ranging from heavy manufacturing to intricate fabrication tasks.

Before diving into the benefits and applications, it’s important to understand the main components that make up a steel laser cutting machine:

The process of steel laser cutting involves several key steps:

One of the main advantages of steel laser cutting machines is their ability to achieve extremely high levels of precision. Laser cutting can achieve tolerances as tight as ±0.1mm, which is ideal for industries that require extremely detailed and accurate cuts. The cutting head follows a computer-generated path, ensuring that each cut is exactly where it’s needed.

Laser cutting is a highly efficient process that minimizes material waste. Since the laser beam is so focused, it cuts along a precise line, leaving minimal offcuts. This is particularly important for industries like aerospace and automotive, where reducing waste can result in significant cost savings.

Steel laser cutting machines are capable of cutting at impressive speeds. Depending on the material’s thickness and the laser’s power, laser cutters can cut through steel sheets at speeds up to 20 meters per minute. This high-speed cutting reduces production time, making it an ideal choice for high-volume production.

Laser cutters excel at cutting complex shapes and intricate designs. Unlike mechanical cutting methods, a steel laser cutting machine can easily handle curves, angles, and detailed features such as perforations and small holes. This capability makes laser cutting the preferred method for designs requiring high detail.

Laser cutting generates less heat compared to traditional methods like plasma cutting or flame cutting. This results in a smaller heat-affected zone (Cría), which reduces the risk of warping or discoloration on the edges of the steel. The clean cuts also reduce the need for post-processing like deburring or smoothing.

Steel laser cutting machines are versatile and can be used in various industries. Below are some of the primary applications of steel laser cutting:

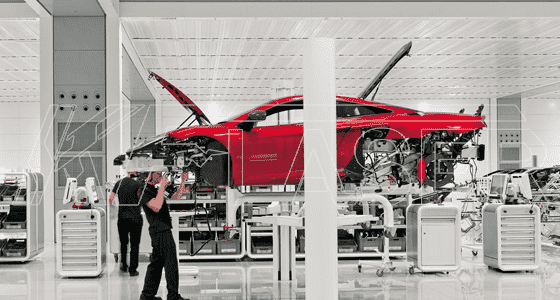

The automotive industry requires precise, high-quality parts for everything from body panels to engine components. Steel laser cutting machines are used to cut steel parts that need to fit together perfectly, ensuring the high standards of safety and functionality required in automotive manufacturing.

Aerospace manufacturers rely on steel laser cutting for components that must meet tight tolerances and perform under extreme conditions. Steel laser cutting helps produce complex parts with precision, which is critical for both structural and functional components in the aerospace industry.

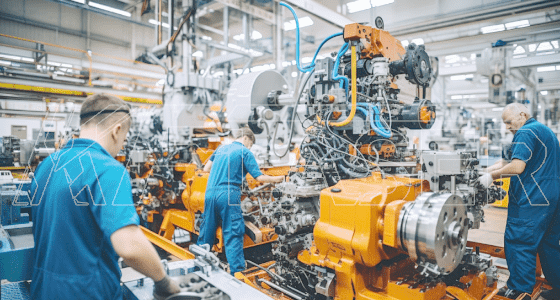

Steel is used extensively in heavy machinery and equipment. Laser cutting ensures that parts are cut with precision, whether it’s for large structural elements or smaller components. The durability and strength of steel make it a go-to material in this industry, and laser cutting ensures the parts meet the required standards.

Steel laser cutting machines are used to cut structural steel for buildings, puentes, and other large construction projects. The precision and clean cuts provided by laser technology ensure that the steel components fit together correctly, reducing the need for post-cutting adjustments.

Metal fabrication businesses often use steel laser cutting machines to create parts for various industries, from electronics to consumer goods. The precision and ability to cut complex shapes make laser cutting an ideal choice for fabricators working with steel.

When investing in a steel laser cutting machine, several factors should be considered:

Potencia del láser: Higher laser power is required for cutting thicker steel. The power of the laser also impacts cutting speed and efficiency.

Espesor del material: Consider the range of material thicknesses you will be working with. Some machines are better suited for thin sheets, while others can handle thicker steel.

Velocidad de corte: Faster cutting speeds improve productivity, but make sure the machine can maintain the necessary precision while cutting at higher speeds.

Automatización y software: Many steel laser cutting machines come with automated loading and unloading systems, which help streamline production. Además, advanced software can help program complex cutting paths, improving efficiency.

Mantenimiento y soporte: Like any advanced technology, regular maintenance is crucial for keeping a steel laser cutting machine running smoothly. Look for a machine with easy-to-access parts and excellent after-sales support.

In today’s manufacturing landscape, steel laser cutting machines have become an essential tool for industries that require precision, eficiencia, and high-quality cuts. From automotive and aerospace to construction and metal fabrication, the benefits of laser cutting are clear: minimal material waste, velocidades de corte rápidas, and the ability to handle complex designs with high accuracy.

Whether you are cutting thin sheets or thicker plates, steel laser cutting machines offer an unparalleled combination of speed, precisión, y versatilidad. By understanding how these machines work and how they can benefit your business, you can make informed decisions that will enhance your production processes and deliver high-quality steel parts for your projects.