News

The Intricate Cost Breakdown of Steel Plate Laser Cutting Machines

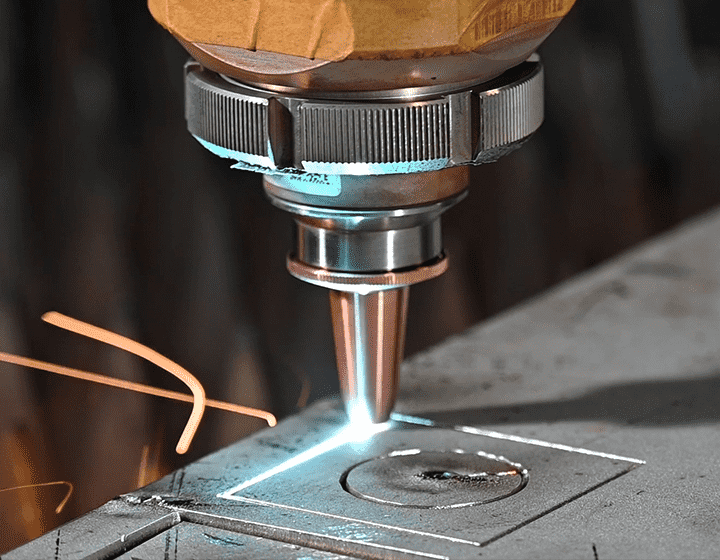

In the world of modern manufacturing, precision and efficiency are paramount. Steel plate laser cutting machines stand at the intersection of these two principles, offering unmatched accuracy for cutting through thick, durable materials. However, the price of these advanced machines can vary significantly depending on various factors. Whether you’re an entrepreneur seeking to expand your production capabilities or a seasoned manufacturer looking to upgrade your equipment, understanding the nuances behind the steel plate laser cutting machine price is essential.

What Affects the Steel Plate Laser Cutting Machine Price?

The Steel Plate Laser Cutting Machine Price is not one-size-fits-all. It depends on several key factors, each contributing to its overall cost. Below are the most significant influences:

1. Machine Power and Cutting Capacity

One of the primary determinants of price is the power of the laser. Machines with higher wattage capabilities tend to be more expensive due to their ability to cut thicker plates at faster speeds. For example, a 500-watt laser cutting machine might be more affordable but can only handle thinner plates, while a 6,000-watt laser cutter can slice through thicker steel, making it much more expensive.

2. Brand and Manufacturer

Although we’ll refrain from discussing specific brands, it’s worth noting that different manufacturers offer varying levels of reliability, warranty, and support. High-end manufacturers typically charge more due to their long-standing reputation for quality and precision, which ensures less downtime and better long-term results.

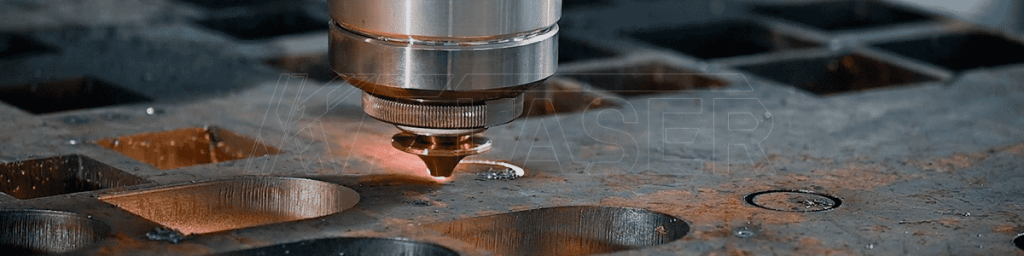

3. Machine Size and Configuration

Laser cutting machines come in different sizes and configurations. Smaller, compact models are typically less expensive but may not offer the same flexibility as larger, more advanced machines. For businesses that need to cut large steel plates, investing in a larger machine is often necessary, albeit at a higher price.

4. Automation Features

Automation capabilities such as auto-focus, CNC control, and advanced software integration can also increase the price of a steel plate laser cutting machine. These features improve productivity and reduce human error, making the investment worthwhile for large-scale operations, but they add to the upfront cost.

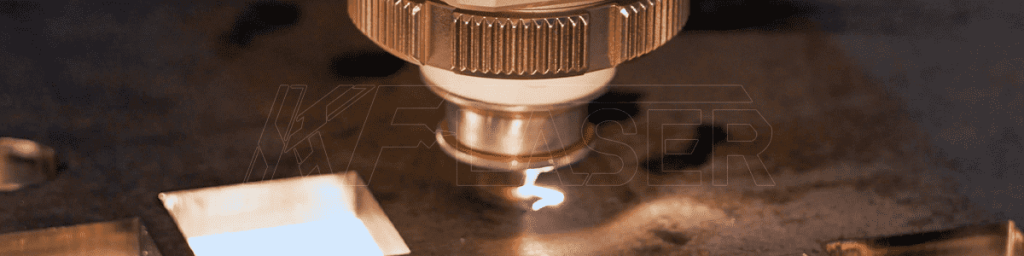

5. Laser Type: Fiber vs. CO2

Laser type plays a pivotal role in determining price. Fiber laser cutters, known for their efficiency and precision, tend to be more expensive than traditional CO2 lasers. While CO2 lasers are still widely used, fiber lasers are more efficient for cutting metal plates, offering faster speeds, lower operational costs, and superior cutting quality.

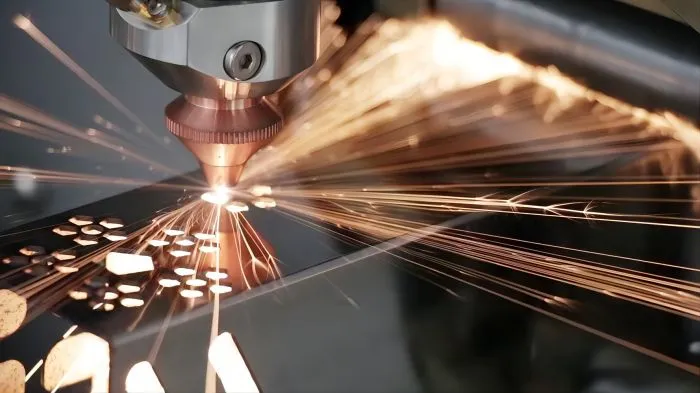

6. Cutting Technology and Precision

Machines with cutting-edge technology that provide better precision are naturally more expensive. The precision of a laser cutter impacts the quality of cuts, which can influence the quality of the final product, particularly in industries where tight tolerances are critical.

7. Additional Costs: Maintenance and Consumables

While the upfront cost is a significant factor, ongoing operational expenses also play a key role in the total cost of ownership. Regular maintenance, repairs, and consumables like lenses, nozzles, and gases contribute to the overall expense of running a laser cutting machine.

What Is the Typical Price Range?

Steel plate laser cutting machines can range from a few thousand dollars for entry-level models to several hundred thousand dollars for high-end industrial machines. Typically, a mid-range fiber laser cutting machine with a power output between 1,000 and 3,000 watts will cost anywhere from $50,000 to $200,000, depending on the configuration and features.

High-power machines with larger cutting areas and advanced automation can cost upwards of $300,000 or more. It’s important to balance the price with the features you truly need, rather than opting for the most expensive model on the market without considering your specific requirements.

Is the Investment Worth It?

For many businesses, investing in a steel plate laser cutting machine is a strategic decision that pays off over time. The benefits are clear: enhanced precision, speed, and versatility. However, it’s crucial to evaluate the specific needs of your business and match those needs with the right machine.

Consider factors like the type of material you’re cutting, the volume of production, and the size of your workpieces. While a high-end machine might offer premium capabilities, a more budget-friendly option might still meet your production needs.

How to Save Money When Purchasing a Laser Cutting Machine

While the initial investment in a steel plate laser cutting machine can be substantial, there are strategies to help reduce costs:

Consider Used or Refurbished Machines: Purchasing a used machine can significantly cut down the cost. Many reputable suppliers offer refurbished models that work like new but at a fraction of the price.

Lease Instead of Buy: Leasing a machine can spread out the cost and reduce the financial burden, especially for businesses with fluctuating cash flow.

Negotiate the Price: Don’t accept the first offer. Manufacturers may be willing to negotiate on price, especially for bulk purchases or long-term agreements.

Look for Financing Options: Many suppliers offer financing packages that allow you to pay for your machine over time, easing the upfront costs.

Understanding the ROI of Steel Plate Laser Cutting Machines

Although the initial investment is high, many businesses find that the return on investment (ROI) for steel plate laser cutting machines is worth it. Over time, the efficiency gains, reduced waste, and higher-quality cuts lead to greater profitability. Laser cutting machines are particularly beneficial for industries that require high precision, like aerospace, automotive, and heavy machinery manufacturing.

Moreover, automation features allow businesses to cut labor costs, while the consistency of laser cutting reduces scrap material and enhances material utilization. This translates into long-term savings and improved operational efficiency.

By understanding the factors influencing the steel plate laser cutting machine price and evaluating your specific needs, you can make a well-informed decision that aligns with both your immediate and long-term goals.

Top Stories

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine