News

Laser Cut Titanium: A Game Changer in Precision and Durability

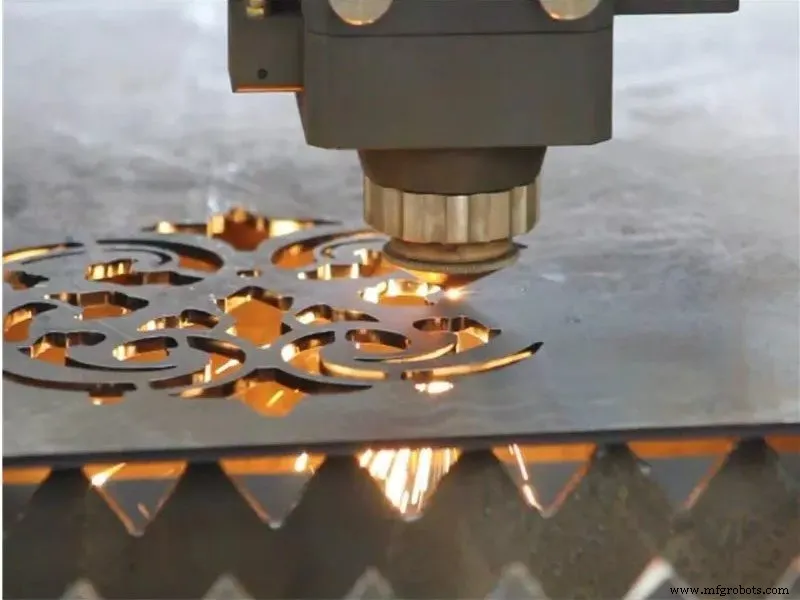

When it comes to precision engineering and durable materials, laser cut titanium stands at the forefront of innovation. Titanium, known for its strength, corrosion resistance, and lightweight properties, has been a critical material in industries ranging from aerospace to medical devices. However, the advent of laser cutting technology has elevated its usability and versatility to new heights.

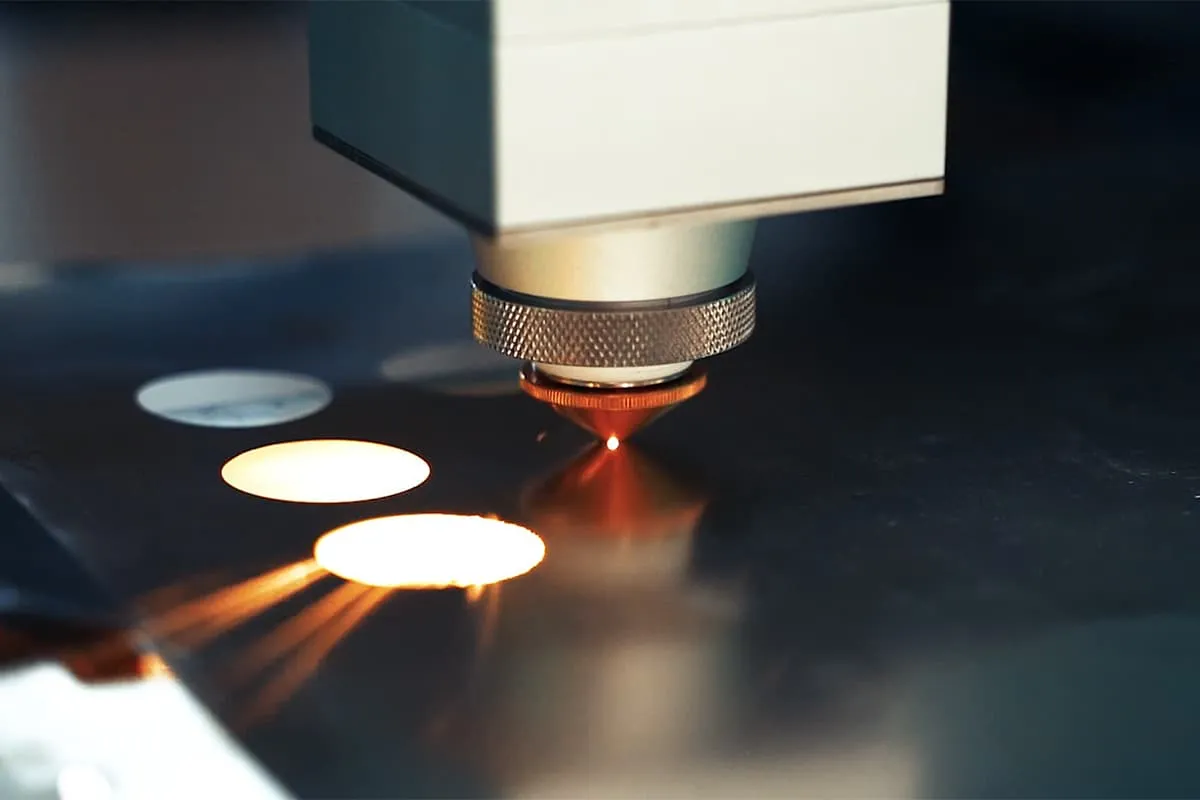

Laser cutting involves the use of a high-powered laser beam to slice through materials with remarkable precision. In the case of titanium, a material known for its toughness, achieving clean, accurate cuts was once a challenging feat. Thanks to laser cutting technology, manufacturers can now achieve superior results with intricate designs, tight tolerances, and minimal material wastage. But why is laser cutting such a game changer for titanium?

Ⅰ.Why Laser Cutting Titanium Is Essential for Modern Manufacturing

Titanium’s natural resilience and heat resistance make it an ideal candidate for laser cutting. Traditional methods like plasma or mechanical cutting often struggle with titanium, especially when the material’s thickness increases. Laser cutting, on the other hand, provides several advantages:

Unmatched Precision: Laser cutting produces extremely fine cuts that are consistent throughout the material. Whether it’s a thin sheet or a thicker titanium piece, the technology allows for tight tolerances, which is crucial in industries like aerospace, where precision is paramount.

Cleaner Cuts: Unlike mechanical methods, which can introduce burrs or other imperfections, laser cutting results in smooth, clean edges. This reduces the need for secondary finishing processes, saving both time and money.

Minimal Heat Affected Zone (HAZ): The heat-affected zone is critical when working with materials like titanium that are sensitive to temperature fluctuations. Laser cutting minimizes the HAZ, preventing potential material deformation and preserving the integrity of the cut.

High-Speed Efficiency: Laser cutting is faster than many conventional cutting methods, allowing for quicker turnarounds in production. This is especially beneficial for high-volume manufacturing operations.

Versatility in Complex Shapes: Laser cutting allows manufacturers to create intricate and complex shapes with ease. This opens the door to more creative and innovative designs in industries like medical implants, automotive, and beyond.

Ⅱ.Applications of Laser Cut Titanium

The ability to cut titanium with such precision has led to a surge in its application across various industries. Below are some notable areas where laser cut titanium is making a significant impact:

Aerospace and Aviation: Titanium is commonly used in aircraft components due to its strength-to-weight ratio. Laser cutting has enabled manufacturers to create parts like engine components, airframes, and landing gear with unparalleled precision.

Medical Devices: In the medical field, titanium is widely used for implants and prosthetics because of its biocompatibility and strength. Laser cutting allows for the creation of customized implants and intricate surgical instruments with fine details and minimal wastage.

Automotive: The automotive industry relies on titanium for exhaust systems, wheels, and other high-performance components. Laser cutting ensures that these parts meet stringent specifications, providing superior durability and lightweight benefits.

Marine: Corrosion-resistant titanium is used extensively in marine environments for applications like shipbuilding and offshore platforms. Laser cutting facilitates the creation of durable, custom parts that withstand harsh oceanic conditions.

Ⅲ.The Future of Laser Cut Titanium

As technology continues to advance, the future of laser cut titanium looks incredibly promising. New laser technologies, such as fiber lasers and ultra-fast lasers, are pushing the boundaries of what is possible with titanium. The potential for more precise cuts, faster production speeds, and even more complex designs is on the horizon.

Moreover, as industries continue to explore the capabilities of laser cutting, the demand for laser cut titanium is expected to grow exponentially. Manufacturers will continue to seek ways to leverage this technology to improve efficiency, reduce costs, and innovate their product designs.

In conclusion, laser cutting titanium has proven to be an essential process for modern manufacturing, offering unmatched precision, durability, and efficiency. As industries continue to rely on titanium for its unique properties, laser cutting technology will undoubtedly remain a cornerstone of innovation. Whether it’s aerospace, medical, automotive, or marine applications, the future of laser cut titanium is bright and filled with opportunities for advancement.

Top Stories

-

The Largest Laser Cutting Machine: Innovations in Precision and Efficiency06 Jun 2025

The Largest Laser Cutting Machine: Innovations in Precision and Efficiency06 Jun 2025 -

The Largest Laser Cutting Machine: Innovations in Precision and Efficiency19 Apr 2025

The Largest Laser Cutting Machine: Innovations in Precision and Efficiency19 Apr 2025 -

CNC Laser Metal Cutting Machine: Precision and Efficiency in Modern Manufacturing18 Apr 2025

CNC Laser Metal Cutting Machine: Precision and Efficiency in Modern Manufacturing18 Apr 2025 -

Laser Cutting Machine for Sheet Metal: A Game-Changer in Precision Manufacturing17 Apr 2025

Laser Cutting Machine for Sheet Metal: A Game-Changer in Precision Manufacturing17 Apr 2025 -

Laser Tube Cutting Machine: The Future of Precision Fabrication16 Apr 2025

Laser Tube Cutting Machine: The Future of Precision Fabrication16 Apr 2025

Product Categories

- Metal Laser Cutter

- Laser Welder Machine

- Laser Cleaner Machine

- Laser Marker Machine

- Press Brake Machine